CP CPL40 Operation instructions

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

1

o

f

19

C.P. srl – Via Perotti, 5 – 25125 BRESCIA - ITALY

USE AND MAINTENANCE INSTRUCTION MANUAL

PLANETARY MIXER

CPL40

MECHANICAL SPEED

VARIATION

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

2

o

f

19

USE AND MAINTENANCE INSTRUCTION

MANUAL

MECHANICAL SPEED VARIATION PLANETARY

MIXER

CPL40

This instruction, use and maintenance manual provides the instructions necessary

for

transportation, starting-up, use and maintenance of the mixer. It must be consulted before

any

one of these

acts.

The manual must be read not only by maintenance technicians, but also by operators in

charge

of the mixer who must correctly carry out what is within their line of

competence.

The manual is an integral part of the mixer. It must be kept in a suitable place where it can remain intact

and

where it can be consulted during the whole life of the

machine.

INDEX

SAFETY

INSTRUCTIONS ...........................................................................................................................................................................3

RESIDUAL RISKS

.......................................................................................................................................................................................3

RESIDUAL RISKS,

PROHIBITIONS, OBLIGATIONS:

Summarized table

..................................................................................................4

SYMBOLSUSED AND

QUALIFICATIONS

OF THE

PERSONNEL............................................................................................................5

USE AND DESCRIPTIONOF THE

MIXER .................................................................................................................................................5

INSTRUCTIONS

FOR USE

........................................................................................................................................................................6

IDENTIFICATION,

POSITION OF THE OPERATOR AND DANGEROUS

AREAS .................................................................................... 8

TECHNICAL DATA, PACKAGING,DIMENSIONSAND WEIGHT

............................................................................................................9

TRANSPORTATION

AND

HANDLING........................................................................................................................................................9

STORAGE

..................................................................................................................................................................................................10

INSTALLATION

..........................................................................................................................................................................................10

PRESERVATIONOF THE

MIXER............................................................................................................................................................. 10

WARRANTY TERMS

................................................................................................................................................................................10

CLEANINGAND MAINTENANCE

OPERATIONS..................................................................................................................................... 11

ROUTINE MAINTENANCE

.....................................................................................................................................................................12

EXTRAORDINARY MAINTENANCE ......................................................................................................................................................... 12

PERIODICAL MAINTENANCE

.................................................................................................................................................................13

SPARE PARTS

.........................................................................................................................................................................................13

MAIN

COMPONENTS................................................................................................................................................................................ 13

DISMANTLINGAND WASTE DISPOSAL

.................................................................................................................................................13

SPARE PARTS

LIST..................................................................................................................................................................................14

BLOCKAGE OF MACHINERY AND NECESSARY REMEDIES

...............................................................................................................16

ELECTRICAL LAYOUT

.............................................................................................................................................................................16

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

3

o

f

19

SAFETY

INSTRUCTIONS.

The safe and systematic use of the mixer is subordinated to compliance with behavior and standards

listed

hereafter.

Safety standards

§Personnel must be in good physical and mental conditions and be adequately instructed on the

use

of the mixer having read this

publication.

§The safety manager of the company, of the operating area and of the department, when

choosing

the person who must use this equipment (a person suitable for the job according to Standards

in

force), must consider his/her cultural preparation, physical suitability and the psychological

aspect

(mental stability, sense of responsibility, etc.). Moreover, based on the attitudes and capacity

that

were verified, the manager must provide this person with proper training, having him/her read

the

present publication, in order to have full knowledge of the mixer and of the rules of

behaviour

applying to

it.

§The area around the mixer must be well lit, free from other objects and

clean.

§The personnel in charge of running, cleaning and carrying out maintenance on the mixer must

wear

the required PPE (personal protective

equipment).

§Do not wear dangling clothing or fluttering hems (ties, napkins, torn suits, open jackets etc.) to

avoid

getting

entangled.

§During maintenance and cleaning, the operator must disarm the master switch and place the

system

in safe conditions (for example, removing the

plug).

§Never leave the mixer unattended while it is running. Be careful of abnormal noises or

behavior.

Keep away from rotating parts. Never open the grid before the equipment has come to a

complete

stop.

§At the end of work, empty the machine completely, disconnect the master switch cutting the

power,

place it in safe conditions and clean it with a neutral degreasing agent (i.e. with Marseille

soap).

Safety devices.

§The mixer is equipped with some devices which protect its operation as well as the safety of

the

operator. They must not be removed or modified. Their functioning must be checked

periodically.

§Master switch: cuts power from the mixer, for maintenance in safe

conditions.

§Circuit breaker switch: cuts power if the electric motor

overheats.

§Fixed guards: All casings and guards fixed with screws or mechanical locks can be removed only

for

maintenance, by specialized personnel and in the prescribed modalities. When the work is over,

they

must be mounted

immediately.

§Mobile guards: Movement of the grid activates a micro switch which prevents the mixer from

running

if the grid is open. If the grid is lifted while the mixer is running, it stops the cycle unconditionally,

just

like an emergency stop. The start button must be pressed for the mixer to

restart.

Safety Standards applied to the mixer.

§EN 292 Safety of

machinery.

§EN 294 Minimum distances to prevent accidental

contact.

§CEI 17-13. Low-voltage switchgear and control gear

assemblies.

§Community Directives: 89/392/EEC, 89/336/EEC, 91/368/EEC, 93/44 EEC, 93/68

EEC.

RESIDUAL

RISKS

Danger for limbs: Going beyond the protective grid or removing the casing during maintenance, it

is

possible to access the moving organs of the

mixer.

They are dangerous areas where serious physical injuries can occur. Do not introduce limbs or

other

objects without having placed the mixer in safe

conditions.

Danger of electrocution: the mixer must not operate without an adequate earthing system. It must

be

connected to a system built in compliance with construction standards in force in the country where

it

is

installed.

Automatic cycle: after starting up the mixer, it follows an automatic operating cycle. Never go

past

the safety barriers with your limbs or other objects while it is

running.

RESIDUAL RISKS, PROHIBITIONS, OBLIGATIONS: Summarized

table.

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

4

o

f

19

Obligation to

disconnect

mixer before working

on

it.

Stability for machinery: if there is

the

possibility of slipping on wet or

greasy

surfaces or positioning the equipment

in

unstable places (ships, planes or

other),

use the appropriate attachments

for

stable fixing (4 anchoring devices

with

200 kg resistance, M8

screws)

Obligation to carry

out

earthling.

