CryopAL TP-35 User manual

1

Self-pressurizing storage tanks

TP 35 – TP 60 – TP 100

User’s manual

2

Copyright 2017 by Cryopal

Document code: NH78163 – English version

Edition January 2017 – Revision I

All rights reserved. This document may not be reproduced in any form whatsoever, in whole or in part, without

written permission from Cryopal.

Cryopal

Parc Gustave Eiffel

8 Avenue Gutenberg

CS 10172 Bussy Saint Georges

F - 77607 Marne la Vallée Cedex 3

Tel: +33 (0)1.64.76.15.00

Fax: +33 (0)1.64.76.16.99

Web: http://www.cryopal.com

3

Contents

1.

About this manual ............................................5

1.1

Purpose of the manual ...............................5

1.2

Who this manual is for................................5

1.3

Structure of the manual..............................5

1.4

How to use this manual..............................5

1.5

Skimming the manual.................................5

1.6

The included document..............................5

1.7

Trade names cited......................................5

2.

Safety.................................................................6

2.1

Symbols used.............................................6

2.2

Operator safety...........................................6

2.3

Precautions in the event of operating faults7

2.4

Important Safety Elements (ISE)................7

2.5

Destruction of the unit.................................8

3.

Components supplied....................................10

4.

General.............................................................12

4.1

Guide to components ...............................12

4.2

Function....................................................12

4.3

Principle....................................................12

5.

Description......................................................14

5.1

Storage tank .............................................14

5.2

The control head.......................................15

5.3

Main accessories......................................15

6.

Unpacking and installation............................18

6.1

Unpacking.................................................18

6.2

Installation.................................................18

6.3

Installation checklist..................................18

7.

Installing the components .............................20

7.1

Control head.............................................20

7.2

Removing the control head.......................21

8.

Use ...................................................................22

8.1

Storage precautions .................................22

8.2

Moving......................................................22

8.3

Handling....................................................22

8.4

Filling the tank ..........................................22

8.5

Withdrawal................................................24

9.

Maintenance....................................................26

9.1

Operating incidents...................................26

9.2

Preventive maintenance...........................27

9.3

Inspections ...............................................27

9.4

Adjusting the level indicator......................29

9.5

Changing components..............................30

9.6

Interview frequency ..................................31

10.

Technical specifications.................................34

10.1

Tank..........................................................34

10.2

Control head..............................................35

11.

Spare parts and accessories .........................36

11.1

Tank..........................................................36

11.2

Control head..............................................36

11.3

Accessories...............................................37

12.

Warranty and limit of liability.........................38

12.1

Warranty....................................................38

12.2

Limit of liability...........................................38

13.

Index.................................................................40

4

5

1. About this manual

1.1 Purpose of the manual

This manual refers specifically to cryogenic storage

tanks in the TP range, i.e. self-pressurizing tanks

intended for storing and transporting liquid nitrogen.

1.2 Who this manual is for

This manual is for any professional who wishes to use

a cryogenic container in the TP line.

1.3 Structure of the manual

For ease of consultation, the structure of this manual

follows the steps normally taken by the user, as

described below:

Topic Page

Overview of the TP tank 12

Assembly (parts and options) 20

Use 22

Maintenance 26

Technical specifications 3434

1.4 How to use this manual

The instructions in this manual are in the same

sequence as those followed by the users of the

product (section 1.3).

1.5 Skimming the manual

Given the specific nature of the cryogenic products

and storage tanks, we would advise against skimming

through this manual. We strongly recommend reading

the chapters thoroughly in the order given.

1.6 The included document

The accompanying document contains:

This manual in electronic pdf format.

Manuals issued by Cryopal.

Note: you will need to have the software known as

Acrobat Reader installed on your computer to be

able to read or print from this pdf manual in pdf

format.

1.7 Trade names cited

Adobe and Adobe Acrobat Reader are trademarks of

Adobe Systems Incorporated.

6

2. Safety

2.1 Symbols used

Symbol Meaning

Important

information about using the

equipment. Failure to follow the

instructions given for this point does not

result in danger for the user.

Warning: General danger. In this

manual, failure to observe or

implement the instructions preceded

by this symbol may

cause bodily

harm, or may damage the equipment

and installations.

Name and address of manufacturer.

Mandatory

: Protect your hands using

appropriate personal protection

equipment.

Warning

: Low temperature.

