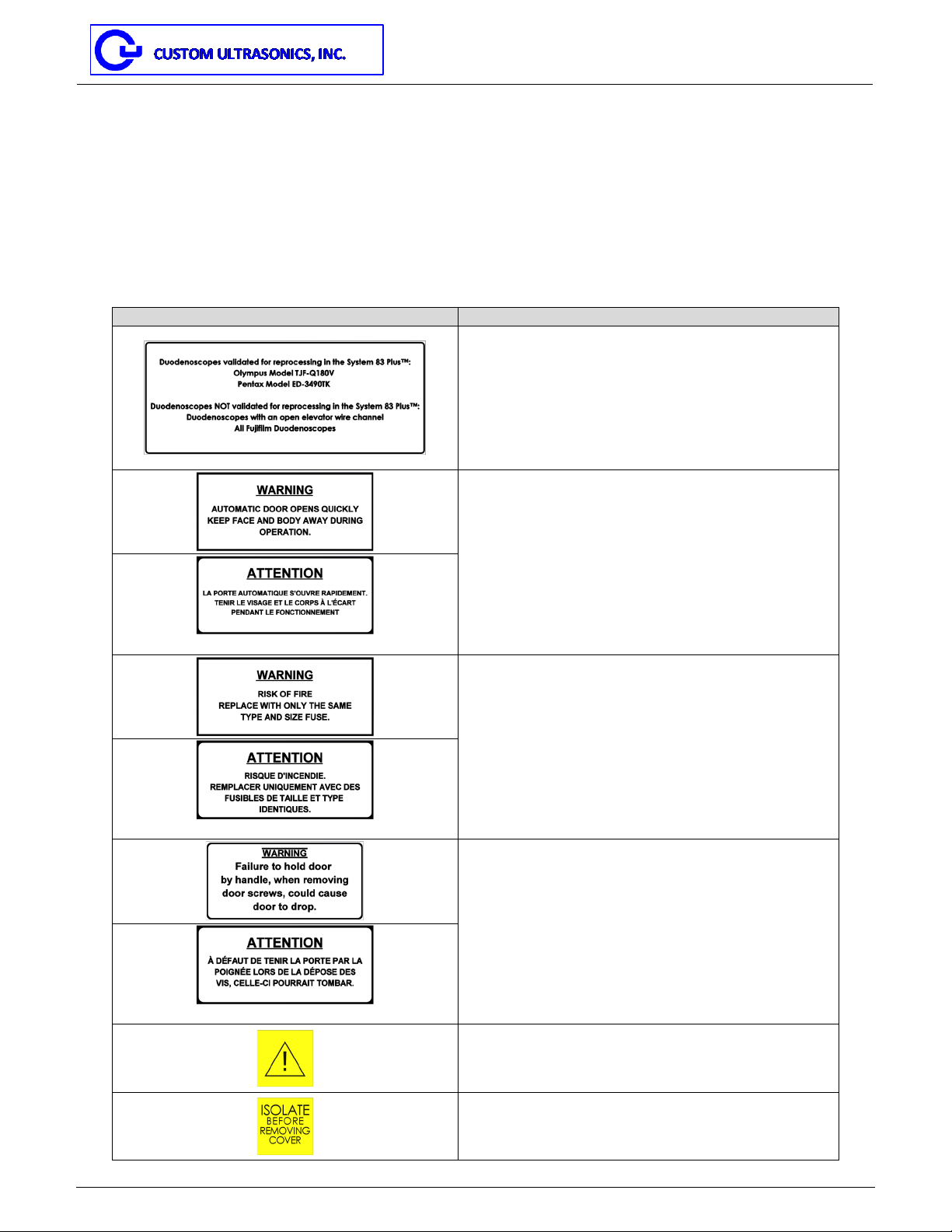

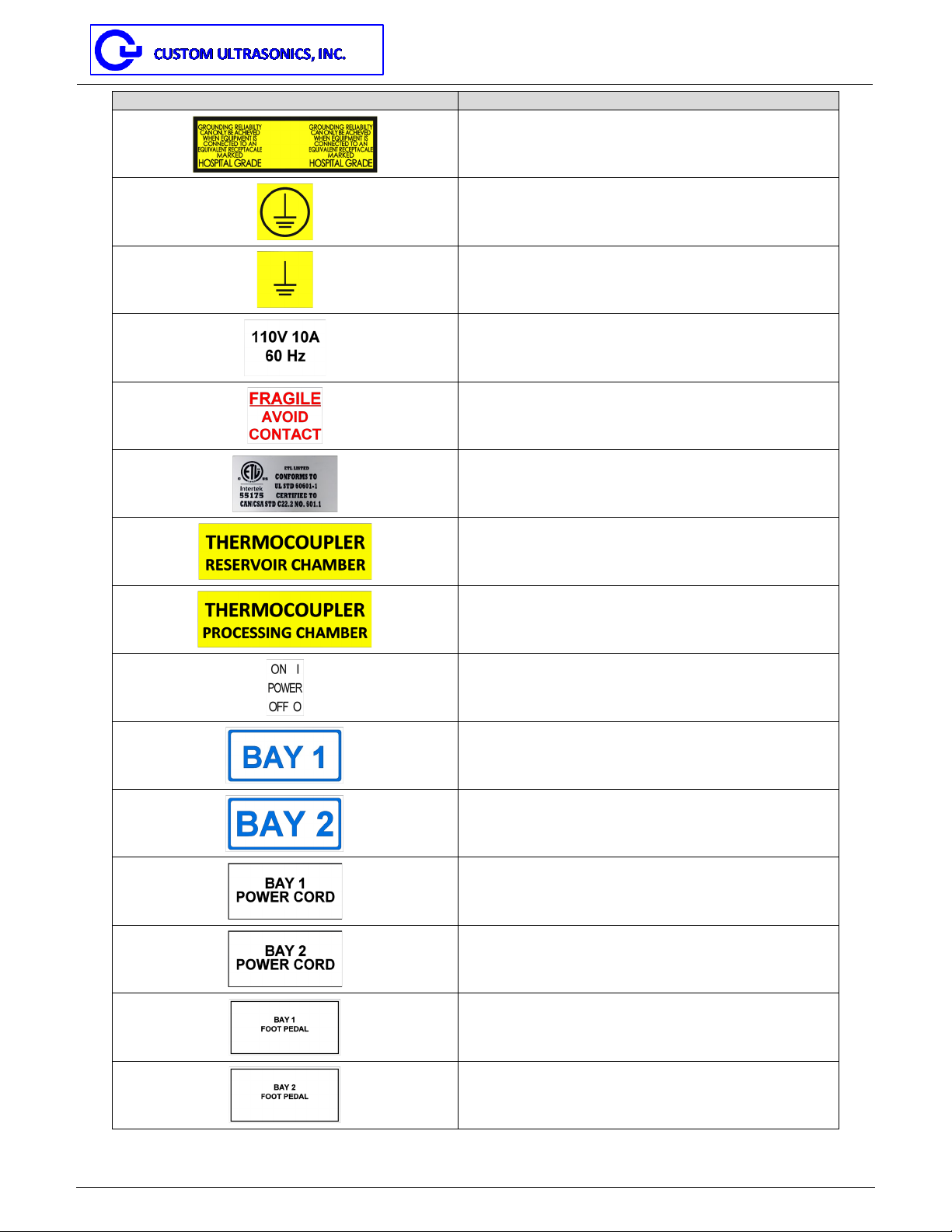

System 83 Plus™ Washer/Disinfector

Service Manual

MAN–202 Revision 03082022 Page 3 of 54

Ventilation Sensors.......................................................................................................................................22

