2

Content / Sommaire / Contenido / Índice / İçindekiler / Содержание / Зміст /

Мазмұны /

English

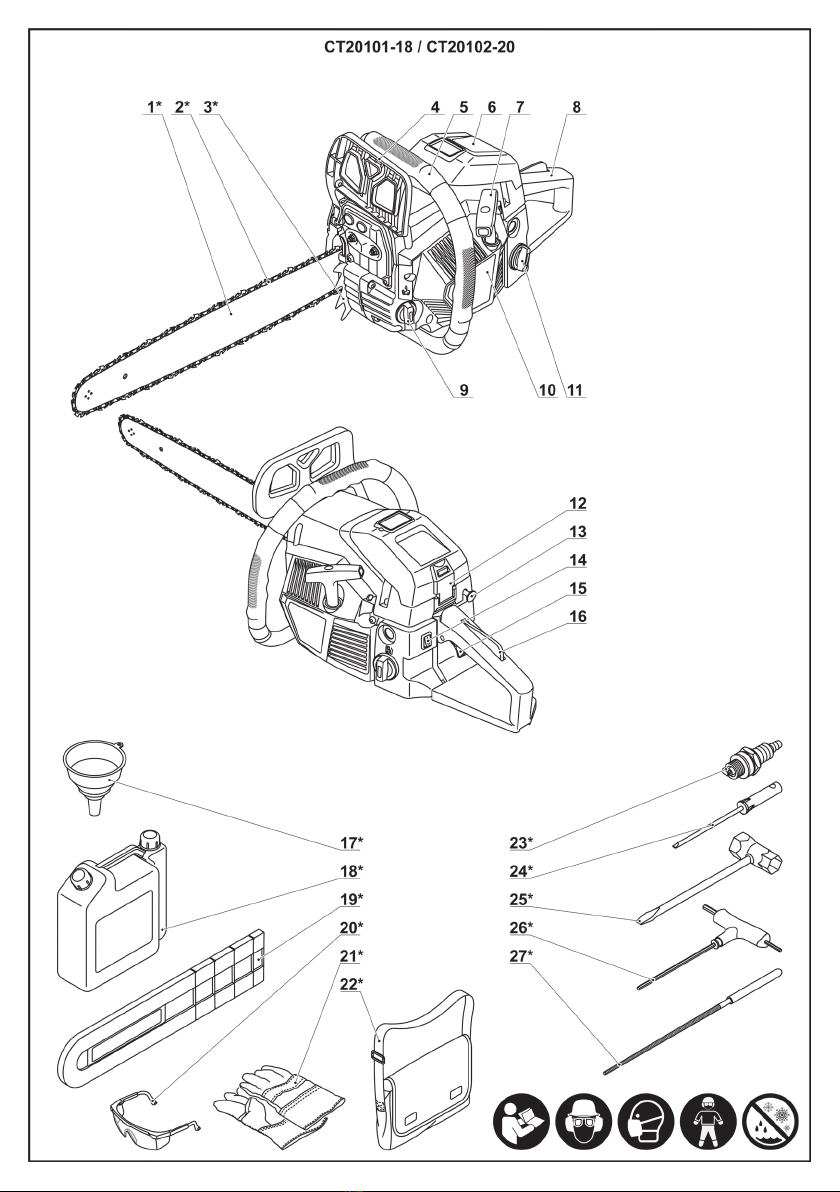

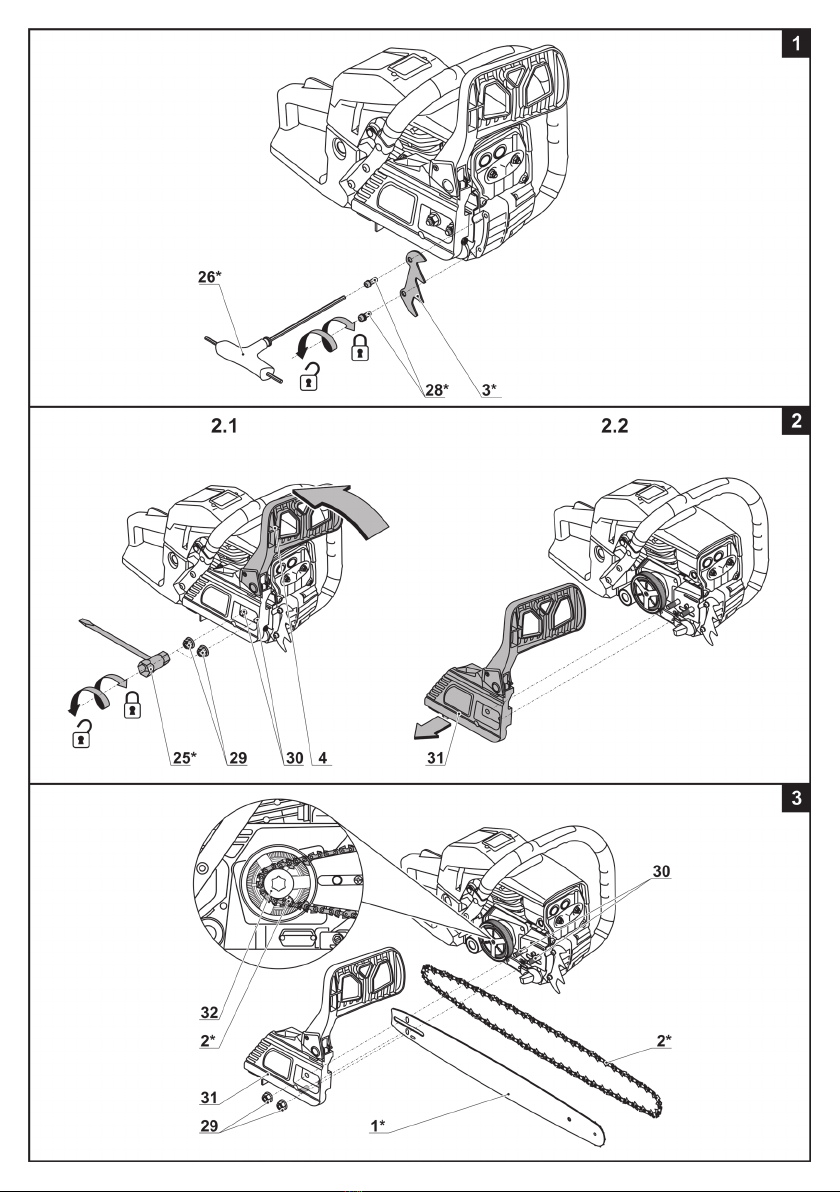

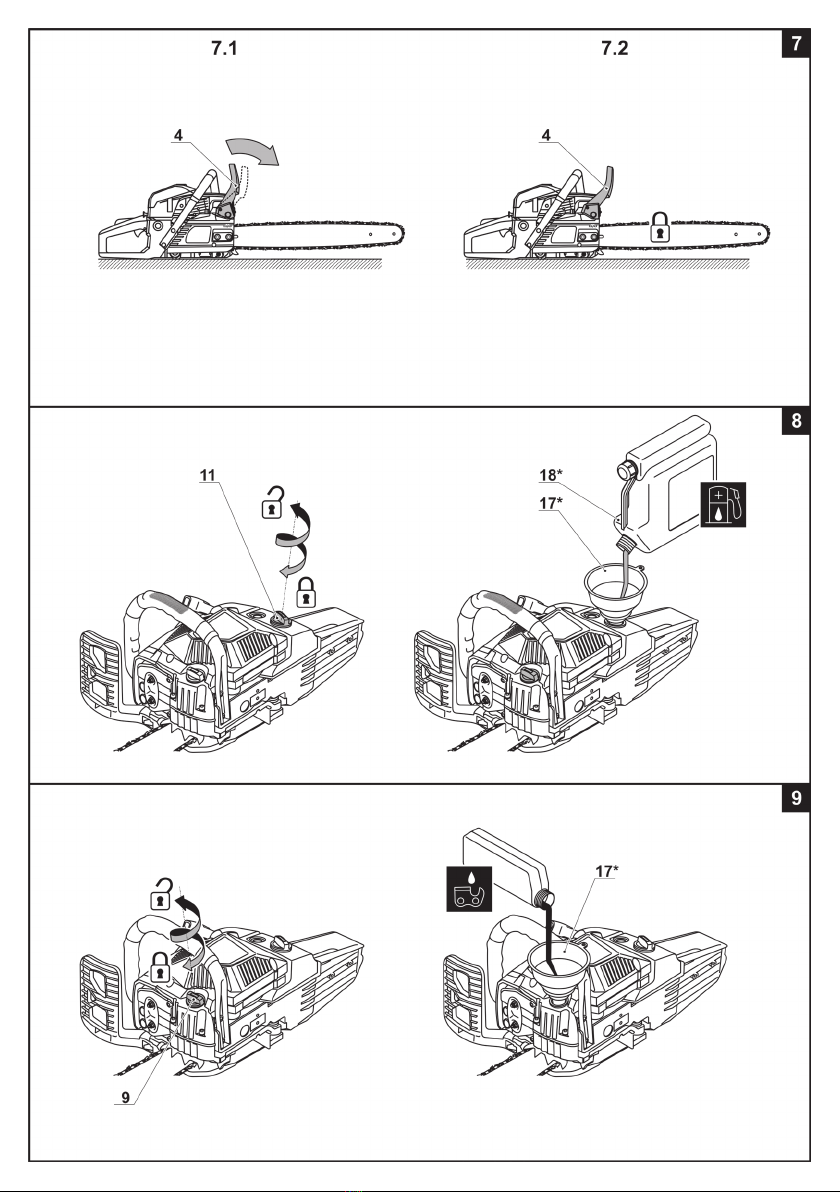

Explanatory drawings �������������������������������������������������������������������������������������������������������������pages

General safety rules, instructions manual ����������������������������������������������������������������������������� pages

CROWN warranty �������������������������������������������������������������������������������������������������������������������� page

Warranty card and service cards ������������������������������������������������������������������������������������������� pages

4 - 11

12 - 21

118

136 - 138

Français

Dessins explicatifs ������������������������������������������������������������������������������������������������������������������ pages

Recommandations générales de sécurité, mode d'emploi ���������������������������������������������������� pages

Garantie CROWN �������������������������������������������������������������������������������������������������������������������� page

Garantie coupon et cartes de service ������������������������������������������������������������������������������������ pages

4 - 11

22 - 32

119

136 - 138

Español