Product reference

Date of

manufacturing

Capacity in liters

Batch number

To maintain perfect operating conditions and ensure

that the equipment is used safely, you must follow the

instructions and take note of the symbols given in this

manual. The tank has been designed for

liquid nitrogen only.

When the device cannot be used in conditions of total

safety, the equipment should be withdrawn from

information about using the

equipment. Failure to follow the

instructions given for this point does not

result in danger for the user.

Warning: General danger. In this

manual, failure to observe or

implement the instructions preceded

cause bodily

harm, or may damage the equipment

Name and address of manufacturer.

: Protect your hands using

appropriate personal protection

: Low temperature.

To maintain perfect operating conditions and ensure

that the equipment is used safely, you must follow the

instructions and take note of the symbols given in this

manual. The tank has been designed for

use with

When the device cannot be used in conditions of total

safety, the equipment should be withdrawn from

service and protected against accidental usage. Full

safety cannot be guaranteed in the following cases:

The equipment is

visibly damaged.

The equipment no longer works (applies

particularly to accessories).

After prolonged storage in unsuitable conditions.

After severe damage sustained during transit.

2.2

Operator safety

2.2.1

General safety precautions

Only personnel who have fully read this manual

and the safety recommendations (see NH78380)

are authorized to handle and use the apparatus

described in this document.

Like every other system, your apparatus may be

subject to a mechanical

failure. The manufacturer

cannot be held liable for any production losses

subsequent to defective operation of the kind

described above, even during the warranty period.

If the cryogenic tank appears to have an operating

fault when used under normal condi

properly trained and qualified personnel are

permitted to service it. The user must not be

permitted to attempt repairs as this could present

a risk to that person's health and/or safety.

The equipment described in this manual is designed

exclu

sively for use by qualified personnel.

Maintenance operations should only be carried out by

qualified and authorized personnel. To ensure the

safe and correct use of the device during service and

maintenance, it is essential that all personnel observe

standard safety procedures.

service and protected against accidental usage. Full

safety cannot be guaranteed in the following cases:

visibly damaged.

The equipment no longer works (applies

particularly to accessories).

After prolonged storage in unsuitable conditions.

After severe damage sustained during transit.

Operator safety

General safety precautions

Only personnel who have fully read this manual

and the safety recommendations (see NH78380)

are authorized to handle and use the apparatus

described in this document.

Like every other system, your apparatus may be

failure. The manufacturer

cannot be held liable for any production losses

subsequent to defective operation of the kind

described above, even during the warranty period.

If the cryogenic tank appears to have an operating

fault when used under normal condi

tions, only

properly trained and qualified personnel are

permitted to service it. The user must not be

permitted to attempt repairs as this could present

a risk to that person's health and/or safety.

The equipment described in this manual is designed

sively for use by qualified personnel.

Maintenance operations should only be carried out by

qualified and authorized personnel. To ensure the

safe and correct use of the device during service and

maintenance, it is essential that all personnel observe

7

2.2.2 Safe use of liquid nitrogen

The temperature of liquid nitrogen is -196 °C. As a

result:

You must never touch objects which

have been in contact with liquid

nitrogen with your bare hands.

Always wear special gloves and visors

when handling liquid nitrogen

Liquid nitrogen used in storage

freezing chambers evaporates into the

air; 1 litre of liquid nitrogen releases

around 700 litres of nitrogen in the

gaseous state. Nitrogen is an inert,

non-toxic gas, but displaces oxygen

when released into the atmosphere.

Once the atmospheric oxygen content

falls below 19% there is a risk for

humans.

Any room or place where liquid

nitrogen containers are kept must

always be completely ventilated and, at

least, equipped with an oxygen

detector; it should not be used for

other purposes than those defined by

your integrator. All personnel should

be informed of the risks associated

with the use of nitrogen.

The storage tank is designed for use

with liquid nitrogen only.

When in new condition, the tank must

always be transported empty, in its

original packaging and in compliance

with current national and international

regulations. Never stack storage tanks

on top of each other.

According to the ADR directive on

transporting dangerous goods by road,

in order to avoid falling under the

TPED directive, TP tanks must be

transported without being under

pressure (at atmospheric pressure)

and with their neck open.

The tank may be moved across short

distances (using the dolly base) with

its head installed, with the tank not

being under pressure (i.e. at

atmospheric pressure).

