DASHCLEAN G12 User manual

w w w . d a s h c l e a n . c n

Operating Manual

Dust Extractor G12/G18/G22/G32

Read all instructions carefully before use

page- 2

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

Introductions

Dear Valued Customer,

Thank you for your trust to Dashclean and for your choosing the single phase, 2 stage

HEPA dust extractor!

We hope the machine will be to your satisfaction and meet your expectations.

Dashclean is a manufacturer of dust extractors, industrial vacuums, air scrubbers, floor

tools, accessories, and etc. Our teams have honed more than a decade of experience in

the construction industry, and are committed to making continuously improvements to

supply the market with quality products via technical innovation and professional

services.

This manual provides all the information and instructions needed to use and to service the

machine. Please keep this manual with care and make sure that users read it prior to

operating the vacuum. In case of loss of or damage to the manual, please don’t hesitate

to contact us for a new copy.

We would be glad to receive any notice or suggestion in order to improve our products

and service. For any question please contact the closest Customer Service or directly

Dashclean Industries Inc.

Notice!

These instructions are for single phase, 2-stage HEPA dust Extractors

G12/G18/G22/G32 only.

The machines are designed to clean construction area and can be connected to

powered hand tools, small/medium size grinders, and etc.

Please pay particular attention to the safety regulations.

Read the complete operating manual prior to using the machines.

All repairs must be performed by a qualified service person. Use only the

replacement parts supplied or specified by Dashclean.

Dashclean shall, under no circumstances, be deemed liable for any accidents or

damage caused if the machine is used for other applications or been used in a way

other than those required in the operating manual.

2019. 12

Dashclean Industries Inc.

page- 3

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

Table of Contents

1

Unpacking….….….….….….………….….….….….….………

4

2

Intended use….….….….….….…... ….….….….…….………

4

3

Identification of main parts………….….….….….….………

5

4

Technical data…………………….. ….….….….….….……

6

5

Declaration of conformity………..….….….….….….………

7

6

Warranty……………………………. ….….….….….….………

7

7

Safety precautions………………...….….….….….….………

8

8

Electric safety………………………….….….….….….………

9

9

Thermal protection………………. ….….….….….…. ………

9

10

Grounding instructions……………….….….….….….………

10

11

Service……………………………….….….….….….….………

10

12

Operating instructions……………….….….….….….………

10

12.1

Vacuuming process……………….….….….….….…………

10

12.2

Filter cleaning process……………………..….….…………

11

12.3

Dust storage and release……………….….….….….….…

11

12.4

Dust collecting and bagging……………….….….….….….

