Clean Marker Brush-E User manual

www.greising.com

Made in Germany

1

2

3

4 5 6 7

Operation Manual

Brush-E ∙ Brush- S ∙ Brush-P ∙ Brush-T ∙ Brush-TP

Kai GreisinG e. K.

Clean MarKer

www.greising.com

Info@greising.com

Industriestraße 29/2

D-73340 Amstetten

Tel.+49 (0)73 31/30 58 - 0

Fax +49 (0)73 31/98 17 22

ORDER PROCESSING

+ 49(0)73 31/30 58 - 20

ORDERING STENCILS

+ 49(0)73 31/30 58 - 22

Operation Manual Clean Marker Brush −Page 2

instructions for use

PRODUCT DESCRIPTION

Model:

Unit No.:

Built:

CUSTOMER REGISTRATION

Stock No.:

THE USER IS OBLIGED TO:

• observationofECRegulations89/655andtheir

national implementation

• observationofthecurrentnationalregulations

concerning industrial safety

• utilisationofthemachineinaccordancewithin-

structions

Allrightsreserved.

Printing, in whole or in part, is only allowed

with prior consent of the manufacturer.

Errorsandomissionsexcepted.

Operation Manual Clean Marker Brush −Page 3

index

1 saFeTY reGUlaTiOns 5

1.1 Correct utilisation 5

1.2 Tips and definitions 5

1.3Obligationsandliability 5

2 inTrOdUCTiOn 7

2.1 Technical data 7

2.2 Conformity 7

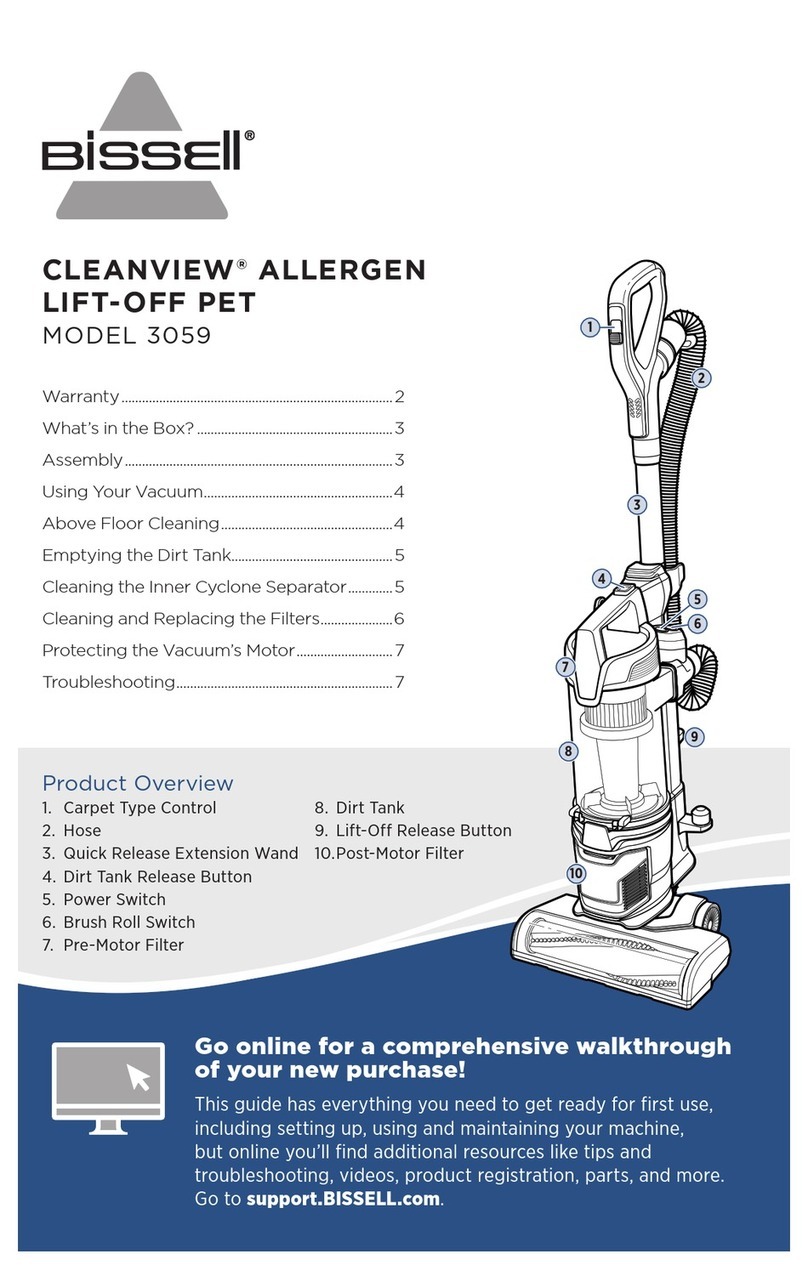

2.3Generalview 8

2.4 Accessories 8

3 FUnCTiOn, MeTHOd OF OPeraTiOn 8

3.1Functionreview 8

3.2 Method of operation 9

3.3 Safety and monitoring equipment 9

3.4Switchingoversupplyvoltage 9

3.5 Operating and display elements 9

4 TransPOrT, seTTinG UP 12

4.1 Safety regulations 12

5 OPeraTinG 12

5.1 Initial operation 12

5.2 Cleaning with the Clean Marker Brush attachment 13

5.3 Marking with the Clean Marker Brush (flat tool head) 14

5.4 Dealing with short-term stencils 15

5.5 Closing down the unit 15

5.6BlastingwiththeCleanMarkerBrush-TandBrush-TP 15

5.7 Connecting up the automatic electrolyte feed on

CleanMarkerBrush-PandBrush-TP 16

6 MainTenanCe 17

6.1Safetyregulations 17

6.2Generalremarks 17

instructions for use

7 FaUlTs 18

7.1 Correcting faults 18

8 serViCinG 21

8.1 Safety regulations 21

9 ClOsinG dOWn, sTOrinG 21

9.1 Preparing for storage 21

9.2 Packaging, transporting and retransporting 21

9.3 Maintenance during storage 21

10 disPOsal 21

10.1 Method of procedure 22

11 YOUr OPiniOn 23

12 deClaraTiOn OF COnFOrMiTY 24

Operation Manual Clean Marker Brush −Page 4

1 saFeTY reGUlaTiOns

1.1 CORRECT UTILIZATION

Theunitsareintendedforcleaningweldedseams,forremovingoxide

coatingonstainlesssteelweldedseams,foretchingconductivemetal

surfacesandforgalvanizingandblastingsmallareas.Thefunctionisonly

guaranteedwhenoriginalpartsareused.Anyotheroranyusebeyond

thosedeterminedisnotconsideredtobecorrect.