If the tank is moved without the head,

the control head can be reinstalled in

the tank once full. This installation

phase must be conducted with caution

(

operator equipped with all required

cryogenic personal protection

equipment: gloves, apron, visor, etc.)

in order to avoid any liquid nitrogen

splashing.

The neck of the tank must never be

hermetically sealed. Use the stopper

provided.

The tank must always be kept vertical.

2.3 Precautions in the event of

operating faults

If you suspect that the integrity of the equipment has

been compromised (for example as a result of

damage sustained during transit or during use), it

should be withdrawn from service. Make sure that the

withdrawn equipment cannot be accidentally used by

others. The defective equipment should be handed

over to authorized technicians for inspection.

2.4 Important Safety Elements

(ISE)

These ISE are:

Design rules for the EC Medical directives.

Technical documentation (maintenance

instructions and services),

Components integral to the products (valves,

solenoid valves, electronic equipment such as

control and traceability electronics, overflow

prevention and degassing devices, sensors and

interfaces for remote monitoring (by an automation

controller etc.), the cover contact); these elements

are not necessarily present on the product.

Obligatory safety recommendations or advice (the

wearing of personal protection equipment when

using our products, instructions for the use of

equipment etc.).

During filling and transfer operations, ensure that

equipment and procedures that ensure safety are

used (hose, vacuum valve).

8

2.5 Destruction of the unit

In order to protect the environment the equipment (the

tank and its peripheral equipment) must be disposed

of via the proper channels.

9

10

3. Components supplied

The product is delivered complete with:

Ref. Designation Qty

1.

Insulating stopper. 1

2.

ATP container (see table of capacities on

page 34). 1

3.

Document containing this manual in pdf

format. 1

Figure 3-1: The delivered parts.