11

13

Filter change…………………….. ….….….….….….………

12

13.1

Changing of main filter…………….….….….….….………

12

13.2

Changing of HEPA filter……………….….…….….….………

12

14

Problem solving……………………….….….….….….………

13

15

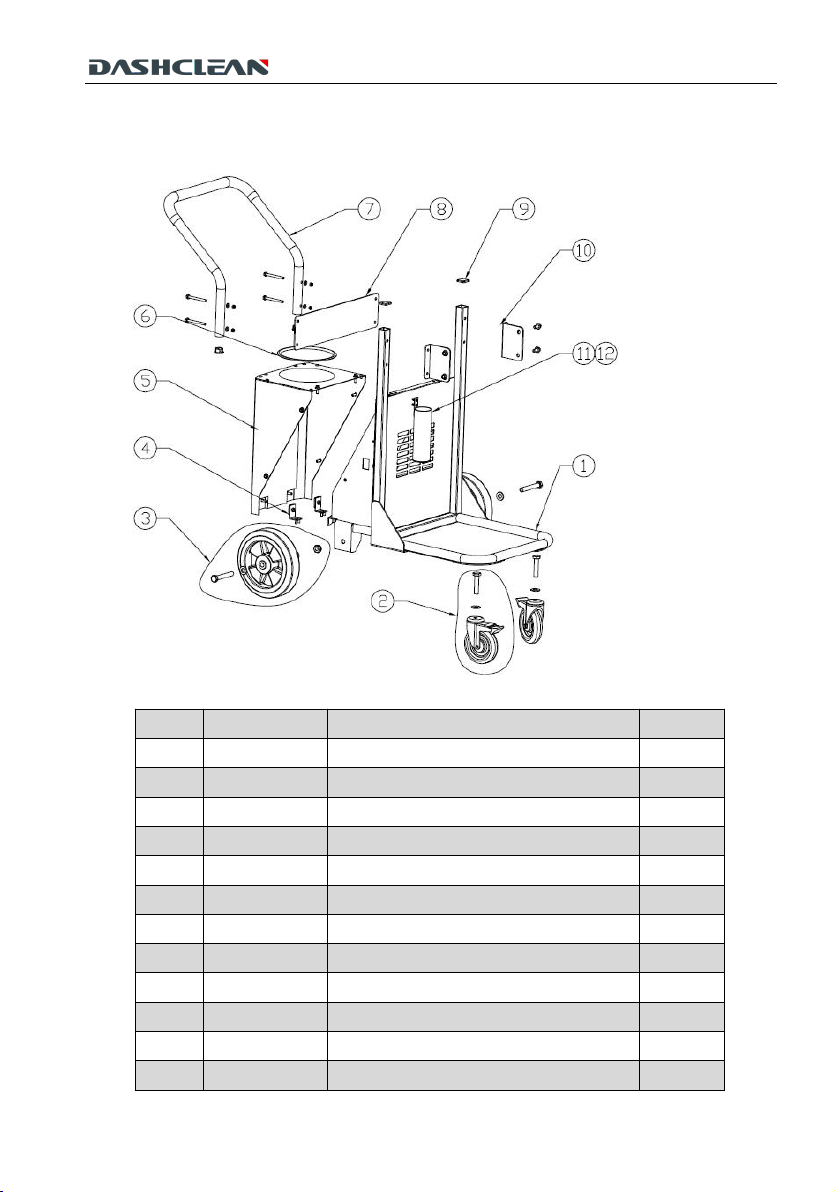

Exploded view and part list- G12/G18…….….….….……

14

15.1

G12 /G18 wagon frame assy………………………………

16

15.2

G12 motor complete assy, 230v……………………………

17

15.3

G12 motor complete assy, 120v……………………………

19

15.4

G18 motor complete assy, 230v & 120v……………………

21

16

Exploded view and part list - G22………………….….……

24

16.1

G22 wagon frame assy………………………………………

26

16.2

G22 motor complete assy, 230v & 120v……………………

28

17

Exploded view and part list - G32………………….………

30

17.1

G32 wagon frame assy….……….……….……….……….…

32

17.2

G32 motor complete assy, 230v & 120v….……….….……

33

17.3

G32 motor complete assy, 230v/50A….……….…………

36

18

Accessories- G12/G18………………..….….….….………

38

19

Accessories- G22 & G32 …………….….….….….….………

38

20

Declaration of conformity………….….….….….….………

39

page- 4

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

1. Unpacking

When unpacking the machine, make sure that the following accessories are

included:

A hose with end fittings

Metal wands

Floor tools and its spare parts

If any of the above mentioned parts are missing, please contact your local

distributor or our sales representative.

Please dispose of packaging materials and used machine components in

accordance with the local environmental disposal law or regulations. Always

remember to recycle.

2. Intended use

The machine is designed for vacuuming and separating dry, non-combustible dust

with an explosion limit value of 0.1mg/m3.

Notice!

Do not use the machine outdoors or on wet surface, this machine is designed for

indoor and dry use only.

Do not expose machine to rain or moisture, store indoors only.

Do not use to pick up any type of liquids.

Do not use to pick up any flammable or combustible substances, or the

substances which could cause explosions (fuels, solvents, etc.), don’t use in an

area where they may be present.

Do not use to pick up any substances that is burning or smoking substances, such

as cigarettes and matches, or hot ashes.

Dashclean shall, under no circumstances, be deemed liable for any accidents

or damage caused if the machine is used for other applications.

