4

!! IMPORTANT !!

Failure to closely follow operational and

maintenance procedures may result in damage to

the unit and / or void your warranty. Coldelite

Corporation will not be responsible for any

machine not properly operated or maintained.

Part I – Installation

Before starting this procedure, ensure that the

shipping carton does not show any evidence of

damage due to dropping or mishandling. This

may indicate that the dispenser was damaged

during transit or delivery.

!! IMPORTANT !!

Should the outside of the shipping carton give

any indication of possible damage, state this on

the bill of lading prior to signing. Contact the

freight carrier and request an inspection of

damage. If this procedure is not adhered to, you

will forfeit your rights to file a damage claim

and be responsible for subsequent repair costs.

A) Uncrating the Dispenser

1) The outer shipping carton is secured to the

shipping pallet with strapping. When cutting this

strapping, do so with caution as it may spring out

quickly. After cutting the strapping, lift the

shipping carton straight up and off of the freezer.

2) Remove the protective foam boards and plastic

wrapping from the outside of the freezer.

3) Unwind the power supply cord and inspect for

any damage that may have occurred during

transportation. If the cord is damaged or cut in

any way, contact an Authorized Service Agent

before connecting to a power source.

B) Positioning the Machine

After removing the machine from the shipping

pallet, it is now ready to be located in its final

location. Prior to choosing a location keep in

mind that the dispenser should be accessible for

periodic maintenance and have adequate space

for necessary airflow. Please allow 6 inches of

clearance on both sides of the dispenser.

The dispenser must also be level to ensure proper

drainage from the mix tank. To level, place a

level on all corners and shim as needed.