1

2

3

11

12

4. General

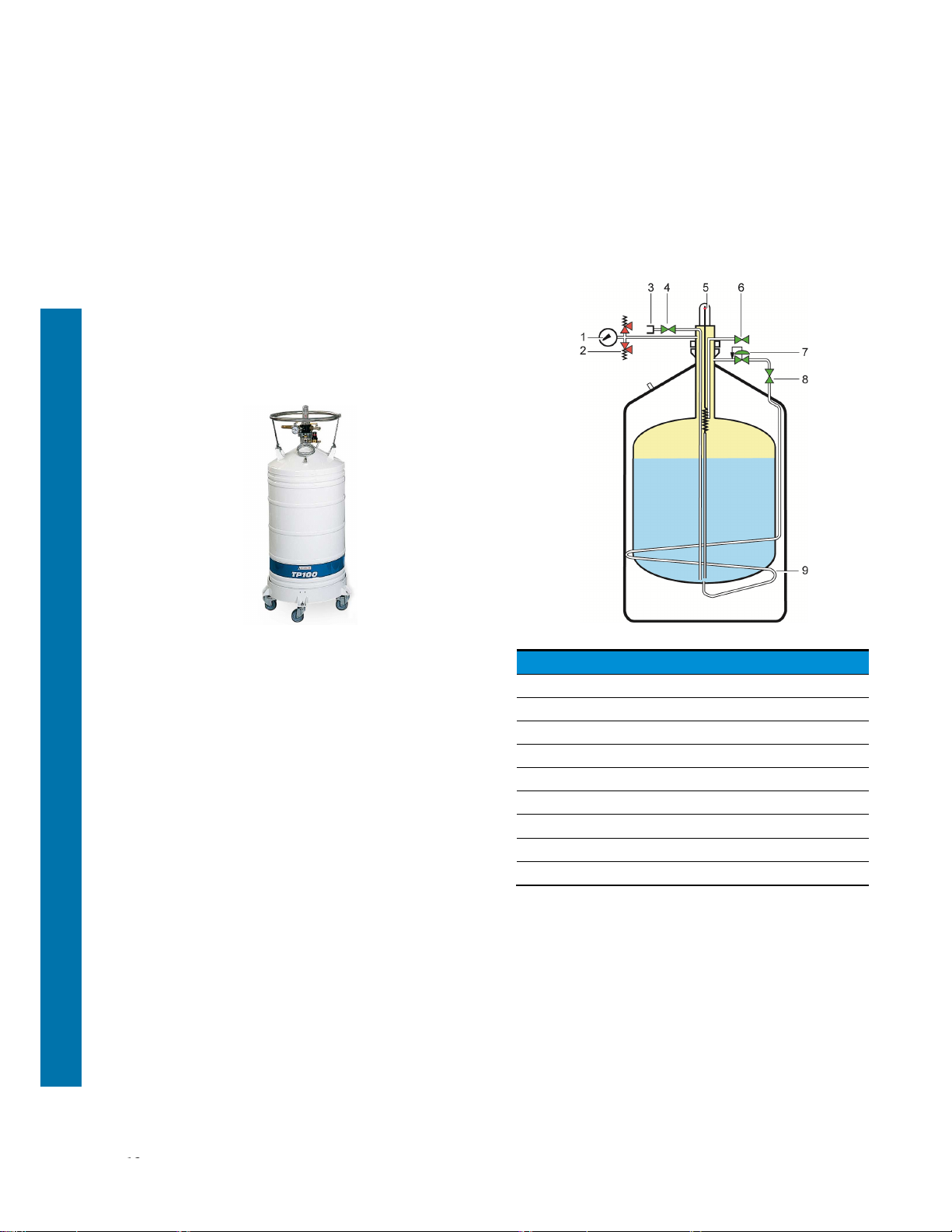

4.1 Guide to components

This illustration shows the main parts, both included

ones and options that make up a storage tank in the

TP

product line. These are described in greater detail

in the following paragraphs and pages. The tanks will

be used in an appropriate environment.

Figure 4-1: General view of the parts of a type TP storage tank.

4.2 Function

Cryogenic containers in the

TP

range are self-

pressurizing aluminium storage tanks for storing and

withdrawing liquid nitrogen at low pressures. A float-

type level indicator enables the amount of available

liquid to be checked. The removable control head is

fitted with a pressure gauge and two safety valves.

4.3 Principle

The storage tank contains liquid nitrogen. It is

pressurised by means of an exchanger (9) [regulating

valve (7) and shutoff valve (8)] located between the

walls. This exchanger vaporises liquid gas and thus

ensures that the tank is pressurised. The pressure

can be read off the pressure gauge (1). Two safety

valves (2) calibrated to 0.5 bars protect the tank. It is

filled via the connector (3) and valve (4) assembly.

Figure 4-2: Principle.

Ref. Designation

1. Internal pressure gauge.

2. Safety valves.

3. Connector (filling/withdrawing)

4. Filling and withdrawing valve.

5. Mechanical level indicator.

6. Venting /overflow valve.

7. Internal pressure regulating valve.

8. Pressure-building valve.

9. Pressure-building coil.

13

14

5. Description

This section describes the two main parts, i.e. the

storage tank and the control head.

5.1 Storage tank

The self-pressurizing aluminium storage tank enables

liquid nitrogen to be stored and withdrawn. It consists

of the following parts:

A tank (6) consisting of two aluminium alloy

enclosures connected by a collar of composite

materials. It is thermally insulated by means of a

vacuum between the two annular spaces and

several layers of insulation on the internal

container. The exterior of the tank is coated with

polyurethane paint for a good finish and durability.

A flange head DN50 (3), onto which the control

head is fastened (see next section).

Two handles (5).

A vacuum valve (7) which also acts to keep the

annular spaces safe.

A controller (2) intended to control the tank's once

the installed control head and the pressure-

building valve (1) have been opened. The basic

setting is 0.5 bar.

A pressure-building heating coil (4).

An insulating, enclosing stopper (8) that limits

nitrogen loss. This stopper must be placed on the

flange whenever the control head is not fitted on

the tank.

The neck of the tank must never be

hermetically sealed.

Two self-adhesive labels carrying warnings and

product identification.

Refer to:

On page 12 for details of how these components

operate.

On page 34 for the technical specifications of the

various models.

