CAT240 2 Rev. 02/24/09

This insTrucTion Manual conTains

• Alwaysoperate,inspectandmaintainthistoolin

accordancewithAmericanNationalStandards

InstituteSafetyCodeofPortableAirTools(ANSI

B186.1)andanyotherapplicablesafetycodes

andregulations.

• Forsafety,topperformanceandmaximumdurability

ofparts,operatethistoolat90psig;6.2barmax

airpressurewith3/8"diameterairsupplyhose.

• Alwayswearimpact-resistanteyeandface

protectionwhenoperatingorperformingmaintenance

onthistool.

• Alwayswearhearingprotectionwhenusingthis

tool.Highsoundlevelscancausepermanenthearing

loss.Usehearingprotectionasrecommendedby

youremployerorOSHAregulation.

• Keepthetoolinefficientoperatingcondition.

• Operatorsandmaintenancepersonnelmustbe

physicallyabletohandlethebulk,weightand

powerofthistool.

• Airpoweredtoolscanvibrateinuse.Vibration,

repetitivemotionsoruncomfortablepositionsover

extendedperiodsoftimemaybeharmfultoyour

handsandarms.Discontinueuseoftoolifdiscomfort,

tinglingfeelingorpainoccurs.Seekmedicaladvice

beforeresuminguse.

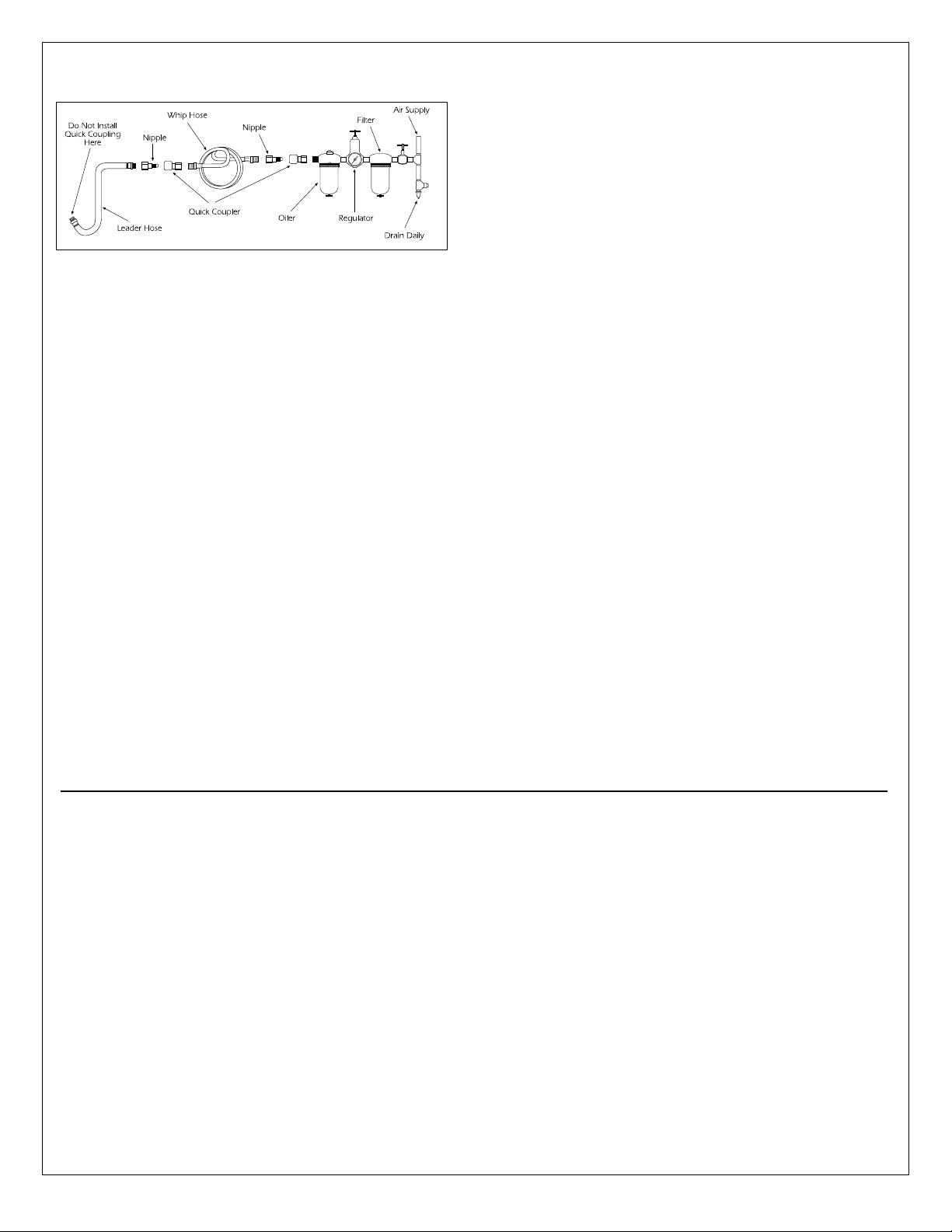

• Airunderpressurecancausesevereinjury.Never

directairatyourselforothers.Alwaysturnoffthe

airsupply,drainhoseofairpressureanddetachtool

fromairsupplybeforeinstalling,removingor

adjustinganyaccessoryonthistool,orbefore

performinganymaintenanceonthistool.Failureto

dosocouldresultininjury.Whiphosescancause

seriousinjury.Alwayscheckfordamaged,frayed

orloosehosesandfittings,andreplaceimmediately.

Donotusequickdetachcouplingsattool.See

instructionsforcorrectset-up.

• Placethetoolontheworkbeforestartingthetool.

• Slipping,trippingand/orfallingwhileoperatingair

toolscanbeamajorcauseofseriousinjuryor

death.Beawareofexcesshoseleftonthewalking

orworksurface.

• Keepbodyworkingstancebalancedandfirm.Do

notoverreachwhenoperatingthetool.

• Anticipateandbealertforsuddenchangesinmotion

duringstartupandoperationofanypowertool.

• Donotcarrytoolbythehose.Protectthehosefrom

sharpobjectsandheat.

•Toolshaftmaycontinuetorotatebrieflyafterthrottle

isreleased.Avoiddirectcontactwithaccessories

duringandafteruse.Gloveswillreducetheriskof

cutsorburns

• Keepawayfromrotatingendoftool.Donotwear

jewelryorlooseclothing.Securelonghair.Scalping

canoccurifhairisnotkeptawayfromtooland

accessories.Chokingcanoccurifneckwearisnot

keptawayfromtoolandaccessories.

• Drillbitscanbindsuddenlyandcauserotationof

theworkpieceortool,causinginjurytoarmsand/or

shoulders.

Enoughtorqueisgeneratedtocausefalls.Always

usesharpbits.Uselessdownwardpressureat

breakthrough.

• UseaccessoriesrecommendedbyCornwell.

• Donotlubricatetoolswithflammableorvolatile

liquidssuchaskerosene,dieselorjetfuel.

• Donotforcetoolbeyonditsratedcapacity.

• Donotremoveanylabels.Replacedamagedlabels.