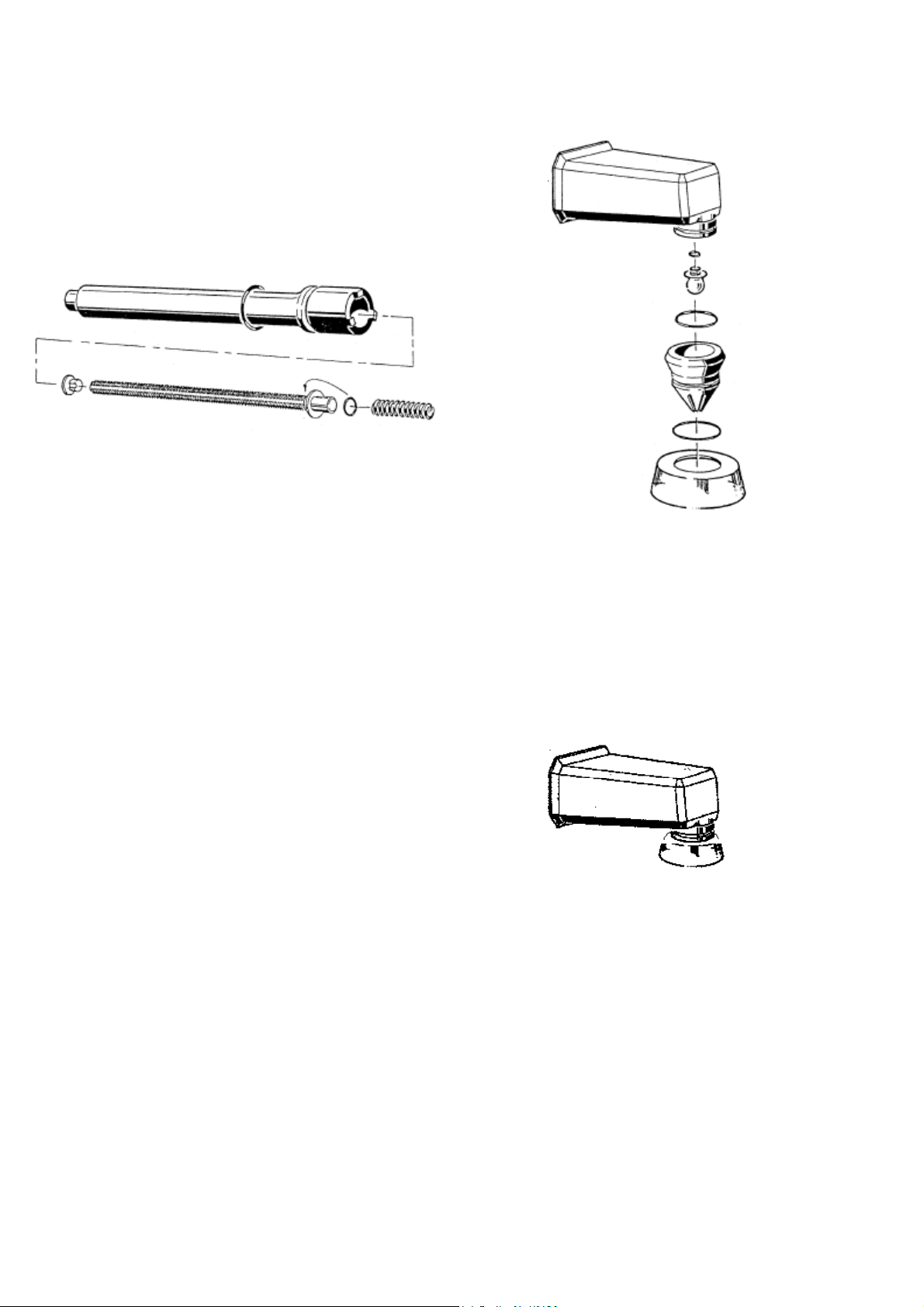

To seal the dispenser to the counter, proceed as

follows:

Determine the exact location you would like to

install the dispenser. Clean the counter top

thoroughly of any dust, dirt or oil.

Apply a thin bead (1/4”) of General Electric

RTV-102 (or equivalent) silicone sealant to the

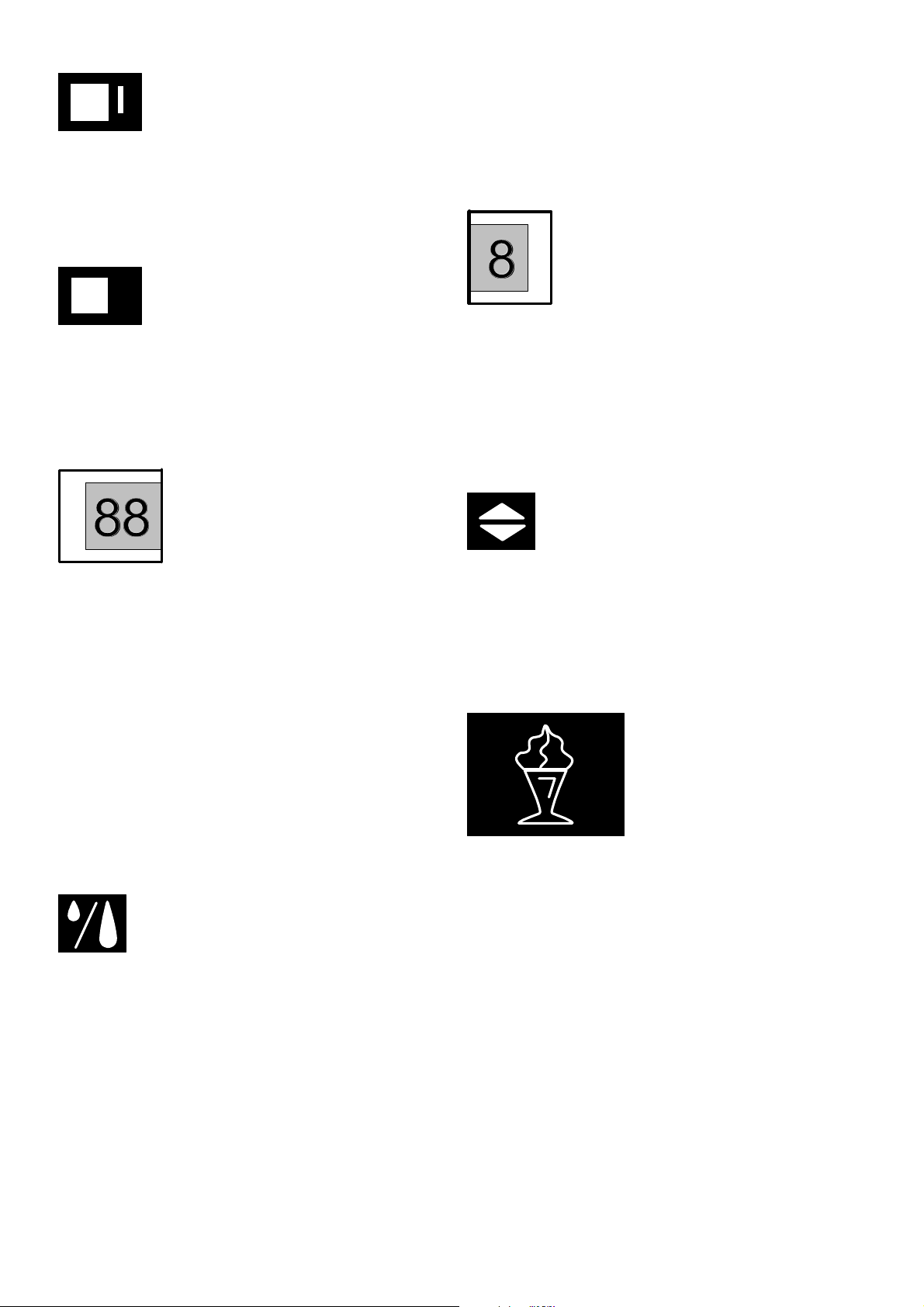

lower mounting rim of the dispenser. (Refer to

Figure 1)

Figure 1

Carefully lift the machine and place on the

counter in the exact predetermined location.