ATTENTION!

§Where the required PPE during

operations.

§Clean the mixer thoroughly after

use.

§Do not remove the safety devices or protective

casings.

§Do not introduce any object through the protective grid with organs in movement: danger of objects

being

thrown.

§Before carrying out any maneuver beyond the protective grid, wait for the mixer to come to a complete

stop.

SYMBOLS USED AND QUALIFICATIONS OF THE

PERSONNEL.

The following indicates the qualifications of personnel required to operate the

mixer.

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

5

o

f

19

The symbols placed on a chapter mean to recall the specific skill needed for the intervention

described

therein. Wherever no symbols are present, the chapter applies to

everyone.

Symbol Description

Features

OPERATOR Person acquainted with operating, adjusting and programming the mixer and

its

protection and safety systems, who knows possible work cycles and

ingredients

to be used with relative maximum admitted amounts and who has read

and

understood the use and maintenance

manual.

ELECTRICAL

MAINTENANCE

TECHNICIAN

Person in good health who due to qualification, job or experience is qualified

to

carry out the profession of electrical maintenance technician and who has

read

and understood the use and maintenance

manual.

MECHANICAL

MAINTENANCE

TECHNICIAN

Person in good health who due to qualification, job or experience is qualified

to

carry out the profession of mechanical maintenance technician and who has

read

and understood the use and maintenance

manual.

PERSON

IN

CHARGE

OF

HANDLING

ZIONE

ASSISTANCE

Tel.

+3

030.3581864

Fax

+3

030.358185

Person in good health who due to qualification, job or experience is qualified

to

carry out handling of loads and who has read and understood the use

and

maintenance

manual.

§Requesting manual

updates.

§Phone customer assistance concerning functioning, starting or faults

of

machinery.

§Requesting spare parts, repairs, system overhauls, interventions on

site.

§Training

courses

ATTENTION. This sign requests you to pay particular attention to the operations

indicated.

Lack of compliance can cause harm to personnel or damage to the

mixer.

USE AND DESCRIPTION OF THE

MIXER:

CPL40 planetary mixers are highly professional machines, capable of excellent performance. Driven by

a

high-power motor they use a belt speed variator with a high transmission ratio that is capable of a

great

excursion between low and high speed and a proportional speed of the

instrument.

The change of speed allows you to perfectly whip, beat, mix, amalgamate and air out ingredients

ensuring

excellent results of the finished

product.

The cemented, hardened and rectified gears and the wide size of the belt allow use of the high

power

installed. Together with the steel structure, they make the mixer sturdy and

reliable.

The bowl-lowering device, easy disassembly and the tools supply the mixer with great

professionalism.

The accessories provided with the machine have been built with the utmost care: whisk, blade and

spiral,

together with the shape of the bowl ensure the best mixing

results.

The safety devices and electrical control equipment complying with European Standards complete

the

machinery.

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

6

o

f

19

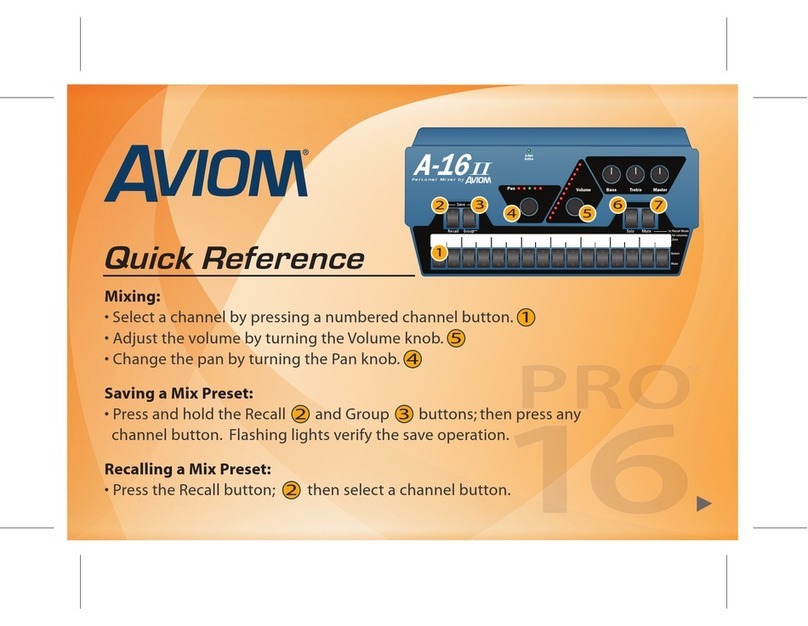

ELECTRICAL

PANEL

SPEED

CHANGE

GRID

PROTECTION

BOWL

LOCKING

HANDLES

INSTRUCTIONS FOR

USE

To be able to work; the bowl must be mounted and the bowl protective grid closed. Otherwise it will

be

blocked by the safety

systems.

DO NOT REMOVE OR TAMPER WITH THE ELECTRICAL OR MECHANICAL GUARDS OR

SAFETY

DEVICES ON THE

MACHINE.

The bowl must be in position BEFORE the tools. It must be inserted with the

bowl

lever down, putting the bowl plate, placed at the back of the bowl, on the bowl

lifting

arc.

Complete positioning by having the holes on the bowl support plates match

with

the centering pins. Block the bowl with the

handles.

If it was not previously done, rotate the protective grid of the

bowl

to the open position and, after having chosen the tool, insert

it

into the tool holder shaft. Once it is inserted, turn the

tool

clockwise, having the transmission pin enter the work position

as

indicated in the figure. Lower it and insert the tool lock

ring.

Using the arrows éand ê, on the control panel to lift the bowl to the working position and

close

the

protective grid of the bowl. At this point, after inserting the ingredients, start the work

cycle.