Themanufacturecannotbeheldresponsibleforanydamagesresulting

from such incorrect use.

Thefollowingarealsoconsideredtobepartofcorrectutilization:

•Compliancewithinstructionsonuse.

•Compliancewithinspectionandmaintenancerequirements.

•Useofprotectiveclothing,especiallyglovesandgoggles.

1.2 TIPS AND DEFINITIONS

Warning

A possibly dangerous situation which could lead to serious

injury or even death.

Warning

A possibly dangerous situation, which could lead to light

physical injury. This sign is also used as a warning for heavy

material damage.

Information

Concerning usage and other useful information.

Information

The arrow describes a following process occurring automati-

cally and / or the condition which should now be set.

1.3 OBLIGATIONS AND LIABILITY

1.3.1 Necessary qualications of operators

Operation,maintenanceandinspectionmayonlybecarriedoutbyautho-

risedandqualiedspecialists.Theminimumageoftheoperatoris18.

Authorisedspecialistsareunderstoodtobespecialiststrainedbytheuser,

themanufacturerortheservicepartner.

Theseoperatorsmustbe:

• trainedintheuseoftheunit

• conversantwiththeinstructionsforuse

• conversantwiththesafetyequipmentoftheunit

• conversantwiththerelevantregulations,(especiallywithaccident

preventionregulations)

• authorisedtousethenecessarychemicals

Operation Manual Clean Marker Brush −Page 5

instructions for use

1.3.2 Risks involved when using the unit

Theunithasbeenbuiltinaccordancewiththelatesttechnicalstandards

andtherecognizedregulationsconcerningsafety.Inspiteofthis,dangerof

injury to the user or a third party and/or damage to the unit or other materi-

alscouldarisingduringuse.Theunitmayonlybeused:

• fortheprocesspreviouslydetermined

•in a perfectly safe condition

1.3.3 Guarantee and liability

Our „General Conditions of Sale and Supply“ apply. Claims of warranty

andliabilitymadeforpersonalinjuriesandmaterialdamagesareexcluded

if they are resulting from one or more of the following causes:

•incorrect use of the unit

• non-observanceofinstructionsforuse

•unauthorised structural changes on the unit

1.3.4 Safety measures

Theinstructionsforusearetobekeptneartheunitandaretobepassed

onbysaleorexchangeofthemachine.

Allsafetyanddangersignsontheunitaretobeclearlyvisibleatalltimes.

1.3.5 Risks arising from electrical energy

• Workonthepowersupplyisonlytobecarriedoutbythesame

electrician.

• Theelectricalequipmentistobecheckedregularly.

• Looseconnectionsanddamagedcablesmustberemediedimmediately

1.3.6 Special risks arising from chemicals

Dealingwithchemicalsshouldbeconsideredaspecialrisk.Payattention

to the Safety Data Sheets and the following remarks in these instructions.

•Eye protection

Eyesshouldbeprotectedfromchemicalswithgoggles

•Hand protection

Putonrubberglovesbeforeworkingwithchemicals

•Clothes protection

Wearprotectiveclothingbeforeusingchemicals(acid-proofapron,wor-

king coat)

•Breathing protection

Fumes arise when using chemicals. Always wear a face mask!

•Accident with chemicals

Should chemicals come into contact with eyes in spite of wearing

goggles, then:

• rinsetheeyeswithplentyofclearwater

• seekmedicalattention.

Operation Manual Clean Marker Brush −Page6

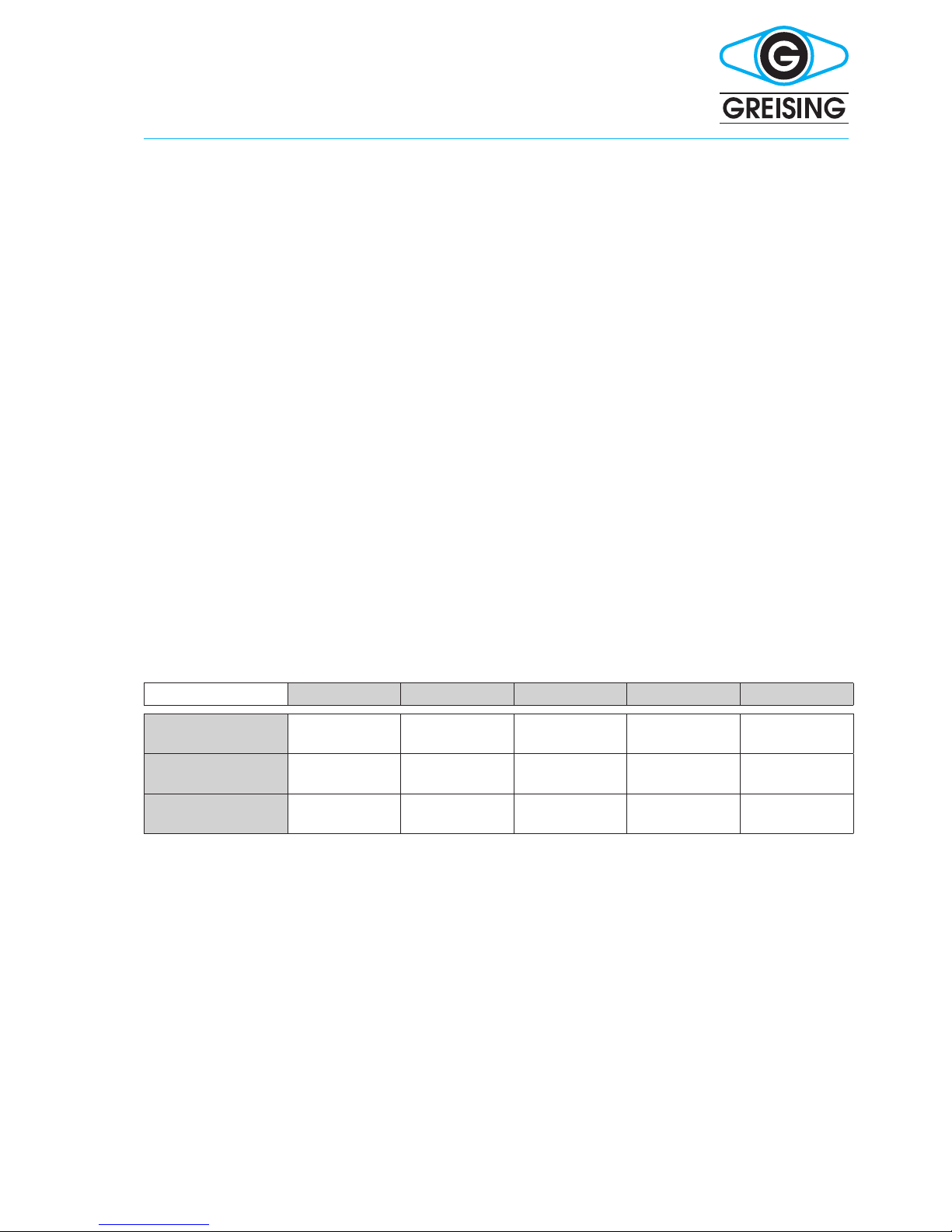

generel data Brush-E Brush-S Brush-P Brush-T Brush-TP

dimensions

WxHxD[mm]

