Index

1. ABOUT THIS MANUAL ........................................................................................................ 1

2. INTRODUCTION ................................................................................................................. 1

2.1. IDENTIFICATION ......................................................................................................................................... 1

2.2. INTENDED USE ............................................................................................................................................ 2

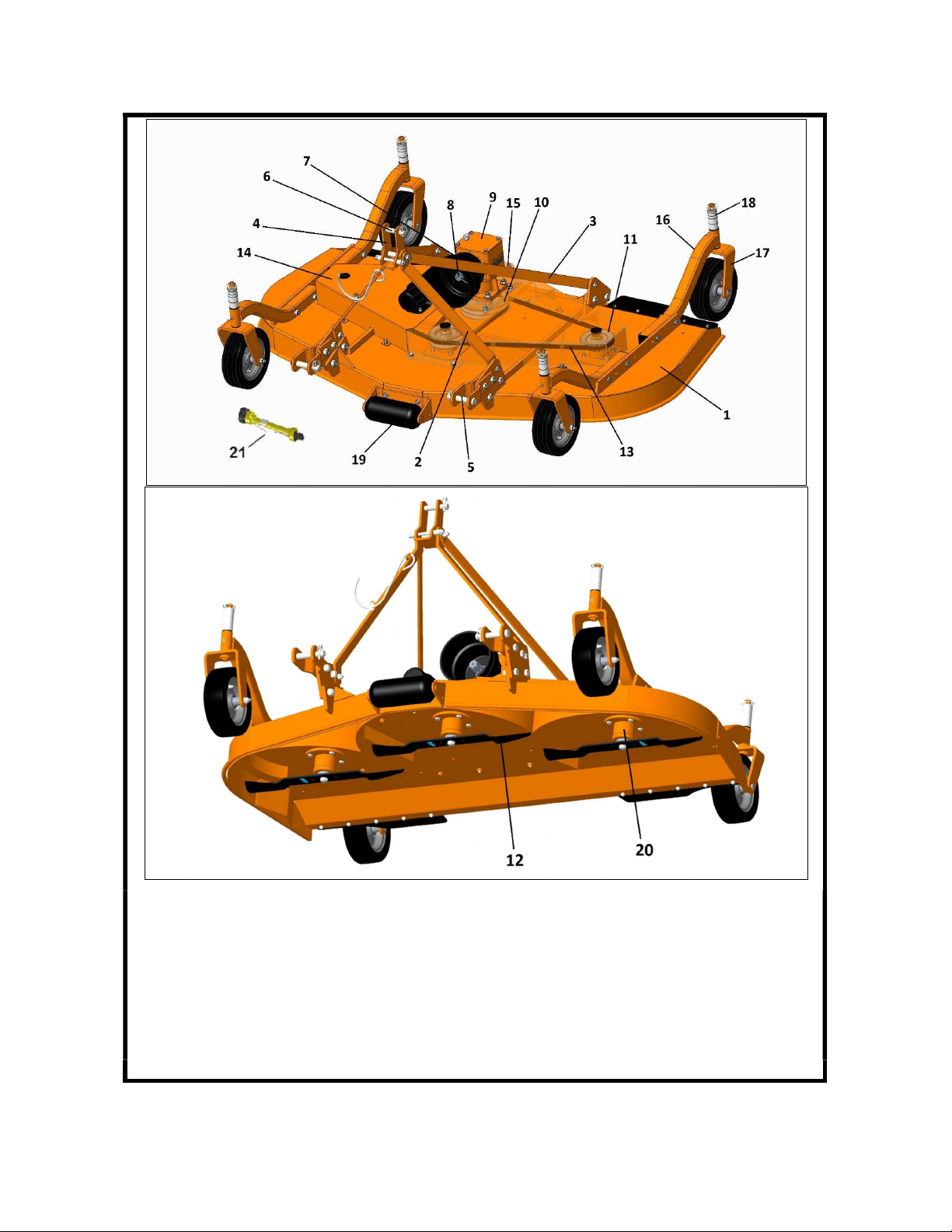

2.3. MAIN PARTS DESCRIPTION ....................................................................................................................... 3