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

7

o

f

19

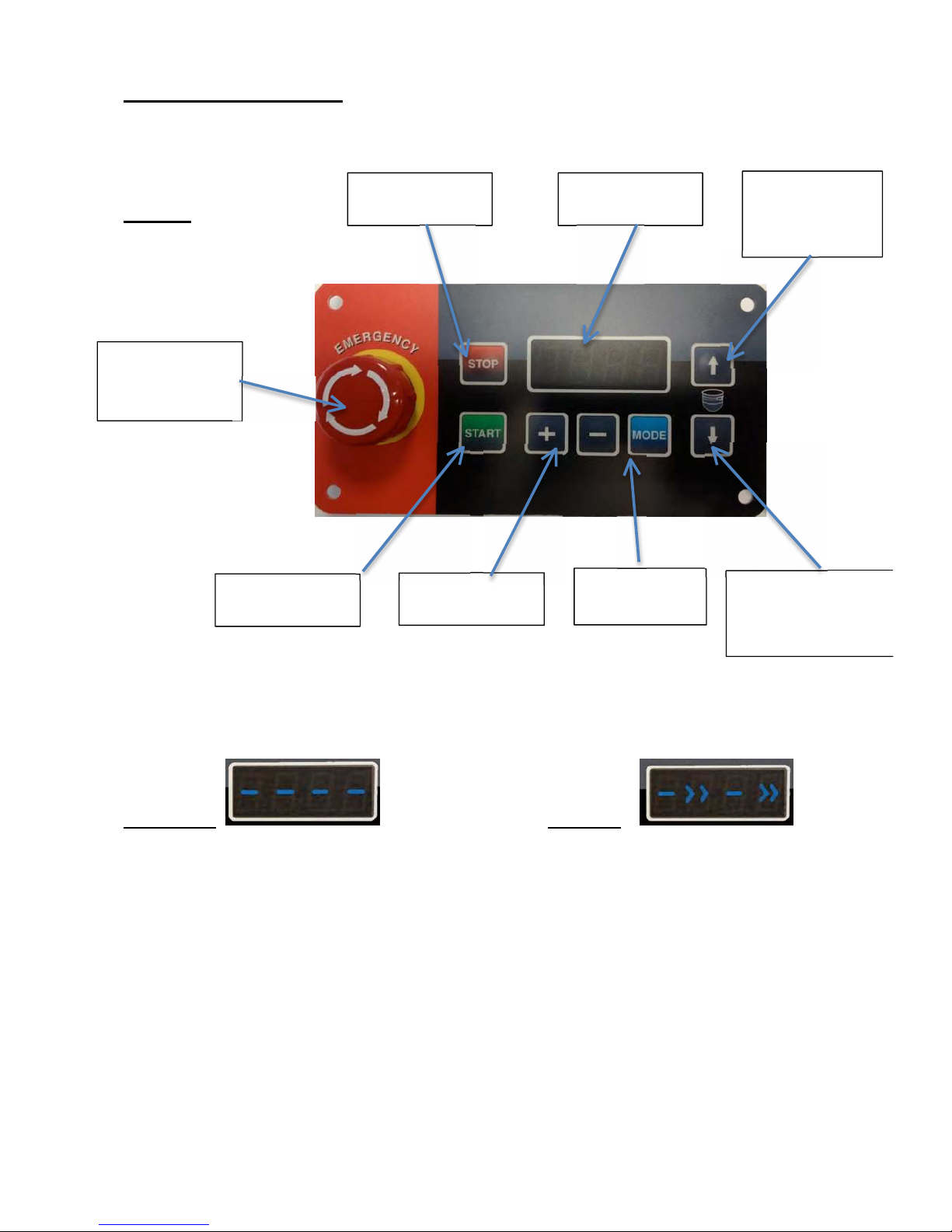

Best Mix control Panel

Figure 1 STOP

BUTTON DIGITAL

DISPLAY

BOWL

LIFT UP

BUTTON

STOP

EME

RGENCY

BUTTON

START

BUTTON SELECTIONS

BUTTONS SETTING

BUTTON BOWL

LIFT

DOWN

BUTTON

First of all be sure the Emergency stop button is released . The mixer can properly work

as Manual or under the Digital timer. If grid and bowl are in the correct position, you will

see 4 blue lines in the center of the lcd display. (figure 2a).

Figur

e

2a

figure 2b

In event of blue light blinking, double check the grid alignment or final bowl position. If

the light are fixed and you would like to operate manually, just press “START”. The Mixer

will work till you do not press “STOP” or turn the grid from its position.

While the mixer is running as manual , you will see on the digital display, blue lights

moving towards right as you can see (figure 2b). Just pressing “Stop” the mixer will

immediately stopped it-self and the blue light will come back fixed as “figure 2a”.

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

8

o

f

19

WORKING WITH THE DIGITAL TIMER:

If you would like to set the Timer, please press button “MODE” . You should see onto the

digital lcd display, the last programmed time as “minutes: seconds” . (figure 3). In case you

agree with the timing already set, just press “START” and the mixer will begin to work and

the countdown will indicate the resting working time. When time get the 00:00 , the

planetary mixer will be automatically stopped.

Figur

e3

Setting the Timer:

If you need to set a different timing press for some seconds button “MODE”. You should

see the “minutes” blinking. Just pressing buttons “+” and “-“ is possible to change the mas

you prefer. Pressing once again the button “MODE” , you will be able to set “seconds” too.

To exit from setting, just press again button “MODE”. The time will stop blinking . Now

you are ready to press “start” once again and begin the working cycle.

Pay Attention:

The Best Line Planetary mixers have a mechanical variable belt drive system with 7

speeds. DO NOT CHANGE SPEEDS IF THE MIXER IS NOT RUNNING. Moving the

Speed lever while the mixer is not running, can cause serious problem on the Belt and

gears.

While the mixer is running, if you open the protection grid or move the bowl down, i twill be

automatically stopped.

Before begin to work with the planetary mixer, please check the speed lever position. To

avoid any kind of issues, we suggest to move the lever to the lower speed at every single

use. If you are going to use the Dough-Hook and the mixer start spinning at the fastest

speed, it might be broken in seconds.

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

9

o

f

19

The mixer is provided with a lever to change the tool rotation speed. This mixer has 7

different

speeds. ATTENTION: ALWAYS change the speed while the mixer is moving to allow

the

variable pulley belt to position

correctly.

In order to remove the mixture, wait until the tool has stopped. Then turn the protection

grid.

Use the arrow êinto the control panel to lower the bowl and release the tool from

the

attachment sleeve. Remove the tool and release the bowl from the

handles.