400 x 170 x 370 400 x 170 x 370 520 x 170 x 350 520 x 170 x 350 590 x 170 x 350

weight,ca.[kg] 12,8 12,8 14,5 14,5 15,5

serviceoutput 500 VA, IP 23 500 VA, IP 23 500 VA, IP 23 500 VA, IP 23 500 VA, IP 23

2.2 CONFORMITY

Theunitfullsthefollowingregulationsandstandards:

• EMV-Regulations2004/108/EG

• LowVoltageRegulations2006/95/EG

TheCE-labelisonthefrontoftheunit.

Thetypeplatewiththespecialunitnumberisattachedtotherear.

Further information

•Shouldskinorclothescomeintocontactwithchemicals,theyshouldbe

washed immediately with plenty of water.

•Donoteatordrinkattheworkplace.

•Alwayswashyourhandsbeforetakingabreak.

•Keeptheequipmentandchemicalsawayfromchildren.

1.3.7 Maintenance and servicing, repairing faults

Theprescribedmaintenanceworkandinspectionsaretobecarriedout

onschedule.Beforebeginningmaintenancework,inspectionorrepairs,

switchtheunitoffandsecureby„pullingtheplug“.

1.3.8 Constructional changes on unit

Withoutthepriorconsentofthemanufacturer,noalterations,additionsor

removalsofanysortmaybemadeontheunit.Onlyspareorreplacement

partsoriginatingfromthemanufacturerorhisauthoriseddealermaybe

used.

1.3.9 Emission

Electrolytemayvaporiseduringetchingandcleaning.Thesevapours

shouldnotbeinhaled.Providefreshaircirculationinyourplaceofwork.

2 inTrOdUCTiOn

2.1 TECHNICAL DATA

Operation Manual Clean Marker Brush −Page 7

instructions for use

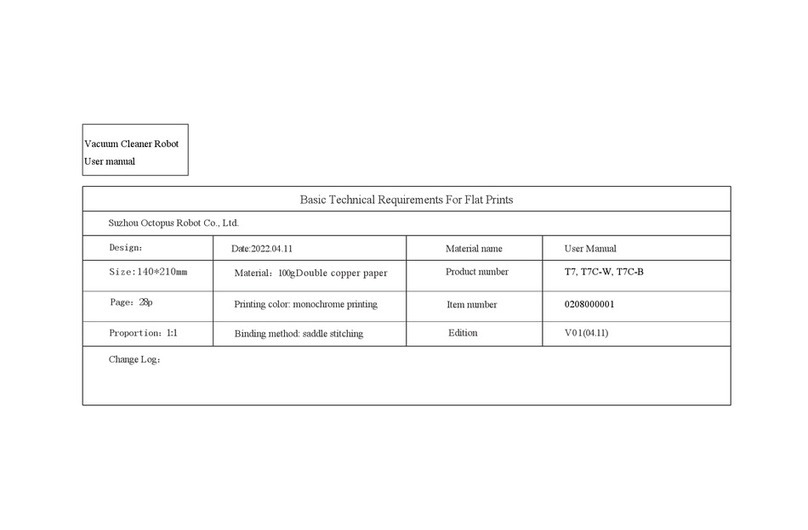

Brush-E Brush-S Brush-P Brush-T Brush-TP

picklinglevel1*

picklinglevel2*

picklinglevel3*

picklinglevel4**

electropolishing

dark marking

light marking

blasting

electrolyte supply

3 FUnCTiOn, MeTHOd OF OPeraTiOn

3.1 FUNCTION

2.3 TRANSPORT, SETTING UP

Please pay attention to the transport instructions on the packaging.

Keepupright.Ifpossible,storevibration-free.

2.3.1 Surrounding conditions

•Temperature

- 5 °C to + 55 °C

•Humidity

Dry, indoors, dew-protected

•To be erected

Dust-free,level,awayfromexplosivegases

• Suitable materials

Allconductivemetalsurfaces

2.4 ACCESSORIES

Thecontentsofthevariousaccessorysetscanbereadinthecurrent

price-lists.Theunitpriceonlyincludesthepowercable.

Operation Manual Clean Marker Brush −Page 8

*withbrushattachment

**withattoolhat

3.2 METHOD OF OPERATION

• electrochemicallypicklingandcleaning

• etchingelectrochemically

• blastingwithglasspearlsoraluminousabrasive

3.3 SAFETY AND MONITORING EQUIPMENT

• 35Amp(1)and4Amp(2)

Aexcesscurrentswitchonthefrontoftheunit6,3Acut-outfuseonthe

rear of the unit (12).

3.5 OPERATING AND DISPLAY ELEMENTS

3.5.1 Front Side, Operating Panel

(1) Safety cut - out 35 Amp

(2) Safety cut - out 4 Amp

(3) Redindicatorlightforsafetycut-out35Amp

(4) Selector switch

(5) Redconnectingsocketfortheworkpiece(earthingcable)

(6) Blackconnectingsocketforthetool(wand)

(7) Green indicator light, showing state of operation

Connecting socket for blasting agent tubing

(8) 6mmtubingforblastingagentexpulsion

(9) 4mmbluetubing

(10) 4mmblacktubing

Operation Manual Clean Marker Brush −Page 9

instructions for use

1

5

8

6

9

7

10

2 3 4

Clean MarKer BrUsH-e

Clean MarKer BrUsH-s

Clean MarKer BrUsH-P

Clean MarKer BrUsH-T

Clean MarKer BrUsH-TP

picklinglevel1

picklinglevel2

electropolishing

dark marking

picklinglevel1

picklinglevel2

picklinglevel3

electropolishing

dark marking

light marking

electrolyte supply

only Brush-P

picklinglevel1

picklinglevel2

picklinglevel3

electropolishing

dark marking

light marking

blasting

electrolyte supply

only Brush-TP

Operation Manual Clean Marker Brush −Page 10

Whenelectro-polishing,materialisremovedfromthesurfaceoftheworkpi-

ecebyspecicelectrolytesusedinconjunctionwithanexternalDCsource.

