Freeze-dryer Alpha 3-4 LSCbasic

Version 11/2018, Rev. 1.2 of 05/03/2019 • sb-pe

Translation of the original operating manuel

1General information.............................................................................................................9

1.1 Importance of the operating manual..................................................................................9

1.2 Intended use.....................................................................................................................9

1.3 Warranty and liability.......................................................................................................10

1.4 Copyright........................................................................................................................10

1.5 Explanation of symbols...................................................................................................10

1.6 Standards and regulations..............................................................................................10

1.7 Scope of supply..............................................................................................................11

2Layout and mode of operation.......................................................................................... 12

2.1 Layout of the freeze-dryer...............................................................................................12

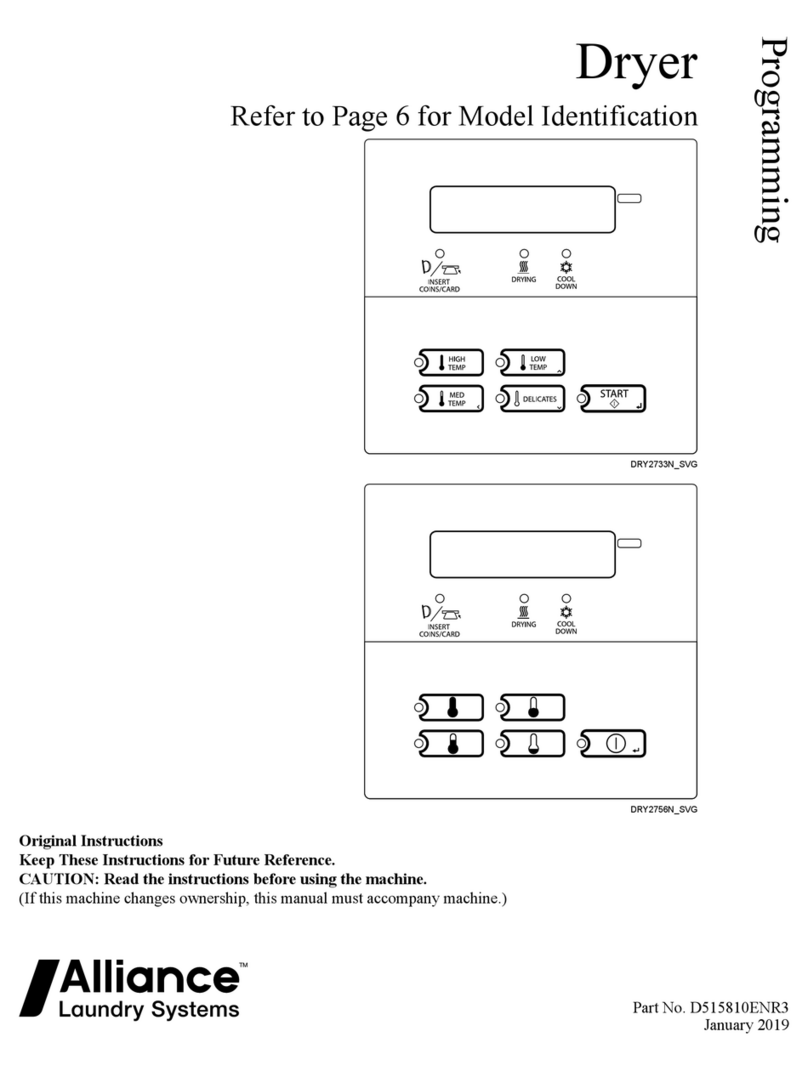

2.1.1 Functional and operating elements............................................................................12

2.1.2 Name plate................................................................................................................14

2.2 Mode of operation...........................................................................................................15

2.2.1 General information on freeze-drying.........................................................................15

2.2.2 Freeze-drying process...............................................................................................18

2.2.2.1 Preparation........................................................................................................18

2.2.2.2 Freezing.............................................................................................................18

2.2.2.3 Main drying........................................................................................................19

2.2.2.4 Final drying........................................................................................................19

2.2.2.5 End of drying and aeration.................................................................................19

2.2.2.6 Defrosting ..........................................................................................................20

3Safety..................................................................................................................................21

3.1 Marking of the unit..........................................................................................................21

3.2 Explanation of the symbols and notes.............................................................................22

3.3 Responsibility of the operator..........................................................................................23

3.4 Operating personnel .......................................................................................................24

3.5 Informal safety notes.......................................................................................................24

3.6 Safety notes concerning the transport, set-up and connection and initial start-up

of the freeze-dryer ..........................................................................................................25

3.6.1 General hazards........................................................................................................25

3.6.2 Hazards caused by improper transport......................................................................25

3.6.3 Hazards caused by improper set-up..........................................................................25

3.6.4 Hazards caused by improper connection...................................................................26

3.7 Safety notes concerning the operation............................................................................26

3.7.1 Hazards caused by electricity ....................................................................................26

3.7.2 Hazards caused by the refrigeration system (natural, flammable refrigerants)...........27

3.7.3 Hazards caused by harmful products.........................................................................27

3.7.4 Hazards caused by acids in the products...................................................................27

3.7.5 Hazards caused by contaminated condensate (defrosting water)..............................28

3.7.6 Hazards caused by hot surfaces................................................................................28

3.7.7 Hazards caused by cold surfaces..............................................................................28