Figure 5-1: Overview of the tank

Ref. Function

1. Pressure-building valve.

2. Controller.

3. Head flange, nom. dia. 50 mm

4. Heating coil.

5. Handle

6. Tank.

7. Annular space safety device.

8. Stopper.

1

2

3

4

5

6

7

8

15

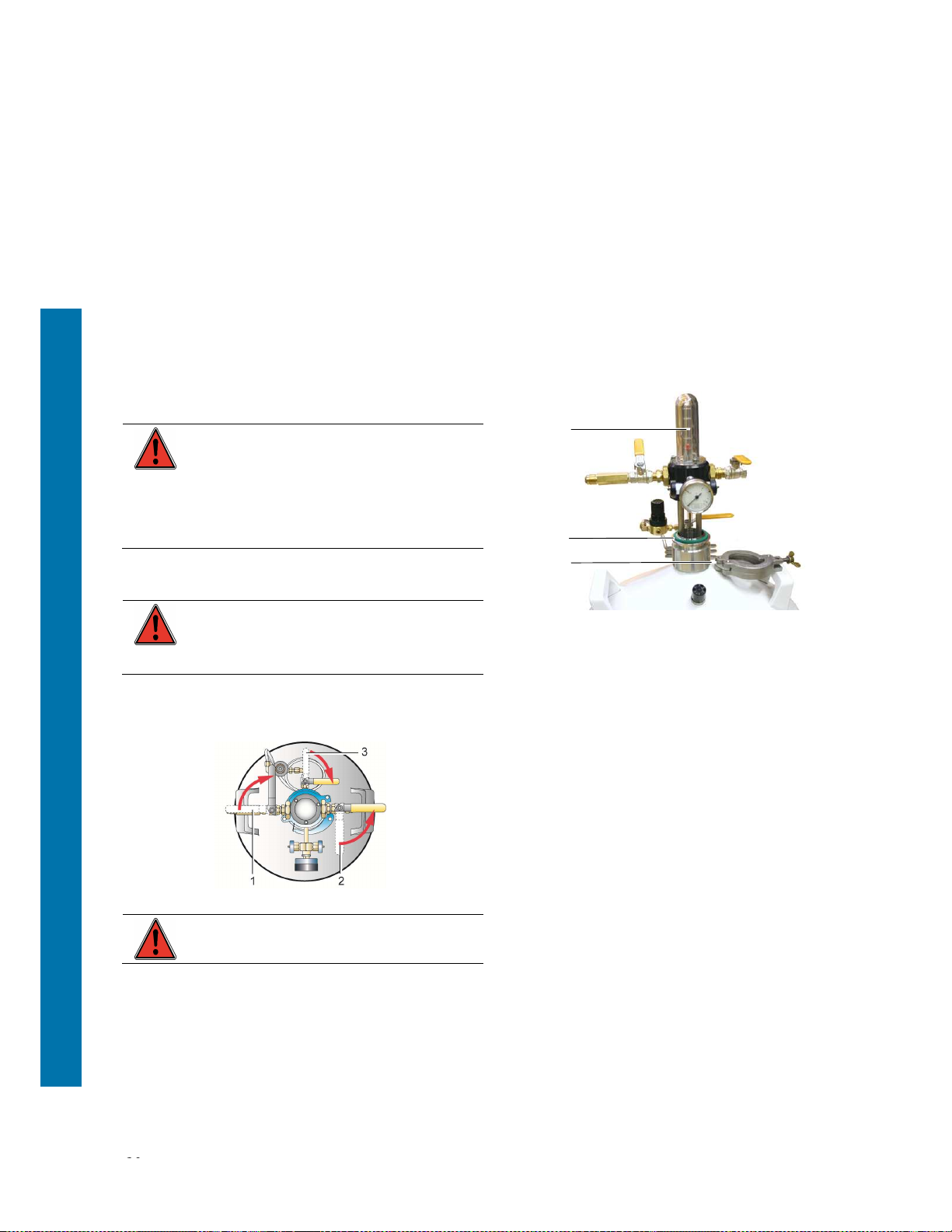

5.2 The control head

The control head can provide a quick check of the

amount of available liquid in the tank. It includes the

following withdrawal, level reading and safety devices:

Figure 5-2: Overview of the control head.

Ref. Function

1. Mechanical level indicator.

2. Filling / withdrawing valve.

3. Filling/utilisation connector.

4. 0.5 bar valves.

5. Pressure gauge (internal pressure).

6. Venting /overflow valve.

7. Venting connector

8. Quick-release clamping ring

9. Leak proof seal.

A floating level indicator (1). The coloured part

shows the percentage of liquid nitrogen remaining.

A filling valve (2) and its connector (3) for

connecting to the supply tank connector or to the

supply line via a suitable flexible transfer line. This

valve (2) and its connector (3) are also used for

withdrawal (drawing liquid nitrogen off into another

vessel for use).

Two safety valves calibrated to 0.5 bar (4),

protecting the tank from any excess internal

pressure .

A pointing pressure gauge (5) indicating the tank's

internal pressure in bars (kPa). A red mark at 0.5

bars shows the maximum service pressure of the

TP

.