The work load of the planetary mixers is established by the customer. Very many problems arise

from

improper use. If recommended amounts are exceeded, the quality of the product will suffer, as well as

the

duration of the mechanical organs of the mixer. See the following table for indications on maximum

amounts:

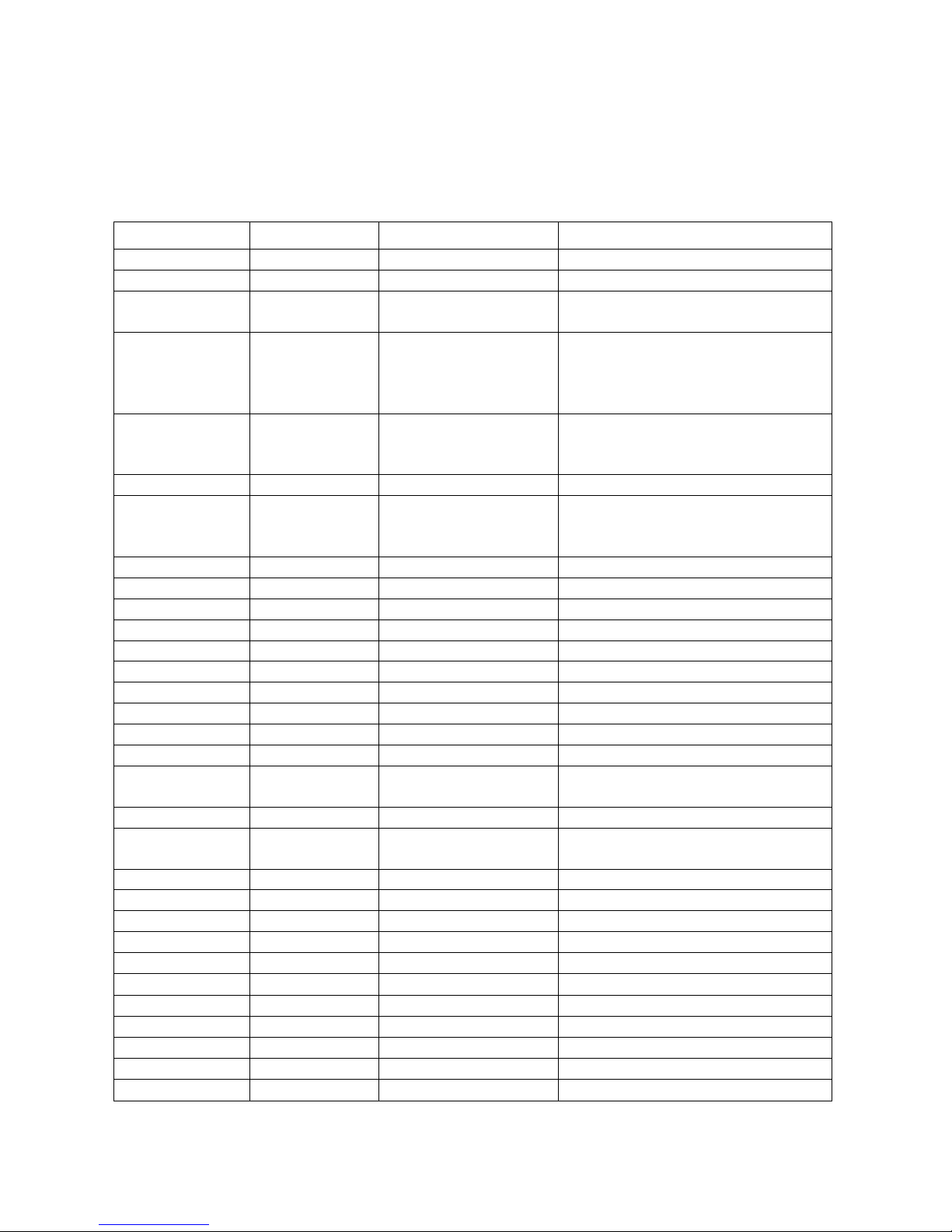

APPLICATION

INGREDIENTS

CPL

10

CPL

20

CPL

30

CPL

40

CPL

60

TYPE

OF

TOOL

POSIT

LEVER

M

i

x

w

it

h

55

%

wa

t

e

r

F

l

ou

r

+

W

a

t

.

Kg

3

6

9

12

18

Dough

-

hook

1

Pasta for

croissants

Flour

Kg.

2,5

5

7

9

15

Dough-hook

1

Pasta for

profiteroles

Flour

Kg.

2

4

6

8

12

Dough-hook

1

Meat

Kg.

5

10

15

20

30

Dough-hook

/butter

biter

1-2

Purée

Potatoes

Kg.

5

10

15

20

30

butter

biter

/whisk

1-2

Egg

white

Number of

eggs

16

32

50

70

96

Whisk

1-4

Biscuits

Number of

eggs

15

30

45

60

90

Whisk

1-3

Meringues

Sugar

Kg.

0,75

1,5

2,25

3

4,5

Whisk

1-4

Whipped

cream

Litres of

cream

2

4

5,5

7

10

Whisk

1-4

CONDITIONS FOR

USE:

Atmospheric conditions: The mixer needs to be installed inside of a lit, ventilated building, on top of a

solid

and level support. Temperatures from 5 to 40°C with humidity no greater than

90%.

Lighting: the light at disposal of the operator must comply with the type of work carried out, in relation

to

general lighting, according to the Standards in force. It must on any account be sufficient to read the

controls

and danger signs and must not blind the

operator.

§Vibrations: in correct working conditions, vibrations do not create dangerous

situations.

§Noise emissions: 70 dbA for normal

use.

§Electromagnetic environment: the machine has been built to work correctly in an industrial type

of

electromagnetic

environment.

Environments with risk of explosion: An atmosphere capable to being transformed into

an

explosive atmosphere due to room and/or operating conditions is defined a potentially

explosive

atmosphere.

The mixer was not built to work in environments with potentially explosive

atmospheres.

IDENTIFICATION, POSITION OF THE OPERATOR AND DANGEROUS

AREAS.

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

10

o

f

19

There is a plate on the back of the mixer like the one shown which carries indications concerning

the

manufacturer, the type of machine, serial number, electrical features, frequency, absorbed power and

the

number of phases and the year of construction. The figure at the side shows the position of the plate, that

of

the operator respect to the mixer and the AS danger area which must be free from people for a distance A

=

250

mm.

