De Soto Airflow User manual

*AIRFLOW DE SOTO

(CODE SE)

BODY SERVICE MA NU AL

• FOREWOR D •

Many new and revolutionary principles of design , which heretofore

have never been applied to the manufacture of automobile bodies , are

encompassed in the new Airflow body.

These improvements are such that they reduce body service to a

minimum by increasing the natural rigidity of the all-steel unit to a

point far beyond that considered possible in the past. ·At the same

time , should body repairs become necessary due to collision or other

abnormal causes, the ease with which such damage may be repaired

has been greatly increased .

As an example, whole body sections fractured beyond the point

where they may be economically repaired, may be cut out with a torch

and a complete new section welded in its place, not affecting any other

part of the body structure and restoring the all-steel unit to its original

state of incomparable rigidity . Small punctures in any part of the

body metal may likewise be repaired by merely cuttin g out the metal

around the fracture and welding a small piece of sheet steel in its place.

As a result of these fundamental advancements in constru ction , the

methods employed in servicing Airflow bodies will differ in a great

many respects from those with which the averag e body mecha nic is

familiar .

It is th e purpos e of this Body Service Man ual to cover in as much

detail as possible the servicing of each indiv idua l part of the Airflow

Body, starting with maintenance items such as lubr ication and tight -

ening, and progressing to major body repai rs invol ving the straighten-

ing and replacing of body braces and pillars.

The procedures described in this Body Service Manual for the serv -

icin g of Airflow bodies are not presented in elementary form and are

not int ended to constitute a textbook for t hose who have not had

previo us experience in this class of work. It will, however, prove to be

a valuabl e guide when servicing bodies of the Airflow type and, con-

sequently, should be carefully studie d by all those engaged in work of

this nature . •

DE SOTO MOTOR CORPORATION

Division of Chrysle r Corporation

DETROIT, MICHIGAN

PR ICE 50C N ET

PRINTED I N U. S. A .

OE SO T O MOT O R CORPORAT ION

DI V IS ION OF CHR Y SLE R CORPOR AT ION

2. 3

24 2·s 26

6

2 28 29 30 3·1

I- Cowl inside panel ass e mbly - not ser viced

2-Front pillar and reinfo rcement

3- Instrument panel

4-Windshield center post

5- Center pillar and reinforc e meat - not

serviced

6- Fr ont pillar rail - serviced with front

pillar and reinforcemen t

7-Windshield header rail-not serviced

8- W indsh ield header to roof brace

9- Roof strainer-front

10- Roof fram e support - front

I I-Front do or header rail and reinforcem e nt

12-Roof fram e support -side

13- Roof strain er-center

14___:.Re ar door header rail and reinforcement

-not serviced

15-Rear hinge pillar rail and reinforcemen t-

upper - not serviced

3·2

10 11 12 13 14

3·3 34 3·5 36 37 38

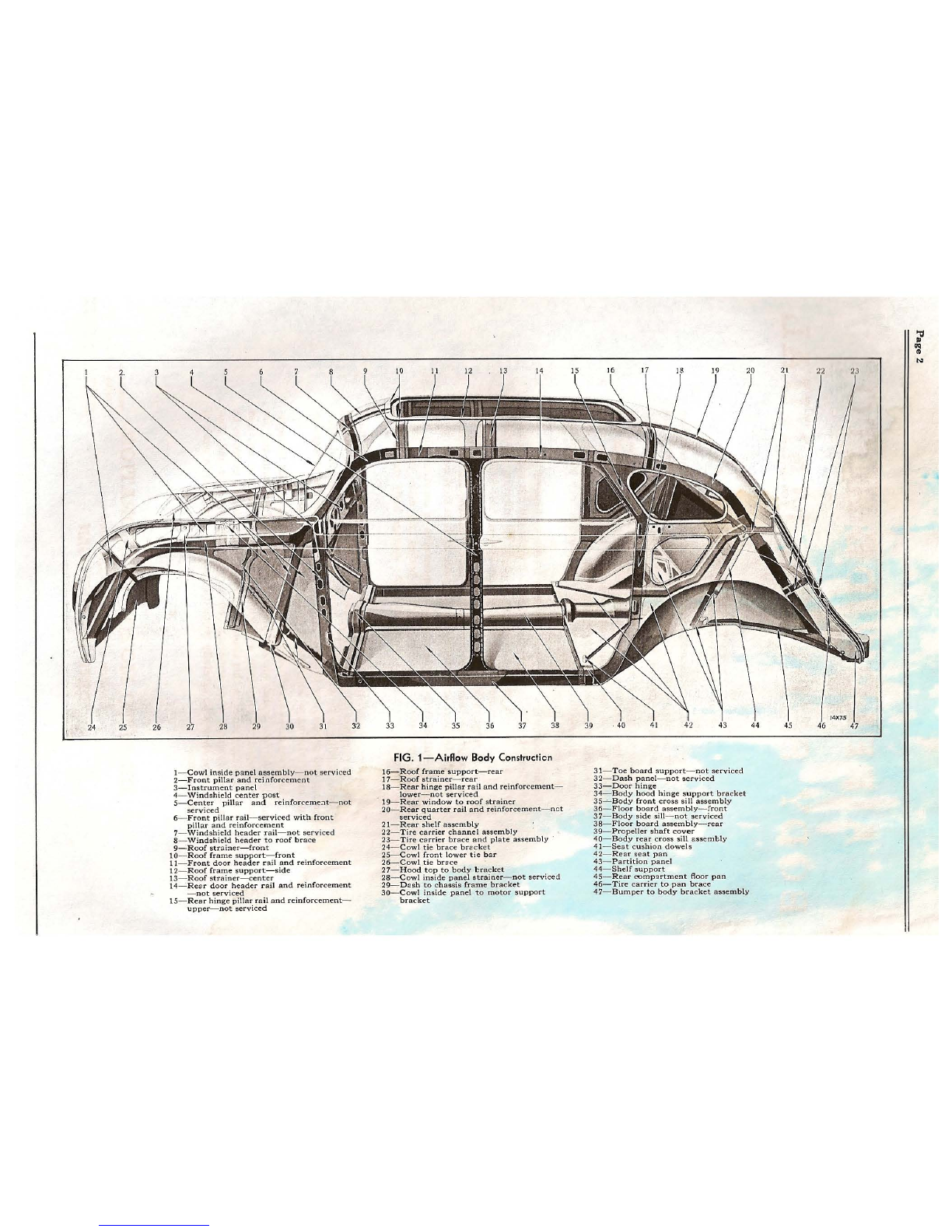

FIG. 1-Airflow Body Constructicn

16- Roof frame support - rea r

17-Roof strainer - rear

18-Rear hinge pillar rail and reinforcement-

lower - not serviced

19- Rear window to roof strainer

20-R ear quarter rail and reinforcement - net

serviced

21- Rear shelf assembly

22-Tire car rier channel assembly

23-Tire carrier brace and plate assembly

24- Cowl tie brace bracket

25- Cowl front lower ti e bar

26- Cowl tie brace

27-Hood top to body bracket

28-Cowl inside panel strainer - not serviced

29- D ash to chassis frame brack et

30 - Cowl inside pan el to motor support

bracket

15

39

17 18 20

· 40 41 42 43

31-Toe board support-not serviced

32- Dash panel-not ser vice d

33-Door hinge

34-Body hood hing e support bracket

3S~Body front cross sill assembly

36-Floor board assemb ly - front

37- Body side sill - not .serviced

38-Floor board assemb ly - rea r

39-Pr opeller shaf t cover

40-Body rear cross sill ass emtly

41- Seat cushion dowels

42- Rear seat pan

43-Partition panel

44-Shelf support

45-Rear cumpartment floor pan

46-Tire carrier to pan brace

47-Bumper to bo dy bracket ass embly

44

21

4·5 46 4·7

;;,u

~

N

AIRFLOW BODY SERVICE

MANUAL

CONSTRUCTION

The Airflow body is of all-steel unit construction,

fabricated from steel panels and pressed steel

rails, channels and braces welded and riveted into

one solid, rigid structure of incomparable strength

and durability. Beyond this one fundamental

similarity to other all-steel body designs the

construction of the Airflow body differs in practi-

cally every respect from anything heretofore

applied to automobile body design.

Were it possible to remove the outer shell, the

braces , channels and rails, some of which are

int egral with the outer panels, would appear as

illustrated in Fig. 1. As will be seen by referring

to this phan tom view, the Airflow body requires

no chassis fram e for rigidity but the body struc -

tur e is augmented by an additional lower body

frame, upon which the various parts of the chassis

are mounted, bolted with from 22 to 40 body bolts

to the lower contour of the body itself.

A rail extends from the extreme rear corners of

the body up each side of the sloping rear quarters

and along the inside of the roof panel to join box -

like steel body door hinge pillars above the corners

of the windshields. By placing an inverted pressed

steel channel or reinforcement in the corners of

th e sloping windshi eld stanchions a rigid brace is

provided which ties the top of the body door hinge

pillar to a solid steel flanged plate, constituting

the cowl inner panel.

This plate is welded in one solid piece from the

line of the base of the windshield, the full depth of

the engin e compartment, forward to the front

bumper bracket. Vertical and lateral members,

also of pressed steel, tie the entire assembly

together , with the lower box -like body rails into

a most rigid, dur ab le and serviceable unit.

It is quit e appa rent from the foregoing brief

description of th e construction of an Airflow

body that th e metho ds to be employed for servicing

it will differ in a gre at many respects from those

employed on other all -stee l bodies.

These bodi es are built to withstand tremendous

strains and stresse s without requiring any atten-

tion, therefore the necessity for service has been

reduced to a mini mum . Should servicing become

imperative due t o collision or other abnormal

causes, how ever, the Airflow body is so designed .

that it may be repaired an d restored to its original

state of rigidity and durability with comparatively

litt le lab or expens e. This feature has been ob -

tained as mentioned in the "Foreword " to this

manual by so constructing the body that whole

or partial body sections may be cut out with a

torch and a new section welded in as a unit, or

plates of sheet metal of approxim ately the same

thickness as the original panel may be cut out of

sheet steel, formed to follow the contour of the

body shell and welded into place after cutting

out the damaged piece .

INSPECTION

Any automobile body, regardless of its natural

rigidity, must be periodically inspected for settling.

This is particularly important during the first

thousand miles of service of a new car. The follow-

ing points should be carefully checked and adjusted

for maximum body service and quiet operation :

1. Check all body bolts to be sure they are tight.

2. Check floor-board screws and tighten if

necessary.

3. Inspect all door hinges, locks, window

regulators and remote controls and tighten.

