Cristofoli Distiller User manual

CRISTÓFOLI’S MISSION

Cristófoli Equipamentos de Biossegurança Ltda., established at Rodovia BR-158, nº

127, Jardim Curitiba in Campo Mourão, Paraná, Brasil, manufactures biosafety

equipment to assist the health field having as policy: “Develop innovative solutions for the

health field by using agile, robust and objective processes to better serve its clients. Fulfill

the requirements for regulatory purposes of the applicable standards, promote the

continuous improvement of its quality and environmental systems, prevent pollution,

reduce its environmental impacts and continuous training of its employees, achieving this

way, a sustainable profitability and the maximization of the company’s value”. Rev. 2.

CRISTÓFOLI’S QUALITY AND ENVIRONMENTAL POLICY

Develop innovative solutions to protect life and promote health.

Cristófoli Distiller

*BPF - Boas Práticas de Fabricação: Brazilian standard similar to the GMP - Good

Manufacturing Practices (FDA / US).

13485

D

E

S

G

A

E

M

S

E

T

T

Ã

S

O

I

S

Cristófoli, Brazilian company importer and manufacturer of health

products certified by ISO 9001 - Quality Management System,

ISO 13485 - Medical Devices - Quality Management System -

Requirements for Regulatory Purposes, ISO 14001-Environmental

Management and *BPF - Boas Práticas de Fabricação - ANVISA.

2

Thanks for choosing us. You, our clients, are the reason of Cristófoli's commitment.

We put together this manual to guide you as best as possible, for the use and

maintenance of your Cristófoli Distiller.

We would like to thank all our customers and partners for helping us to continually

improve and innovate our products and services.

Special thanks to Liliana J. P. Donatelli, Cristófoli’s Biosafety Consultant who provides us

a valuable assistance in the coordination of the Cristófoli's Biosafety Project,

complementary products research, our employees, representatives and technicians’

trainings, and as a lecturer of Biosafety Courses for professionals, academics and

assistants.

For any complaints or suggestions about our products, please get in touch with our

CSD - Customer Service Department, through the address below.

“Cristófoli. Valuing life!”

Cristófoli Equipamentos de Biossegurança Ltda.

Rodovia BR-158, nº127, Campo Mourão, Paraná - Brasil.

CEP 87309-650

E-mail: cac@cristofoli.com

CSD - CUSTOMER SERVICE DEPARTMENT

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

Documentos/Layout Informativos/Manual Destilador Cristófoli/Destilador Cristófoli Inglês - Rev.5

3

Introduction.................................................................................................................

Legend of Symbols.....................................................................................................

Important Safety Information.......................................................................................

Installation Instructions.................................................................................................

Safety Features and Devices.......................................................................................

Distiller General Features.............................................................................................

How to Use the Cristófoli Distiller...................................................................................

Requirements to Be Observed for the rocessDistillation P ............................................

Possible Failures...........................................................................................................

Preventive Maintenance.............................................................................................

Troubleshooting...........................................................................................................

Quality control.............................................................................................................

How to Identify your Distiller..........................................................................................

Technical Data ...........................................................................................................

Suggested maximum limits of contaminants in and specification for water for

steam sterilization .......................................................................................................

Warranty Certificate.....................................................................................................

How to Proceed When Service is Needed..................................................................

Guidance for the Final Disposal of the Equipment......................................................

Links of Interest ...........................................................................................................

Bibliographical References........................................................................................

ÍNDICE

04

05

06

08

09

10

13

15

15

16

17

18

18

19

20

21

22

22

23

24

ATTENTION!

READ ALL THE INSTRUCTIONS IN THIS MANUAL BEFORE USING

YOUR CRISTÓFOLI DISTILLER. INCORRECT USE MAY RESULT

IN DAMAGE TO THE EQUIPMENT AND/OR ACCIDENTS!