page- 5

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

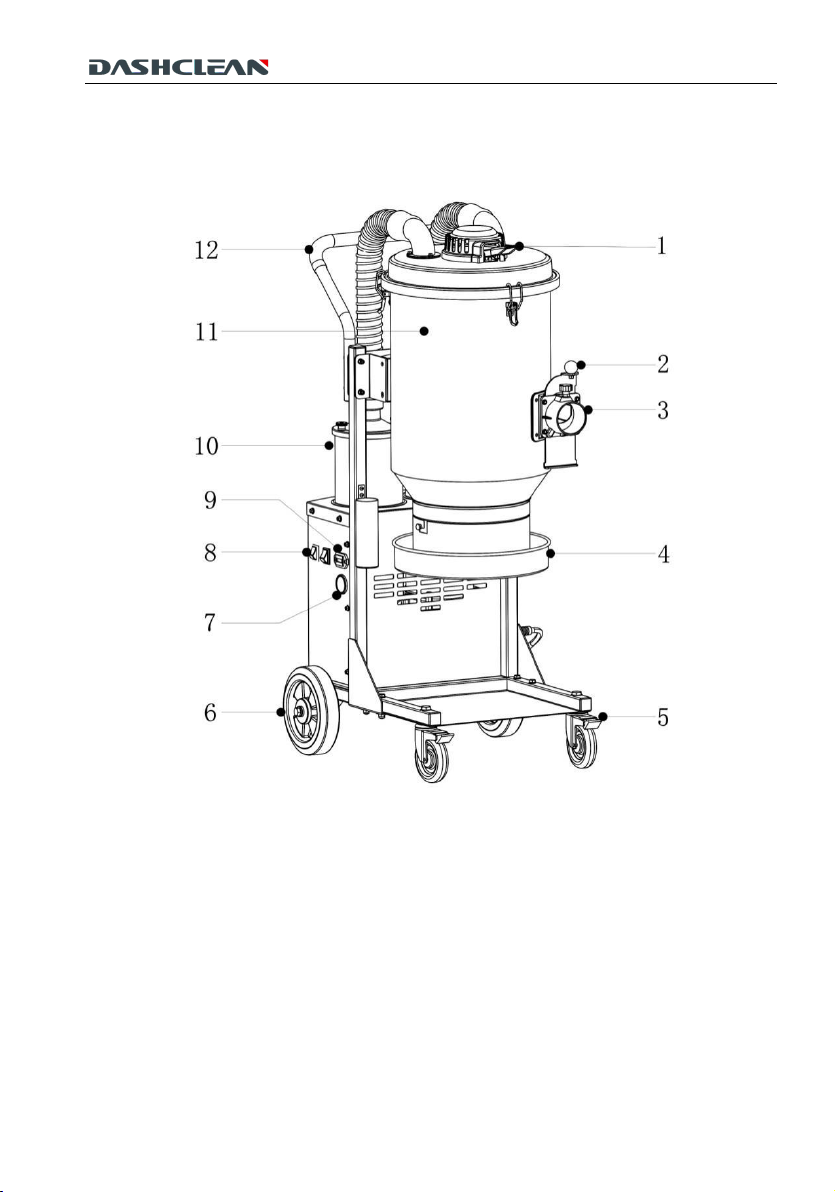

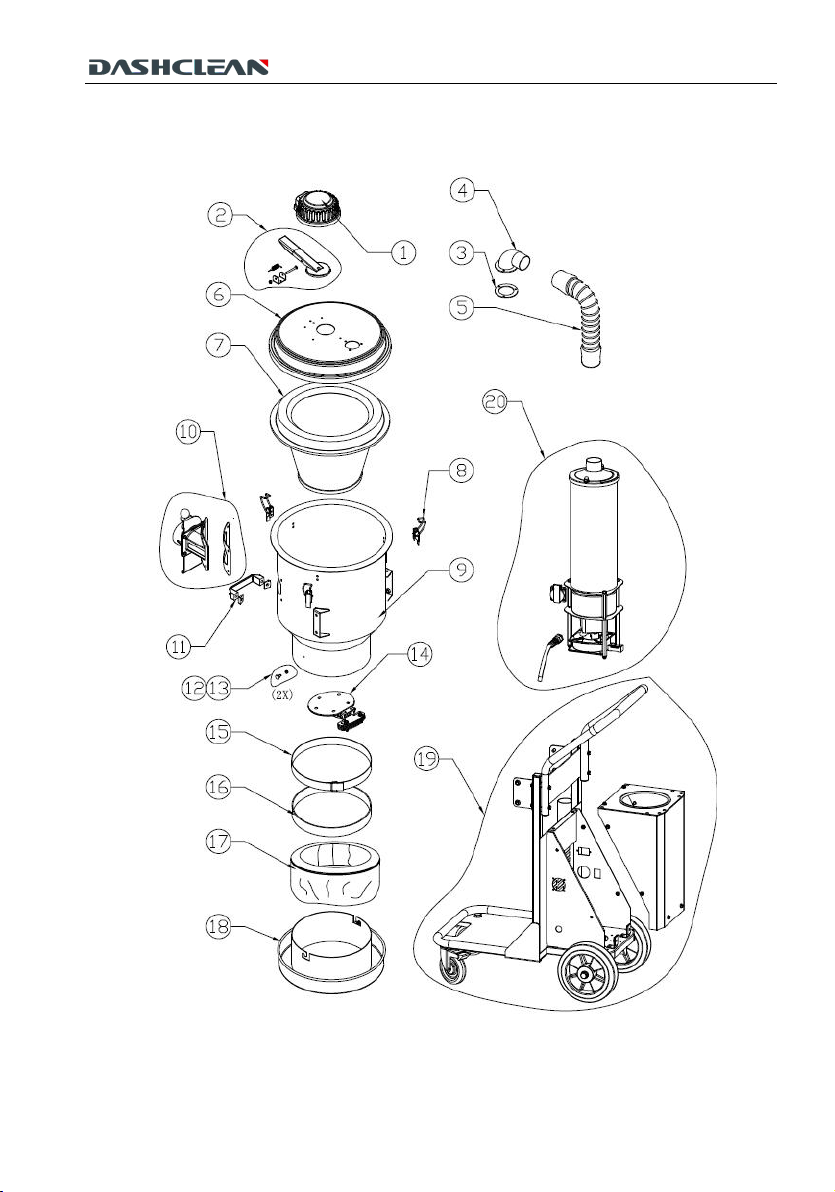

3. Identification of main parts

1

filter purge handle

7

vacuum meter

2

inlet open/close plate

8

power switch

3

die-casting inlet unit

9

hour meter

4

continuous fold bag assy.