4. Ch eck door lock striker plates and adjust.

5. Check all window glass for side play and

metal contact with garnish mouldings and

reveals. Eliminate side play by shimming

runs with card board and eliminate metal

contacts by moving glass roller or weather-

strip.

6. Road test car and enumerate points requiring

adjustment. Refer to proper section of this

Body Service Manual for suggestions on

method of making any nec essary corrections.

LUBRICATION

Door hinge pins should be lubricated with a

drop or two of light machine oil periodically, to

insure quiet and smooth operation and also to

prevent the hinge pins and hinges from galling at

the bearing surfaces, resulting in excessive clear-

ances at these points and causing objectionable

door ratt les which can only be completely elimin-

ated by replacement of parts . Excess oil on the

outside of the hinge should be removed im-

mediately, to prevent dust from collecting and

damaging the lacquer finish.

Door latches may be lubricated with a light

application of vaseline or similar lubricant. Soap

may be applied to all points of friction, with

marked success .

Do not apply oil or grease of any kind to rubber

weatherstrips, anti-rattl e buttons, etc . Castor oil

is not only an exceptional lubricant but also a

rubber preservative and should be employed at

all such points.

Page 4 A-, RF L O W BO D Y SERV I CE M A N U A L

FIG. 2-Accessibility to Side of Engine

1- Front wheelhouse panel clinch nuts

2-F ront wheelhouse panel

Window regulator, door ventilator regulator

and door latch shafts should be sparingly lubri -

cated as frequently as possible, or wh eneve r it

becomes necessary to remove the door trim panels

for any reason.

Leather-bound weathercord, around the door

fram es, may be lubricated to prcve~t possib~e

squeaks from developing by making a hght apph-

catiori of tan paste shoe polish to the leath er,

wiping off the excess polish with a clean cloth.

One application of this nature should suffice for

at least six months .

TIGHTENING

Annoying rattles, difficult to locate, might de-

velop around the floor-boards, door hinges and

body to assembly member bolts unless these are

periodically ti ghtened. .

It is advisable to give preferred attention to

these bolts arid scr ews during the first 1000 mil es

of operation of a new car, t ight ening th em as fre-

quently as possible during t he breaking -in peri od.

ALIGNMENT

The Airflow body being rigid m construction,

and its component parts having been weld ed

together in a stat e of alignment, is therefore in

correct alignment whe n manufactured, and will

remain so unless subject ed to a severe blow or

twistin g strain, such as might be experienced in

an accident. Any condition of misali gnment which

may develop will, in a majority of instanc es, be

only visual in the body, or appar ent on the road

by th e front an d rear wheels not following in the

sam e track. This can result from a brok en spring,

bent axle or spr ing hanger, and can be corrected

by straigh te ning or replacing th e affected part.

Misalignm ent of the body itself can be isolated

by comparin g diagonal dimensions tak en from the

int erio r of th e car body at different heights and

differe nt angles.

For example, the distance from a point on the

front of th e left body door hing e pillar to a point

on the right rear body hinge pilla r should be exactly

equal to the distance from the corresponding point

on the right front body hinge pillar to the cor-

responding point on the left rear body hinge pillar.

Similar measu rem ents ma y be ·taken from other

angles where the misalignment is suspected to

exist on some other plan e.

Once located, it is only neces sary to st raighten

the bent or sprung brac e or cross member. In

extreme -cases, it may be necessary to remov e the

affected-cross bracing , align the body , straighten

the brace and gas weld it back in place, or replace

the entire part. This will depend upon the nature

of the damage which must be repai red .

The Airflow body cannot be sprung or twisted

by placing shims under body bolts. Such practice

might result in seriously distorting the lower body

frame side members subjecting them to unwonted

strains and stresses.

ACCESSIBILITY

The Airflow body and chassis are designed to

afford the utmost in acc essibility from a service

standpoint.

As an example of the consideration given to

this most importan t service problem refer to Fig. 2

illustrating the manner in which the side of the

engine is exposed for adjustments or replacements.

To obtain ready access to the sides of the engine

it is only necessary to remove one front wheel, the

front wheelhouse panel studs fron.1.the clinch nuts

(1, Fi g. 2) and the wheelhouse panel (2).

By permitting the mechanic to work in the

position illustrated, th e necessity of removing

the manifo ld is obviated when grinding valves ,

et c., and either side of the engine may be clearly

exposed for making the most exacting inspections

and adjustments.

FIG. 3- BatteryInspection

1- Front seat cushion support 4- Ba tte ry cable terminal (negativ e)

2- Battery cover lid 5- B attery filler cap

3- Battery cover lid thu mb screw 6- Battery cover assem bly

A I R FL O W BO D Y S ERV I C E M-A t\( U A L Page 5

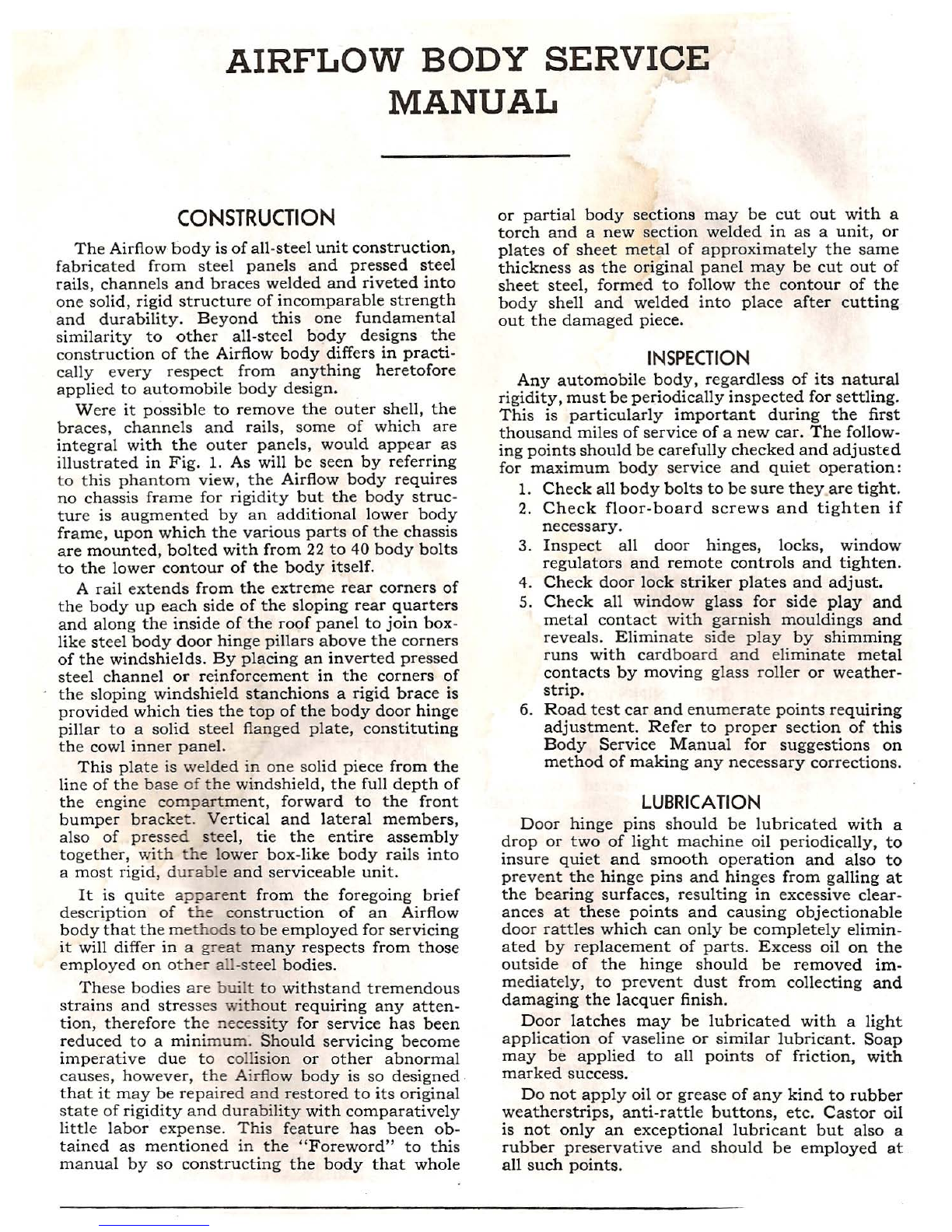

FIG.4-Battery Removal

1- Fronts eatframerearcross tube 5-Front seat guide tie rod assemhlv

2- Battery cover assembly 6-Battery cable terminal-negative

3-Front seat cushion support 7-Battery filler caps

4-Battery hold down clamp . 8-Battery cable terminal-positive

A further example is offered in Figs. 3 and 4

showing the accessibility of the storage battery

for the replacement of distilled water, the testing

of specific gravity or cleaning of battery terminals·

operations which must be performed at compara~

tively frequent intervals. The front seat cushion

may be removed from the seat cushion supports.

(1, Fig . 3) the battery cover lid thumb screw (3)

unscrewed and the battery lid (2) lifted off for

the replacement of water or testing of electrolyte

through the battery filler caps (5) or if it is desired

to replace the battery or clean the battery ter-

minals (6 and 8, Fig. 4) the ba tt ery cover assembly

(2) may be removed expos ing all necessary parts

including the battery hold-down clamp (4). '

Throughout the enti re vehicle, it will be found

that the same though t ful solicitude has been given

to the design of the body minimizing the incon-

venience to the mechanic and reducing the labor

expense to th e owner when it is found necessary

to perform an y cla ss of repair or adjustment

whether it ap ply to body or chassis.

UPHOLSTERYAND TRIM PANELS

All trim pane ls bel ow the line of the belt mould-

ing are mount ed on padded wood or heavy fibre -

board foundati ons , and are secured to the Airflow

body by mean s of expanding fasteners. This

construction per mits the trim to be disassembled

from any part of the body in units without the

possibility of da mag e.