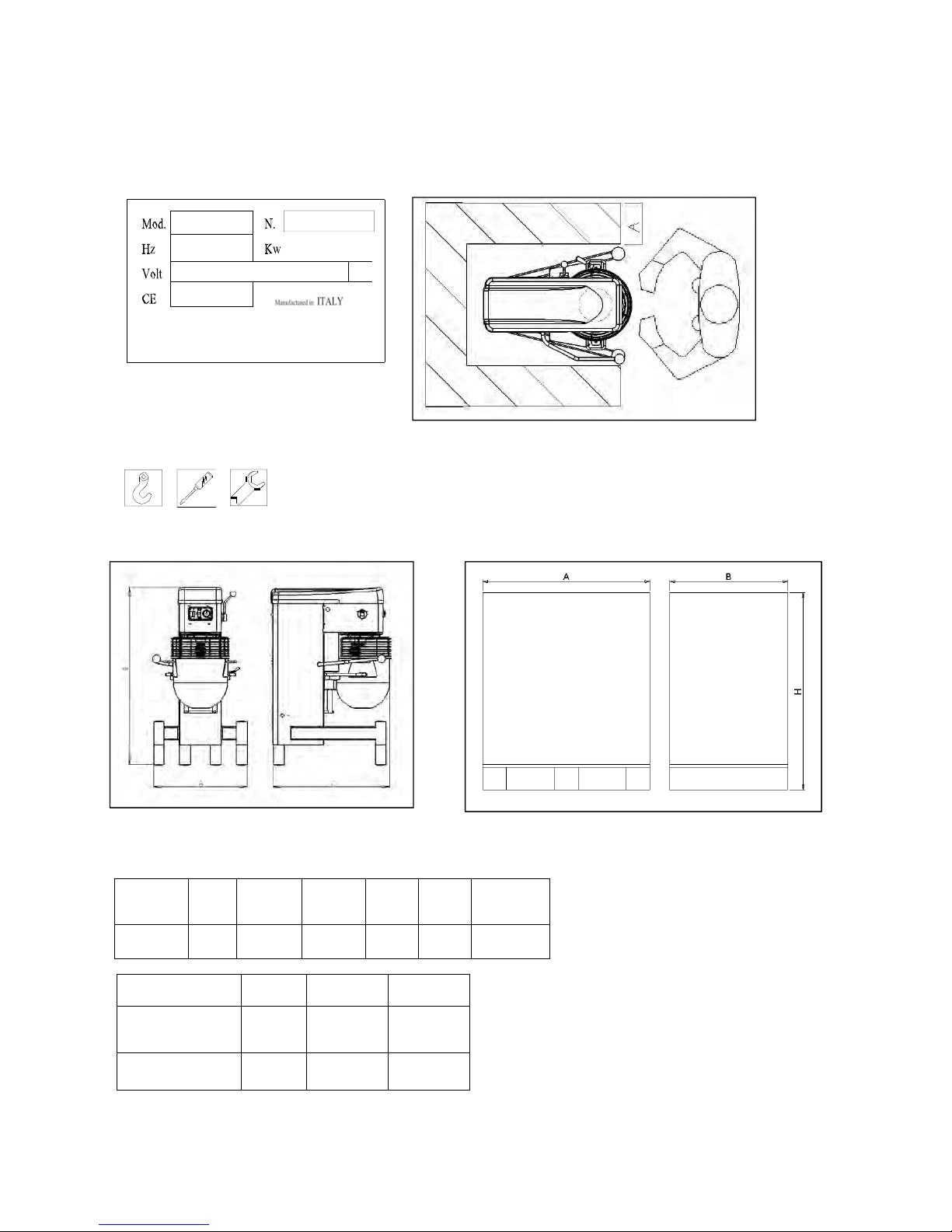

TECHNICAL DATA, PACKAGING, DIMENSIONS AND

WEIGHT.

There are four types of packaging: machine on pallet wrapped in cellophane, machine on

pallet

in cardboard box, machine on pallet in wooden cage, machine on pallet with

crate.

Model

A

mm

B

mm

C

mm

Weig

ht

[Kg]

Bowl

litres

Power

[Kw]