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

4

INTRODUCTION

This equipment was developed to assist you in the important procedure of distilling

water to be used in steam sterilization autoclaves or any other application where it is

necessary to use distilled water. We dedicated ourselves intensively to guarantee you the

highest quality and safety. We hope to obtain this way, the highest level of satisfaction from

our clients.

The purpose of this manual is to familiarize you with the features and proper operation

of your Cristófoli Distiller so you know how to take good care of it, as well as increase the

equipment lifespan.

It is important to know some aspects that can void this warranty as a result of

negligence, improper use, non-authorized repairs, etc.

You will find the Warranty Certificate on page 21.

Responsible Technician

Eder William Costa Camacho

CREA/PR – 87826/D

IMPORTER

Cristófoli Equipamentos de Biossegurança Ltda.

Rod. BR 158, nº127 - Campo Mourão - PR - Brasil

CEP 87309-650

CNPJ 01.177.248/0001-95 - Inscr. Est. 90104860-65

Website: www.cristofoli.com - e-mail: [email protected]

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

5

LEGEND OF SYMBOLS

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

Fragile

Handle with Care

This Side Up Serial Number

Batch Number

Keep Away from

Sunlight

Recyclable

Maximum Pile

Caution, consult

accompanying documents

Manufacturer

Alternate Current

Keep Dry

ISO 13485

ISO 9001

ISO 14001

Date of

Manufacture

LOT

SN

~

Caution

Hot Surface

5

13485

D

E

S

G

A

E

M

S

E

T

T

Ã

S

I

O

S

6

IMPORTANT SAFETY INFORMATION

The intended use of this equipment is to distill water to be used in steam sterilization

autoclaves or any other application where it is necessary to use distilled water. In order

to determinate the quality of the water obtained with the use of the Cristófoli Distiller,

we have used the reference parameters found on the Table C.1 from the Standard EN

13060, Annex C “Suggested maximum limits of contaminants in and specification for

water for steam sterilization” (Page 20). In some specific cases, it may be necessary

that the water is purified by special processes. Check whether the parameters

obtained satisfy your needs. It is essential that the operator reads attentively all the

instructions before using the distiller to make sure they are correctly understood.

WARNING! To perform any kind of maintenance or everyday cleaning, always make

sure to unplug the equipment and wait at least 30 minutes for it to cool down before

handling. Improper use may cause burns. Cristófoli is not responsible for incorrect

procedures that may cause accidents;

We recommend reading this manual until it is fully understood. Keep it at hand and

use it as a constant reference source;

Do not allow non-qualified people to handle the distiller, prevent patients and

especially children to get close to the equipment;

Make sure all the air openings for ventilation on the top of the distiller and on its sides

are not obstructed;

As a routine, make sure all the distiller components are properly fitted before using it.

Non-observance of this procedure may interfere in its correct functioning. See “How to

Use the Cristófoli Distiller ” (Page 13);

Never put any liquid in the distiller other than regular tap water (potable water

provided by the urban water system) or filtered water, do not perform any use of this

equipment other than the one described in this manual.

Note: The use of filtered water reduces the formation of scales (deposits of mineral

crusts) on the heating element and makes cleaning easier;

SAFETY STEPS TO PROPERLY OPERATE YOUR CRISTÓFOLI DISTILLER

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

7

Never remove the main unit or touch the boiling tray while the distiller is on.

Never place your distiller near any heat source (electric heaters, gas ovens, etc);

Never use extensions, voltage transformers or any kind of adapters, do not plug the

distiller into inappropriate voltage outlets;

When the Distiller is not in use, disconnect the power cable from the outlet;

When the main unit is lifted or tilted, the distiller will turn off automatically;

When the water in the tap water container empties and the water level in the boiling

tray falls to the minimum pre-set point, the distiller will shut off automatically;

In case a power outage occurs, the distiller will need to be manually reset to continue

operation when energy is restored. To reset the distiller, press “OFF” on the “OFF/ON-

Reset” switch, wait for about 3 seconds until the red LED turns off, then, press “ON-

Reset”.

