2007 Eagle Electric Golf Car Service Manual © December 2007ii

Table of Contents

SECTION 5 - ACCELERATOR AND BRAKES

Accelerator Pedal ...................................................................5-2

Mechanical Brake System......................................................5-2

General................................................................................ 5-2

Periodic Brake Inspection.................................................... 5-2

Annual Brake Inspection ..................................................... 5-2

Mechanical Rear Drum Brake ............................................. 5-3

Brake Cable Replacement .................................................. 5-5

Mechanical Brake Adjustments ........................................... 5-5

Hydraulic Brake System .........................................................5-6

General................................................................................ 5-6

Periodic Brake Inspection.................................................... 5-6

Annual Brake Inspection ..................................................... 5-6

Hydraulic Rear Drum Brake ................................................ 5-6

Hydraulic Master Cylinder ................................................... 5-9

Hydraulic Front Disc Brake ............................................... 5-10

Hydraulic Brake Adjustments ............................................ 5-12

SECTION 6 - FRONT WHEELS, STEERING

& FRONT SUSPENSION

General................................................................................... 6-2

Specifications ......................................................................... 6-2

Front Wheels and Hubs.......................................................... 6-2

Removing Front Wheels and Hubs ..................................... 6-2

Inspecting/Replacing Wheel Hub Bearings......................... 6-2

Installing Front Wheel Hubs and Wheels ............................ 6-2

Tires........................................................................................ 6-4

General................................................................................ 6-4

Removing Tire ..................................................................... 6-4

Installing Tire ....................................................................... 6-4

Steering Wheel....................................................................... 6-5

Removing Steering Wheel................................................... 6-5

Installing Steering Wheel..................................................... 6-5

Rack and Pinion Steering Assembly....................................... 6-5

Removing Rack and Pinion Steering Assembly .................. 6-5

Disassembling Rack and Pinion Steering Assembly........... 6-5

Assembling Rack and Pinion Steering Assembly................ 6-6

Installing Rack and Pinion Steering Assembly.................... 6-6

Front Suspension System ...................................................... 6-6

Replacing Shock Absorbers ................................................ 6-6

Replacing Front Leaf Spring................................................ 6-6

Disassembling Kingpin, Steering Arm and A-Arm ............... 6-6

Assembling Kingpin, Steering Arm and A-Arm .................... 6-7

Steering and Front suspension Adjustments.......................... 6-7

Camber Adjustment............................................................. 6-7

SECTION 1 - SAFETY

Overview................................................................................. 1-2