CPL

40

700

1290

920

204

40

1,5

Packaging

A

mm

B

mm

H

mm

Pallet +

cardboard

box

950

740

1610

Cage

1110

900

1550

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

11

o

f

19

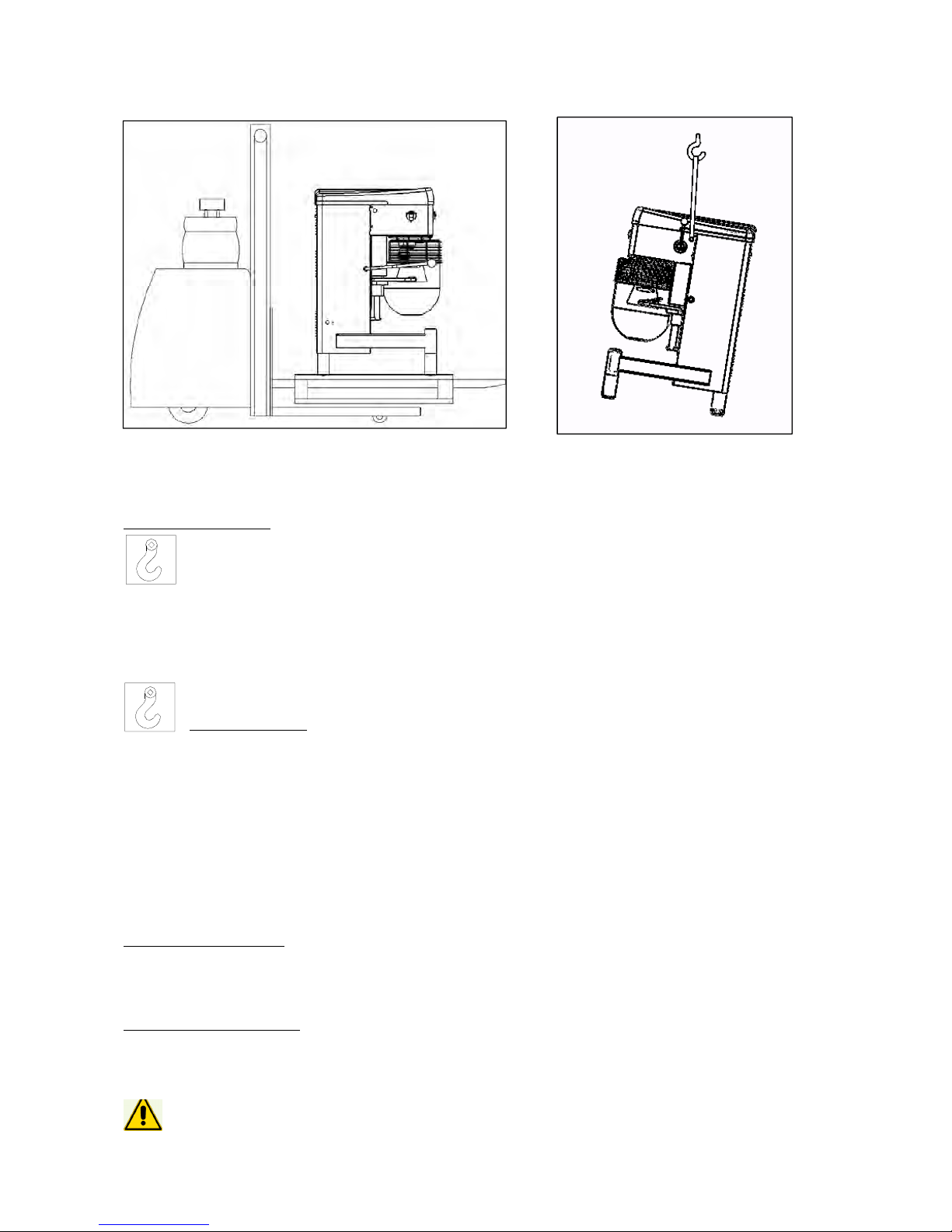

TRANSPORTATION AND

HANDLING.

Machine without pallet.

Due to its instability , the mixer must be handled with a suitably-sturdy strap, having it pass

below

the head, as in the figure at the

right.

Before lifting, stand the grid up

vertically

§Make sure the lift equipment is adequate for the load. Work in an empty area.

During

movement, always keep the load as close to the ground as

possible.

§Use the

required

P.P.E.

§The mixer inclines slightly by 10-15 degrees

when

lifted.

Lifting standards with lift truck: always use a pallet when handling the

mixer.

Machine on pallet.

§Make sure the lifting device is adequate for the

load.

§Widen the lifting forks as much as possible and make sure they come out from

the

pallet.

§Work in an area free from persons

and

animals.

§During movement, always keep the load as close to the ground

as

possible.

§Use the

required

P.P.E.

STORAGE:

Storage of packed mixer:

The mixer must be stored in a closed and covered place, on a smooth and solid surface protected from

dust

and filth, sheltered from atmospheric agents and hygienically

safe.

The temperatures must remain between –20 and +50°C, and humidity no greater than

90%.

Storage of unpacked mixer.

If the mixer has already been unpacked, in addition to that above, it must be lifted from the ground with

a

pallet or other and covered in order to protect it from humidity, dust and filth. If wrapped in cellophane

or

another type of plastic, avoid airtight closing below the mixer in order to prevent corrosion linked

to

condensate.

ATTENTION! The mixer must not be stored

outdoor!!

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

12

o

f

19

INSTALLATION

The mixer must stand in a vertical position, on a smooth surface sufficiently sturdy for the load

(floor

with resistance over 20 km/cm2). If in danger of tipping over, anchor the mixer to the floor using

4

plugs or bolts with a traction resistance over kg 300

(M8).

Connection to electrical

mains

The electrical connection must be carried out by a specialized electrician, according to the

modalities

and standards in force in the country where it is installed. Make sure that the voltage and

frequency

of the system are the same as those on the mixer identification plate. Incorrect connection

makes

the warranty

void.

PRESERVATION OF THE

MACHINE

Storage before a long period out of

service

Clean the mixer

thoroughly.

Disconnect it from the electrical

mains.

If possible, put it back into its original

packing.

WARRANTY

TERMS

Validity: The warranty starts from the delivery date and lasts 12 months,

if:

§The mixer was not damaged during transportation, and it was installed, commissioned, used

and

serviced as prescribed in this

manual.

§It was not tampered with, modified and no unintended tools were installed on

it.

§It did not undergo modifications or repairs carried out by the customer or third parties in

an

incompliant fashion or without the prior consent of the

supplier.

The following conditions constitute improper use of the

mixer:

•

Loading more than what is allowed or use of unsuitable

ingredients.

•

Cleaning with unsuitable tools or instruments that can scratch the bowl or damage the mixer or

paint.

•

Use of the mixer in unsuitable

places.

Modality for granting the warranty

If the customer finds defects in the mixer, he must immediately inform the supplier, who will carry out a

quick

analysis of the lack of compliance and will establish the intervention mode with the

customer.

After agreement with the supplier, the customer must provide him with the needed time and opportunity

to

carry out modifications, improvements, repairs or the supply of spare parts which the supplier

deems

reasonably necessary. If this does not occur, the supplier will not be held

liable.

Parts subject to wear

Some components are scaled for a life duration far longer than that of normal mixer use during the time of

its

warranty. Breakage or malfunctioning of these pieces depends on their use. They are therefore

considered

parts subject to wear and are not included in the warranty, unless they manifest evident defects in the

parts

or

machinery.

The parts subject to wear are: transmission belts, motors, bearings and bowl.

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

13

o

f

19

Control

Interval

Method

a

F

Control

Interval

Method

m

F

Control

Interval

Method

a

F,

M

CLEANING AND MAINTENANCE

OPERATIONS.

CONTROL OF INSTALLED SAFETY SYSTEMS AND ELECTRICAL

SYSTEM

The installed safety systems and the electrical system are subject to periodical checks carried out

by

a specialized

electrician.

Key of control

intervals:

(INTERVAL)

Key of how to carry out the

controls:

(METHOD)

d =

daily.

w =

weekly.

m =

monthly.

a =

annually.

O = observation: requires simple eye check (i.e. alarm

light)

F = Function: requires a physical control of the action (i.e. pressing

the

emergency button the mixer must

stop)

M = Measurements: requires a control with an appropriate instrument

(i.e.

control of earthling

values).

Master switch.

Purpose: protection of power

line.

Function: this equipment separates the machinery from the mains, it is placed

on

the upright of the mixer, downstream the differential protection

board.