Note: In case the “OFF/ON-Reset” switch is returned to “ON-Reset” before the red LED

turns off, the distiller will not work.

WHEN THE LED FLASHES - When the LED flashes during operation it is indicating that

scale deposits have formed on the filter, boiling tray and heating element. These parts

should be cleaned with white vinegar or lemon vinegar (see “Preventive

Maintenance” (Page 16).

The distiller will also stop working automatically in case the process takes longer than 8

hours. Clean the filter, boiling tray and the heating element as mentioned above.

When continuous cycles are desired push the reset button once to override the 8-hour

time limit.

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

8

PHYSICAL INSTALLATION

Install the distiller on a flat, leveled and firm surface, at a proper height for the

operator to handle it. Leave enough room next to the distiller for handling and

exchange of the water containers. Install the distiller in a ventilated and clean room,

apart from the place where the patients are treated or people not qualified to

operate the distiller may have easy access to it.

Important! Install your distiller where it can be easily unplugged. This is the proper

way to turn the equipment off completely.

ELECTRICAL INSTALLATION

The voltage of the distiller is 127V or 220V, as informed on the identification

label located on the right side of the distiller main unit (Fig.2, page 11 and

Fig.7, page 12). Make sure the wiring where it will be installed is in voltage

accordance with the value marked on the Identification Label. Attention! Non

compliance with this requirement may damage your equipment. Cristófoli

is not responsible for damages caused by inappropriate installations and/or

voltage.