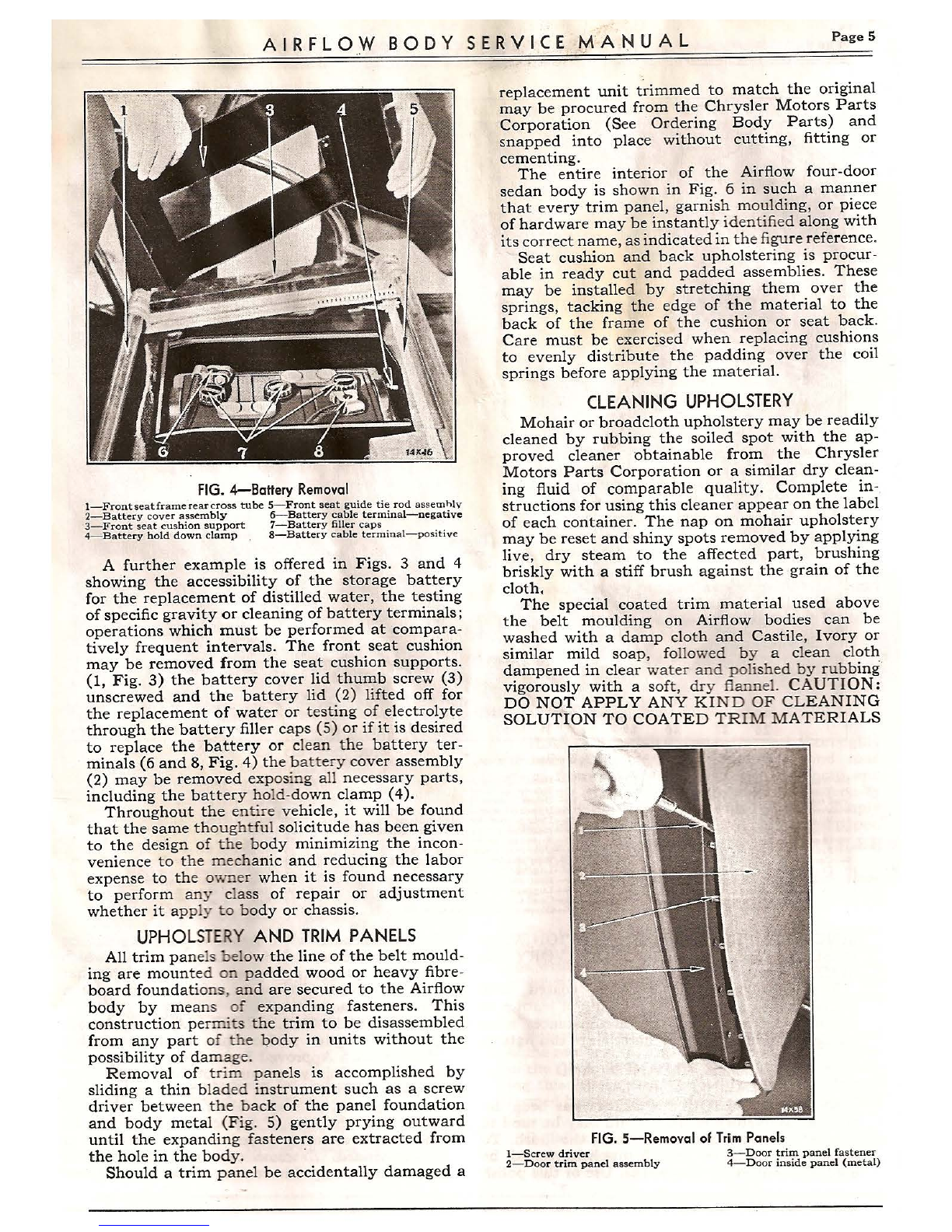

Removal of t rim panels is accomplished by

sliding a thin blade d instrument such as a screw

driver between the back of the panel foundation

and body metal (Fig. 5) gently prying outward

until the expanding fasteners are extracted from

the hole in the body.

Should a trim panel be accidentally damaged a

replacement unit trimmed to match the original

may be procured from the Chrysler Motors Parts

Corporation (See ·Ordering Body Parts) and

snapped into place without cutting , fitting or

cementing.

The entire interior of the Airflow four-door

sedan body is shown in Fig. 6 in such a manner

that every trim panel, garnish moulding, or piece

of hardware may be instantly ident ified along with

its correct name, as indicated in the figure reference.

Seat cushion and back upholstering is procur-

able in ready cut and padded assemblies. These

may be installed by stretching them over the

springs, tacking the edge of the material to the

back of the frame of the cushion or seat back.

Care must be exercised when replacing cushions

to evenly distribute the padding over the coil

springs before applying the material.

CLEANING UPHOLSTERY

Mohair or broadcloth upholstery may be readily

cleaned by rubbing the soiled spot with the ap-

proved cleaner obtainable from the Chrysler

Motors Parts Corporation or a similar dry clean-

ing fluid of comparable quality. Complete in-

structions for using this cleaner appear on the label

of each container. The nap on mohair upholstery

~ay be reset and shiny spots removed by applying

hve, dry steam to the affected part, brushing

briskly with a stiff brush against the grain of the

cloth.

The special coated trim material used above

the belt moulding on Airflow bodies can be

washed with a damp cloth and Castile, Ivory or

similar mild soap, followed by a clean cloth

dampened in clear wate r and pol ished by rubbing

vigorously with a soft, dry flan nel. CAUTION:

DO NOT APPLY ANY KIND OF CLEANING

SOLUTION TO COATED TRI M MATERIALS

FIG.5-Removal of Trim Panels

1-Screw driver 3-Door trim panel fastener

2- Door trim panel assembly 4-Door inside panel (metal)

Pag-~ 6 A I RFL O W e:o~D Y SERV l~CE M A N U A L

I- Windshield regulator handle

2- W indshield garnish moulding

3-Front door hinge pillar trim paud

4-- Ventilating window adjusting handle

5- Windshi eld header trim panel

6- Fr ont door garnish moulding

?- Headlining front garnish moulding

8...---Front door opening garnish moulding

9- Center pillar garnish mou lding

· FIG. 6-Body Interior, Trim Panels and Hardware

14-Headlining center trim panel

IS-Rear door opening garnish moulding

16 -~ Uppcr quarter trim panel

28-Remote control handle

29-Front door trim panel

17-Upp er quarter garnish moulding

18- Door header dovetail-upper

30-Front seat cushion 9.ssembly

31-Center pillar lower trim panel

32-Front seat back assembly

19- H ead lining rear garnish moulding 33-Front door weathercord assembly

34- Front door lock striker

20-Rear seat back assembly 35- Front seat frame

21-Over rear window trim pan el 36-R ea r door lower wedge

22- Rear window garnish moul ding 37-R ear seat ba ck frame sector

38-Rea r seat cushion as sembly

39-Rea r side arm rest support assembly

40-Rear side arm rest cover assembly

I0- Do me light switch 23- Luggage compartment light

24-Rear window glass

I I- Center pillar trim pan el- upper

12-Door bod y header tr im panel

13- Headlining side garnish mou lding 25-Luggage compartment

26-Cowl trim panel

27-Glo ve compartment door

SIN CE COMPLETE DETERIORATION WILL

RESULT. USE ONLY CASTILE, IVORY OR

SIM ILAR SOAP.

The instructions for cleaning coated trim

materi als also apply to the cleaning of leather or

imitat ion leather. Under no circumstances must

a clean ing fluid be used on materials of this nature.

POLISHES,CLEANERSAND

SEALING COMPOUNDS

APP ROVED LIQUID POLISH has been de-

·.-eloped by factory engineers and may be used to

::-esto re the lustre without harming the finish. To

o:>:ain the best results this polish should be

a?pli ed about every two weeks. Use of this polish -

is recommended when frequent polishing can ·be

done. This must not be used on a surface which

has been previously waxed, unless the wax has

been removed with paste cleaner . Otherwise a

gummy surface will result.

APPROVED POLISHING WAX may be ap-

plied, after the surface has been thoroughly

cleaned, with Approved Paste Cleaner, to protect

the finish. This wax must not be applied over

chalked surfaces or over liquid polished surfaces.

Liquid polish or Saxon Glaze are recommended

because of the ease of application. However; for

those who desire a waxed surface, this ·wax is

recommended. Extreme care must be used to

apply <:>nlya very thin coating of wax . The thinner

AIRFLOW BODY SERVICE MANUAL Page 7

th e wax coat the better will be the finish . A thick

coating of wax, caused by heavy applications or

rep eated thin coats, should be avoided. Best re-

sults will be obtained by cleaning the surface with

paste cleaner before applying wax at any time.

APPROVED SAXON GLAZE which produces

a wax -like finish, is in liquid form and can be applied

to a new car in much less time than wax. It pro-

duces a very hard, mirror finish which lasts con -

siderably longer than wax. It is especially service -

able on the sea coast where salt air and fog prevail.

Saxon Glaze applied three times a year will check

color bleeding and will maintain that new car

appearance. In cases where the car has been

previ ously wax ed, it is necessary to thoroughly

clean the body , removing all old wax with ap -

proved paste cleaner before applying Saxon Glaze.

However , successive tre atments of th e Glaz e tak e

from one-t hird to one-fourth the tim e normally

required for a waxing operation.

APPROVED PASTE CLEANER should be

used only on surfaces that are extremely dull or

heavily chalked. This cleaner contains a stronger

abrasive than the liquid polish and Saxon Glaze,

therefore should be used sparingly. Care should

be exercised when applying paste cleaner over

stripes as they are applied over the lacquer finish

and will rub off with less rubbing than will the

main body finish. After cleaning the surfac e with

the paste cleaner, and wiping it clean with a

polishing cloth, polish with either Liquid Polish or

Saxon Glaze.

APPROVED FABRIC CLEANER has been

developed for the purpose of cleaning upholstery.

This cleaner may also be used for removing tar

and oil from the fenders and body without harm -

ing the finish of either. Fabric cleaner must not

be used for cleaning the coated headlining material

in the Airflow bodies.

AUTO TOP SEAL is a top dressing which

renews the life of the car top, and prevents

det erioration, from the effect s of sun, snow, sleet

and rapid changes in temp erature.

It is scientifically pre pared to dry slowly and

will remain pliab le and elastic over a long period.

11 12 13 l~

14

14X40

FIG. 7-Cross Seciion of Top Deck and Headlining

1- Roof scre en (an tenna )

2-Wadding

3- Roof rail

4-D eck material

5- Roof rail sup por t

6-Roof seal

7- R oo f panel

8- Trim panel garnish mouldin g screw

9-- Tri m panel garn ish m ou lding

10-- T rim pan el material

11-Ro of rail screw

12-Roof r ail screw lock washer

13-Roof rail anti-squeak

14- Trim panel foundati on

6 9 10

FIG. 8-Cross Section of Headlining Panel Installation

1- Roof screen (a ntenna)

2- W addi ng

3- D eck mat erial

4-Silen cer

5- Roof bow

6-F asten er

7-He ad lin in g found ation

8- H ea d lining mat erial

9- H ea d lin ing rivet

IO-Sil encer

It gives the top a smooth , brilliant finish and

thoroughly waterproofs and preserves as well as

beautifies th e top material.

