Claudgen ScreenZone HE8370 User manual

41000664 Iss 05

Installation Requirements ---------------------------------------------------- 1

Dimensions ---------------------------------------------------------------------- 2

Technical Specifications ------------------------------------------------------ 3

Wiring Details ------------------------------------------------------------------- 4

Energy Saving Configuration ----------------------------------------------- 5

Installation Details ------------------------------------------------------------- 6

Servicing & Maintenance ---------------------------------------------------- 7

Spare Parts ---------------------------------------------------------------------- 8

Fault Finding ------------------------------------------------------------------- 9

Parts Replacement -----------------------------------------------------------10

User Instructions -------------------------------------------------------------- 11

1 This appliance must only be installed by a competent person in accordance with the requirements

of the Codes of Practice or the rules in force.

2 All external wiring MUST comply with the current IEE wiring regulations.

3 Warning this appliance must be earthed.

2

41000664 Iss 05

1.1 Introduction

1.2 General

1.3 Electrical Supply

1.3.1 Electronic Controller

1.4 Location

1.5 Clearance Distance

1.6 Health and Safety

1.7 Standards

2.1 Air Curtain

2.2 Electronic Program Keypad

3.1 General Data

3.2 Electronic Controls

4.1 Installer Wiring - 18 & 24kW

4.2 Factory Wiring - 18 & 24kW

4.3 Network Wiring - Electronic Controller

5.1 Introduction

5.2 Control with ’outdoor’ temperature sensor

5.3 Control with ’indoor’ temperature sensor

5.4 Optional Features

6.1 Mounting

6.2 Electrical Supply

6.3 Installation

6.4 Controller

6.5 Installation Wiring

8.1 General

8.2 Electronic Controller

9.1 General

9.2 Electrical Heated Units

9.3 Electronic Controller

10.1 Rotor and Motor Replacement

10.2 Electrical Element Replacement

11.1 Keypad Buttons

11.2 Manual Operation

11.3 Automatic Control

11.3.1 Auto Mode

11.3.2 Auto Mode Settings

11.3.3 Door Switch Mode

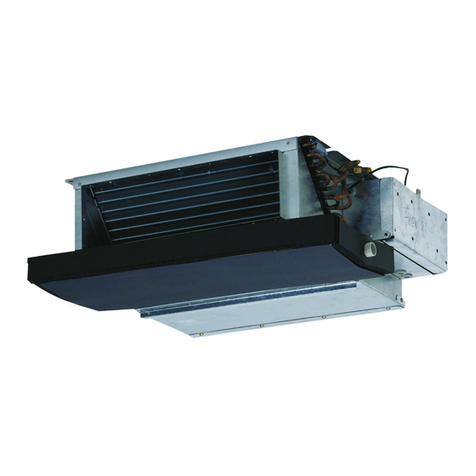

This instruction manual describes the ScreenZone

Large commercial range of air curtains.

Models range from 1500mm to 2000mm in length,

in both Standard and High capacity and are

available in Electrically Heated versions only.

They are designed for mounting above or slung on

drop rods above doorways.

Each air curtain is supplied with a fully electronic

controller giving multi fan and heat settings

(electrically operated units) via a simple key pad

which can be mounted up to 50m from the air

curtain. Optional BMS time control, external

thermostats and door interlocks can be installed.

The shown above allows

the user to control either a single air curtain, or a

network of up to 6 air curtains with the same

settings, and provides the following functions:-

- Heat On Off or Auto via optional thermostat

- Off or Low, Medium and High Fan Speeds

For further details please refer to section 11.2.

3

41000664 Iss 05

All installations must be in accordance with the

regulations in force in the country of use.

These instructions must be handed to the user on

completion of the installation.

Installers and service engineers must be able to

demonstrate competence and be suitably qualified

in accordance with the regulations in force in the

country of use.

To ensure continued and safe operation it is

recommended that the appliance is serviced

annually.

The manufacturer offers a maintenance service.

Details are available on request.

The air curtain outlet grille and case air inlet slots

must not be obstructed during use.