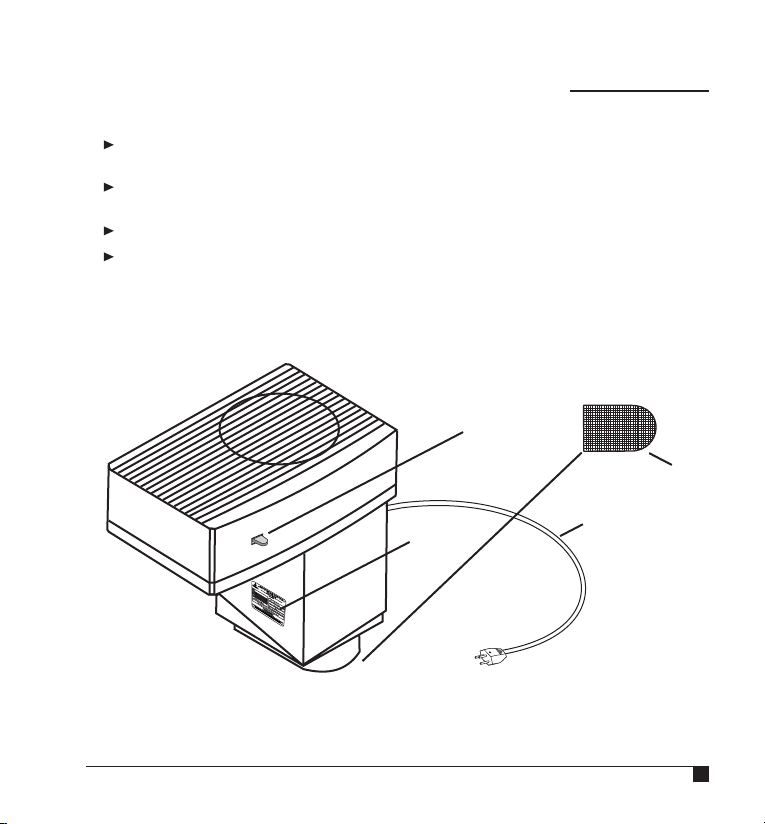

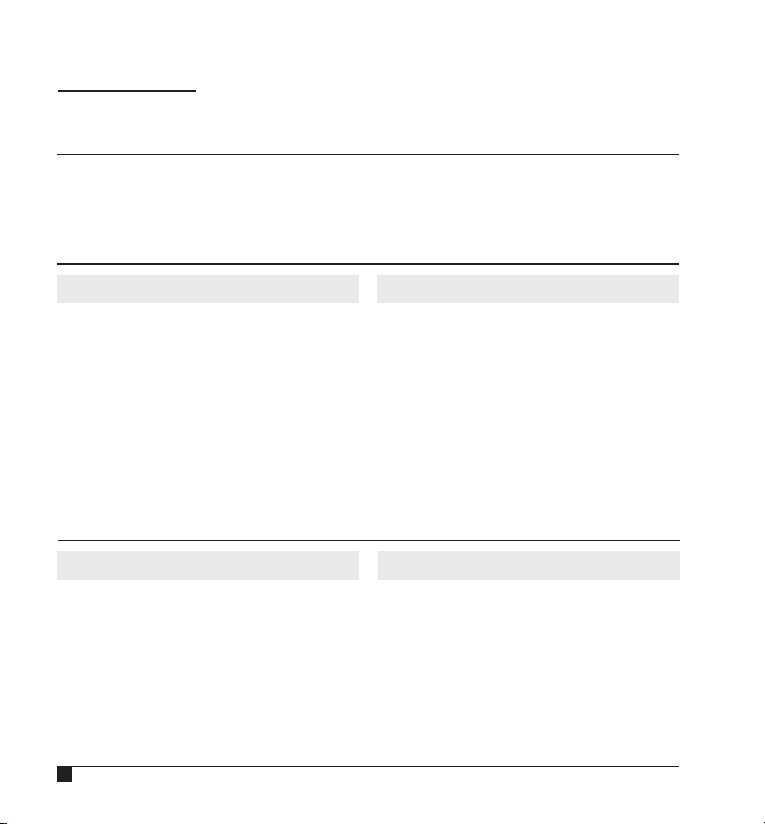

For the installation, use a three pin outlet, (2P + T, 10A), with grounding pin (Fig.

1, page 9);

Never use extensions, voltage transformers or any kind of adapters.

1

2

3

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

INSTALLATION INSTRUCTIONS

9

The electrical installation must follow the data from the table below:

Your Cristófoli Distiller has the following safety devices:

SAFETY FEATURES AND DEVICES

THERMAL FUSE (equipment internal device) - There is a thermal fuse attached to

the heating element. Its function is to limit equipment overheating during

operation. If the thermostat fails, the thermal fuse will be activated to cut the

current safely;

THERMOSTAT - (equipment internal device) - Its function is to limit equipment

excessive heating during operation;

WATER LEVEL DEVICE - It is located in the back part of the main unit (Fig.7, item 12,

page 12). The purpose of this device is to turn the distiller off automatically in the

following cases:

- the water in the tap water container is finished or its water exit is obstructed;

- the tap water container is removed;

After filling the tap water container, the distiller must be reset. Press “OFF” on the

On/Off Switch to and then back to “ON-Reset”;

When the distiller is tilted or lifted it will shut off automatically.

Outlet and plug with grounding pin

(three pins or 2P + T) 10A.

MODEL AMPERAGE

VOLTAGE

Cristófoli Distiller 127 V~ - - - - - - - - - - - 4,3 A

220 V~ - - - - - - - - - - - 2,2 A

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

Fig.1 Fig.1A

10

MAIN UNIT - Upper part of the equipment made with injected ABS plastic where the

heating element, cooler and On/Off Switch are located (Fig.2, page 11and Fig.7,

page 12);

ON/OFF SWITCH - It is in the front side of the main unit (Fig.2, page 11), its function is to

turn the distiller on and off, it also works as “RESET” button;

PREHEATING AREA - Area located around the boiling tray, it allows the pre-heating of

the water (Fig.3, page 11);

BOILING TRAY - Made with heat resistant plastic, it is where the boiling actually occurs,

it is removable and can be easily cleaned, manually or in a dish washer (Fig.3, page

11);

WATER LEVEL TRAY - Its purpose is to contain the water to be distilled, (Fig.3, page 11);