APPROVED RUBBER .CEMENT. In the

performance of various body repair operations ~t

is nec essary to bond rubber or felt to meta l. This

is particularly true when installing weatherseals

around the cowl ventilators, windshield frames,

and door openings, replacing running board mats

or installing felt pads to pan els or floor mats .

Approved rubber cement has been selected by

the engineers, after painstaking research, as the

most satisfactory product available for all around

usage. it forms a permanent union between the

rubber or felt and steel faces which "sets" or dries

in a few seconds and is absolutely imp erv ious to

the actions of the elements.

Complete instructions for the application of

Approved Rubber Cement appear on the label of

each container which should be carefully read

before using.

GLASS CLEANER instantly and thoroughly

removes grease, grime, bugspatters, and road

stains from windshield, windows, headlamp and

tail lamp lenses . Polishes chromium. A necessity

for clear vision after rain, snow or sleet. Simply

spray on and wipe off with clean rag or newspaper':' .

These items are all distributed by CHRYSLER

MOTORS PARTS CORPORATION.

Division of Chrysler Corporation

TOP DECK

The top deck is so designed that it is stretched

tightly and sealed completely against water leak-

age without the use of sealing compounds, tacks

or screws and ma y be replaced in a fraction of the

customary time without the necessity of removing

the top deck frame or headlining.

Removal is accomplished by prying up the end

of the roof seal (6, Fig. 7) at the point in the center

of the rear quart er where the two ends meet, pull-

ing this moulded rubber strip out of the channel

formed by the roof pan el (7) and roof rail support

(5).

Installation of a new top deck is made in the

following manner:

?age 8 A 1.R F L O W B O D Y. SERV I C E .M A N U A L

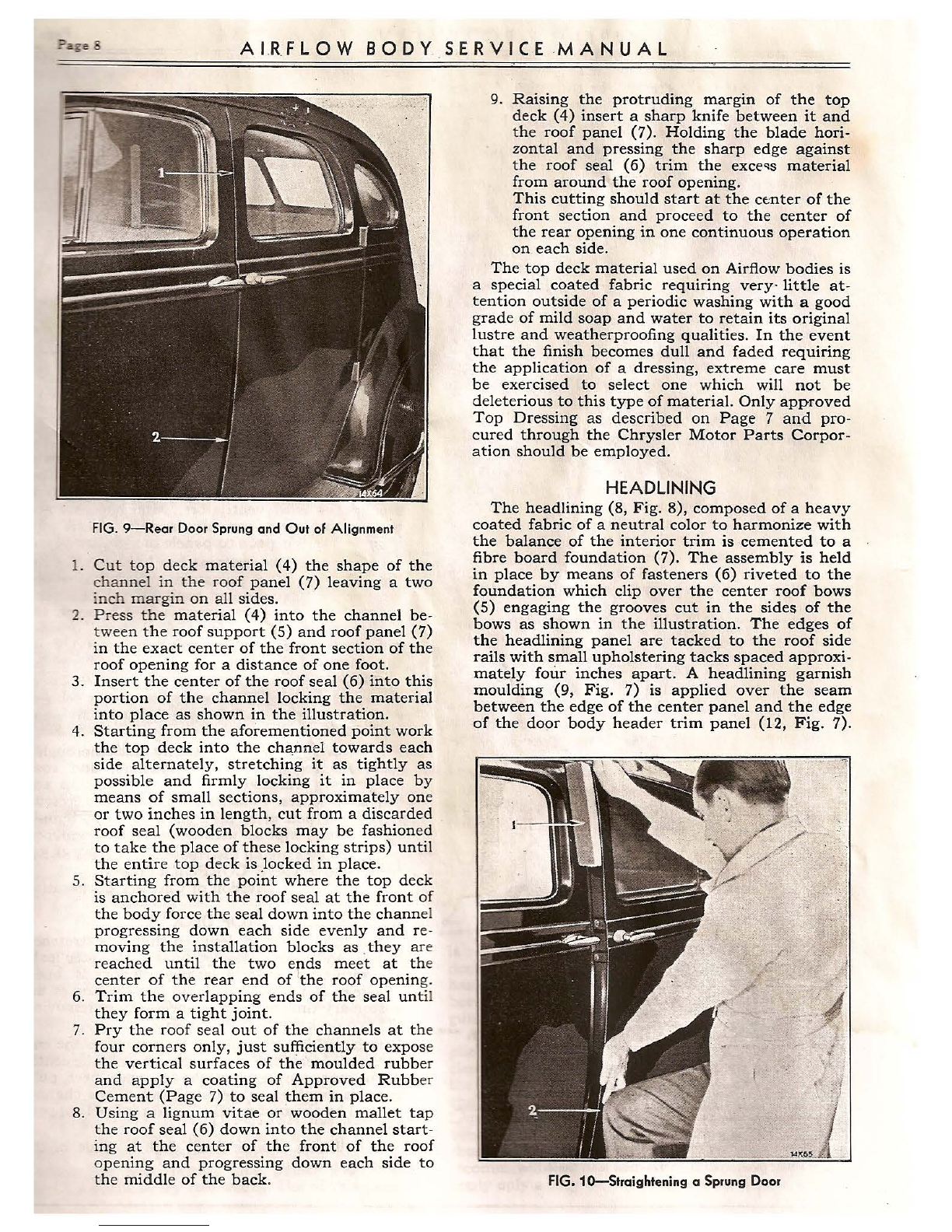

FIG. 9-Rear Door Sprung and Out of Alignment

1. Cut top deck material (4) the shape of the

channel in the roof panel (7) leaving a two

inch margin on all sides .

2. Pr ess the material (4) into the channel be-

twee n the roof support (S) and roof panel (7)

in the exact center of the front section of the

roof opening for a distance of one foot.

3. Insert the center of the roof seal (6) into this

portion of the channel locking the material

into place as shown in the illustration .

4. Starting from th e aforementioned point work

the top deck into the channel towards each

side alternately, stretching it as tightly as

possible and firmly locking it in place by

means of small sections, approximately one

or two inches in length, cut from a discarded

roof seal (wooden blocks may be fashioned

to take the place of these locking strips) unt il

the entire top deck is _locked in place.

5. Starting from the point where the top deck

is anchored with the roof seal at the front of

the body force the seal down into the chann el

progressing down each side evenly and re-

moving the installation blocks as .they are

reached until the two ends meet at th e

center of the rear end of the roof openin g.

6. Trim the overlapping ends of the seal unti l

they form a tight joint.

7. Pry the roof seal out of the channels at the

four corners only, just sufticiently to expos e

the vertical surfaces of the moulded rubber

and apply a coating of Approved Rubb er

Cement (Page 7) to seal them in place.

8. Using a lignum vitae or wooden mallet tap

the roof seal (6) down into the chann el start -

ing at the cent er of the front of the roof

opening and progressing down each side to

the middle of the back .

9. Raising the protruding margin of the top

deck (4) insert a sharp knife between it and

the roof panel (7). Holding the blade hori-

zontal and pressing the sharp edge against

the roof seal (6) trim the exce~s material

from around the roof opening .

This cutting should start at the ce:nter of the

front section and proceed to the center of

the rear opening in one continuous operation

on each side.

The top deck material used on Airflow bodies is

a special coated fabric requiring very- little at-

tention outside of a periodic washing with a good

grade of mild soap and water to retain its original

lustre and weatherproofing qualities . In the event

that the finish becomes dull and faded requiring

the application of a dressing , extreme care must

be exercised to select one which will not be

deleterious to this type of material. Only approved

Top Dressing as described on Page 7 and pro-

cured through the Chrysler Motor Parts Corpor -

ation should be employed.

HEADLINING

The headlining (8, Fig . 8), composed of a heavy

coated fabric of a neutral color to harmonize with

the balance of the interior trim is cemented to a

fibre board foundation (7). The assembly is held

in place by means of fasteners (6) riveted to the

foundation which clip over the center roof bows

(S) engaging the grooves cut in the sides of the

bows as shown in the illustration . The edges of

the headlining panel are tacked to the roof side

rails with small upholstering tacks spaced approxi-

mately four inches apart. A headlining garnish

moulding (9, Fig. 7) is applied over the seam

between the edge of the center panel and the edge

of the door body header trim panel (12 , Fig. 7).

FIG.10-Straightening a Sprung Door

FIG. 11-Door Properly Straightened and Aligned

This moulding is held in place with wood screws

and washers (8, Fig. 7).

DO NOT APPLY CLEANING SOLUTIONS

OF ANY NATURE TO SPECIAL COATED

HEADLINING - SEE SPECIAL INSTRUC-

TIONS FOR CLEANING ON PAGE 5.

The headlining trim panel is supplied by the

Chrysler Motors Parts Corporation for replace-

ment purposes approximat ely one-half inch larger

in all dim ensions than the opening in the roof. It

is important that th ese panels be carefully marked

and cut to exactly fit the opening in the body into

which it is to be installed, inasmuch as they are

not interchangeable from one body to another.

UPPERBODYTRIMPANELS

All trim material above the line of the belt

moulding, consisting of th e following:

Windshi eld head er trim panel (5, Fig. 6)

Front door hinge pillar trim pan el (3, Fig. 6)

Door body header trim panel (12, Fig. 6)

Center pillar trim panel upp er (11, Fig . 6)

Upper qua rter trim pan el (16, Fig. 6)

Ov er rear window trim panel (21, Fig. 6)

are fabricated in the sam e manner as the head-

linin g, namely, a specia l coated fabric (10, Fig. 7)

is cemented to a fibre board foundation (14, Fig. 7).

All of th ese panels are held in place, for as-

sembly, by means of small tacks driven into trim

sticks after which the garnish mouldings (9, Fig. 7)

are applied with garn ish moulding screws (8,

Fig. 7).

Th e various mou lding s are indicated very clearly

in Fig. 6 at (7), (8), (9),(13), (15), (17), (19)and(22) .

DO NOT APPLY CLEANING SOLUTIONS

OF ANY NATURE TO SPECIAL COATED

TRIM MATERIAL - SEE SPECIAL IN -

STRUCTIONS FOR CLEANING ON PAGE 5.

DOORS

The correct ~ psition of a door is determ_ined _by

the alignment of the moulding on the body w~th

that on the door (Fig. 9 illustrates a door which

has become sprung throw ing the moulding out of

alignment) and by the uniformity of the clearance

between the door frame and door on all four sides

when closed. The door must not interfere with the

metal of the door frame at any point.