Thematerialsetfreebytheelectrolyteisnon-pollutingandfollowsunder

atteningconditions.Incontrasttomechanicalremovalprocesses,atte-

ningbyelectro-polishingbeginsinthemicrorangeandincludes,during

longerpolishingperiods,largerstructureswhichareroundedandattened

off on their top surface. During electro- polishing, two different mechanisms

worksimultaneously,oneattenstheuppersurfaceinthemicrorangeand

theotherachievesnedeburringinthemacrorange.

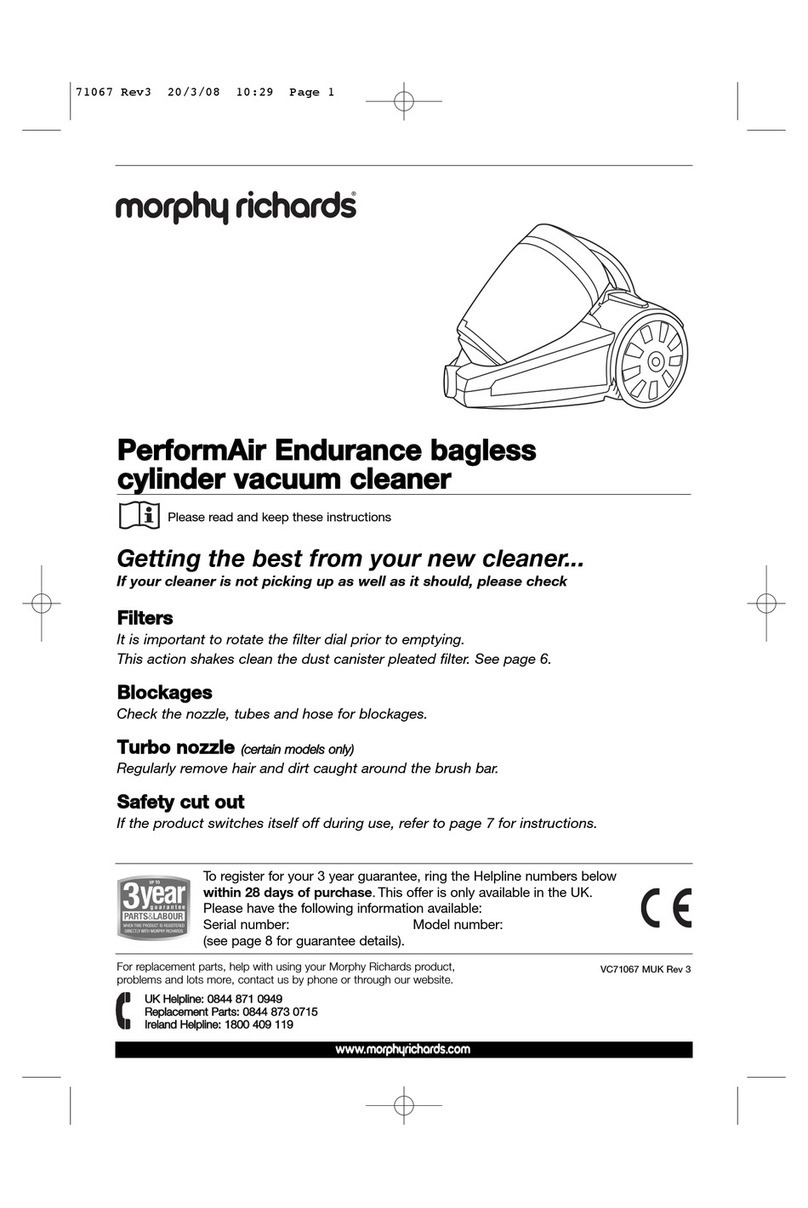

3.5.2 Reverse

(11) Main switch

(12) Fuse6,3Amp

(13) Connectingsocketformainscable

Operation Manual Clean Marker Brush −Page 11

11 12 13

11openap(withscrewdriver)

removefuseslider

exchange fuses

instructions for use

4 TransPOrT, seTTinG UP

4.1 SAFETY REGULATIONS

4.1.1 Temporary storage

Always keep the unit in its outer packaging and in a dry room indoors.

4.1.2 Unpacking

Withoutusingsharptools,removetheouterpackagingcarefully.

Keeptheoriginalpackaging.Alwaysuseitforstoringandtransportingthe

unit.

4.1.3 Putting the machine into operation

• checkthatthemainsvoltageisthesameasthatonthetypelabelandis

the same as the setting

• usingthemainscableconnecttheunittothemainsvoltage

pushtheredcableintotheredconnectingsocket(5)

• fixtheearthingclamptotheredcableandthenontheworkpiece

• pushtheblackcableintotheblackconnectingsocket(6)

• fixtheotherendofthecableintothetoolforlettering/cleaning

• switchontheunitatthemainswitch(11),theyellowlight(7)should

belit,theunitisready

• settheunitasdesired

5 OPeraTinG

5.1 INITIAL OPERATION

Carryoutacheckandinspection,notonlypriortoinitialoperation,butalso

priortoeverysetup.Setuptheunitasdescribedabove.

Workingwithchemicalscanbedangerous.Alwayswearafacemask,

acid-proofapron,gogglesandgloves.WhenusingGreinox1000/2000/

Polish,RapidpleasereadtheSafetyDataSheetsrst(currentlytobe

foundunderwww.greising.com/CleanMarker/Service).

Donotingestthevapoursarising.Shouldtherebeskincontact,washwith

plenty of water.