Stop circuit and safety micro switch of grid.

Purpose: to stop the mixer immediately and unconditionally. Function:

pressing

the STOP button or lifting the protective grid cuts the motor power, stopping

the

mixer totally and not systematically. To restore functioning of the machinery,

the

operator must start the cycle once again by pressing the START

button.

Controls of system

Periodically the mixer's automation functioning and earthling must be

checked.

The operating modes, safety functions, terminal board contacts need to

be

controlled as well as the integrity of the cables, luminous LEDs and

earthling

system.

ROUTINE

MAINTENANCE.

DO NOT CARRY OUT ANY MAINTENANCE OR CLEANING WITH ELECTRICITY

CONNECTED

DO NOT CARRY OUT ANY MAINTENANCE OR CLEANING WITH ELECTRICITY CONNECTED The

mixer

does not require particular maintenance operations. After the first three months of work, check the wear

of

the

belt.

Every 4 ÷6 months, grease and oil the points indicated in the following layout (use MOLYKOTE 165

LT

grease).

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

14

o

f

19

grease

nipples

Grease

manually

Grease

manually

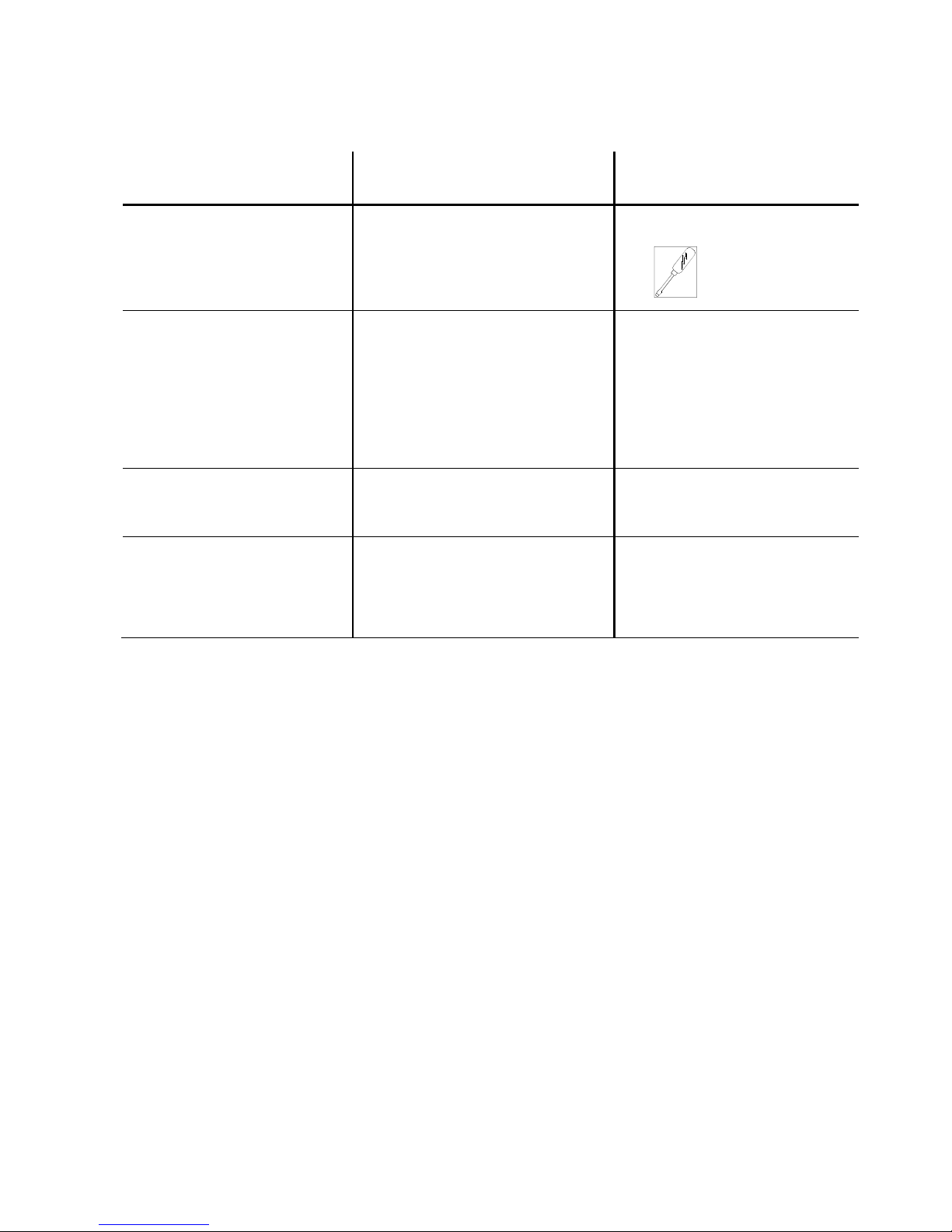

Should a power

cable be

damaged, replace

it with a

H07RN/F

cable with a 3x1.5

mm2 section.

EXTRAORDINARY

MAINTENANCE:

A

Cleaning: the mixer is not jet-

proof. Do not wash it

with

running water. Clean it with

a

moist cloth and

neutral

detergents, such

as

degreasing agents based

on

Castile

soap

To carry out interventions not specially mentioned in the manual,

refer

to personnel authorized by C.P. SRL. To replace the motor or

the

circuit boards, or else if the mixer falls, contact our assistance

service

for an intervention on site or else an overhaul at the

factory

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

15

o

f

19

PERIODICAL

MAINTENANCE.

DAILY CLEANING AND CONTROL

OPERATIONS:

•

Cleaning outside surfaces of the bowl and tools with cloth and neutral degreasing

agent.

•

Operative and emergency controls

check.

MONTHLY, ANNUAL MAINTENANCE

OPERATIONS

Monthly

maintenance:

•

Thorough cleaning of the

mixer.

•

Operative and emergency controls functioning

check.

•

Mixer's external components' check: tools, bowl, protective

grid.

•

Transmission noise

check.

Annual

maintenance:

•

Thorough cleaning and check of entire

machinery.

•

Thorough check of transmission

organs.

•

Bolt tightening check for entire

machinery.

Bolt tightening

torques.