10

HEPA chamber

5

4” front swivel casters, lockable

11

main filter chamber

6

8” wheels

12

ergonomic handle

page- 6

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

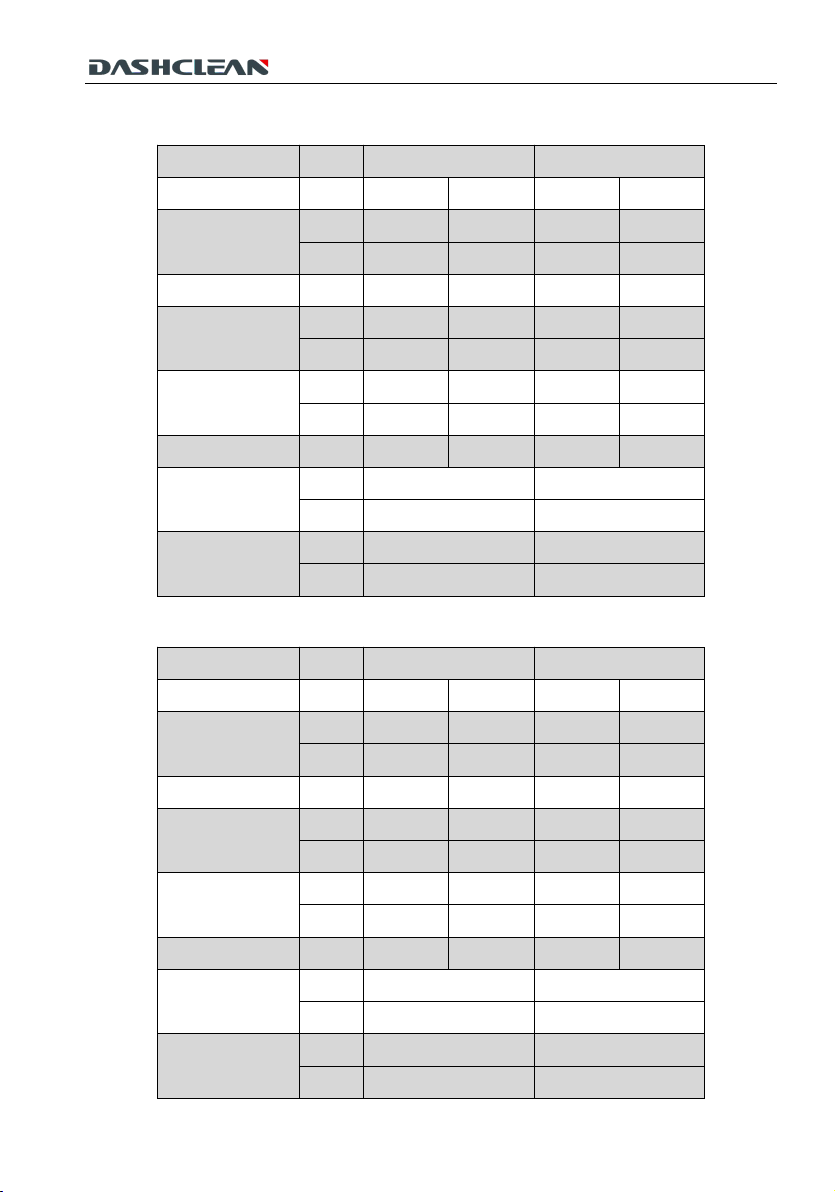

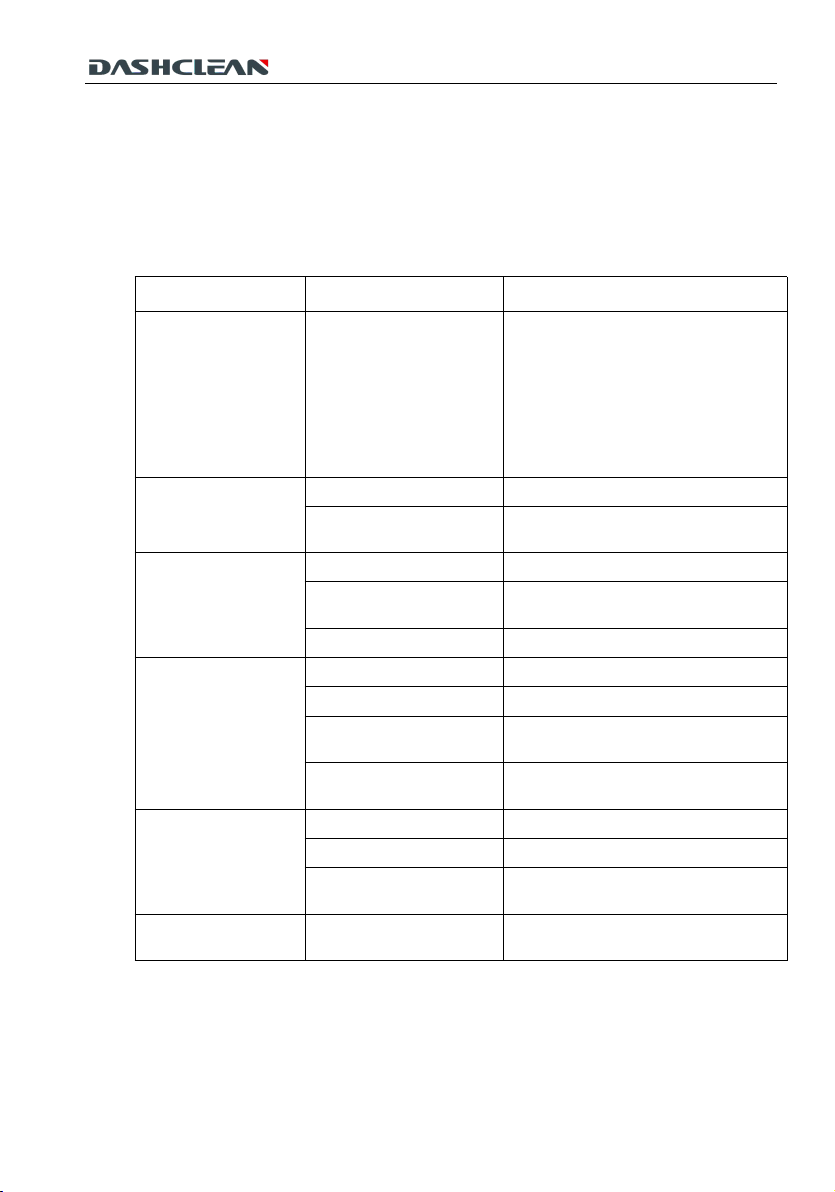

4. Technical data

data

unit

G12

G18

voltage

v

120

230

120

230

max. power

kw

1.2

1.2

1.7

1.7

hp

1.6

1.6

2.2

2.2

current

A

8

4

13.8

7

max. air flow

m3/h

200

200

300

300

cfm

118

118

176

176

max. vacuum

mbar

240

220

340

345

inch

100

90

140

140

noise level

dB(a)

70

70

70

70

dimensions

with carton

cm

65x42x107

65x42x107

inch

25.6x16.5x42

25.6x16.5x42

weight

kg

40

40

lbs

88

88

data

unit

G22

G32

voltage

v

120

230

120

230

max. power

kw

2.4

2.4

2.4

3.6

hp

3.2

3.2

3.2

4.8

current

A

16

8

16

12

max. air flow

m3/h

400

400

485

600

cfm

236

236

285

354

max. vacuum

mbar

240

220

200

220

inch

100

90

81

90

noise level

dB(a)

70

70

70

70

dimensions

with carton

cm

65x57.5x126

78x59x146

inch

25.6x22.6x49.6

30.7x23.2x57.5

weight

kg

50.5

61.5

lbs

111.5

136

page- 7

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

5. Declaration of conformity

Dashclean Industries Inc.