Operation Manual Clean Marker Brush −Page 12

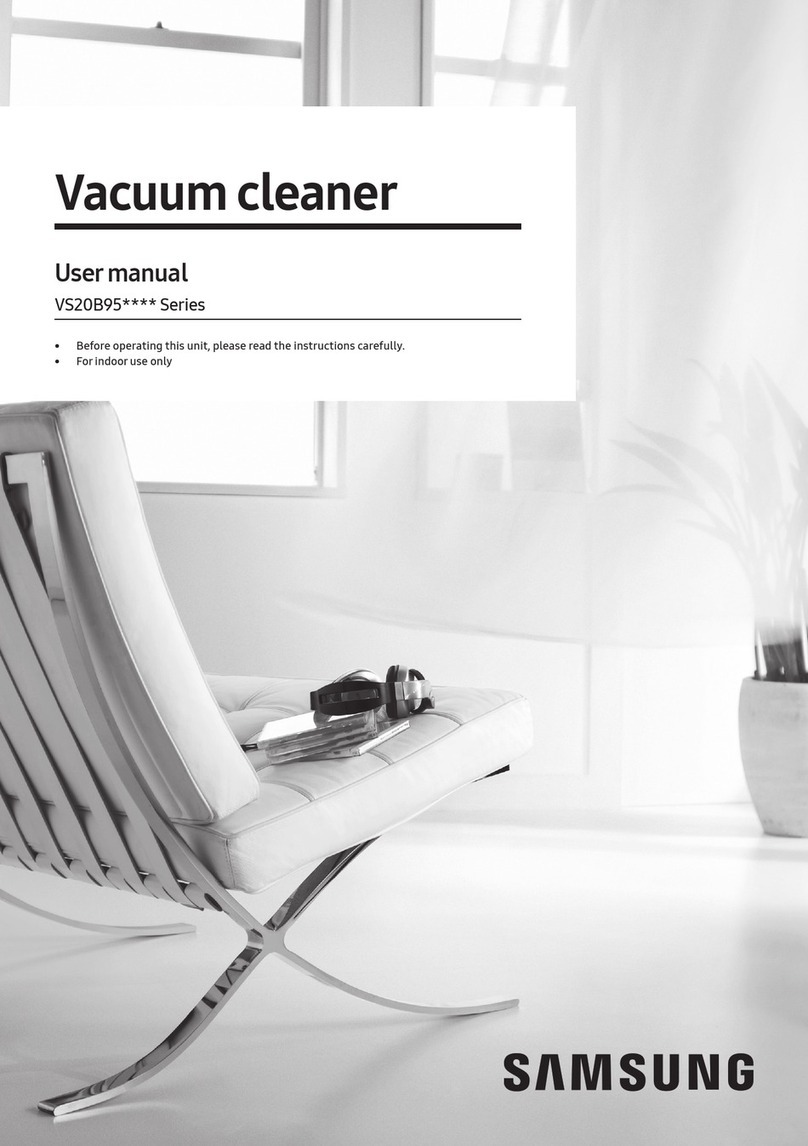

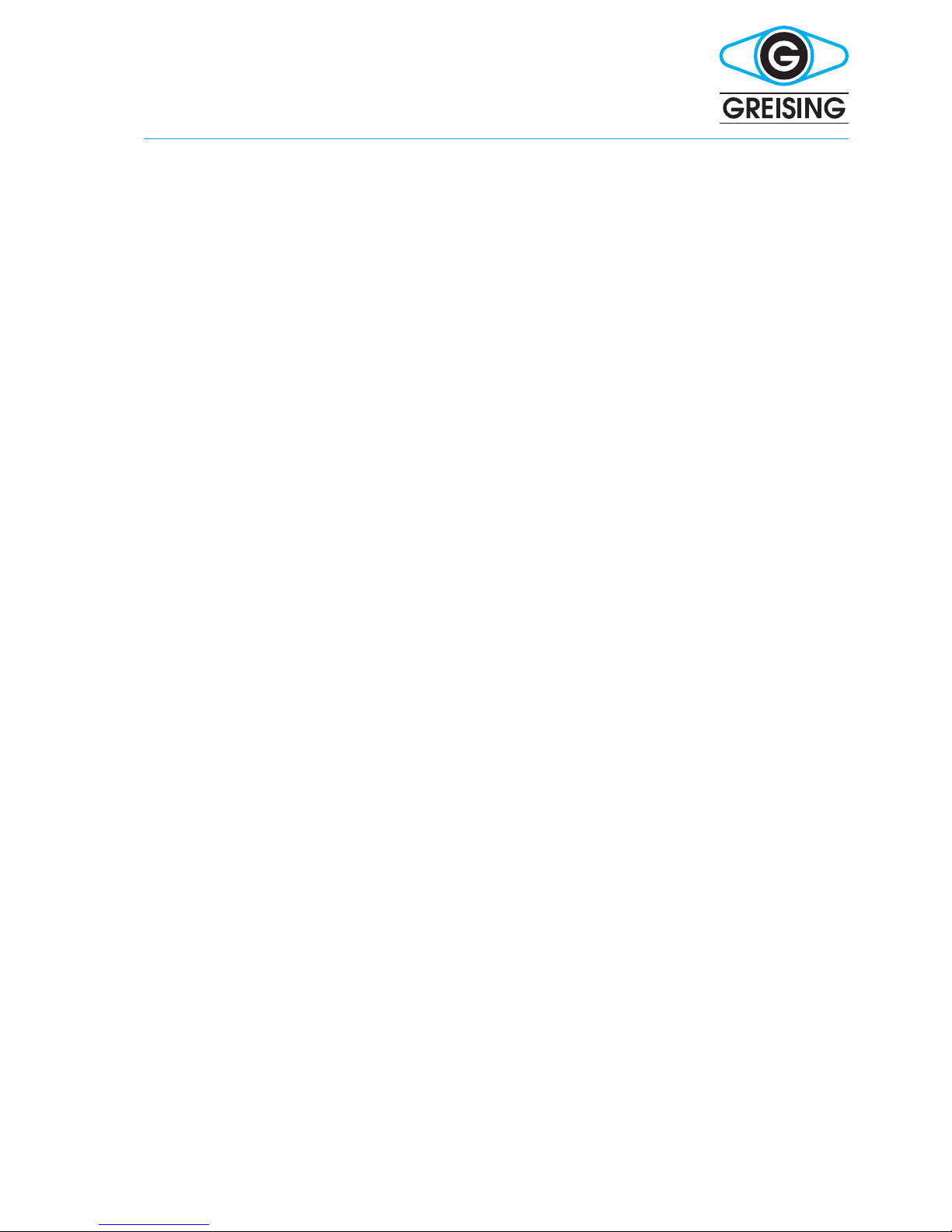

5.1.1 Unit adjustments for cleaning for Clean Marker Brush devices

selector switch (see page 10)

5.2 CLEANING WITH CLEAN MARKER BRUSH ATTACHMENTS

5.2.1 Tips for maximum cleaning effect

WiththeCleanMarkerbrushattachmentyoucancleaneveninaccessible

parts.Theshortbrushshowsmorepowerfullperformance,thelongbrushis

especiallyforbigareas.Chancethebrushintimetoavoitshortcircuits.