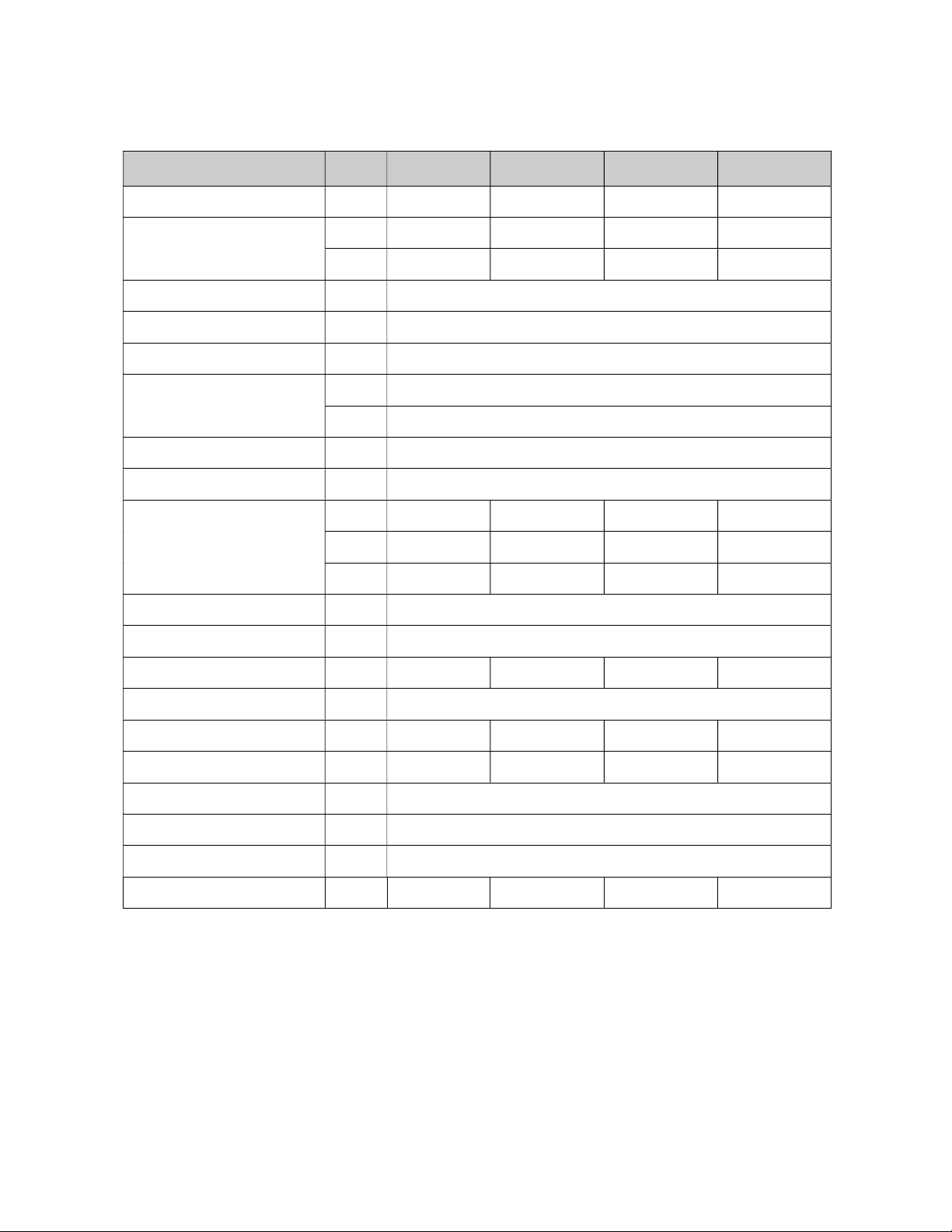

2.4. SPECIFICATIONS ......................................................................................................................................... 4

3. SAFETY ............................................................................................................................... 5

3.1. GENERAL SAFETY INSTRUCTION .............................................................................................................. 5

3.2. EQUIPMENT SAFETY INSTRUCTIONS ....................................................................................................... 6

3.3. OPERATING SAFETY INSTRUCTION .......................................................................................................... 7

3.4. TRANSPORTING SAFETY INSTRUCTIONS................................................................................................. 8

3.5. MAINTENANCE SAFETY INSTRUCTION .................................................................................................... 9

3.6. STORAGE SAFETY INSTRUCTIONS ............................................................................................................ 9

3.7. SAFETY LABELS ........................................................................................................................................ 10

4. SET UP .............................................................................................................................. 13

4.1. CONNECTING TO THE TRACTOR ............................................................................................................. 13

4.2. DRIVELINE INSTALLATION ..................................................................................................................... 15

4.3. TRACTOR-MOWER STABILITY ................................................................................................................ 16

5. OPERATING ...................................................................................................................... 17

5.1. START UP AND REUSING .......................................................................................................................... 17

5.2. OPERATING INSTRUCTIONS .................................................................................................................... 19

5.3. ADJUSTMENTS .......................................................................................................................................... 21

5.4. STOPPING AND DISCONNECTION ........................................................................................................... 25

5.5. TRANSPORT ............................................................................................................................................... 26

6. MAINTENANCE ................................................................................................................. 27

6.1. BELTS TENSIONING .................................................................................................................................. 27

6.2. BELTS REPLACEMENT.............................................................................................................................. 29

6.3. BLADES REPLACEMENT ........................................................................................................................... 29

6.4. GEARBOX LUBRICATION .......................................................................................................................... 31

6.5. SPINDLE SHAFTS LUBRICATION ............................................................................................................. 32

6.6. WHEELS AND WHEEL SUPPORTS LUBRICATION .................................................................................. 32

6.7. DRIVESHAFT MAINTENANCE .................................................................................................................. 33

7. STORAGE .......................................................................................................................... 33

8. SCRAPPING ...................................................................................................................... 33

9. TROUBLESHOOTING ........................................................................................................ 34

10. TORQUE VALUES TABLE .............................................................................................. 35

11. WARRANTY .................................................................................................................. 36

12. SPARE PARTS ............................................................................................................... 38

13. "EC " DECLARATION OF CONFORMITY ......................................................................... 39