For full electrical loadings, please refer to the

individual technical data sheets within this manual.

It is recommended that the electrical supply to the

base unit in the air curtain is via an appropriate

switched isolator in accordance with the reg-

ulations in force in the country of use and must be

via a fused isolator having a contact separation of

greater than 3mm in all poles.

BMS control, time switches, room thermostats and

door interlocks can be installed at the discretion

and responsibility of the installer.

All units must be wired in accordance with I.E.E

regulations for the Electrical Equipment of

Buildings and the installer should ensure that a

suitable isolating switch is connected in the mains

supply.

Warning

For safety reasons a good earth connection must

ALWAYS be made to the heater and control box.

Electrically heated supply is 415V 3 phase,

Neutral and Earth. Max cable inlet size is 4mm² or

6mm² (refer to individual technical specification).

Remote unit is wired to the base unit via a

screened twisted pair 28AWG (or direct equiva-

lent).

All units should be installed horizontally directly

over the door opening. It is recommended that the

air curtain is installed on the inside of the building,

within the open room space against a wall or

ceiling.

Care must be taken to allow complete free air

movement into the inlet grilles of the unit to ensure

correct working operation of the air curtain. The

discharge opening should be as close to the top of

the door as possible and to cover the entire door

width.

Units can be mounted adjacent to each other to

cover the full door opening across wider

entrances.

These units are designed for surface mounting

and should not be placed into a ceiling void, due

to possible obstruction of airflow and difficulty in

routine cleaning and maintenance.

It is recommended that a minimum clearance of

300mm is allowed around the top and front of the

unit. The clearance allows for cable entry and

prevents combustible surfaces overheating.

The minimum mounting height (floor to grille

outlet) is 1.8m. The recommended maximum

mounting height is 3m for standard and 4m for

high capacity models.

Sole liability rests with the installer to ensure that

all site safety procedures are adhered to during

installation.

Sole liability rests with the installer to ensure that

protective safety wear such as hand, eye, ear and

head protection is used during installation of the

product.

Do not rest anything especially ladders against the

product.

Units conform to the European electrical standard

BS EN 60335-2-30 and to the following European

CE directives-

73/23/EEC - amended 98/68/EEC low voltage;

89/336/EEC electromagnetic compatibility.

THIS AIR CURTAIN SHOULD NOT BE

INSTALLED WHERE THERE IS A

CORROSIVE ATMOSPHERE.

4

41000664 Iss 05

SIDE VIEW

65

395

350

300

119

TOP VIEW A (see table) SUSPENSION POINTS

REAR VIEW

B (see table) WALL FIXING POINTS

240crs 75

FRONT VIEW

C (see table) DUCT OUTLET

D (see table) OVERALL WIDTH

mm

1562 2062

1492 1992

1553 2053

1638 2138

Cable

Entries

13.35

43.5

SELECT

87.0

60.3crs 60.3crs

Cable

Entries

7.3560.3crs

7.35

60.3crs

Earthing

point

SELECT

60.3crs

75.0

Cable

Entries

13.35

43.5

SELECT

87.0

60.3crs 60.3crs

5

41000664 Iss 05

* Motor current only at high speed

Maximum height M3.0 4.0

Door width M2.0 1.5 2.0

Heat medium Electric heated

Heat setting kW 9 / 18 9 / 18 12 / 24

Fan type / dia Crossflow / 150mm

Fan settings 3

Switching type AC-ACR-PANEL

Weight kg 60.0 49.0 60.0

Supply voltage 415V 3ph 50Hz

Total load kW 18.4 24.4

A/pha 25.6 34.0

Motor power W370

Max Starting current* amps 5.0

Max Running current* amps 2.1

External fuse size amps A/pha 32 32 40

Programmer keypad pt. no. AC-ACR-PANEL

Program keypad control wiring Screened twisted pair 28AWG

Cable terminal size 6.0mm² Max

Mains terminal block position Separate din rail E; N; L1; L2 & L3

Control terminal block position Right side of base unit terminals +12V, DATA & GND

