Copyright © 2001 Condec. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

December 2001

Contents

About This Manual................................................................................................................................... 1

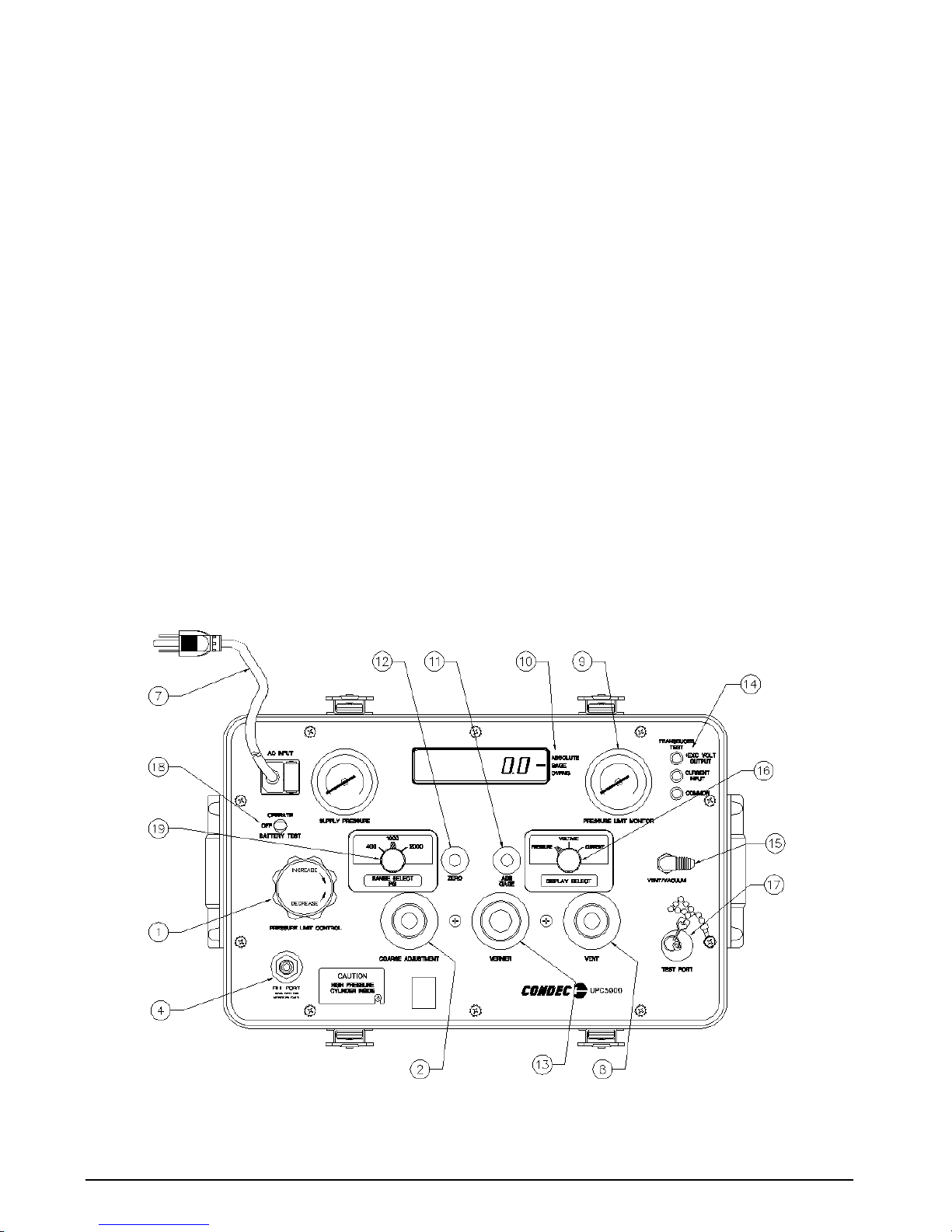

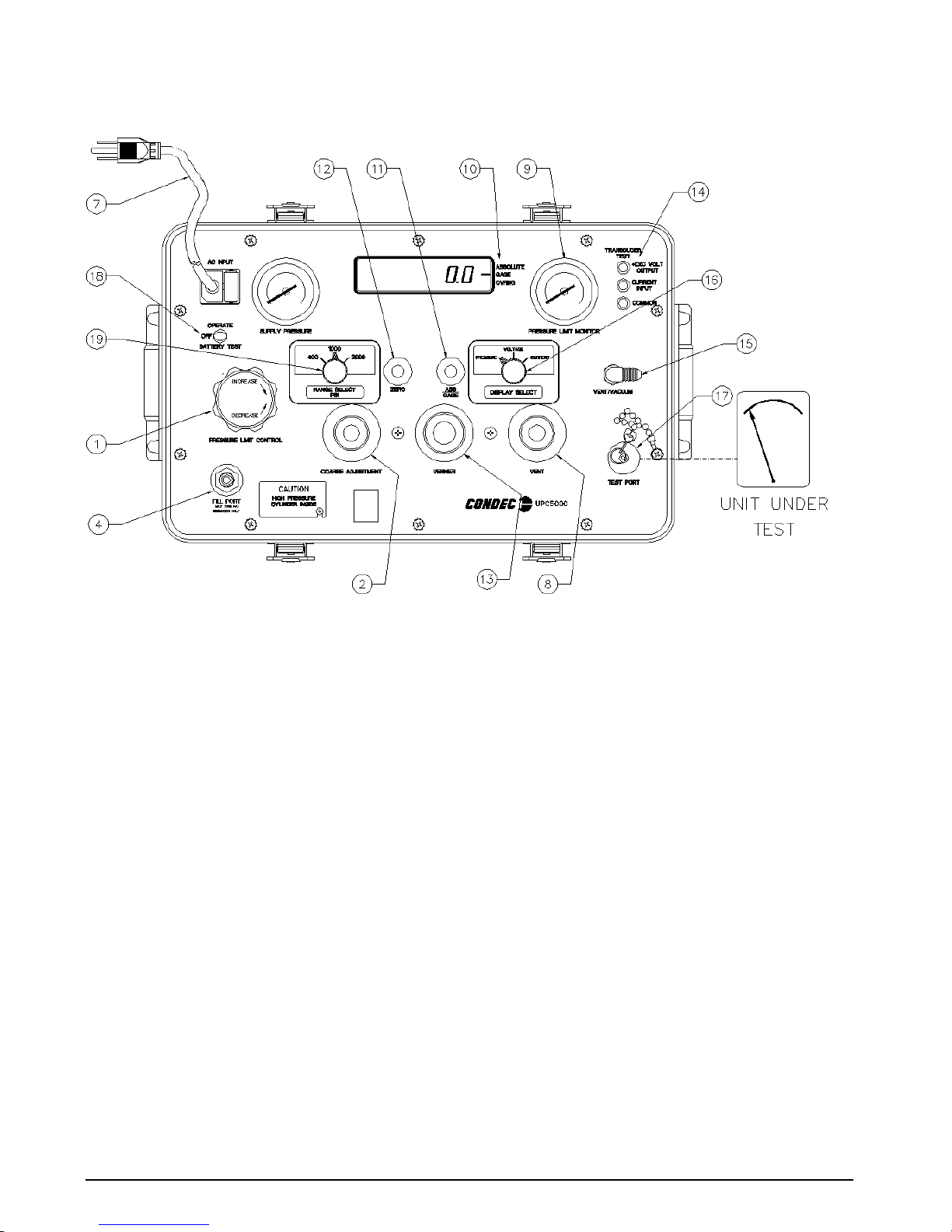

1.0 Introduction.................................................................................................................................. 1

2.0 Operation...................................................................................................................................... 3

2.1 Pressure Cylinder Filling Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Initial Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Pressure Measurement Sequence for Absolute/Gage Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Pressure Measurement Sequence for Gage Only Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Pressure Measurement Sequence for Absolute Only Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6 Battery Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.0 Calibration.................................................................................................................................... 8