The doors on Airflow bodies are quite rigid

st ruc tures, but if they become _warped or spru~g,

may be straightened by applying th e following

methods:

CAUTION : Lower the glass as far as possible.

I. Lateral adjustments of the door .may be

.. made .by loosening the screws in the body

· pillar half of th e hinge plate and sliding them

"in" or "out" on their elongated holes.

2. The lock side of the door may be raised or

lowered by placing the end of a wrench ·or

suitable flat tool between the hinge leav es,

closing the door ~arefully until the ~ing e. is

sprung sufficient ly to move the door mto -1ts

desired position. This ·operation will also

adjust the door closer to the lock pillar. ·

3. To adjust the door closer to the hinge pillar,

bind the protruding leaves of the door hinge

as close to the door frame as possible ,

securely together with a " C" clamp, first

protecting the finish on the hing e plates and

body from scratches. Slowly open the door

until the hinge is sprung sufficiently to close

up any excessive gap whic h may exist be-

tween the back of the door and the door

hinge pillar post. It is recomm ended that

the hinge plate screws be loosened one turn

and the door opened and closed several times

after performing operations 2 or 3, tightening

them without disturbing their natural posi -

tion. 1.'!lis will permit the hinge pins to seek

their own alignment and prevent undue

binding, wear and objectionable noises.

WARPEDDOORS

To correct a warp in a door such as that indi-

cated by the excessive gap between the door and

door frame at (2, Fi g. 9) as compared to the open-

ing at (1, Fig. 9), lower th e door glass, place a

padded block of wood (1, Fig. 10) between the

door frame and latch pillar post at th e top an d

apply pressure to the door at (2, Fi g. 10). It is

possible to obtain perfect alignment of the opening

in this manner if care is taken when performing

this operation to not spring the door any more

than necessary to obtain a perf ect fit.

An excessive gap at the top of the door may be

corrected by plac ing the padded block at the bot-

tom of the door latch pillar app lying pr essure at

the top of the door.

After springing a door in this manner it is neces-

sary to readjust tension on the door weatherstrip

(1, Fig. 12) by reset ting the door latch plate

(34, Fig. 6). (See instructions for Adjusting Door

Bumpers and Strikers.)

A perfectly fitting door with the mouldings

correctly lined -up is shown in Fig. 11.

Page 10 AIRFLOW BODY SERVICE MANUAL

1

l--- -----"'--'-+------8

I

I

I

14Jl55

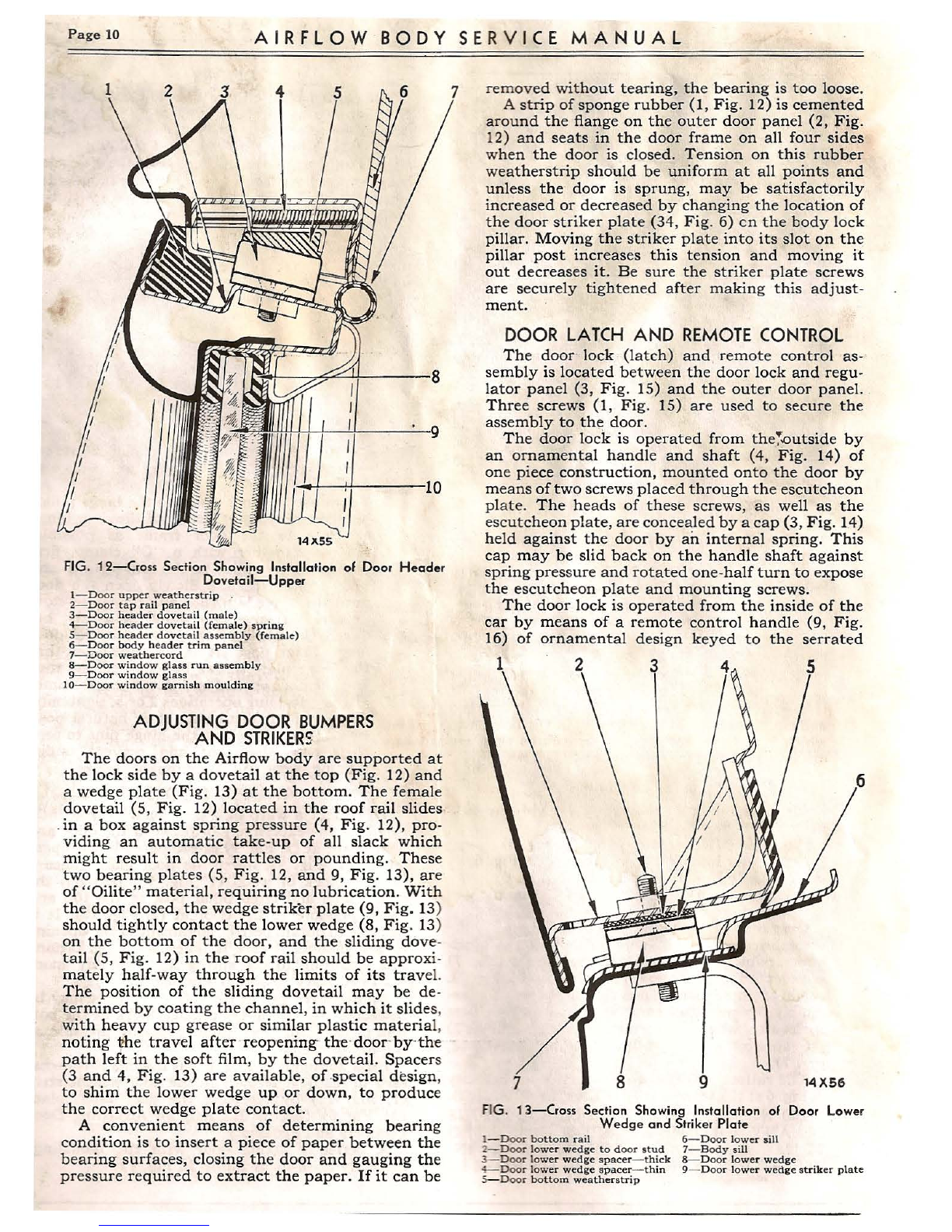

FIG. 12-Cros s Section Showing Installation of Door Header

Dovetail-Upper

1- D oor upper weathe rstrip .

2- Door tap rail panel

3-Doo r header dovetail (male)

4- Door header dovetail (female) spring

S- Door header dovetail assembly (female)

6-Door body header trim panel

7- Door weathercord

8-Door wind ow glass run assembly

9- Doo r window glass

IO- Door window garnish moulding

ADJUSTING DOOR BUMPERS

AND STRIKERS

The doors on th e Airflow body are supported at

the lock side by a dovetail at the top (Fig. 12) and

a wedge plate (Fig. 13) at the bottom. The female

dovetail (5, Fig. 12) located in the roof rail slides

.in a box against spring pr essure (4, Fig. 12), pro-

viding an automatic tak e-up of all slack which

might result in door rattl es or pounding. These

two bearing plates (5, Fig. 12, and 9, Fig. 13), ar e

of "Oilite " material, requiring no lubrication. With

th e door closed, the wedge striker plate (9, Fig. 13)

should tightly contact the lower wedge (8, Fig . 13)

on the bottom of the door, and the sliding dove -

tail (5, Fi g. 12) in the roof rail should be approxi-

mately half-way through the limits of its travel.

The position of the sliding dovetail may be de-

termined by coating the channel, in which it slide s,

with heavy cup grease or simi lar plastic materia l,

noting 1lhe travel after reopening the ·doo r by·the

path left in the soft film, by the dovetail. Spacer s

(3 and 4, Fig. 13) are available, of .special design,

to shim the lower wedge up or down, to produce

the correct wedge plate contact.

A conv enient means of determining bearing

condition is to ins ert a piece of paper between the

bearing surfaces, closing the door and gauging the

pressure required to extract the paper. If it can be

removed without tearing, the bearing is too loose .

A strip of sponge rubber (1, Fig. 12) is cemented

around the flange on the outer door panel (2, Fig.

12) and seats in the door frame on all four sides

whe n the door is closed. Tension on this rubber

weatherstrip should be uniform at all points and

unless the door is sprung, may be satisfactorily

increased or decreased by changing the location of

the door striker plate (34, Fig. 6) en the body lock

pillar. Moving the striker plate into its slot on the

pillar post increases this tension and moving it

out decreases it. Be sure the striker plate screws

are securely tighten ed after making this adjust-

ment.

DOOR LATCH AND REMOTECONTROL

The door · lock (latch) and . remote control as-

sembly is located between the door lock and regu-

lator panel (3, Fig. 15) and the out er door panel.

Three screws (1, Fig. 15) are used to secure the

assembly to the door .

The door lock is operated from the;.outside by

an ornamental handle and shaft (4, Fig. 14) of

one piece construction, mounted onto the door by

means of two screws placed through the escutcheon

plate . The heads of these screws, as well as the

escutcheon plate, are concealed by a cap (3, Fig. 14)

held against the door by an internal spring. This

cap may be slid back on the handle shaft against

spring pres sure and rotated one-half turn to expose

the escutch eon plat e and mounting screws.

The door lock is operated from the inside of the

car by means of a remote control handle (9, Fig.