Air volume Low speed m³/h2900 1600 2900

Medium speed m³/h4100 2400 4100

High speed m³/h5000 3300 5000

Air velocity Low @ 0M m/s 6.0

Medium @ 0M m/s 8.5

High @ 0M m/s 11.0

High @ 1M m/s 5.2 5.5 5.2

High @ 2M m/s 3.6 3.7 3.6

High @ 3M m/s 2.4 2.5 2.4

High @ 4M m/s 1.4 1.6 1.4

Delta T Low speed °C 27 35 36

Medium speed °C 19 27 26

High speed °C 15 22 20

Noise level @ 3M

in free field

Low speed dBA 50

Medium speed dBA 55

High speed dBA 60

Length mm 2138 1638 2138

Depth (width) mm 350

Height including outlet mm 395 ( Chassis - min 502 max 563)

Outlet length mm 2095 1595 2095

Outlet depth mm 65

Outlet height mm Flush ( Chassis - min 107 max 168)

Drop rod mounting rear to ctr on depth mm 119

Drop rod side to 1st Centre mm 38

Drop rod mounting centres on length mm 2062 1562 2062

Wall mounting side to 1st centre mm 73

Wall mounting top to 1st centre mm 75

Wall mounting centres on length mm 1992 1492 1992

Wall mounting centres on height mm 240

6

41000664 Iss 05

Sensor input NTC

Protection 2 x ‘slow blow’ fuse for the protection of the heater switching devices.

Fan Output 3 off Relay for High, Medium and Low Fan setting 3A max 240Vac

Connection

Screw terminals 4 for supply, 6 for heater output, 4 for fan output, 2 for

BMS (time) control, 2 for sensor input, 2 for external thermal trip, 2 for

external door switch.

Supply 415 3Ph

Dimensions Program panel 88mm(L) x 88mm(W) max.

Mounting positions Program panel fixing centres 60.3mm

Temperature 5 to 50 ºC operating; -20 to 65 ºC storage

Display Three 7-segment LCD red for parameter display

Push buttons 3 positive feedback tactile push buttons

7

41000664 Iss 05

T1

T2

B2

D2

S2

S1

D1

B1

DATA

GND

+12V

BASE UNIT

(located in air curtain)

415V 50Hz

Mains Supply

Chassis

Earth

PROGRAM PANEL

(rear view shown)

External

Switch

J1

Remove link J1 for

external time switch

DATA

GND

+12V

F1

F2

F3

N

N

AC1-T3

L3

AC2-T3

AC1-T2

L2

AC2-T2

AC1-T1

L1

AC2-T1

Door

Switch

Sensor screen

Contractors

Terminal

NNeutral 6mm² max

L1 3 phase supply 6mm² max

L2 3 phase supply 6mm² max

L3 3 phase supply 6mm² max

+12V Supply to remote unit

1.0mm2 max

DATA Data to remote unit

GND(s) 0v Terminal

D1, D2 Option door contact

B1, B2 Option BMS switch

S1, S2 Option internal/external sensor

F1 T2A (slow blow)

F2 T3.15A (slow blow)

External circuit breaker with the

appropriate rating should be

installed for the protection of the

installation.

-

The program panel is connected to the base unit via a set of 3 way connectors marked "+12V”, “DATA”

and “GND". Interconnecting wiring is via screened twisted 28AWG as shown. It is rec-

ommended that this cable is run separately within its own trunking to avoid external interference.

(i.e. BMS enable) to be volt free and wired via normally open contacts to terminal

pair, B1 and B2. Remove factory fitted jumper J1.

to be volt free and wired via terminal pair, D1

and D2 (contacts closed to enable

door mode). Refer section 11.3.3 -

Door Switch Mode.

to be

wired to terminal pair, S1 and S2.

Refer section 11.3.1 - Auto Mode.

