DRINK10 Distiller Operation Manual

REV-A Page 2 of 26

Content

Regulatory Requirement ...........................................................................................................................1

Revision History.......................................................................................................................................1

Regulatory Requirements .........................................................................................................................1

Content .....................................................................................................................................................2

Chapter 1 Introduction .............................................................................................................................3

1.1 Attention..............................................................................................................................3

1.2 Application Range...............................................................................................................3

1.3 Method ................................................................................................................................3

1.4 Contradictions .....................................................................................................................3

Chapter 2 Safety ....................................................................................................................................... 4

2.1 Symbol Explanation............................................................................................................4

2.2 General Safety Recommendations ......................................................................................4

2.3 Safety Parts .........................................................................................................................5

2.4 Operating Risk ....................................................................................................................5

Chapter 3 Receiving and Installation .......................................................................................................6

3.1 Checking the Package .........................................................................................................6

3.2 Open the Accessories List ...................................................................................................6

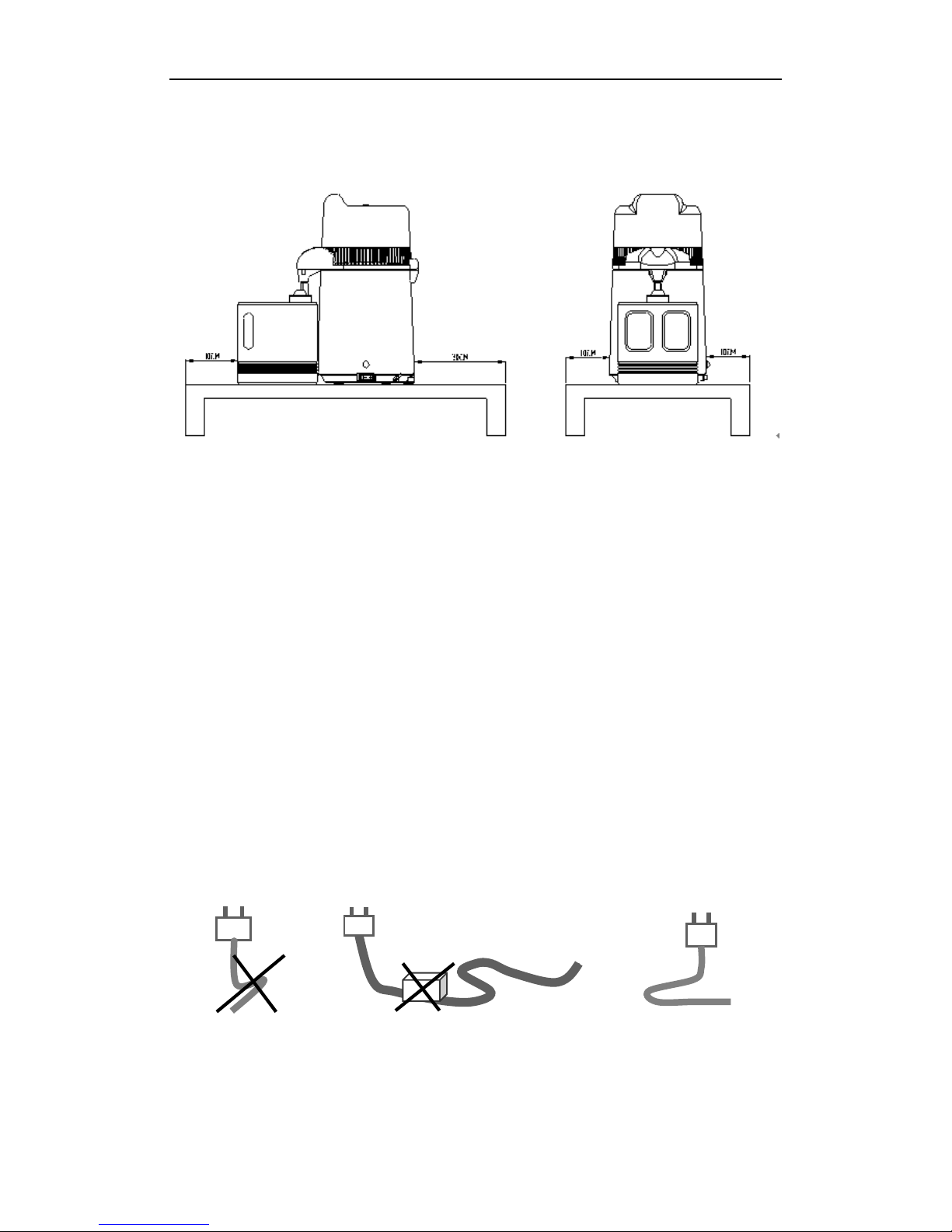

3.3 Working Environment .........................................................................................................7

3.4 Installation...........................................................................................................................7

3.5 Power Connector.................................................................................................................7

Chapter 4 Product Description and Specification....................................................................................8