No.68, Danghu Road, Suzhou

Wuzhong District, Suzhou, China

declares under its sole responsibility that the following machine

G12 / G18 / G22 / G32

included in this declaration, follows the provisions of the:

EN ISO 12100:2010

EN 60204-1:2006/AC:2010

EN 61000-6-2:2005/AC:2005

EN 61000-6-4:2007/A1:2011

according to

Machine Directive 2006/42/EC

Low Voltage Directive 2006/95/EC

EMC Directive 2014/30/EU

6. Warranty

Dashclean offers to its customer the vacuums and accessories a 12-month factory

warranty for material and manufacturing defects.

In the event of any complaint, the machine or agreed part must be returned to us or

our authorized representative for a warranty examination and for any warranty

repair or replacement. And the machine or parts must be sent to us carriage free

unless otherwise agreed.

A warranty repair shall be conducted in a Dashclean facility only or in an authorized

Technical Support Centre. If the repair claims appear warranty invalid, the costs

relating to repair and/or replacement of parts shall be charged to the buyer.

The warranty does not cover defects which are the result of normal wear and tear,

negligence, defective use, unauthorized repair or the vacuums being connected to

the incorrect voltage.

The warranty shall be invalidated in the event of the machine having been repaired

by unauthorized person or its serial number has been removed or altered.

page- 8

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

7. Safety precautions

The employer must inform and train the user according to the provisions of

applicable laws. Use of the machine by untrained and unauthorized persons is

strictly forbidden.

Read the complete instruction manual before operating your dust extractor. Pay

particular attention to the safety regulations. Failure to observe the safety

regulations could cause serious accidents and injuries.

This machine is not intended for use by children or the persons with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge.

Make sure the assembly area is firm, so the machine does not tip over. Risk of

personal and material injury.

Pay extra attentions when cleaning on slopes, ramps, or stairs.

Make sure the parked machine remains stable by operating the braked wheel.

Risk of pinching when handling the toggle fasteners.

Keep children and unauthorized persons away from machine when in use. Close

attention is necessary when operated closed to children.

Keep hair, loose clothing, fingers and all parts of body away from openings and

moving parts (accept during a filter cleaning procedure).

Make sure all the guards and protection devices are in place and that all the

safety devices are in place and working properly.

Do not open the vacuum container with the machine running.

Do not wear loose or hanging clothing such as ties, scarves or torn garments that

could become trapped and be sucked up by the cleaner.

Do not use without dust bag and/or filters in place. Replace collection system

and/or filters as described in manual.

Do not modify machine from its original design.

All repairs must be performed by a qualified service person. Use only

manufacturer supplied or specified replacement parts.

page- 9

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

8. Electric safety

Improper connection of the equipment-grounding conductor can result in a risk

of electrical shock. Check with a qualified electrician or service person if you are

in doubt as to whether the outlet is properly grounded.

Do not modify the plug provided with the machine. If it will not fit the outlet, have

a proper outlet installed by a qualified electrician.

Before using the machine, make sure that the power & voltage corresponds with

the voltage shown on the machines rating plate.

Do not leave machine when plugged in. Unplug cord from outlet when not in

use and before cleaning or servicing machine.

Cables damaged through crushing or splitting can be dangerous if used and

should be replaced immediately. Risk of personal injury.

Do not use with damaged cord or plug. If the machine is not working as it should,

has been dropped, damaged, left outdoors or dropped in water. Make sure it is

repaired by a qualified person.

Do not pull or carry by cord, use cord as handle, close a door on cord, or pull

cord around sharp edges or corners. Do not run the machine over cord. Keep

cord away from heated surfaces.

Do not unplug by pulling on cord. To unplug, grasp the plug. Not the cord.

Do not handle plug or machine with wet hands.

Regularly inspect cord and plug for damage. If cord is damaged, it must be

replaced by a qualified person in order to avoid hazard.

Turn off all controls before unplugging.

If using an extension cord make sure the cord rating is suitable for this machine.

Connect to a properly grounded outlet only. See grounding instructions.

9. Thermal protection

The dust extractor is equipped with a safety thermal protector to prevent motor from

overheating. Should thermal protector activate, turn off machine, unplug power

cord and check for full dust bag, vacuum hose clog or filter blockage. It may take

up to 45 minutes for the thermal protector to reset.

page- 10

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

10. Grounding instructions

The dust extractor must be grounded. If a dust extractor malfunctions or

breakdowns, grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. The dust extractor is equipped with a cord having

an equipment-grounding conductor and grounding plug. The plug must be inserted

into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

11. Service

When cleaning and servicing the machine, you must switch off the machine and

remove the plug from the outlet.

Don’t clean the machine with a high pressure cleaner. If necessary, do not

direct at the openings on the machine, especially the opening for cooling air.

Before moving the machine from the work area, the machine must be cleaned.