16) of ornamental design keyed to the serrated

1 3

6

7 8 9 14X56

FIG. 13-Cross Section Showing Installation of Door Lower

Wedge and Striker Plate

1- Doo r bottom rail 6- Door lower sill

2-D oor lower wedg e to door stud 7- Body sill

3--Door low er wedg e spacer - thick 8- Door lower wedge

4--Door lower wedge spacer - thin 9- Door lower wedge striker plate

~D oor bo ttom weatherstr ip

AIRFLOW BODY SERVICE MANUAL Page 11

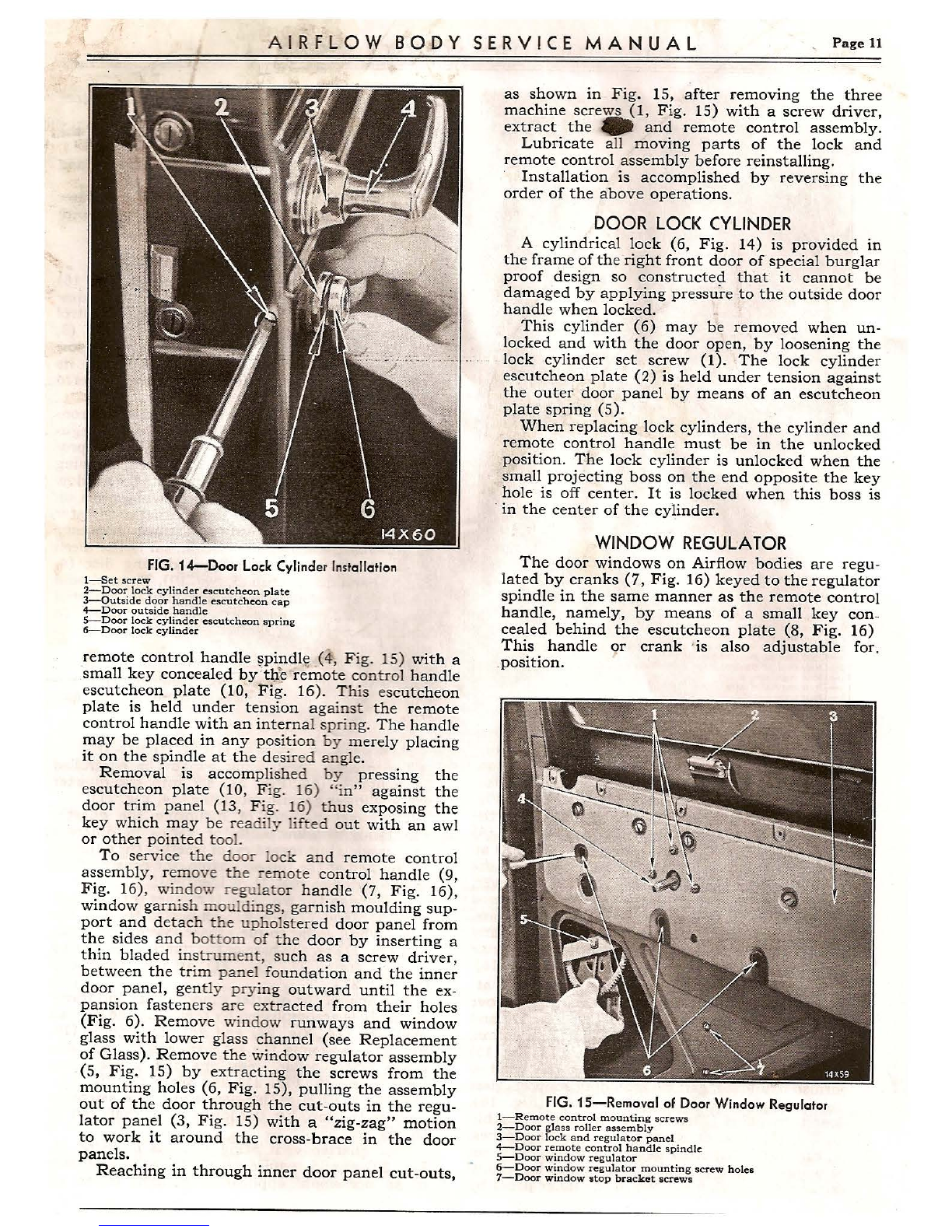

FIG. 14-Door Lock Cylinder Installation

1-S et screw

2-Door lock cylinder escutcheon plate

3-0utside door handle escutcheon cap

4-Door outside handle

S--Door lock cylinder escutcheon spring

6-Door lock cylinder

remote control handle ~pindl c:;(4, Fi g. 15) with a

small key concealed by :tl,1.j: "remote control handle

escutcheon plate (10, Fig. 16). T his escutcheon

plate is held under tension against the remote

control handle with an intern al sprin g. The handle

may be placed in any position by merely placing

it on the spindle at the desired angle.

Removal is accomp lished by pressing the

escutcheon plate (10 , Fig. 16) "in" against the

door trim panel (13, Fig. 16) thus exposing the

key which may be readi ly lifted out with an awl

or other point ed too l.

To service the door lock and remote control

assembl y, remove the remote control handle (9,

Fig. 16), window regu lator handle (7, Fig. 16),

window garnish mou ldin gs, garnish moulding sup -

port and detach the uphol stered door panel from

th e sides and bottom of the door by inserting a

thin blad ed instrument, such as a screw driver,

between the trim panel foundation and the inner

door panel, gently prying outward until the ex-

pansion fastene rs are ext racted from their holes

(Fig. 6). Remove window runways and window

glass with lower glass channel (see Replacement

of Glass) . Remov e the win dow regulator assembly

(5, Fig. 15) by extra cting the screws from the

mounting holes (6, Fig. 15), pulling the assembly

out of the door through the cut-outs in the regu-

lator panel (3, Fig. 15) with a "zig-zag" motion

to work it around the cross-brace in the door

panels.

Reaching in through inner door panel cut-outs,

as shown in Fig. 15, after removing the three

machine screws (1, Fig. 15) with a screw driver,

extract the • and remote control assembly .

Lubricate all moving parts of the lock and

remote control assembly before reinstalling.

Installation is accomplished by reversing the

order of the above operations .

DOOR LOCK CYLINDER

A cylindrical lock (6, Fig. 14) is provided in

the frame of the right front door of special burglar

proof design so constructe9 that it cannot be

damag ed by applying pressure to the outside door

handle when locked.

This cylinder (6) may be removed when un-

locked and with the door open, by loosening the

lock cylinder set screw (1). The lock cylinder

escutcheon plate (2) is held under tension against

the outer door panel by means of an escutcheon

plate spring (5).

When replacing lock cylinders, the cylinder and

remote control handle must be in the unlocked

position. The lock cylinder is unlocked ·when the

small projecting boss on the end opposite the key

hole is off center . It is locked when this boss is

· in the center of the cylinder.

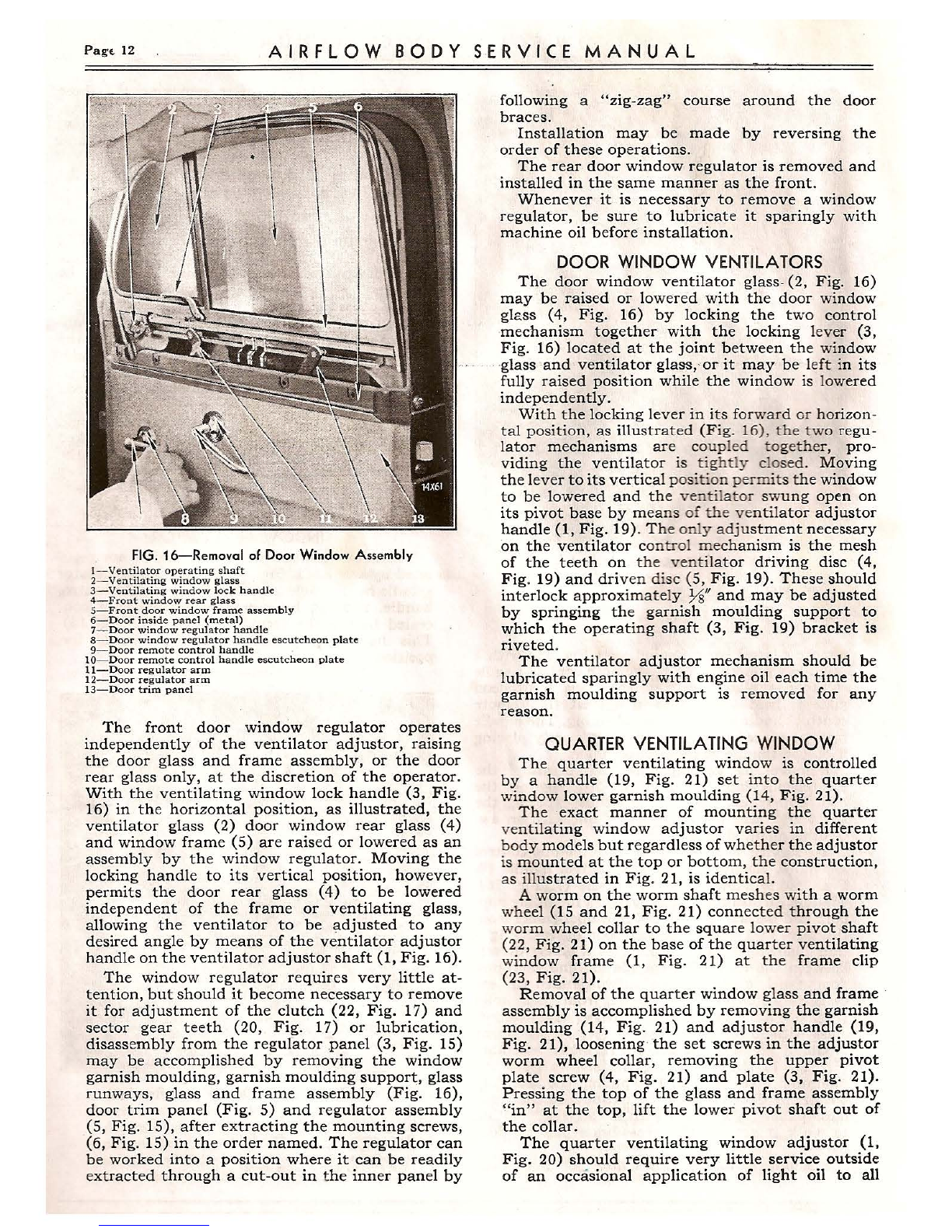

WINDOW REGULATOR

The door windows on Airflow bodies are regu-

lated by cranks (7, Fig. 16) keyed to the regulator

spindle in the same manner as the remote control

handle, namely, by m eans of a small key con-

cealed behind the escutcheon plate (8, Fig. 16)

This handle 9r crank 'is also adjustable for.

.position.

FIG. 15-Removal of Door Window Regulator

1-R em ote cont rol mount in g screws

2-Door glass roll er assemb ly

3-D oor lock and regu lat or panel

4- Door re mote control handl e spindle

5-Door window regu lat or

6-Door window regu lato r mounting screw holes

7-Door window atop bracket screws

PagE- 12 AIRFLOW BODY SERV I CE MANUAL

FIG. 16-Removal of Door Window Assembly

I- Ventilator operating shaft

2- Ventilating window glass

3- Ventilating windo w lock handle

4- Front window rear glass

5-Front door window frame assembly

6- Door inside panel (metal}

7-Door window regulator handle

8-Door window regulat or handle escutcheon plate

9- Door remote control handle

10-Door remote control handle escutcheon plate

11-Door regulator arm

12-Door regulator arm

13- Door trim panel

The front door window regulator operates

independently of the ventilator adjustor, raising

the door glass and frame assembly, or the door

rear glass only, at the discretion of the operator.

With the ventilating window lock handle (3, Fig.