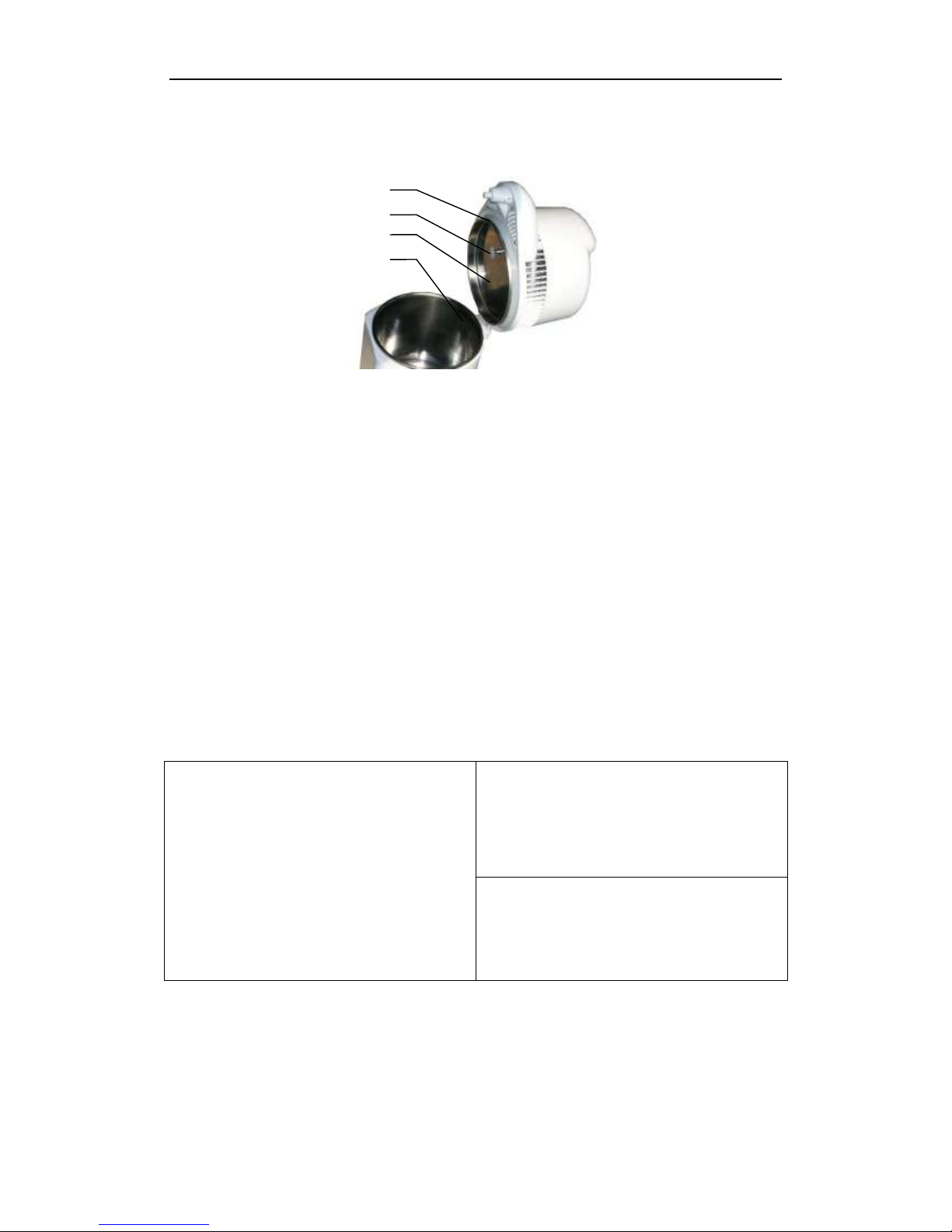

4.1 Front View...........................................................................................................................8

4.2 Lateral View ........................................................................................................................8

4.3 Open View...........................................................................................................................9

4.3 Size and Capacity................................................................................................................9

4.5 Specification........................................................................................................................9

Chapter 5 Operation Process .................................................................................................................10

5.1 Setting ...............................................................................................................................10

5.2 Water-adding .....................................................................................................................10

5.3 Power Connector...............................................................................................................10

5.4 Starting ..............................................................................................................................10

5.5 Ending ...............................................................................................................................10

5.6 Power Off.......................................................................................................................... 11

Chapter 6 Maintenance .......................................................................................................................... 11

6.1 Maintenance Schedule Chart............................................................................................. 11

6.2 Daily Maintenance ............................................................................................................11

6.3 Monthly Maintenance .......................................................................................................12

6.4 Quarter Maintenance.........................................................................................................12

Chapter 7 Troubleshooting ..................................................................................................................... 13

Chapter 8 Transport and Storage ........................................................................................................... 14

8.1 Preparing for Transport and Storage .................................................................................14

8.2 Transport and Storage Conditions .....................................................................................14

8.3 Package .............................................................................................................................14

Appendix 1 Electrical Connection Diagram........................................................................................15