Proper personnel protective equipment must be used while replacing the main

filter or the HEPA filter. If possible, use a special suitable room.

All parts which are contaminated after service must be properly disposed of in

plastic bags according to all regulations.

If the machine has to be used for other purposes, it is extremely important that

the machine is cleaned, to avoid the spread of hazardous dust.

Do not puncture the HEPA filter. Risk of dust dispersion.

12. Operating Instructions

1) Vacuuming process

Before starting a vacuuming process,

make sure the machine is properly connected to a grinder or a floor tool via

the provided hose and fittings.

chek the power cable and the plugs are in a good condition.

make sure the power voltage corresponds to that on the rating plate and

connect correctly the power plug to a power socket

Turn on the power switch to start a vacuuming process.

During the vacuuming process, dust-laden air is sucked through the flexible hose

and inlet valve at a high speed. The air is then slowed down by the cyclone, and

coarse dust particles are separated out partly by centrifugal force and partly by

gravity. Air and finer particles pass through the main filter at the first and the

HEPA filter at the final stage where separation is made.

page- 11

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

2) Filter cleaning process

The machine is designed for filter cleaning by reverse air “jet-pulse”.

The filter must be cleaned from time to time. This must be done before changing

the bag collection system and should also be done when work is completed or

whenever there is a poor suction.

Filter cleaning procedure:

Cover the inlet by lifting up the inlet valve and let the machine build up

vacuum for 4 to 5 seconds,

Quickly push down the filter cleaning handle and release it. Repeat the

procedure five times. It is important to let the machine rebuild the vacuum in

between every repetition,

Open the inlet again by pushing down the invlet vavle.

If suction remains poor, the conical main filter needs to be replaced. If suction

still remains poor afterwards, the HEPA filters needs to be replaced. See

instructions in chapter 13 Filter change.

3) Dust storage and release

The separated dust accumulates in the conic bottom during the vacuuming

process, and it drops through the bottom flap into the plastic bag when the

machine is switched off. In some extreme cases the adhesive ability of the dust

must be broken manually. This can be done by hitting the dust through the bag

or tapping the tank using i.e. a rubber hammer.

4) Dust collecting and bagging

The machine is equipped with a continuous fold bag system for an effective dust

collecting and bagging. The supplied fold bag is a 22 m long plastic tube that

will be divided into individual bags using the zip ties attached with the machine.

To assemble a new fold bag:

Release the belt holding the last bag and take off the bag holder.

Put in a new fold bag & pull out the inner end upwards.

page- 12

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

Assemble the holder onto the machine and strap the opening facing upwards

with the belt.

Pull down the outside end and close it using a zip tie.

Before changing a fold bag or a regular bag, make sure the filter cleaning cycle

has been completed.

13. Filter change

Unhealthy dust can be spread during filter change. Accordingly, the user should

wear protective glasses, protective gloves, and a breathing mask conforming to

protection class FFP3.

WARNING! Remember to switch off the machine and pull the plug out of the outlet

before servicing.

1) Change of main filter

Loosen the 3 hooks and remove the top cover. Take out a new filter from its

bag. Lift out the used filter from its chamber and place it gently into the filter

bag. This bag must be closed and diposed properly.

Insert a new filter.

Put back the top head and close the 3 hooks properly.

IMPORTANT! If you are removing the main filter in order to clean it. Hitting the

filter with force or use of compressed air will destroy the filter. It can handle water,

but high pressure water cleaning will destroy it.

2) Change of HEPA filter

Loosen the 2 nuts on each filter cover. Take out a new filter from its bag. Lift out

the used HEPA filter from its chamber and place it gently into the filter bag.

This bag must be closed and diposed properly.

Insert a new filter to the filter chamber.

Put back the filter cover and close the 2 nuts properly.

IMPORTANT! HEPA filters can’t be cleaned, trying this might destroy it. When

installing the replacement filter, make sure not touch the inside of the filter. Any

kind of force/damage on the inside of filter media will destroy the new filter.