Dibujos explicativos ������������������������������������������������������������������������������������������������������������ páginas

Recomendaciones generales de seguridad, manual de instrucciones ������������������������������ páginas

Garantía CROWN ����������������������������������������������������������������������������������������������������������������� página

Tarjetas de mantenimiento y cupón de garantía ����������������������������������������������������������������� páginas

4 - 11

33 - 43

120

136 - 138

Português

Esboços explicativos ���������������������������������������������������������������������������������������������������������� páginas

Recomendações gerais de segurança, manual de instruções ������������������������������������������� páginas

Garantia CROWN ����������������������������������������������������������������������������������������������������������������� página

Cupão da garantia e cartões de reparação ������������������������������������������������������������������������ páginas

4 - 11

44 - 54

121

136 - 138

Türkçe

Açıklayıcı resimler �������������������������������������������������������������������������������������������������������������� sayfalar

Genel güvenlik tavsiyeleri, kullanım kılavuzu ��������������������������������������������������������������������� sayfalar

CROWN garanti koşulları ������������������������������������������������������������������������������������������������������� sayfa

Garanti kuponu ve servis kartları ���������������������������������������������������������������������������������������� sayfalar

4 - 11

55 - 64

122

136 - 138

Русский

Пояснительные рисунки �������������������������������������������������������������������������������������������������страницы

Общие указания по ТБ, инструкция по эксплуатации ������������������������������������������������� страницы

Гарантия CROWN ���������������������������������������������������������������������������������������������������������� страница

Гарантийный талон и сервисные талоны �������������������������������������������������������������������� страницы

4 - 11

65 - 75

123

136 - 138

Украïнська

Пояснювальні малюнки ���������������������������������������������������������������������������������������������������� сторінки

Загальні вказівки по ТБ, iнструкція з експлуатації ��������������������������������������������������������� сторінки

Гарантія CROWN ������������������������������������������������������������������������������������������������������������� сторінки

Гарантійний талон i сервісні талони �������������������������������������������������������������������������������� сторінки

4 - 11

76 - 86

124 - 128

136 - 138