WATER TRAY - Attached on the base unit, it holds the tap water container and the

water to be distilled (Fig.3, page 11);

BASE UNIT - It works as a base for all the other parts of the distiller, it is made with heat

resistant plastic, it is removable and easy to clean, (Fig.4, page 11);

TAP WATER CONTAINER - Fitted in the back part of the distiller, it stores the tap water to

be distilled, it is removable and can be easily filled under the tap, (Fig.5, page 11);

TAP WATER CONTAINER CAP WITH SPRING VALVE - Special cap that acts as a valve for

the water in the tap water container, (Fig.5, page 11);

CARBON FILTER - When the water is to be used for human drinking (considering that

distilled water loses minerals during the distillation process), fit the carbon filter on the

distilled water container entrance for extra fresh tasting water (additional carbon filters

are available for purchasing), (Fig.6, page 11);

DISTILLED WATER CONTAINER - It is the frontal square container where the distilled

water is stored, it has a cap and can be put in the refrigerator to cool the water, (Fig.6,

pág.11);

DISTILLER GENERAL FEATURES

1

2

3

4

5

6

7

8

9

10

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

11

Fig.2

Fig.3

Fig.4

Fig.5

Fig.6

1

2

4

5

3

6

8

9

10

11

7

11

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

WATER LEVEL DEVICE - It is located on the back of the main unit, it turns the distiller off

automatically when the water from the tap water container finishes (Fig.7);

IDENTIFICATION LABEL - Affixed on the right side of the main unit its function is to ,

identify the distiller technical data (Fig.7);

POWER CABLE - Used to connect the equipment to the electric outlet, (Fig.7).

FILTER - It is used to reduce scales (mineral deposits) build-up on the heating element

to ensure maximum heating efficiency and performance of the distiller. It must be

replaced every other 3 months, additional filters are available for purchase, (Fig. 7);

13

12

14

15

12

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

Fig.7

12

13

15

14

1. Remove the distiller from the box;

Note: it is useful to keep the original box, it can be used later in case you need to return the

device to the distributor/manufacturer for repairs or replacement.

2. Check if all the components listed below are present:

- tap water container with spring valve cap;

- distilled water container with cap;

- carbon filter;

- base unit;

- water tray;

- main unit;

- filter;

- metal clip.

3. Place the water tray on the base unit, install the filter over the heating element and

finally fit the main unit on the base unit;

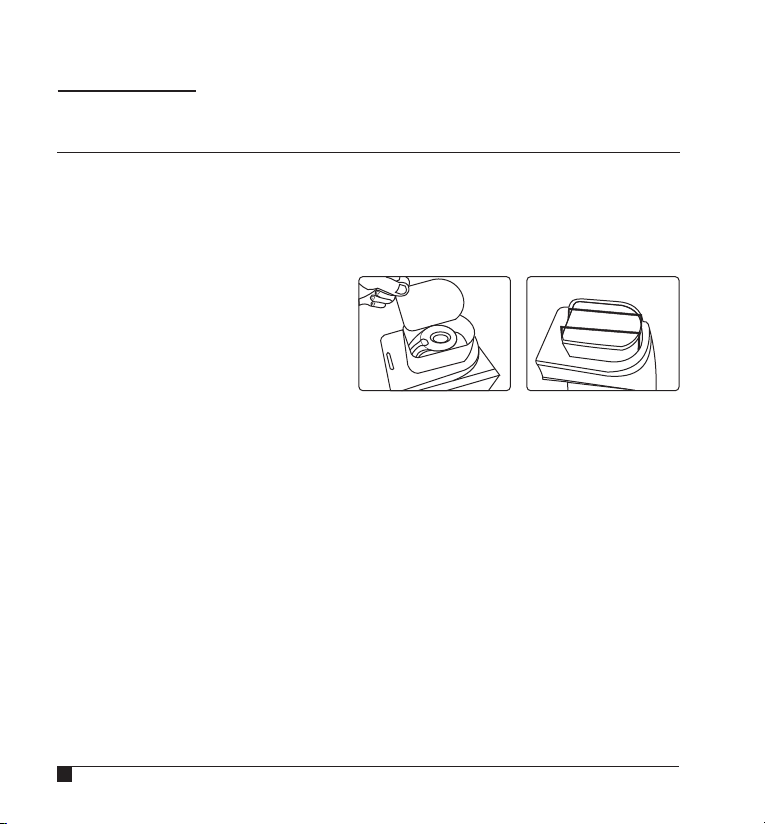

INSTALLING THE FILTER:

A. Remove the filter from the plastic tray and immerse it in water;

B. Put it over the heating element (Fig.8) and use the metal clip provided to hold it in

place (Fig.9);

Note: The function of the filter is to reduce scales (mineral deposits) build up on the heating element

during the distillation process to ensure maximum heating efficiency and performance of the distiller.

The majority of the mineral deposits will adhere to the filter which can be washed and reused. The filter

must be replaced every other 3 months or sooner depending on the water quality;

4. Place the distilled water container on the base unit with the top opening to the back, on

the left. Fill the tap water container with regular tap water, put the valve cap on and fit it on

the base unit;

5. Allow a minute so the water fills the boiling tray. Plug the distiller into the electric outlet

and press “ON-Reset” on the On/Off switch. At this moment, if the red LED is on, it means

that one of the following situations is happening:

13

HOW TO USE THE CRISTÓFOLI DISTILLER

Fig.8 Fig.9

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

14

A. The tap water container is not properly fitted on the base unit, adjust it;

B. The boiling tray is not completely filled with water. Switch it to “OFF”, wait for the red

LED to go out and switch back to the“ON-Reset” position;

6. Check whether the cooler at the top of the distiller main unit is on;

Note. When the cooler is on, the distiller is heating, the water inside the device will reach

100 ºC and will be boiling. It will take from 3 to 5 minutes for the distiller to begin producing

distilled water. In case the cooler is not running, check if all components are in place and

press “On-Reset”. When the tap water container empties out, the distiller will shut off

automatically and the red LED will light.

7. After the distiller shuts off, press “OFF” on the “ON/OFF Switch” and unplug it from the

outlet.

Warning! Make sure the distiller is cool before touching or handling it. Wait at least 30

minutes for cooling after the equipment shuts off.

When indicated for human drinking, consider that distilled water loses minerals during

the distillation process.

Carry out the first two cycles without the carbon filter and discard the water or use it in

steam sterilization autoclaves, air humidifiers, watering plants, etc.

Note: When the distiller is used for the first time, there can be some remaining harmless

matter from manufacturing, packing or shipping that could alter the taste of the water.

Before proceeding with the third cycle, clean the distilled water container, the tap

water container and the boiling tray with water and neutral soap, rinse them well. Get the

carbon filter from the plastic bag and soak it in water for 30 seconds to rinse away any

loose small particles of carbon and put it on the distilled water container opening, as if it

were a cap and start the third distillation cycle.

When the cycle is complete, remove the carbon filter until the next you need it.

Note: The carbon filter will only be necessary if the water is used for drinking;

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

15

We suggest that the operator standardize the distillation process and prepare an

estimate of the daily or weekly amount of distilled water needed, proceeding this way, the

operator will know exactly how much water to distill, optimizing the use of the distiller.

DISTILLED WATER STORAGE

The storage of the distilled water must be done in a clean plastic or glass container

properly closed and protected from light and heat. The storage cabinets must be easy to

clean, located in a dry room with fresh air, free from odors and away from disinfectants

and/or sterilants.

DISTILLED WATER SHELF LIFE

According to the studies performed, the distilled water shelf life for human

consumption and/or use in steam sterilization autoclaves is 15 days from the date it was

distilled.

REQUIREMENTS TO BE OBSERVED FOR THE DISTILLATION PROCESS

Insufficient operation time;

Incorrect handling of the distiller;

Lack of preventive maintenance;

Power outage;

Defective Distiller.