page- 13

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

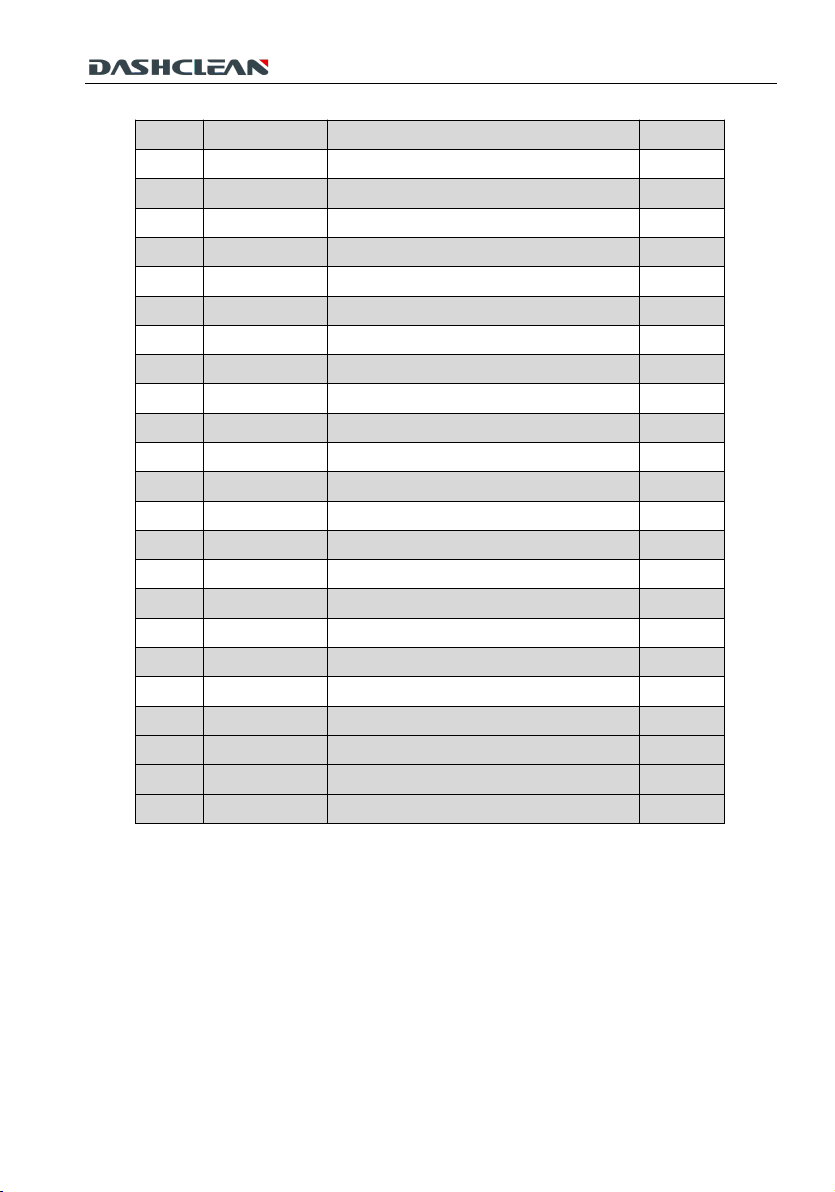

14. Problem solving

The machine is designed and manufactured for a specific severe environments and

tasks. Its filter, seals, attachments, and fittings are customized or selected specifically

for the applications. Please note that the machine must be protected from knocks

and blows. The operator and service personnel must treat the machine with care in

order for it to work correctly for an expected life span.

problem

cause

solution

Motor fails to start

No power

Check power supply.

Make sure power cable and

plugs are in a good condition

and properly connected,

Check the power switch is in a

good condition and properly

connected.

Motor stops shortly

after start

Wrong fuse

Connect to a correct fuse

Shortcut in

cable/machine

Order service

Motor runs but with

no suction

Hose not connected

Connect hose

Hose clogged or

blocked

Clean hose

No dust collection bag

Fit dust collection system

Motor runs but with

a poor suction

Hole in hose

Replace hose

Filter clogged

Clean filter or replace filter

Loose top cover

Make an adjustment of hooks or

top cover

Defective seals or

gaskets

Replace defective seals or

gaskets

Dust leaks out

Hole in hose

Replace the defective hose

Damaged filter

Replace the damaged filter

Poor assembled filters

Make an adjustment of the poorly

assembled filters

Machine works

noisy or abnormal

various causes

Consult the technical support

agent or order a service

page- 14

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

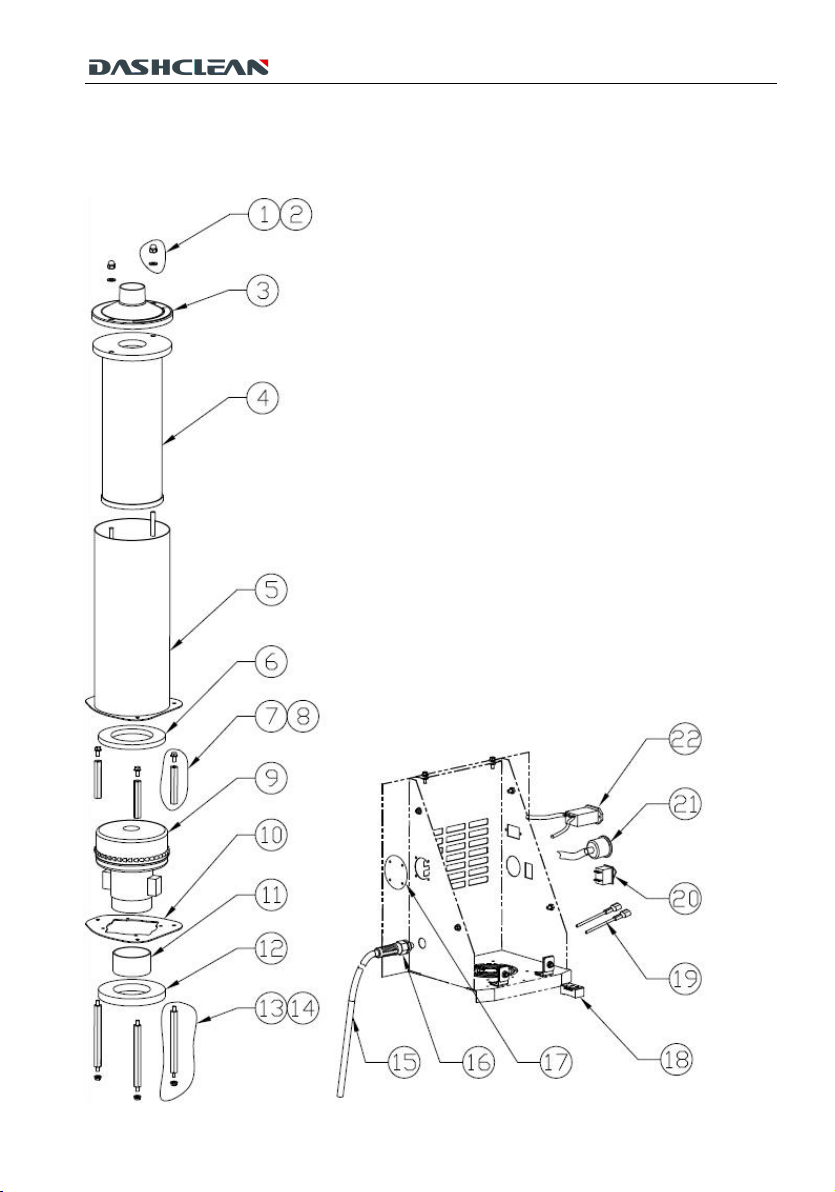

15. Exploded view and part list- G12 /G18

page- 15

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

POS.

