Chapter 9

Electrical and Mechanical

9.1 Introduction

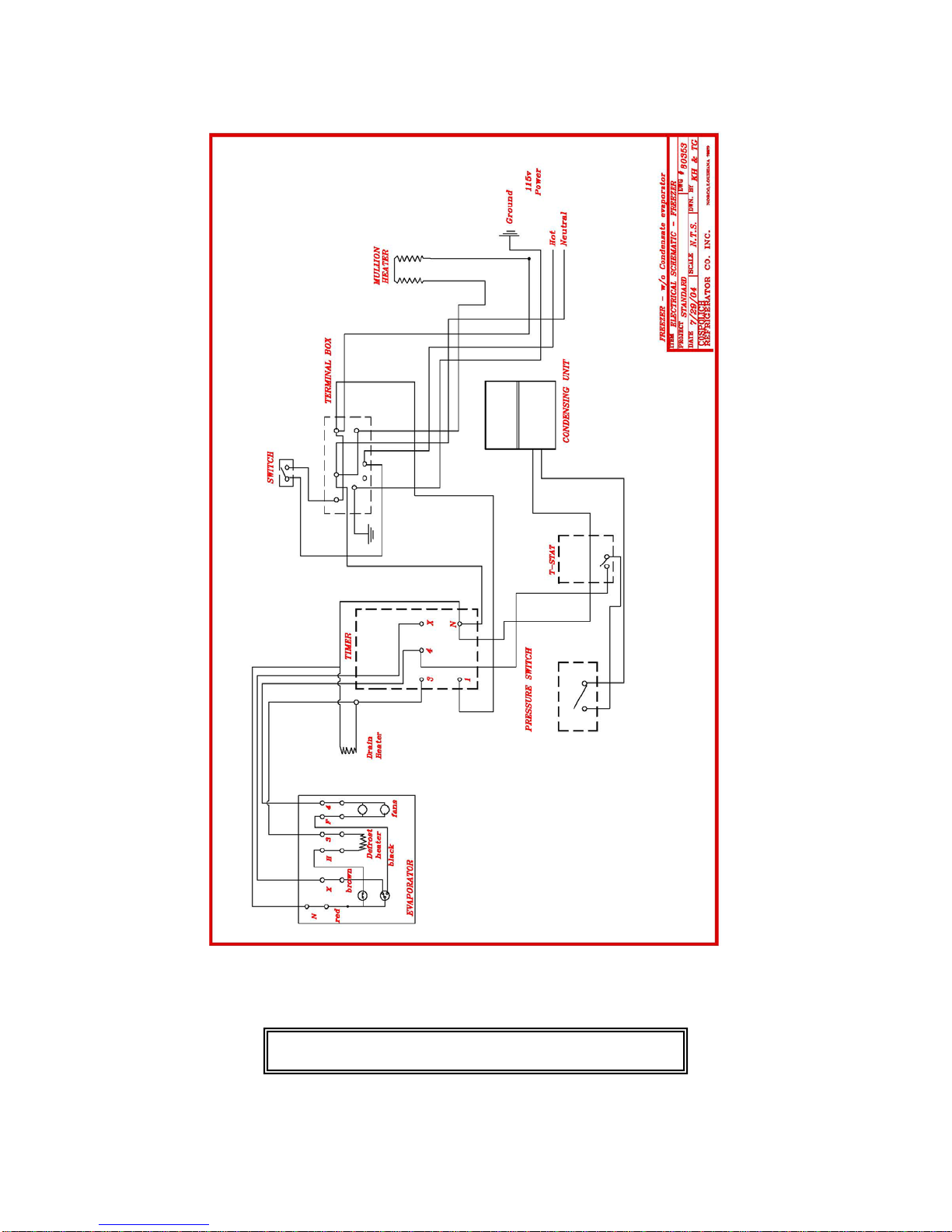

This section of the manual contains drawings and schematics of the electrical and

mechanical piping systems.

9.2 Electrical Abbreviations and Terminology

a. RLA – Rated Load Amperage

1. Rated load amps is a measure of the current drawn by a compressor

when operated at compressor manufacturer rating conditions at

nominal voltage. This value is listed at U.L. and C.S.A. as “RLA”. It

is in agreement with the N.E.C. definition that the RLA be the current

draw when the compressor is delivering rated output.

b. LRA – Locked Rotor Amperage

1. The locked rotor amps of a compressor is the current value recorded

three seconds after rated voltage is applied under locked rotor

conditions from a 75 degree Fahrenheit motor soakout temperature

(The voltage drop is to be predetermined and adjusted accordingly

prior to testing). This value appears on the compressor serial plate and

on all compressor statistics sheets.

2. It may be well to note that the practice in the past was to show an

additional column marked, “LRA U.L. Test Report”. This is no longer

needed since the U.L. investigation work, regarding component rating,

will be guided by the compressor manufacturer’s published value.

c. MCC – Maximum Continuous Current

1. Maximum continuous current is a limiting ampere value that must not

be greater than 156% of the RLA of the compressor as marked on the

nameplate of the particular unit into which that compressor is applied.

9-1