Filter Screen Inspection ................................................................................................................................23

Manual Switch Testing..................................................................................................................................23

Rinse Switch .................................................................................................................................. 23

Air Switch ....................................................................................................................................... 23

High Pressure Channel Monitoring Override Switch ..................................................................... 24

Power Lid and Foot Pedal Switches .............................................................................................. 24

Function Testing ...........................................................................................................................................24

Ultrasonics Testing and Triple Water Filtration System Pressure Differential Check.................... 24

Adapter Inspection ......................................................................................................................... 25

Water Channel Testing .................................................................................................................. 25

Air/Alcohol Purge Testing .............................................................................................................. 25

Printer Testing................................................................................................................................ 26

Solenoid Valve Testing .................................................................................................................................26

Solenoid Valve Inspection and Cleaning ....................................................................................... 26

Internal Filters and Backpack Filter ..............................................................................................................26

100 Micron Capsule Filter .............................................................................................................. 26

HEPA Filter .................................................................................................................................... 26

Backpack (Charcoal) Filter............................................................................................................. 26

Disinfection Procedure for the Alcohol Line and Detergent Line..................................................................27

Equipment ...................................................................................................................................... 27

Alcohol Line Disinfection................................................................................................................ 27

Detergent Line Disinfection............................................................................................................ 27

Biannual Preventative Maintenance ...................................................................................................................... 28

Pumps...........................................................................................................................................................28

Flow Probe.................................................................................................................................................... 28

Annual Preventative Maintenance ......................................................................................................................... 28

Processing Chamber Bulkheads .................................................................................................................. 28

Air Pump Intake Filter ...................................................................................................................................28

Five Year Preventative Maintenance...................................................................................................................... 28

Ultrasonic Generator.....................................................................................................................................28

Water Inlet Filtration System .................................................................................................................................. 29

25 and 5 Micron Filter Replacement Procedure ...........................................................................................29

Required Tools............................................................................................................................... 29

Required Parts ............................................................................................................................... 29

Optional Parts ................................................................................................................................ 29

Filter Replacement......................................................................................................................... 29

0.1 Micron Filter Replacement and Disinfection Procedure .........................................................................30

Required Tools............................................................................................................................... 30

Required Parts ............................................................................................................................... 30

Optional Parts ................................................................................................................................ 30

Filter Replacement and Disinfection .............................................................................................. 30

Cables and Connections ......................................................................................................................................... 32

Post-Preventative Maintenance Testing................................................................................................................ 33

Post-Preventative Maintenance Test Cycle..................................................................................................33

Part Replacement Instructions............................................................................................................................... 34

Power............................................................................................................................................................34

Solenoid Valves ............................................................................................................................................34

Solenoid Valve Component Inspection.......................................................................................... 34

Solenoid Valve Replacement......................................................................................................... 36

Air Solenoid Rebuild Kit Replacement (P/N 71235P3R) ..............................................................................36

Detergent Solenoid Rebuild Kit Replacement (P/N 6-606R)........................................................................37

Hand Spray Solenoid Rebuild Kit Replacement (P/N 6-606R).....................................................................37

HLD Feed and HLD Return/Drain Solenoid Rebuild Kit Replacement (P/N 12-606R) ................................38

Residual Drain Solenoid Rebuild Kit Replacement (P/N 623-606R) ............................................................39

Water Inlet Solenoid Rebuild Kit Replacement (P/N 06-1019R) ..................................................................39

100 Micron Capsule Filter Replacement (P/N 11087)..................................................................................40

HEPA Filter Replacement (P/N 13075) ........................................................................................................40

Charcoal Filter Replacement (P/N 21017)....................................................................................................41

Drain/HLD Return Pump Impeller (P/N 11009) and Pump Shaft (P/N 11135) Replacement ......................41

HLD Feed Pump Impeller (P/N 11009) and Pump Shaft (P/N 11135) Replacement...................................42