POSSIBLE FAILURES

1

2

3

4

5

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

16

PREVENTIVE MAINTENANCE

Some preventive procedures are necessary for the best functioning and durability

of your Cristófoli Distiller:

Use only regular tap water (potable water provided by the urban water system) or

filtered water;

Keep the distiller clean. The water tray must be cleaned after each distillation

cycle, it is removable and can be immersed in water, washed manually or put into

the dishwasher. Never get the main unit wet or put it in a dishwasher;

The cleaning of the external plastic surfaces must be done daily. Use a cloth

dampened with biodegradable neutral detergent, next, clean them with another

cloth dampened with alcohol 70% or peracetic acid at 1%, make smooth

movements in one direction only.

It is important to clean the distiller internal parts (heating element, filter and boiling

tray) regularly. The continuous use of the equipment will result in mineral deposits

build-up on these areas which may cause the distiller to stop working or work

deficiently in case they are not cleaned periodically, the residues will adhere

mostly to the filter, which can be washed and reused, the filter must be replaced

every other 3 months or before that depending on the water quality.

To remove the scales, follow the cleaning instruction below periodically:

- Fill the boiling tray with white vinegar or lemon vinegar, let it rest for at least 3

hours. The cleaning solution will soften the scale deposits. After that, remove the

boiling tray from the base unit and wash it. Fill it again with regular tap water to

rinse the lower part of the main unit. Finally, clean it with a soft damp cloth or

sponge.

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

17

TROUBLESHOOTING

WARNING! For any parts replacement, contact your local dealer. It is strongly not

recommended the replacement of any parts by non-qualified people. We listed below

some possible problems and solutions you can try on your own.

The distiller is not connected to the electric

outlet; Plug the distiller into the electric outlet;

No power; Check if there is a power outage in your

building;

SOLUTIONS

POSSIBLE CAUSES

THE DISTILLER DOES NOT TURN ON

The heating element has burned out; In both cases, contact your local dealer or

Cr istóf ol i dir ec tly t hr oug h th e e-

mail:[email protected]. See “How to

Proceed When Service Is Needed ” (Page

22);

The thermal fuse has burned out;

SOLUTIONS

POSSIBLE CAUSES

THE DISTILLER TURNS ON, BUT IT DOES NOT HEAT UP

Defective power cable; Contact your local dealer or Cristófoli

d i r e c t l y t h r o u g h t h e e m a i l :

cristofoli@cristofoli.com. See “How to

Proceed When Service Is Needed ” (Page

22);

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

If the problem persists after the verification of all the items listed, contact your local dealer

or a Cristófoli’s Authorized Representative.

18

All Cristófoli Distillers are tested on a batch sample basis, according to the parameters

of the table below.