16) in the horizontal position, as illustrated, the

ventilator glass (2) door window rear glass (4)

and window frame (5) are raised or lowered as an

assembly by the window regulator. Moving the

locking handle to its vertical position, however,

permits the door rear glass (4) to be lowered

independent of the frame or ventilating glass,

allowing the ventilator to be adjusted to any

desired angle by means of the ventilator adjustor

handle on the ventilator adjustor shaft (1, Fig. 16).

The window regulator requires very little at -

tention, but should it become necessary to remove

it for adjustment of the clutch (22, Fig . 17) and

sector gear teeth (20, Fig . 17) or lubrication,

disassembly from the regulator panel (3, Fig. 15)

may be accomplished by removing the window

garnish moulding , garnish moulding support, glass

runways, glass and frame assembly (Fig. 16),

door trim panel (Fig. 5) and regulator assembly

(5, Fig. 15), after extracting the mounting screws,

(6, Fig . 15) in the order named. The regulator can

be worked into a position where it can be readily

extracted through a cut-out in the inner panel by

following a "zig -zag" course around the door

braces.

Installation may be made by reversing the

order of these operations.

The rear door window regulator is removed and

installed in the same manner as the front.

Whenever it is necessary to remove a window

regulator, be sure to lubricate it sparingly with

machine oil before installation.

DOOR WINDOW VENTILATORS

The door window ventilator glass- (2, Fig. 16)

may be raised or lowered with the door window

glass (4, Fig. 16) by locking the t wo control

mechanism together with the locking lever (3,

Fig. 16) located at the joint between th e window

· glass ·and ventilator glass, or it may be left in its

fully raised position while the window is lowered

independently.

With the locking lever in its forward or horizon -

tal positio n, as illustrat ed (F ig. 16) , the two regu-

lat or mechanisms are coupled to gethe r, pro-

viding the ventilator is tightly closed . Moving

the lever to its vertica l position permit s th e window

to be lowered and the ventilator swung open on

its pivot base by me ans of the ventilat or adjustor

handle (1, Fig. 19). T he only adjust ment necessary

on the ventilator con trol mec hanism is the mesh

of the teeth on the venti lator driving disc (4,

Fig . 19) and driven dis c (5, Fig. 19). These should

interlock approxim ately ½" and may be adjusted

by springing th e garnish moulding support to

which the operat ing shaft (3, Fig . 19) bracket is

riveted .

The venti lator adjustor mechanism should be

lubricated sparingly with engine oil each time the

garnish moulding support is removed for any

reason.

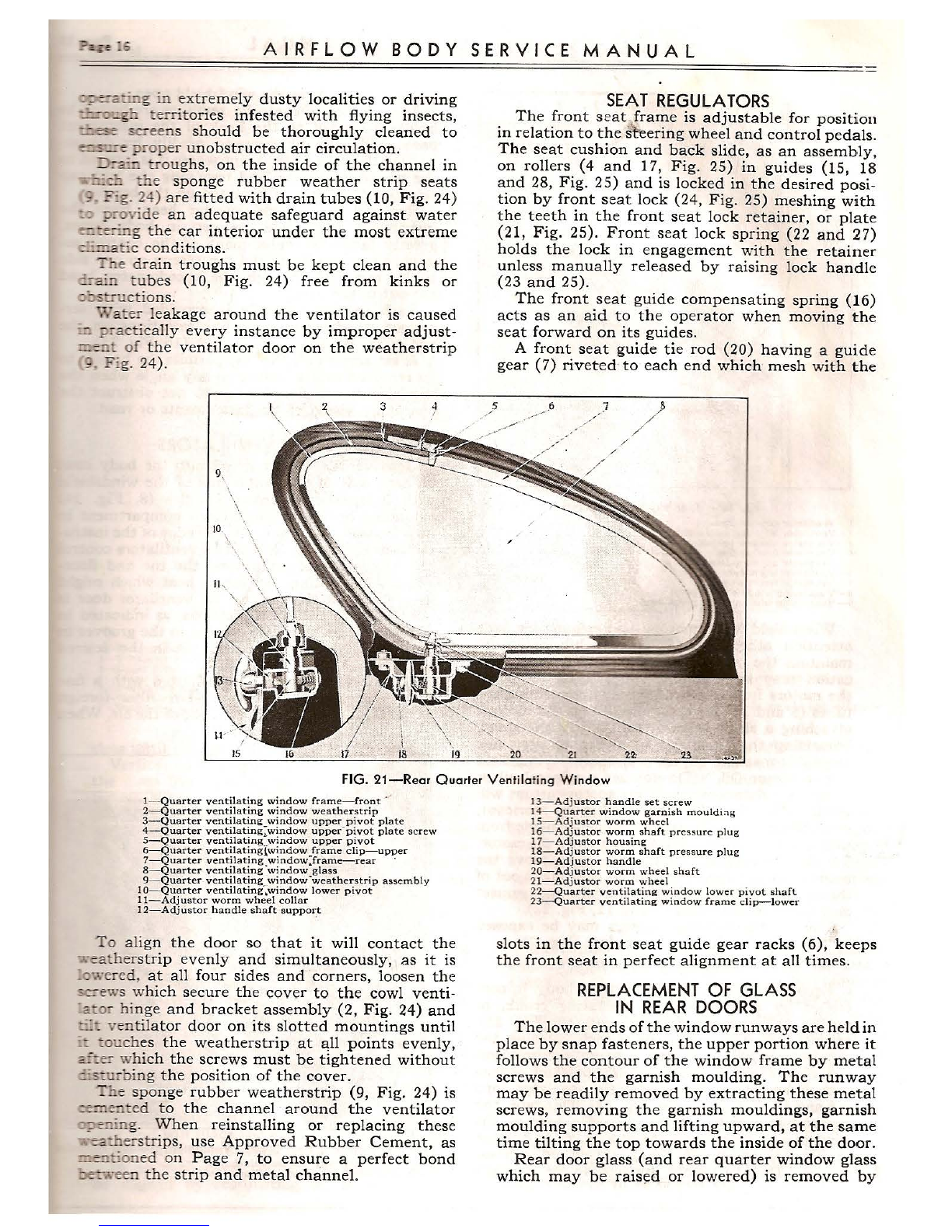

QUARTERVENTILATINGWINDOW

Th e quarter ventilating windo w is controlled

by a handle (19, Fig. 21) set into the quarter

window lower garnish moulding (14, Fig. 21).

The exact manner of mounting the quarter

ve ntilating window adjustor varies in different

body models but regardless of whether the adjustor

is mounted at the top or bottom , the construction,

as illustrated in Fig . 21, is identica l.

A worm on the worm shaft meshes wit h a worm

wheel (15 and 21, Fig. 21) connected through the

worm wheel collar to the square lower pivot shaft

(22, Fig. 21) on the base of the quarte r ventilating

window frame (1, Fig. 21) at the frame clip

(23, Fig. 21).

Removal of the quarter window glass and frame ·

assembly is accomplished by removing the garnish

moulding (14, Fig . 21) and adjustor handle (19,

Fig. 21), loosening the set ·screws in the adjustor

worm wheel collar, removing the upper pivot

plate screw (4, Fig. 21) and plate (3, Fig. 21).

Pressing the top of the glass and frame assembly

"in" at the top, lift the lower pivot shaft out of

the collar .