A venting and overflow valve (6) and its connector

(7).

A quick-release clamping rings (8) to fit the control

head on the storage tank flange.

A seal (9) that prevents any leakage between the

control head and the storage tank flange.

Refer to:

On page 12 for details of how these components

operate.

En On page 35 for the technical specifications.

5.3 Main accessories

These accessories are not supplied with the standard

version and must be ordered separately.

5.3.1 Dolly base

This base (1) can be firmly clamped to the tank and

enables it to be moved inside a building, making it

easier to negotiate uneven floors. It has five castors,

two of which have brakes.

Figure 5-3: Container mounted on the dolly base.

5.3.2 Hand rail

This removable metal accessory (1) makes it easy to

move the tank and also protects the control head. The

handrail (1) fastens on to two lugs mounted on the

tank handles.

Figure 5-4: View of the handrail mounted on a tank.

1

2

3

4

5

6

7

8

9

1

1

16

5.3.3 Flexible transfer lines

5.3.3.1 Type 130/130

This flexible transfer line (or hose), which vary in

length, is intended to fill the

TP

from a supply tank or

vacuum line. There is a screw-on connector at both

ends. One end is connected to the source valve outlet

and the other to the connector (Figure 5-2) on the TP

storage tank.

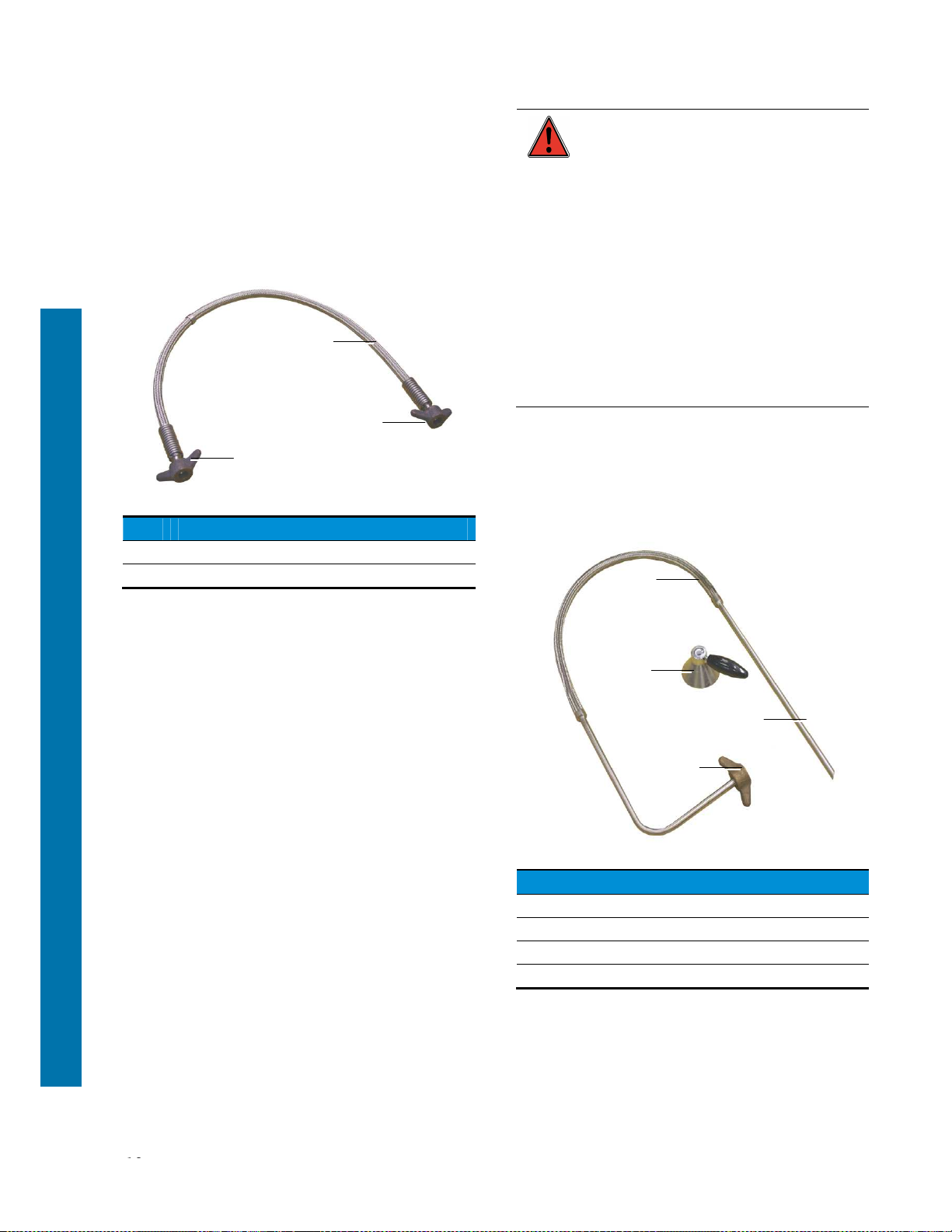

Figure 5-5: View of the 130/130 transfer line.

Ref. Function

1. Screw-on connector.

2. Flexible line.

Cryopal flexible lines comply with the

EN12434 standard.

It is essential to ensure that a safety

valve calibrated to 15 bar maximum is

inserted at one end of the flexible line

(on condition that the operating

pressure of the line is greater than or

equal to 15 bar gauge pressure).

As a reminder, using any accessories

(hoses, fittings etc.) that do not comply

with the requirements set forth by

voids

the manufacturer's liability and warranty

.

We therefore ask you to check that any

flexible lines or connectors used (other

than those supplied by Cryopal) are

approved and certified for an operating

pressure of 15 bar (gauge bar).