8

41000664 Iss 05

Fan Motor

Overheat

AC1-T3

T1

T2

B2

D2

S2

S1

D1

B1

DATA

GND

+12V

L3

AC2-T3

AC1-T2

L2

AC2-T2

AC1-T1

L1

AC2-T1

F1

F2

F3

N

N

Elements

AC1

T1

Contractors

Terminal

L1

T2 L2

T3 L3

A2 A1

Elements

AC2

T1 L1

T2 L2

T3 L3

A2 A1

J1

L1L2L3

N

E

-

The element outputs are connected to contactors "AC1”

and “AC2” on terminals T1, T2 and T3.

The fan output is connected to a 4 way connector

marked "N”, “F1”, “F2” and “F3".

The thermal trip is connected to a 2 way connector

marked "T1" & “T2”

AC1/2-T1 Heater Elements phase 1

AC1/2-T2 Heater Elements phase 2

AC1/2-T3 Heater Elements phase 3

T1 Thermal Overheat trip

T2 Thermal Overheat trip

NNeutral to fan

F1 Fan - low speed

F2 Fan - medium speed

F3 Fan - high speed

J1 Factory BMS link

9

41000664 Iss 05

(rear view shown)

PROGRAM PANEL

To subsequent air curtains

(maximum of 6)

DATA

GND

+12V

DATA

GND

+12V

DATA

GND

+12V

DATA

GND

+12V

Screw terminals

BASE UNIT

(located in air curtain 1)

BASE UNIT

(located in air curtain 2)

BASE UNIT

(located in air curtain 3) 3 core screened cable,

screen

-

This diagram refers only to the

data cable wiring of 2 or more

networked air curtains. (maximum

6 air curtains per control panel).

For mains wiring refer to section 4

of this manual ‘installer wiring

details’.

The program panel is connected

to the base unit in the first air

curtain via a set of 3 way

connector marked "+12V”, “DATA”

and “GND". Each subsequent air

curtain is linked to it’s

corresponding terminal.

Interconnecting wiring is via

Belden cable 8132 or equivalent

as shown.

(Total length of cable used

between program panel and last

air curtain in network).

It is recommended that this control

cable is run separately within its

own trunking to avoid external

interference.

10

41000664 Iss 05

Shops, warehouses and factories are all subject to

the problems caused by frequently opened doors.

The open door not only causes a draft but greatly

increases energy loss and, therefore, the running

cost of the building. Screenzone units offer a cost-

effective, energy efficient solution to these prob-

lems by reducing heat loss. The installation of a

Screenzone air curtain with energy saving controls

provides a barrier of air that keeps the conditioned

or warm air inside the building. The energy saving

control unit when run under automatic control re-

duces both the power consumption and energy

cost. The key benefits of the energy saving con-

trols are:

Simple installation — wiring connections are

direct to the controller, no intermediary ter-

minal blocks are required.

Easy programming — the user sets two tem-

peratures and three fan speeds enabling the

air curtain to vary the required heat output

depending on the selected temperatures.

In conjunction with a door switch the control-

ler can be set to change the fan speed when

the door opens.

Compatible with Building Management Sys-

tems

The air temperature sensor can be mounted

outside or inside to enable temperature con-

trol.

No specialist commissioning required.

Reduced payback period of your investment

thanks to the energy saving generated.

Cabling from the air curtain to the program

panel requires only 3 core cable.

One control unit can control up to six air cur-

tains.

A centralised control unit can be mounted up

to 50m from the air curtain.

This type of temperature control is suitable for

open door trade or frequently used doorways in

large areas where heat from the heater would not

affect the indoor ambient temperature. The control-

ler can be set to vary the heat output depending on

the outside temperature. This type of control

shouldn’t be used in small areas, between two sets

of doors or small shops. In this configuration the

heater is running on a preset speed and variable

heat output depending on two user selected tem-

peratures and (range 0 to 30 degrees C) If

the outside temperature around the sensor falls

below the selected temperature the heater will

be working on 100% heat output. If the tempera-

ture is above the selected temperature but be-

low selected temperature the heater will be

working on 50% heat output. If the outside temper-

ature is above the user selected temperature

there is no heat output but the fan is running on a

selected speed. For example:

t1 - 16 deg C

t2 - 7 deg C

Temperature below 7 - full heat

Temperature above 7 but below 16 - half heat

Temperature above 16 - no heat, cold blow only

This type of temperature control is suitable when

the heater is used in small areas, between two sets

of doors or in small shops where running the heater

on full heat setting for a longer period will bring the

room temperature to a very high level. With a tem-

perature sensor mounted inside the building the

controller can be set to vary the heat output de-

pending on the inside ambient temperature. In this

configuration the heater is running on a preset

speed and variable heat output depending on two

user selected temperatures and (range 0 to

30 degrees C) If the ambient temperature around

the sensor falls below the selected temperature

the heater will be working on 100% heat output. If

the temperature is above the selected tempera-

ture but below the selected temperature the

heater will be working on 50% heat output. If the

ambient temperature around the sensor is above

the user selected temperature there is no heat

output but the fan is running on a selected speed.

For example:

- 20 deg C

- 15 deg C

Temperature below 15 - full heat

Temperature above 15 but below 20 - half heat

Temperature above 20 - no heat, cold blow only

Both types of control can be used in conjunction

with a door switch which will change the fan speed

as selected by the user. In the case where the door

switch is not used a standard one pole switch can

be used to change the fan speed in auto mode. The

heater can be also connected to a Building man-

agement system or 24h 7day timer to run the heat-

er in fully automatic mode. If the heater is not con-

nected to a Building management system or timer

the available terminals can be connected to a

standard one pole switch (light switch) to turn the

heater off or on.

11

41000664 Iss 05

All units should be installed horizontally directly

over the door opening. It is recommended that the

air curtain is installed on the inside of the building,

within the open room space against a wall or

ceiling.

Care must be taken to allow complete free air

movement into the inlet grilles of the unit to ensure

correct working operation of the air curtain. The

discharge opening should be as close to the top of

the door as possible and to cover the entire door

width.

Units can be mounted adjacent to each other to

cover the full door opening across wider

entrances.

These units are designed for surface mounting

and should not be placed into a ceiling void, due

to possible obstruction of airflow and difficulty in

routine cleaning and maintenance.

These units are suitable for connection to a 415

Volt, 50Hz 3 phase and neutral supply.

Electrically heated models consume 18kW &

24kW at 415 volts when switched to the full heat

position depending on their model and capacity

size.

The appliance shall be connected to the supply

via an appropriate switched fused double pole

isolator having a contact separation of greater

than 3mm. Test for correct operation and refit the

cover.

For connection to the mains supply it will be

necessary to remove the outer cover from the unit.

After removing the cover you will note the mains

terminal block and it will be necessary to connect

the mains supply and the lead from the remote

switch box prior to refitting the cover. Wire in

accordance to diagrams in section 4.1 to 4.3.

For safety reasons, a sound earth connection

must always be made to the unit before it is put to

use. The unit should be wired in accordance

with IEE Regulations for the Electrical Equip-

ment of Buildings.

It is the sole responsibility of the installer to ensure

that the points of attachment to the building are

sound. Consultation with the consultant/architect or

owner of the building is recommended to ensure

that a sound, mechanically stable installation is

achieved.

All attachments must be capable of supporting the

weight of the product detailed in Section 3.

Remove all packaging. Remove decorative cover.

Undo screws securing the outlet (not Chassis ver-

sion).

Note All outer metal surfaces are covered by a

protective plastic film, which must be removed

before final fixing and operating of the unit.

Carefully remove the air curtain front cover by

removing four screws.

12

41000664 Iss 05

It is recommended that the chassis is removed

from the back box to avoid having to support the

weight of the product during installation.

To separate the chassis from the back box undo

and remove the nuts shown and lift the chassis

away from the back box.

The product can be installed using either M12

drop rods or fastened direct to the wall using

appropriate sized fixings suitable for the wall

surface and the weight of the product.

To wall mount the product, position the back box

against the wall at the desired mounting height

and mark through the holes in the back box

brackets to enable the wall to be drilled for the

appropriate fixings.

Drill the wall then fix the backbox in position. Lift

the chassis (using lifting gear if necessary) onto

the studs on the back box brackets. Refit and

tighten the nuts.