M6

M8

M10

M12

M14

M16

Mixer screws (8.8)

[Nm]

.7

23

47

80

130

1 6

Stop rod screws (10. )

[Nn]

13.6

33

6

113

180

275

Mixer screws A2

[Nm]

§Installed safety systems

check.

SPARE

PARTS:

C.P. SRL reserves the right to carry out all the modifications that it deems necessary for its

mixer

models. It is therefore always necessary to

specify:

•

Type of

mixer

•

Serial

number

•

Year of

construction

•

Position, description, item code and desired amount of pieces

requested.

Send the request to: C.P. SRL via Perotti 5, 25125 Brescia (BS)

Italy

MAIN

COMPONENTS:

•

Raw materials used: almost all of the components of the mixer are made of steel, cast iron,

brass

and plastic. All of these components can be disposed of easily and do not represent a danger

for

environmental pollution and/or personal safety. Separate the different materials for

subsequent

reuse or differentiated waste

collection.

•

The electrical system must be dismantled and disposed of through a specialized

company.

•

Treatment of surfaces: painting of metallic surfaces with products compatible for food

use.

•

Sigma packaging replies fully with that required by Directive 94/62/EC and by Legislative

Decree

05/02/97 n. 22 (and subsequent amendments and integrations). They thus can easily

be

assimilated with city waste and can be inserted in any public differentiated waste

program.

DISMANTLING AND WASTE

DISPOSAL:

The purchaser is responsible for putting the mixer out of service, who must comply with local standards

and

regulations. Dismantling of mechanical and electrical parts must be entrusted to competent

personnel.

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

16

o

f

19

SPARE PARTS LIST

*

*: this is a brand new generation of C.P.SRL planetary mixers, the following chart can be little bit different

from the machine you have. In case contact the factory to get the updated one. We will soon provide you the

real line diagrams of it.

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

17

o

f

19

SPARE PARTS LIST TABLE:

Position

Quantity

Code

Description

1 1 095016-A Driven pulley CPL-40

2 1 101022-5 Planetary shaft CPL-60

3 1 101023-2 Driving bevel gear Z22 CPL-60

version with reduction gear

4 1

1

1

1

097201 Silkscreen printing CPL20

Timer

START/STOP button

ON/OFF switch

5 2

4

2

194021-1

194022-1

194023-1

Long grid wheel pin

Grid guide wheel

Short grid wheel pin

6 1 095020-2 Tool holder shaft CPL-40

7 1

1

1

095058

095216

095217

Thin wire whisk CPL40

Cast blade CPL40

Cast spiral CPL40

8 1 095122-1 Bowl CPL-40

9 1 095050-2 Bowl lifting rod CPL-40

10 2 095049-3 Bowl lifting plate CPL-40

11 4 095052-1 Plate distance pad

12 1 MARKET Motor Gr.90 B14 for CPL-40

13 1 095036-2 Cogwheel Z15

14 1 095008-9 Motor seat CPL-40,CPL-60

15 1 095208-1 Top casing CPL-40

16

101181-1 2.5 module rack for CPL-40

17 1 097013-4 Planetary pinion CPL-20

18 1 101070-2 (50 Hz)

101017-3 (60 Hz) Countershaft CPL-60

19 2 095013-5 Variable semi-pulley CPL-40

20 1 095080-3 Variator belt

33x10x1322

21 4 MARKET 38x42x15 bushes

22 1 095012-7 Variable pulley shaft CPL-40

23 1 185016 Reduction gear support

24 1 185017 Reduction gear connection shaft

25 1 097016-3 Driven bevel gear Z22 M3

26 2 MARKET Bearings 47-20-14 (6204)

27 1 MARKET Bearings 30-62-16 (6206)

28 1 MARKET Bearings 80-40-18 (6208)

29 2 MARKET Bearings 52-25-15 (6205)

30 2 MARKET Bearings 80-40-18 (6208)

31 2 MARKET Bearings 62-25-17 (6305)

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

18

o

f

19

BLOCKAGE OF MACHINERY AND NECESSARY

REMEDIES

OPERATION

ANOMALIES

POSSIBLE

CAUSES

REPAIR

Turning the master switch

into

position, the warning light

does

not turn

on

1) Plug not inserted correctly or

wires

detached

1) Check

connection

Pressing the START button,

the

mixer does not

start

1) The slide is not in position or

the

front grid is not

closed

2) Safety micro switch

anomalies

1) Lift the slide and reposition

it

after having closed the

front

grid

2) Replace the micro

switch

Intermittent

noise

1) Lack of grease in

transmissions

(gears)

1) Grease as shown in

previous

layout (page

13)

Continuous

noise

2) Check the efficiency of

the

bearings

1)

Replace

the

bearings

I

ns

tr

uc

ti

o

n

m

anua

l

CPL

-

4

0

19

o

f

19

Obligations of informing users

Information model for users of “professional”

products

INFORMATION FOR

USERS

In compliance with art. 13 of the Legislative Decree of July 25, 2005,

n.

151 “Implementing of Directives 2002/95/EC, 2002/96/EC

and

2003/108/EC, relative to the reduction of the use of

hazardous

substances in electrical and electronic appliances as well as disposal

of

waste”

The symbol of the barred waste bin on the appliance or

its

packaging indicates that the product at the end of its useful life

it

must be disposed of separately from other

waste.

Differentiated waste collection of this appliance having reached

the

end of its life is organised and managed by the manufacturer.

The

user who desires to dispose of the present appliance must

therefore

contact the manufacturer and abide by the system that has

been

chosen to allow separate collection of the appliance when

reaching

the end of its

life.

Adequate differentiated waste collection for successive

recycling,

treatment and environmentally compatible disposal contributes

to

prevent negative effects on the environment and on human

health

and favours the reuse and/or recycling of the materials making

up

the

appliance.

Illicit disposal of the product by the user entails the application

of

administrative sanctions foreseen by Standards in

force.

Table of contents

Other CP Mixer manuals

Popular Mixer manuals by other brands

ALLEN & HEATH

ALLEN & HEATH ZED 12 FX user guide

SEVERIN

SEVERIN HM 3812 Dimensions

Phoenix Audio Technologies

Phoenix Audio Technologies Stingray MT700 user manual

Art

Art MyMONITOR Specifications

Oster

Oster MIXMASTER 2700 instruction manual

smaky

smaky SL-800A Installation, operation and maintenance instructions