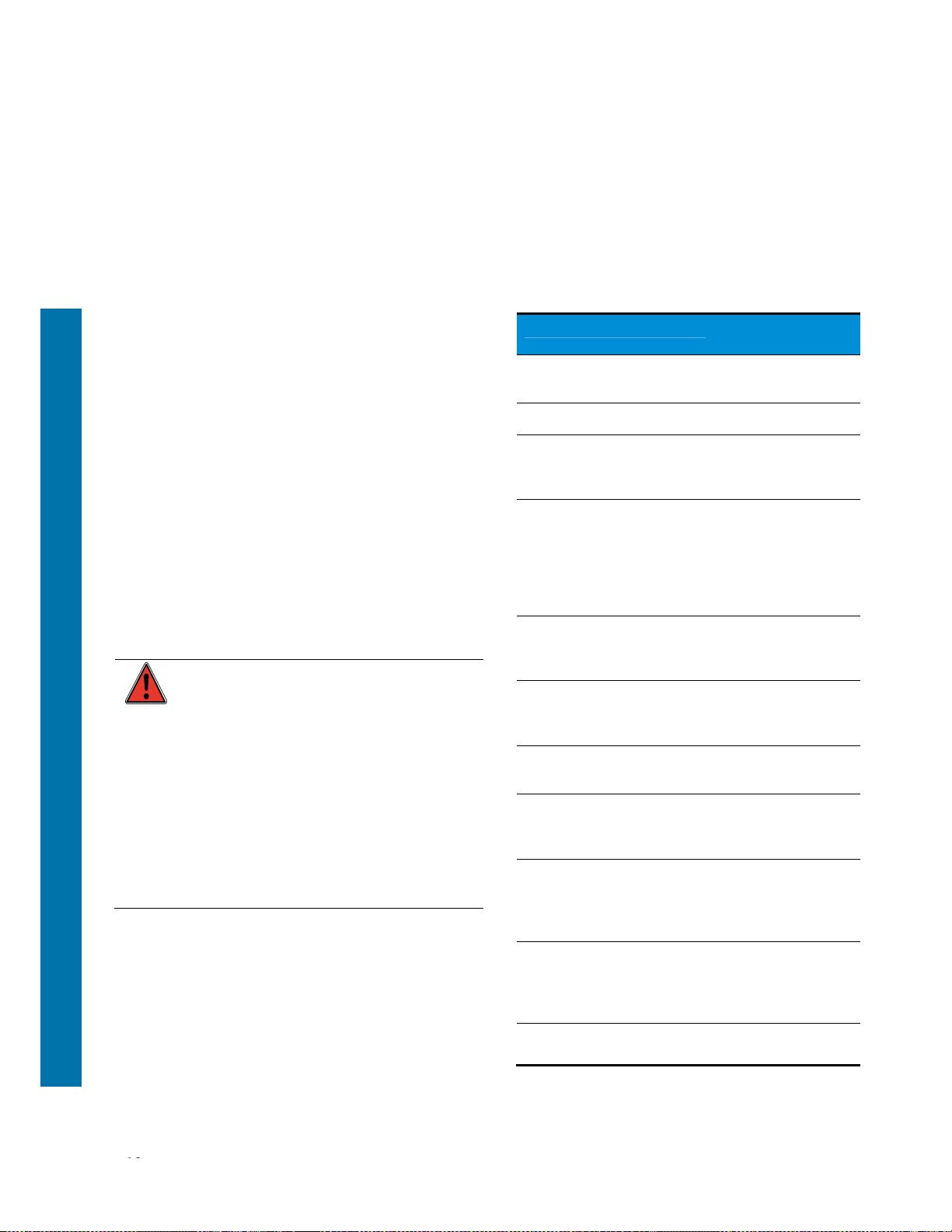

5.3.3.2

Type 130 TC

This hose (1), which is 0.80 m in length, is intended

for transferring between a

TP

tank and a

TR

tank or a

different one. There is a screw-on connector (4) at

one end for connection to the withdrawal valve outlet.

A 10 mm diameter rigid tube (3) with a protective

handle (2) is attached to the other end.

Figure 5-6: View of the 130 TC transfer line.

Ref. Function

1. Flexible pipe.

2. Handle.

3. 10 mm diameter rigid tube.

4. Screw-on connector.

1

2

1

4

3

2

1

17

18

6. Unpacking and installation

6.1 Unpacking

For your own safety you must observe the safety rules

and use suitable tools for unpacking and personal

protection equipment.

At least two able people are needed to unpack the

assembly.

Check the condition of the packaging on delivery.

Unpack the equipment as close as possible to its

place of use to avoid having to move it any great

distance.

Cut the straps and remove the lid.

Remove the tank.

6.2 Installation

The customer is responsible for ensuring that the

premises comply with current regulations and safety

standards and with the following recommendations.

The maximum pressure of liquid nitrogen

supply must be below 3 bars (1.5 bars

recommended). Using a higher pressure

may damage the equipment.

The volume of liquid nitrogen available is

determined by the quantity of liquid present

between the minimum level and the

maximum filling level in the supplying tank.

Before connecting the flexible filling line to

the supplying tank or the liquid nitrogen

supply it is important to purge the lines with

dry nitrogen in order to remove any trace of

moisture.

6.3 Installation checklist

Action Yes,

done No, not

done

Check the general

condition of the apparatus.

Are the users trained?

Does the room satisfy

safety regulations and

standards in force?

Are the dimensions of the

room (in particular the clear

ceiling height after opening

the lid) suitable for

installation of the medical

apparatus?