Slag and scale spots can only be removed by blasting

(Clean Marker Brush-T and Brush-TP)

5.2.2 The „Cleaning“ Process

• screwonthebrushattachment

• adjusttheunitaccordingtoChapter5.1.1

• fillabout1cmGreinox1000,2000,PolishorRapidintothewide-neck

containermorecanbefilledintothecontainersforpumpunits

• moistenthetool

• runthetooloverthebloomuntilthesurfaceisclean

To avoid white edges on the work piece: polish the cleaned

work piece with the cleaning cloth supplied, lightly moistened

with water and Neutralyt.

Croping the brush will increase performance.

On level 3 short circuit signs may appear. It may be necessary

to chance down on level 2.

5.3 ETCHING WITH THE CLEAN MARKER (FLAT TOOL)

5.3.1 Tips for maximum etching effect

Everyelectrolytecontainssalts.Dependingonthematerial,thesesalts

canhaveastronglyoxidizingeffect.Extremecleanlinessmustbeusedwhen

handlingthechemicals.Avoidcarry-overofelectrolytesandwashyour

hands frequently. Make sure of good power contact and moist felt. Felt which

istoodryrestrictstheowofpower.Stencilsbecomecloggedwithsaltsand

metalsafterawhile.Theyshouldalsoberinsedandcleanedfrequently.

Electrolytecanalsobeusedforcleaningstencils.Smallsurfacescanbest

Operation Manual Clean Marker Brush −Page 13

A

B

C

D

selector switch

1picklingwithbrush

2picklingwithbrush

3picklingwithbrush*

4picklingwithelectrod*

5 polishing

6darkmarking

7lightmarking*

brushattachment1(A) brushattachment2(B)

marking stencil (C)

+ marking felt 1

marking stencil

60°(D)+cleaningfelt

symbol

*notwithCleanMarkerBrush-E

instructions for use

beetchedbysimplypressingthefeltonthestencil.Largerareasarebest

etchedbystrokingthetoolheadseveraltimesovertheentiresurfaceofthe

stencil.Thistakesbetween1.5and2seconds.Iftheetchingappears

rusty,theneitherdonotusethetoolquitesolongordecreasethevoltage.

Thetoolshouldbeheldatrightanglestotheworkpieceandthewhole

surface used for contact with the stencil.

the electrolyte ows better through the stencil

Donotallowthestenciltobecometoowarmasthiscouldleadtoprema-

turewearandtear.Whenelectrolytevaporisesitleavesresiduesinthe

stencil tissue. In time this reduces the clarity of the etching. Dark, i. e. dirty,

feltsmustbechangedfrequentlyandthelargerthestencil,thequickerthe

felt needs changing.

Theresultsofletteringdependonvariousfactors.Theresultscanvary

dependingonmaterialorwithinamaterialbatch.Testtheletteringfor

qualityonapieceofwastematerialbeforebeginningtowork.Thelettering

canusuallybeoptimisedbyusingvariousparametersandelectrolytes.By

usingswitch(4)youcansetwhethertheletteringshouldbedarkorlight.

The result differs with different materials.

Morematerialisremovedwithlightlettering.Thestencilgetsdirtyvery

quicklyandmustbecleanedmoreoften.

5.3.4 The „Etching (marking)“ Process

• cleanthespottobeetched

• cutoff30mmetchingfelt(t=2mm)fromthe60x2x1000striporfrom

the sheet

• usingthe„O“-ring,fixthefeltpadtothetoolhead

• usingtheselectorswitch(4)settheunittothedesiredsettingforlight

or dark etching

• addenoughelectrolytetothefeltontheundersideofthetoolsothatit

is wet

• positionthestencilinthedesiredpositionontheworkpiece

• usinglightpressureandsmallswivellingmovementsstrokeoverthe

stencilor,ifthestencilissmallenoughtobecoveredbythetoolhead,

thensimplypressdownandmoveslightlytoandfro,holdingthetool

at right handles to the work piece

• 1.5to2secondsshouldbelongenoughtoproduceagoodetching

althoughthisdependsonthematerialtobeetched

• cleanthesurfaceandtheetching

• neutralizethesurfacewithaclothsoakedinNeutralytGN2severaltimes

• thenfinallyconservethesurfaceandtheetchingwithKonservatGK2

There is a special tool head for etchings wider than 30 mm.

Operation Manual Clean Marker Brush −Page 14

Operation Manual Clean Marker Brush −Page 15

5.4 DEALING WITH SHORT-TERM STENCILS

5.4.1 Marking with short - term stencils

•placetheshort-termstencilwiththeblue/greensidefacingyouintothe

typewriter/matrixprinter(withoutribbon)

•typethedesiredletteringontotheblue/greenside

•removetheshort-termstencilandcutittothedesiredsize.

•removethewhiteprotectivepaper

•moistentheuppersideoftheshort-termstencilwithelectrolyte

•putthestencilintopositionontheworkpiece

•pressthetoolheadontothestencilsothatthewholesurfacecoversthe

stencilandmoveitaroundgently

•afterabout1.5to2seconds(dependsonthematerial)theprocess

shouldbefinished

•cleanthesurfacesothatnoelectrolyteremainsontheworkpiece

•neutralizethesurfaceusingaclothsoakedinNeutralytGN2

•conservetheletteringandthemetalsurfacewithKonservatGK2

5.5 CLOSING DOWN THE UNIT

• switchoffatthemainswitch(11)andremovethemainsplug(13)

• dismantlealltheaccessories

• cleanallparts

5.6 BLASTING WITH THE CLEAN MARKER BRUSH-T AND BRUSH-TP

5.6.1 For precision removal of slag and scale spots on welded

seams

Additionalusesare:roughening,cleaning,de-rusting,de-burring,

polishing,mattingandcompactingsmallareas,byusingsuitableblasting

agents,suchasglassparticles,specialalumina,siliconecarbide,walnut

and plastic granulate in the range of 1 −300µ.

5.6.2 Equipping for blasting

The Clean Marker T4 is equipped with a pressurised container holding 0.8 l.

Thejetnozzleisactivatedbytheswitchonthehandle.Thedesiredworking

pressureissetbythepressurecontrollerandcanbereadonthepressure

gauge.Therearetwoboroncarbidenozzlesd=1.2and1.8mmtochoose

from.Toexchangethenozzle,simplyunscrewtheunionringonthenozzle

handlethenexchangetheboroncarbidenozzle.