Holes are provided in the back box for the feed

cable to enter the case. Choose the appropriate

hole top rear to suit the installation.

Fit suitable cable gland for size of cable.

To install the product using M12 drop rods follow

instructions from step 4. If the decorative tube is to

be used, fit this over the drop rod, then pass the

drop rod through the back box brackets.

13

41000664 Iss 05

Adjust the product to the required height and

ensure that it is fitted level using a spirit level

across the back box as required.

Tighten the lock nuts and re-assemble in reverse

order. Adjust outlet to required angle to give

desired performance, and tighten outlet screws.

The Electronic base unit is pre-installed inside the

air curtain. All the external electrical connections

are via screw terminals onto this base unit.

The program keypad is installed on a separate

facia plate and connected to a surface mounted

back box in a suitable location. Please see Figure

5.

Alternatively, the program panel can be flush wall

mounted with the addition of a suitable conduit

box MK part number 861 ZIC or equivalent.

The distance between the base unit and the

program panel can be up to 50m maximum.

With case removed, connect the electrical supply

and program panel interconnecting wiring to the

relevant terminals on the controller base unit (See

wiring diagrams section 4)

Cable

Entries

13.35

43.5

87.0

60.3crs

THIS AIR CURTAIN SHOULD NOT BE

INSTALLED WHERE THERE IS A

CORROSIVE ATMOSPHERE.

14

41000664 Iss 05

To obtain the best results from the heater, it is

essential to avoid the accumulation of dust and

dirt within the unit on the air inlet and discharge

grilles. For this reason regular cleaning is

necessary, paying particular attention to the

removal of dirt build up on the rotor blades.

Cleaning of the fan is best carried out with a soft

brush.

A single drop of light oil should be applied to the

motor bearing from time to time.

The product should be serviced annually.

Servicing shall be undertaken by a competent

person

Undo screws securing the grille.

Adjust the grille by turning the screw inside with

an allen key.

Remove 4 screws

securing the top

of the case and

remove (not

Chassis version)

Slacken two bolts on

both ends.

Remove three bolts

securing the access

plate.

Carefully hinge down the access plate.

Note Take the weight as access plate swings down.

With a soft brush clean away any dust from the

motor and elements.

Check all connections and components for

soundness or signs of deterioration and replace as

necessary.

Re-assemble and test.

15

41000664 Iss 05

100535Motor

900078

Contactor

(where re-

quired)

100541100540Rotor Left Hand

100538100537

Rotor Right

Hand

900001

Thermal cut-out

x 2

Rating 18kW 3Ph 24kW 3Ph

SE 100842 -

Length 2.0m -

HE 100527 100528

Length 1.5m 2.0m

Element assembly

AC-ACR-PANELProgram Keypad

AC-ACR-PCBBase Unit

SC-OS

Outside Air

Sensor

Due to the nature of it’s construction, it is not advisable to repair damaged electronic components

on either the base unit or Electronic program panel

100541

100538

16

41000664 Iss 05

If the air curtain does not operate after running

through the detail provided in Section 6, then a

suitably competent service engineer should be

called to identify the nature of the fault.

Note The manufacturer operates a service

function from the address provided in these

instructions.

All Air Curtains are fitted with fuse protection and

motor thermal protection.

Other faults in relation to the element, motor and

wiring should be identified using conventional fault

finding techniques.

In the event that electrical components are

replaced, please ensure that electrical safety

checks in accordance with the regulations in force

in the country of use are undertaken.

For the service engineer, please note that there is

a thermal cut-out incorporated in the air curtain

which needs to be manually reset. The cut-out is

located near to the mains terminal block.

Re-setting the thermal cut-out may help to identify

the nature of the fault however we do not

recommend re-set without a thorough

investigation into why the cut-out operated.

If the air curtain goes into thermal trip (overheat)

the Electronic panel keypad displays an ‘ERR’

code. Refer to air curtain instructions to remedy.

The electronic control base unit is protected from

any short circuit on the air sensor or heatsink

sensor as the short circuit will cause the

temperature to go high and trigger over

temperature alarm.