QUALITY CONTROL

6 to 8 hours for 3,8 liters

Cold distiller

3 to 5 minutes

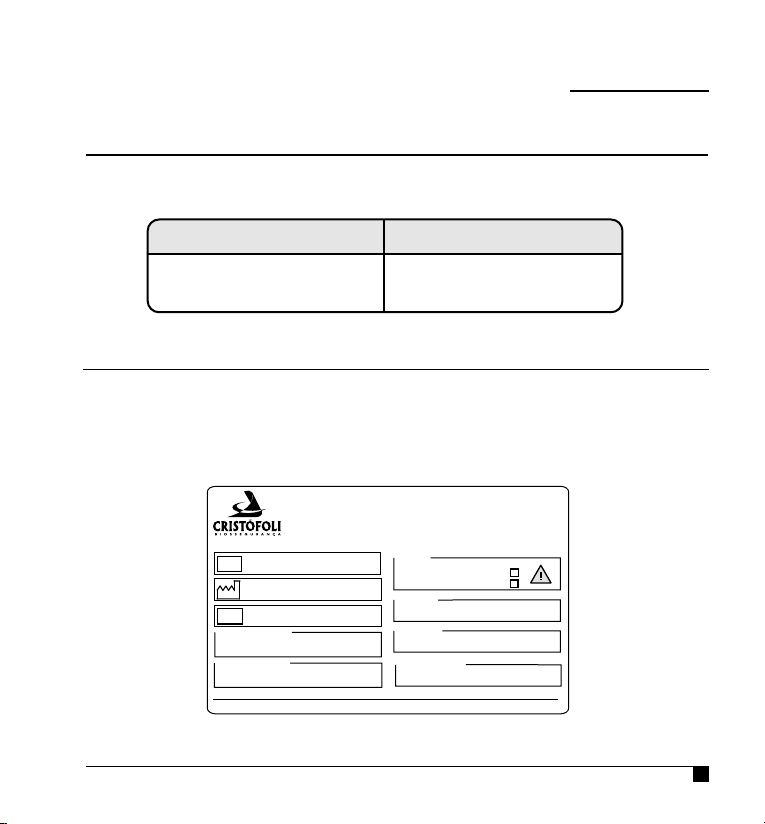

The identification label is affixed on the right side of the equipment main unit. Its

purpose is to identify the distiller technical data.

ATTENTION! - Removing the Identification Label and/or any other stickers from the product

will cause automatic loss of warranty.

HOW TO IDENTIFY YOUR DISTILLER

Fig.10

Heating Time

Distillation Time

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

LOT

S N

Cristófoli Distiller

127V~ - 0,55 kW - 4,3 A

220V~ - 0,45 kW - 2,2 A

3,8 l

EXEMPT - RDC nº 260/02

50/60 Hz

CRISTÓFOLI EQUIPAMENTOS DE BIOSSEGURANÇA LTDA

ROD BR 158 Nº 127 - CAMPO MOURÃO - PR - BRASIL

CEP 87309-650 - TEL.: 55 44 3518-3434

CNPJ 01.177.248/0001-95 - INSCR. EST. 90.104.860-65

Made in China

Eder William C. Camacho - CREA/PR – 87826/D

IMPORTED BY:

POWER

CAPACITY

MODEL

PRODUCT: WATER DISTILLER.

RESPONSIBLE TECHNICIAN

FREQUENCY

USE INSTRUCTIONS, PRECAUTIONS, CONSERVATION AND STORAGE: SEE INSTRUCTION MANUAL.

ANVISA REGISTER

MODEL

Table 1

Note: The label presented above is just a sample model for your reference.

19

TECHNICAL DATA

CERTIFICATIONS.............................................................

TAP WATER CONTAINER CAPACITY...................................

DISTILLED WATER CONTAINER CAPACITY..........................

GROSS WEIGHT (PACKED)..............................................

NET WEIGHT...................................................................

CYCLE TOTAL TIME (full container)..................................

EQUIPMENT DIMENSIONS (W x H x D)..............................

VOLTAGE.......................................................................

FREQUENCY...................................................................

POWER & ENERGY CONSUMPTION.................................

.....................................................................................

PROPER WORKING TEMPERATURE...................................

This equipment is imported by Cristófoli, company which

Quality Management System is certified and in

accordance with the ISO 9001:2008, ISO 13485:2003,

BPF- Boas Práticas de Fabricação - ANVISA (Brazilian

standard similar to GMP-FDA/US) and ISO 14001:2004 -

Environmental Management standards.

4 liters

3,8 liters

4 kg

3,4 kg

6 to 8 hours (for 3,8 liters of distilled water)

27 cm x 33 cm x 27,6 cm

127 or 220V ~ single-phase

50/60 Hz

550 Watts (model 127V) - 0,55 kW/hour

450 Watts (model 220V) - 0,45 kW/hour

15 ºC to 40 ºC

TECHNICAL DATA CHART CRISTÓFOLI DISTILLER

C R I S T Ó F O L I

D I S T I L L E R

I N S T R U C T I O N M A N U A L

Table 2

Table of contents

Other Cristofoli Distilling Equipment manuals