5.6.3 Setting up the blasting unit

Connectingthetubingontheunit:

• connectblastingtube

6mmtubingforblastingagents(8)

4mmtubing,blue(9)

4mmtubing,black(10)

Screwtheblastingnozzletothetubingusingascrewcap.Using

compressedairtubeconnectthecompressortoconnection

instructions for use

make sure the air is dry, otherwise the blasting agent will

form lumps

Set the desired working pressure on the regulator. The compressed air set

willbedisplayedontheManometer.

max. 7 bar, recommended is 2 −4 bar

air consumption about 150 l /min at 5 bar

Fillblastingagentintothecontainer

make sure the blasting agent is dry

Thelid(15)istobeunscrewedwhenblastingagentislledintothe

container.Usingafunnel,llthecontainerwithblastingagentuptoapprox.

onenger’swidthundertherisingpipeinthemiddleofthecontainer.

Close the container.

Youcanbeginworkbyusingthebuttonontheblastinggun

Blastingstopsbyreleasingthebutton

Onceworkhasbeennished,theunitmustbedisconnectedfromthe

compressed air supply.

during blasting, goggles (face mask), dust mask, breathing

mask and gloves are to be worn

5.6.5 Blasting agent

Asarule,thefollowingtwoagentscanbedeliveredexstock:

•EKS 10:

stronglyabrasive,fastremovingagent–leavesaroughsurface

•MGK 10:

hasamorepolishedeffect–leavesashinysurface

5.7 CONNECTING UP THE AUTOMATIC ELECTROLYTE FEED ON

CLEAN MARKER P AND CLEAN MARKER TP

• plugtheblackplugbelongingtothepumptubingsetintotheconnecting

socket (17)

• pushtheacidtubingsofarintothestainlesssteelconnectionofthebulk-

headstuffingbox(20),thatitcannotfalloutbyitself-pressthesafetyring

(21)atthesametime,holditfirmlyandpushthetubeintotheopening

• pushthe3-polepluginthedrivingpowerconnection(16)andscrewitup

tightly

• unwindasmuchasyouneedoftheacidtubefromtheroller(18)andtipit

into the electrolyte container (19)

Liquidwillonlybefedwhenthebuttononthecleaningheadispressed.

Whenpumping,opentheacidcontaineralittlesothatnegativepressure

cannotbuildupwhentheliquidissuckedupanddamagethepump.On

all Clean Markers equipped with pump the electrolyte is sucked up directly

fromanexternal5/10litrecannister,abottleorawide-neckedcontainer.

Theacidtubingmustthereforebehungintotheelectrolytecontainer.

Operation Manual Clean Marker Brush −Page16

15

6 MainTenanCe

6.1 SAFETY REGULATIONS

Maintenancemayonlybecarriedoutbyanauthorisedperson.Before

beginningmaintenance,switchofftheunitandsecureagainstinadvertent

switchingon,e.g.by„pullingtheplug“.Workmustbeexecutedalongthe

linesprescribedinChapter1„safetymeasures“.

6.1.1 Maintenance and inspection check list

6.2 GENERAL REMARKS

Donotusecleaningagents,metalobjectsorcompressedair.Dustand

glueresiduesmustberemovedwithascrapermadeofplastic.

Dismantle and clean the tool after use. If not, acid could

concentrate to such a degree that it becomes a health hazard.

The supply of power through the cable could also be affected

and the performance reduced.

Intervals controlposition/adviceofmaintenance utilities

daily,beforeusing Checkthedeviceandthestencil/brush

If necessary replace worn parts

daily, after using cleanstencils,toolhead,cableandstainlesssteelworkingsurface

clean stencils:

carefullybetween2ngersinclearwater

cleaning tool head:

unscrewhandlefromcarbonheadandcleanbothinplentyofwater

attention:

usingawrench,securemandrelonthepumptubing

clean unit and cable:

wipe with a moist cloth

a soft cloth,

brush

16

17

18

19

Operation Manual Clean Marker Brush −Page 17

instructions for use

7 disTUrBanCes

7.1 REMOVING DISTURBANCES

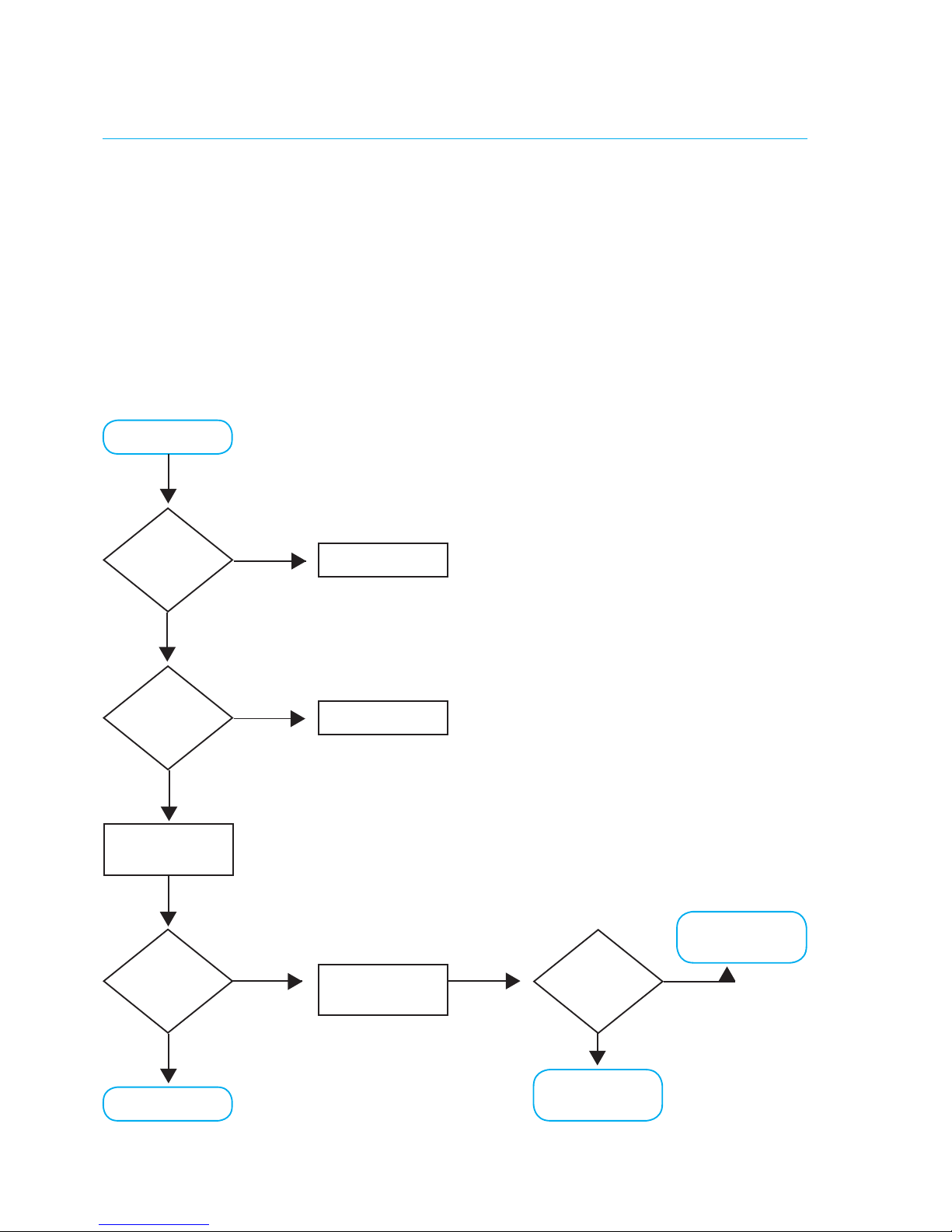

7.1.1 Pump does not work

Operation Manual Clean Marker Brush −Page 18

pump does not

work

okay

pressbuttononnozzle

oftubing

yes

switch unit on

connecttubing

(see page 18)

checktubing(3-pole

pin plugs 1 and 3)

ja

replace or repair

suctiontubing

no

no

no

yes

call specialist to

check unit

no

is the unit

switched on?

tubing

connected?

pump is

running

switch

okay?

no

yes

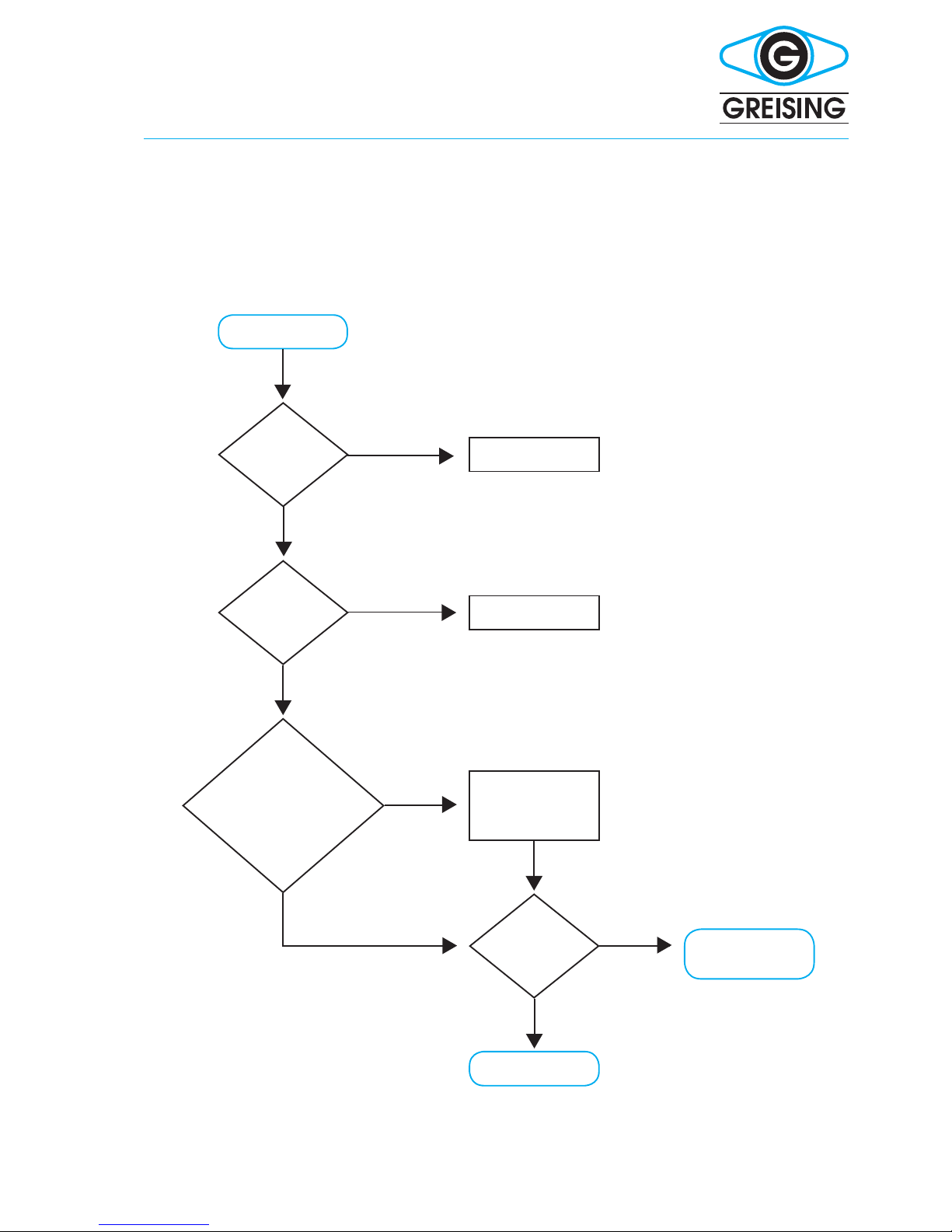

7.1.2 Electrolyte isn´t being pumped

Operation Manual Clean Marker Brush −Page 19

electrolyte isn´t

beingpumped

no

no

call sprecialist to

check unit

switch unit on

see diagram on

previouspage

connecttubingasin

diagram 11

hangthesuctiontube

into electrolyte

no

yes

okay

arethetubes

connected according

todiagram11?(suctiontube

in electrolyte container?)

pump is

feeding electro-

lyte?

unit

switched on?

is the pump

running?

no

yes

yes

yes

yes

instructions for use

7.1.3 Blasting function not working

Operation Manual Clean Marker Brush −Page 20

okay haveunitchecked

byspecialist

yes

yes

connectblastingtube

(3.5.1)

make sure there is dry

compressed air (23)

set operating pressure

on regulator (25)

lldryblastingagent

pressbuttonon

blastingtube

blasting?

bla-

sting

tubingornozzle

blocked?

blasting

agent dry?

cleannozzle

blastingfunctionnot

working

no no no

This manual suits for next models

4

Table of contents