Polarity: Use a multimeter to check correct

polarity between all three cores i.e. that +12V

goes to +12V, DATA goes to DATA, and GND to

GND.

Continuity: Use a multimeter to check continuity

between each end of all three cores.

Short circuit: Use a multimeter to check that

there are no short circuits between any of the

three cores.

This test should be done with both ends of

the cable disconnected to avoid false readings.

Plugs:

Check that the correct length of insulation has

been stripped from each core.

Check the tightness of the cables in the plugs.

-

17

41000664 Iss 05

Warning

Ensure electrical power is isolated from the

product.

Follow steps 1 - 4 below.

Remove 3 screws securing fan

bearing plate to access panel.

Carefully remove plate with

bearing housing from rotor bear-

ing.

Slacken the grub screw secur-

ing rotors to the motor shaft, remove rotor.

Repeat steps 1 - 2 for opposite rotor.

Disconnect the wires from the motor to the mains

terminal rail.

Remove the bolts securing the motor to the

chassis.

Replace motor as required.

Refit in reverse of previous steps and test the

performance of the product.

18

41000664 Iss 05

For access follow steps 1 to 4 above.

Carefully remove connections to element, noting

wiring configuration.

Remove two bolts securing elements.

Lift out element cartridge, replace as required.

Refit in reverse order (including (motor refit on

previous page)

Test performance of the product.

19

41000664 Iss 05

The button will allow you to navigate.

The button will allow you to increase the setting.

The button will allow you to decrease the setting.

On first power up, the display panel will have the

following default settings:

F. 0 (no fan)

H. 0 (no heat)

1. 16 (ºC. Heat set point - Auto mode only)

2. 7 (ºC. Half heat set point - Auto mode only)

D. 2 (fan speed in door switch mode)

Note: Subsequent power ups will retain any entered

settings in the display panel internal memory.

Press the or buttons to toggle between the

‘F’ (Fan), ‘H’ (Heat) and On/Off Parameters.

Prefix ‘F’ denotes the . This can be either

1: slow ; 2: medium or 3: fast speed. 0 setting denotes

the unit is .

To alter the current speed, press the button. The

value will start flashing.

Press the or buttons to increase/decrease the

desired setting.

Press the button to confirm the new setting. A de-

lay of 7 seconds will return to the original display.

Prefix ‘H’ denotes the setting. This can be either

1: low heat; or 2: high heat. 0 setting denotes the unit is

set at fan only.

To alter the current setting, press the button. The

value will start flashing.

Press the or buttons to increase/decrease the

desired setting.

Press the button to confirm new setting. If not

pressed within 7 seconds will return to the original dis-

play.

--

20

41000664 Iss 05

The next parameter will either turn the unit On or Off.

To turn the unit Off, press the button. ‘On’ will start

flashing.

Press the button. ‘Off’ will start flashing.

Press the button to confirm new setting.

To turn the unit On, press the button. ‘Off’ will start

flashing.

Press the button to alter to ‘On.

Press the button to confirm new setting. A delay of

7 seconds will return to the ‘F’ Fan parameter.

To switch the heater ‘On’ or ‘Off’ automatically the ter-

minals B1 and B2 can be used to connect the heater to

a Building management system or 24h 7day timer. If the

heater is not connected to a Building management sys-

tem or timer a standard one pole manual switch (light

switch) can be used.

In this configuration the heater is running on a preset

fan speed (1: slow ; 2: medium or 3: fast speed. 0 set-

ting denotes the unit is in stand-by mode) selected in

manual mode before entering auto mode setting and

variable heat output depending on and , two user

selected temperatures.

(Range: 0 - 30 degrees).

Auto mode can be used in conjunction with a door

switch or movement sensor connected across terminals

D1 and D2. When the switch is activated the heater is

running on a pre-programmed speed and heat setting.

See 11.3.3

To access the auto mode setting, first ensure that the

display is in the (H) HEAT parameter.

Press and hold the b button for 5 seconds.

This manual suits for next models

2

Table of contents