Is access to the room

limited to persons entitled

to enter it?

Are safety instructions and

risks related to liquid

nitrogen posted?

Are instructions available /

accessible close to it?

Is personal protection

equipment available /

accessible in the room?

Is the room equipped with a

permanent ventilation

system suitable for the size

of the room?

Is the room equipped with

an oxygen content

checking system (display

outside the room)?

Are safe distances

observed (at least 0.5 m

19

Action Yes,

done No, not

done

around the apparatus)?

Is the liquid nitrogen supply

pressure lower than 3

bars?

Has the medical apparatus

been blown through (to

eliminate all traces of

moisture)?

20

7. Installing the components

This section describes how to add various peripheral

devices (control head, castor base) to the storage

tank.

7.1 Control head

Proceed as follows:

The control head can be installed in the full

tank. This installation phase must be

conducted with caution (trained operator,

equipped with all required cryogenic

personal protection equipment: gloves,

apron, visor, etc.) in order to avoid any

liquid nitrogen splashing.

1. Before starting, blow dry air or nitrogen through the

lines and the valves to remove any moisture.

This is an essential precaution to avoid the

risks of ice forming in the lines and the

safety accessories and blocking them or

preventing them from working.

2. Open the vent valve (2).

Close the filling/withdrawal valve (1).

Close the pressure-building valve (3).

You must ensure that these two valves

are closed before doing anything else.

3. Fit the metal seal (5) over the flange of the tank.

The length of the control head means that you

must be aware of equipment above you when

installing it (see below).

4. Introduce the bottom of the control head (4) into

the tank, taking care not to knock the neck of the

inner vessel.

5. Position the clamping ring (6) and secure the

assembly.

4

5

6

This manual suits for next models

2

Table of contents