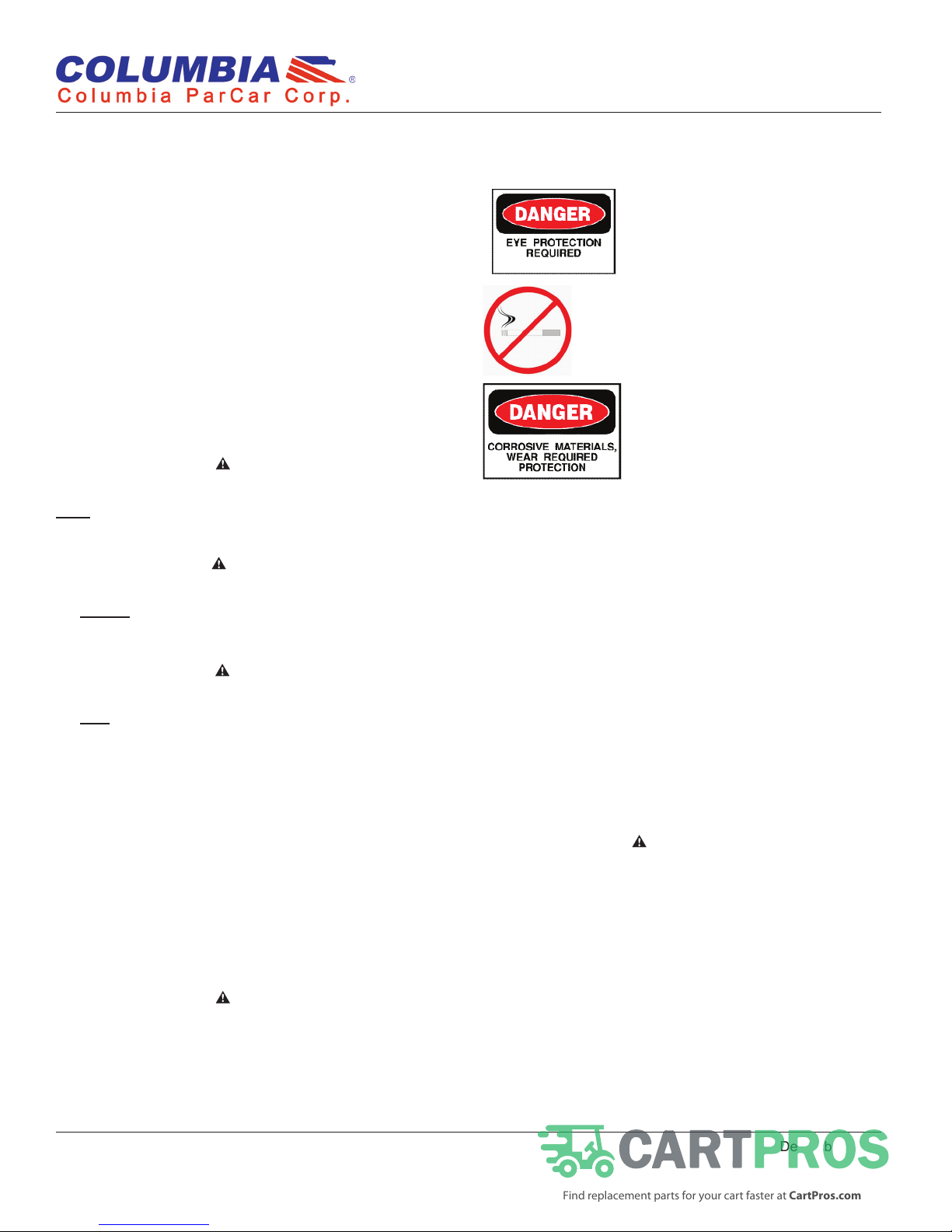

Safety Information .................................................................. 1-2

Safety Preparations................................................................ 1-3

Icons in Procedures................................................................ 1-4

Decals..................................................................................... 1-4

SECTION 2 - GENERAL INFORMATION

Model information................................................................... 2-2

Vehicle Model Information................................................... 2-2

Vehicle Identification Number (VIN) Charts......................... 2-2

Safety Committee................................................................... 2-2

Vehicle Specifications............................................................. 2-3

Controls and Operation .......................................................... 2-4

Location of Controls ............................................................ 2-4

Operation............................................................................. 2-4

Pre-operation Inspections....................................................... 2-5

Pre-operation Check List........................................................ 2-5

SECTION 3 - MAINTENANCE

Periodic Maintenance............................................................. 3-2

Batteries ................................................................................. 3-5

Chassis Lubrication ................................................................ 3-5

Wheel Hubs......................................................................... 3-5

Brake Pedal......................................................................... 3-5

Rear Axle................................................................................ 3-5

Chassis Cleaning.................................................................... 3-5

Seat Cleaning......................................................................... 3-5

Lifting instructions................................................................... 3-6

Tools Required .................................................................... 3-6

Hoist Lifts............................................................................. 3-6

Floor Jack Procedure .......................................................... 3-6

Jack Stands......................................................................... 3-6

Vehicle Storage ...................................................................... 3-7

Returning Vehicle to Service .................................................. 3-7

Towing the Vehicle.................................................................. 3-7

Transporting the Vehicle......................................................... 3-7

Torques and Metric Conversion Factors................................. 3-8

SECTION 4 - TROUBLESHOOTING

Pre-Troubleshooting Steps..................................................... 4-2

Battery Testing........................................................................ 4-3

Troubleshooting Specific Complaints ..................................... 4-4

ACEPlus Sevcon Controller Power System ........................... 4-8

Smartdrive Sevcon Controller Power System ...................... 4-12

Speed Switch (Pot Box) Testing ........................................... 4-14

Component Troubleshooting ................................................ 4-14

Find replacement parts for your cart faster at CartPros.com