Remove any excess sealant from the base and

counter to create a flawless seam between the

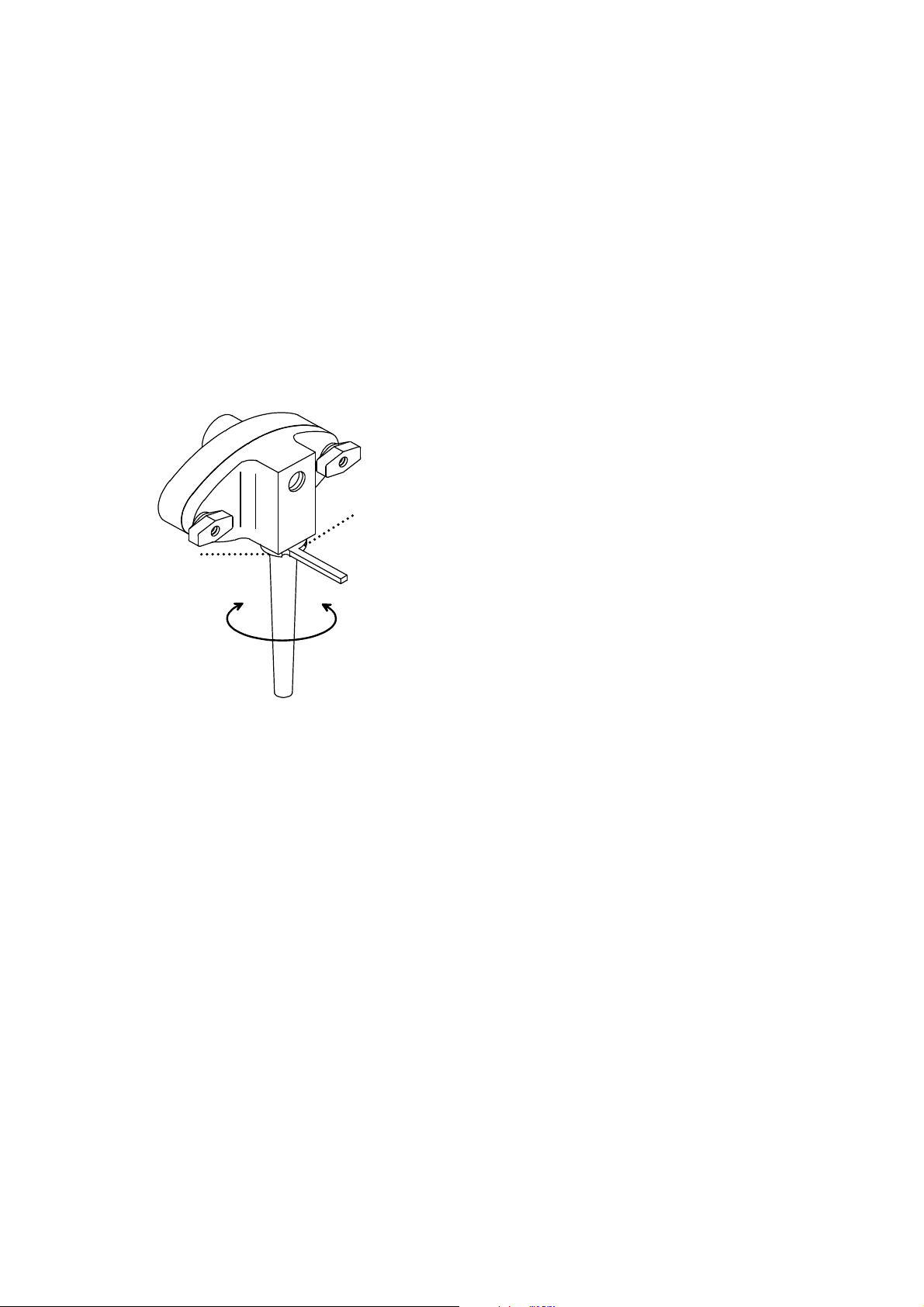

counter top and machine base (Refer to Figure 2)

Figure 2

Machine Bottom

Mounting Rim

Counter

Machine Base

Machine

Counter Surface

Silicone Sealant