Part Number

Description

Qty

1

BD00387

Cover kit

1

2

BD00283

Purge handle kit

1

3

BH00043

Bend connector seal

1

4

BC00188

D50 bend connector

1

5

BM00621

D50x360 hose with fittings

1

6

BC00555

Top cover

1

7

BM00431

Primary PTFE HEPA Filter

1

8

BD00611

Hook 95 kit

3

9

BC00561

Main filter chamber

1

10

BD00351

D70 inlet assy

1

11

BD00616

Hand holder kit

1

12

BM00341

Key M5

2

13

BK00086

Anti-skid nut M5

2

14

BD00321

Flap assy

1

15

BM00397

Packing belt

1

16

BH00099

Anti-skit ring

1

17

BM00241

Drop-down fold bag

1

18

BC00225

Fold bag holder

1

19

BD01016

G12/G18 wagon frame assy **

1

20

BD01021

G12 Motor complete assy, 230v **

1

20

BD01024

G12 Motor complete assy, 120v **

1

20

BD01017

G18 Motor complete assy, 230v **

1

20

BD01016

G18 Motor complete assy, 120v **

1

** refer to the followings for a breakdown of part list

page- 16

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

1) BD01016, G12 /G18 wagon frame assy

POS.

Part Number

Description

Qty

1

BC00765

Wagon frame base

1

2

BD00530

Front wheel kit

2

3

BD00385

Real wheel kit

2

4

BD00382

L bracket kit

2

5

BD01018

Chassis kit

1

6

BH00110

Rubber seal

1

7

BD00345

Handle kit

1

8

BC00404

Back plate

1

9

BH00076

Plastic insert 25x25

2

10

BD00391

Tank holder kit

2

11

BD00343

Cable tie holder

1

12

BD00280

Cable tie pack

1

page- 17

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

2) BD01021, G12 Motor complete assy, 230v

page- 18

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

Part list- BD01021, G12 Motor complete assy, 230v

POS.

Part Number

Description

Qty

1

BK00029

Semi-dome nut M8

2

2

BH00082

Seal washer M8

2

3

BC00387

Filter cover

1

4

BM00287

HEPA filter

1

5

BC00388

HEPA chamber

1

6

BM00344

Motor seal

1

7

BK00035

Bolt M6x12

3

8

BM00071

Female spacer L76.5

3

9

BM00160

Motor 230V 1200W

1

10

BC00389

Motor support

1

11

BM00623

AcryLic Tube

1

12

BM00368

Foam disc adhesive

1

13

BM00620

Male spacer L128.5

3

14

BK00036

Nut M6

3

15

BD00425

Electricity cord set

1

16

BM00217

Cable fix (PG11)

1

17

BD00571

Electricity outlet kit

1

18

BD00572

Terminal block TB1503 kit

1

19

BD00396

Wiring cable kit

1

20

BM00079

Power switch

1

21

BD00349

Manometer kit

1

22

BD00570

Hour counter kit

1

page- 19

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

3) BD01024, G12 Motor complete assy, 120v

page- 20

Operating Manual G12/G18/G22/G32

2020 rev. 4.0

Part list- BD01024, G12 Motor complete assy, 120v

POS.

Part Number

Description

Qty

1

BK00029

Semi-dome nut M8

2

2

BH00082

Seal washer M8

2

3

BC00387

Filter cover

1

4

BM00287

HEPA filter

1

5

BC00388

HEPA chamber

1

6

BM00344

Motor seal

1

7

BK00035

Bolt M6x12

3

8

BM00071

Female spacer L76.5

3

9

BM00362

Motor120V 1200W

1

10

BC00389

Motor support

1

11

BM00623

AcryLic Tube

1

12

BM00368

Foam disc adhesive

1

13

BM00620

Male spacer L128.5

3

14

BK00036

Nut M6

3

15

BM00418

Electricity cord set

1

16

BM00217

Cable fix (PG11)

1

17

BD00635

Cover plate kit

1

18

BD00572

Terminal block TB1503 kit

1

19

BD00397

Wiring cable kit

1

20

BM00079

Power switch

1

21

BD00349

Manometer kit

1

22

BD00570

Hour counter kit

1

This manual suits for next models

3

Table of contents

Popular Vacuum Cleaner manuals by other brands

Drainvac

Drainvac COMMERCIAL Series owner's manual

Samsung

Samsung SC07H40 0V SERIES user manual

Dyson

Dyson v6 SV03 operating manual

Surgically Clean Air

Surgically Clean Air JADE 2.0 Operation manual

Linea 2000

Linea 2000 DOMO DO233SV Instruction booklet

Festool

Festool CLEANTEX CTL 26 E SD Original operating manual