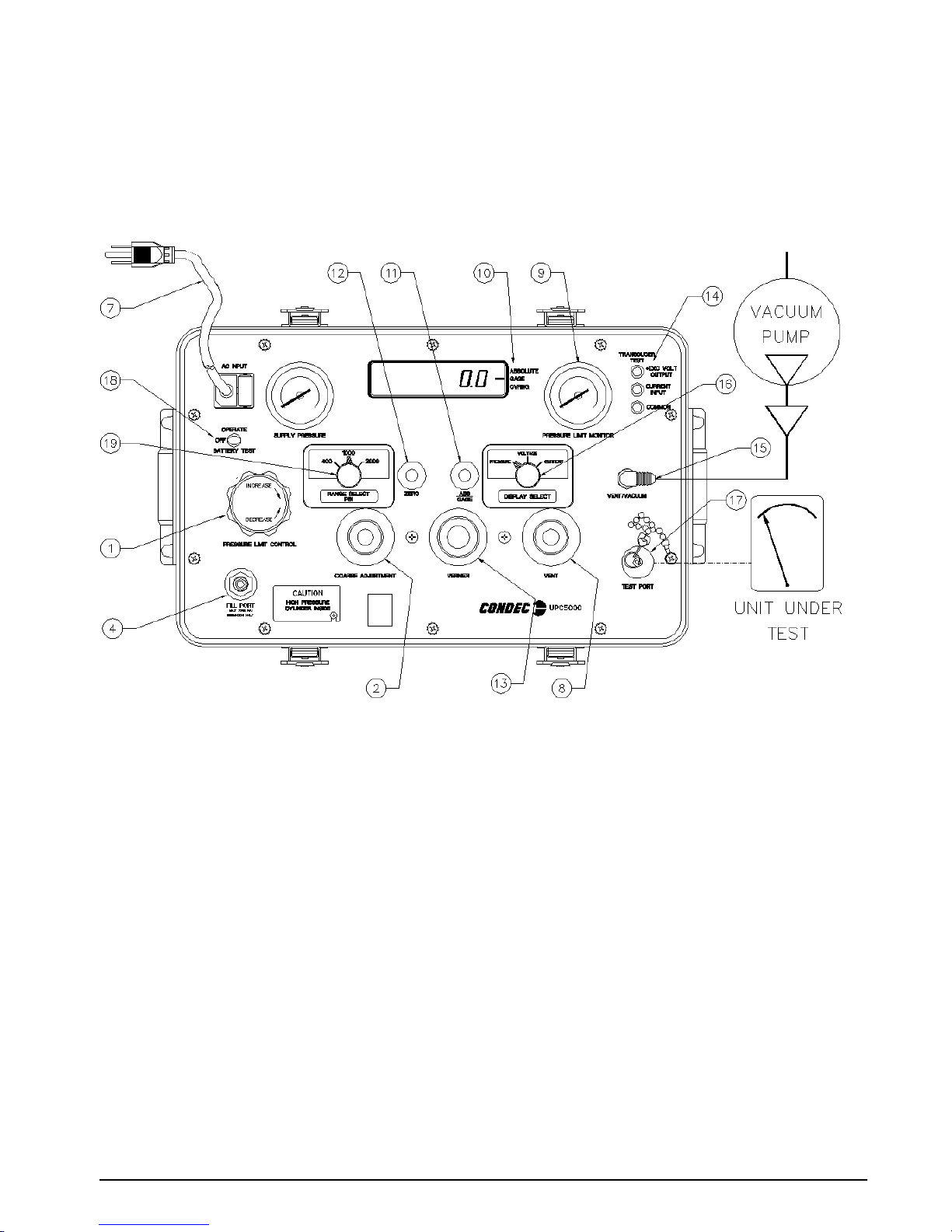

3.1 Pneumatic Calibration Set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Instrument Calibration Set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Zero/Span Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Linearity and Hysteresis Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5 Shunt Resistor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.6 Voltage/Current Input Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.7 Permanent Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.8 Required Barometric Offset for Absolute/Gage Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.9 Normal Mode Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.10 Self-Check Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.0 Maintenance and Service.......................................................................................................... 14

4.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Maintenance and Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.1 Panel/Chassis Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.2 Nitrogen Cylinder Assembly Removal (PN 59531). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.3 Installing New Nitrogen Cylinder Assembly (PN 59531). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.4 ORION-2C Manifold Removal (PN 55283). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.5 ORION-2C Manifold, Valve Seat Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.6 ORION-2C Manifold, Vernier Control Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.7 ORION-2C Manifold, Vernier Control Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.8 ORION-2C Manifold, Valve Seat Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.9 ORION-2C Manifold, Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.10 ORION-2C Manifold, Valve Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.11 Pressure Limit Control (Standard Pneumatic), Regulator Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.12 Pressure Limit Control (Standard Pneumatic), Regulator Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.13 Pressure Limit Control (Tescom), Regulator Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.14 Pressure Limit Control (Tescom), Regulator Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.15 Panel Gauge Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.16 Panel Gauge Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.17 Test Port Quick-Connect Fitting (PN 55426), Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.18 Test Port Filter (PN 54188), Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.19 Inlet Check Valve - Nitrogen Fill Port (PN 60263). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.20 AC Fuse (PN 58076), Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.21 AC Power/EMI Line Filter (PN 58870), Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.22 Power Switch (PN 55187), Removal and Installation (Battery Units). . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.23 Power Switch (PN 58878), Removal and Installation (Non-Battery Units). . . . . . . . . . . . . . . . . . . . . . . 27

4.2.24 Range Select and Display Select Switches (PN 55924), Removal and Installation . . . . . . . . . . . . . . . 27

4.2.25 Absolute and Zero Switches (PN 58886), Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.26 Power Supply Assembly, Removal and Installation (Battery Units). . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.27 Battery (Replacement Kit PN 55354) Removal, Installation and Adjustments. . . . . . . . . . . . . . . . . . . . 29

4.3 Orion 2C Valve Assembly Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32