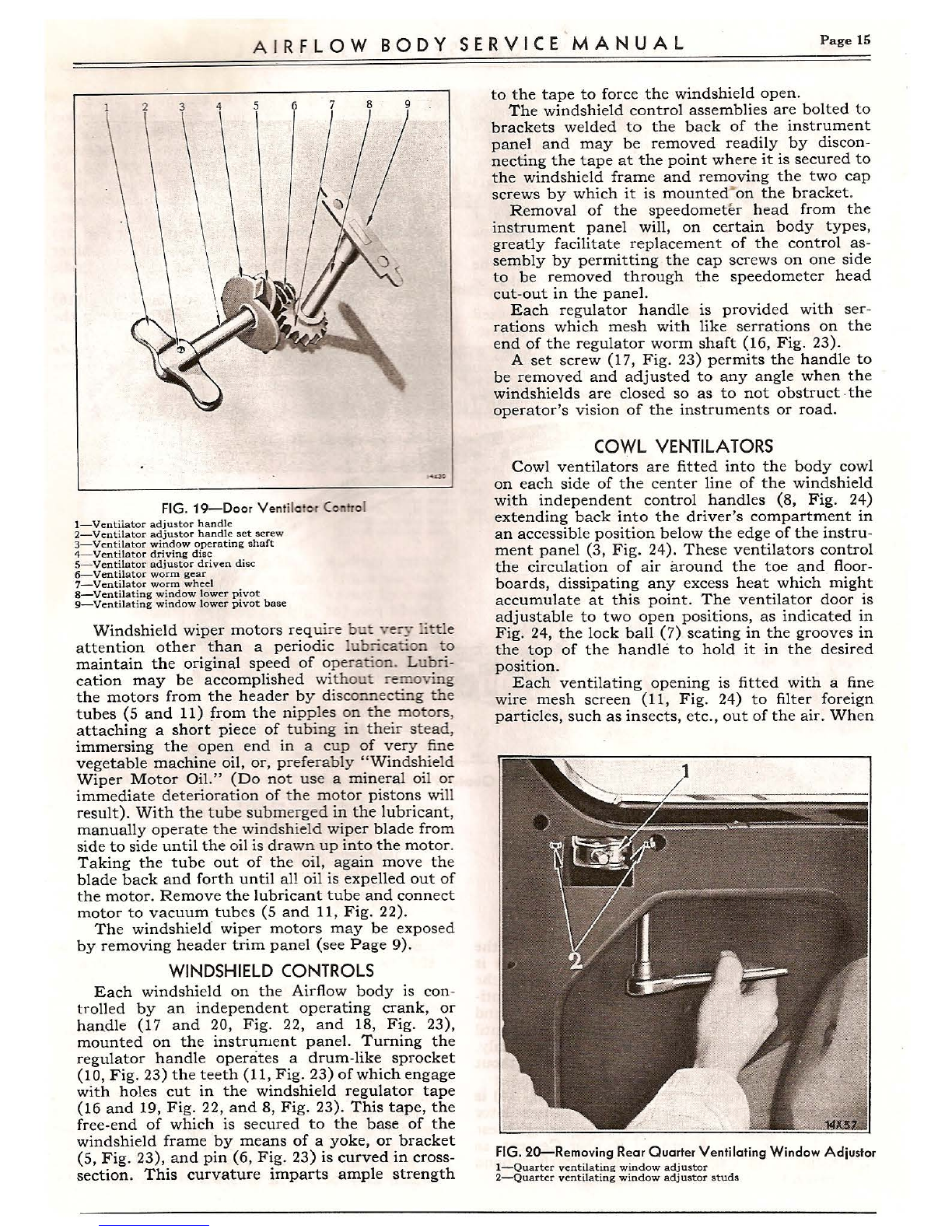

The quarter ventilating window adjustor (1,

Fig. 20) should require very little service outside

of an occasional application of light oil to all

A I RFL O w BO D y sERV I CE M A N uA L Page 13

10 11

12 13 14 16 18 14X31

19 20 21 22

FIG. 17-Front Door Window Regulator and Ventilating Operating Mechanism

I-Window fram e

2- Ventilating window loc king cam

3- Ventilating window fram e

4-V entilat ing window loc kin g ca m striker plate

5-Ventil at ing win dow weat h erstr ip

6- W ind ow supp ort

8-V ent ilator driven dis c

9- Ventil at or worm ret ainer plat e

10- Ventil ator driv ing disc

11-W ind ow fr ame cha nne l

12-Wind ow re gulat or a ssembly

13-Window lower glass channel and bracket assem bly

14-- W indow wea the rstrip

16-Wi ndow regula t or gears

17-Win dow regulator arm

18- Window supp ort

19-Ven til ating win do w latch bar

20--Wi ndow regul ator sector

21- W ind ow lower glas s channel bracket

22- Window regul ator clutch

7-Ven tilating window lower pivot assembly 15- Window re gul ator plate

bearing and gear tooth surfaces. Should it become

necessary to remove this assembly, however, it is

only necessary to remove the rear quarter lower

trim panel foundation, at the end of the rear seat

cushion, after loosening the arm rest suppor t

assembly, unscrewing the studs (2, Fig . 20) and

loosening the worm wheel shaft collar set scre ws.

To install, reverse the order of these operations .

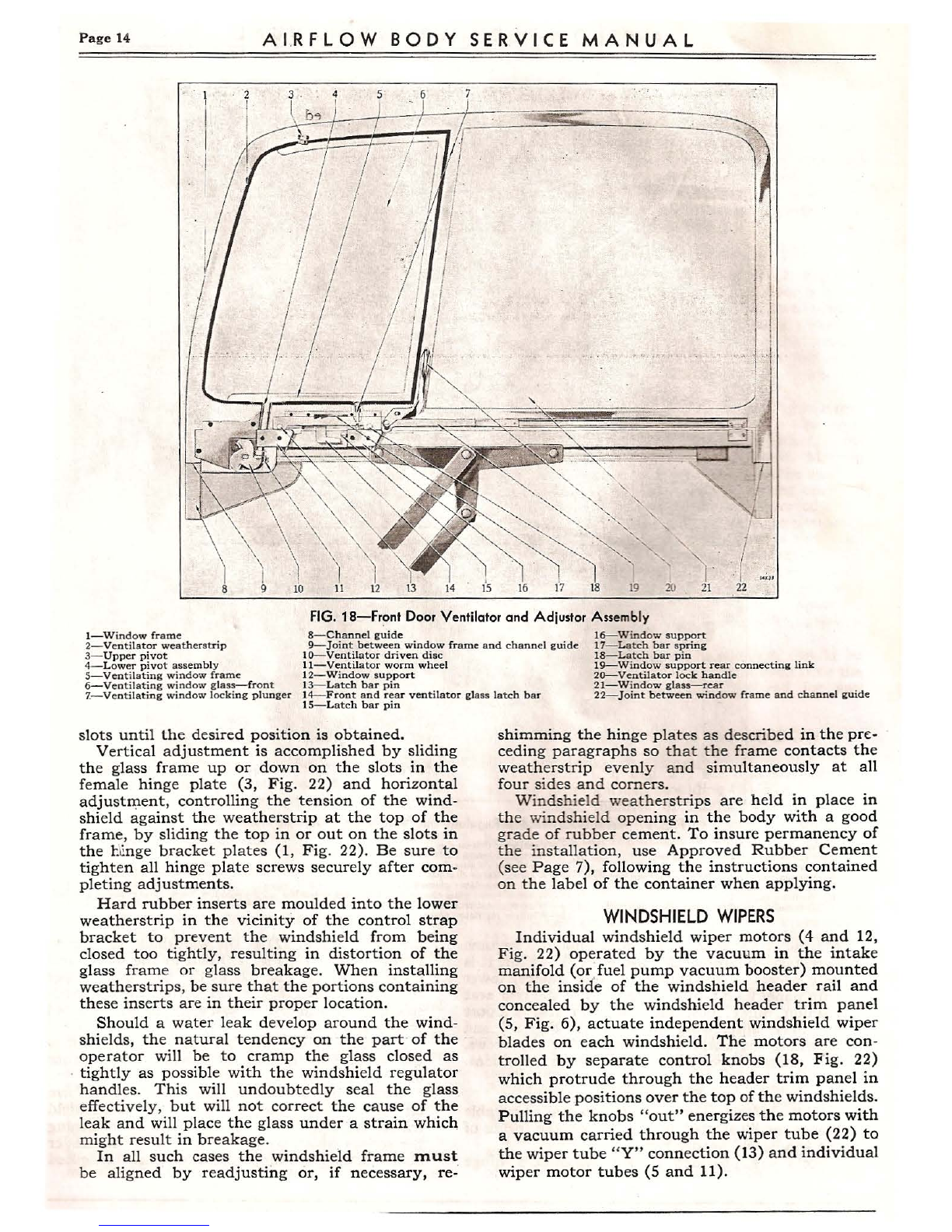

WINDSHIELD

The windshields are mounted on tw o adjus tabl e

hinges, as illustrated in Fig. 22, on th e inside of

the windshield header bar .

Slots are pro vided in th e windsh ield hinge

brac ket s (1, Fig . 22) at the windshield bracket to

header screws (9, Fig. 22) and in the windshield

hinge- female (3, Fig. 22) at the windshield hinge

to bracket screws (8, Fig. 22), permitting the wind-

shield glass and frame assembly to be adjusted

to any position.

A sponge rubber weatherstrip is cemented into

th e windshield opening to prevent the entrance

of water or dust into the car interior.

Tension on this weatherstrip should be uniform

on all four sides and corners of the windshield

frame. Adjustment is accomplished by loosening

the screws which secure the hinges to the header

board, sliding the hinge plates on their elongated

Page 14 A I.R F L O W BO D Y SERV IC E M A N U A L

5 6 7

'.,.

8 9 11 12

I

1· (,.;,,

21 22

FIG. 18-Front Door Ventilator and Adjustor Assembly

1-Window frame 8-Chann el guide

2-Ventila tor weatherstrip

3-Upp er piv ot 9-Joint between window frame and cha nn el guide

10- Ventilator driven disc

16-- Window support

17- Latch bar sp ring

18-L atch bar pin

11- Ventilator worm wheel

12-Wind ow su pport

13- Latch bar pin

19-W indow support rear con nectinii link

20-Ventilator lock handle

21-Window glass- rear

4-Low er pivot assemb ly

5-Venti latin g window frame

6-Vent ila ting window glass- front

1-Ventilating window locki ng plunger 14- Front and rear ventilator glass lat ch bar

15-Latch bar pin 22-Joint between window frame and channel guide

slots until the desired position is obtained.

Vertical adjustment is accomplished by sliding

the glass frame up or down on the slots in the

femal e hing e plat e (3, Fig. 22) and horizontal

adjustment, controlling the tension of the wind-

shield against the weatherstrip at the top of the

frame, by sliding the top in or out on the slots in

the l:foge bracket plates (1, Fig. 22). Be sure to

tighten all hinge plate screws securely after com-

pleting adjustments.

Hard rubber inserts are moulded into the lower

weatherstrip in the vicinity of the control strap

bracket to prevent the windshield from being

closed too tightly, resulting in distortion of the

glass fram e or glass breakage. When installing

weatherstrips, be sure that the portions containing

these inserts are in their proper locati on.

Should a water leak develop around the wind-

shields, the na tural tend ency on the part of the

operator will be to cramp th e glass closed as

tightly as possible with the windshield regulator

hand les. This will undoubt edly seal the glass

effectively, but will not correct the cause of the

leak and will place the glass under a strain which

might result in breakage.

In all such cases the windshield frame must

be aligned by readjusting or, if necessary, re-

shimming the hinge plat es as described in the pre-

ceding paragraphs so that the frame contacts the

weatherstrip evenly and simultaneously at all

four sides and comers .

Windshie ld weather strips are held in place in

the windshie ld opening in the body with a good

grade of rubber cement. To insure permanency of

the installation , use Approved Rubber Cement

(see Page 7), following the instructions contained

on the label of the container when applying.

WINDSHIELDWIPERS

Individual windshield wiper motors (4 and 12,

Fig. 22) operated by the vacuum in the intake

manifold (or,fuel pump vacuum booster) mounted

on the inside of the windshield header rail and

concealed by the windshield header trim panel

(S, Fig. 6), actuate independent windshield wiper

blades on each windshield. The motors are con-

trolled by separate control knobs (18, Fi g. 22)

which protrude through the header trim panel in

accessible positions over the top of the windshields.

Pulling the knobs "out" energizes the motors with

a vacuum carried through th e wiper tube (22) to

the wiper tube "Y" connection (13) and individual

wiper motor tubes (5 and 11).

AIRFLOW BODY SERVICE MANUAL Page 15

FIG. 19-Door Ven tilcrtor Control

1-Ventiiator adjuster handle

2-Ventilator adjuster handle set scre w

3-Ventilator window operating shaft

4- Ventilator driving disc

5-Ventilator adjuster driven disc

6-Ventilator worm gear

7-Ventilator worm wheel

8-Ventilating window lower pivot

9-Ven t ilating window lower pivot base

Windshield wiper motors req uire but \·e:·y :ittl e

attention other than a periodic lubrication to

maintain the original speed of opera tion. Lub ri-

cation may be accomplished without removin g

the motors from the header by disconn ecting th e

tubes (S and 11) from the nipp les on th e moto rs,

attaching a short piece of tub ing in their st ead,

immersing the open end in a cup of very fine

vegetable machine oil, or, preferably " Windshie ld

Wiper Motor Oil." (Do not use a mineral oil or

immediate deterioration of th e motor pistons will

result). With the tube submerged in the lubricant,

manually operate the windshield wiper blade from

side to side until the oil is drawn up into the motor.

Taking the tube out of the oil, again move the

blade back and forth until all oil is expelled out of

the motor. Remove the lubricant tube and connect

motor to vacuum tubes (5 and 11, Fig. 22).

The windshield wiper motors may be exposed

by removing header trim panel (see Page 9).

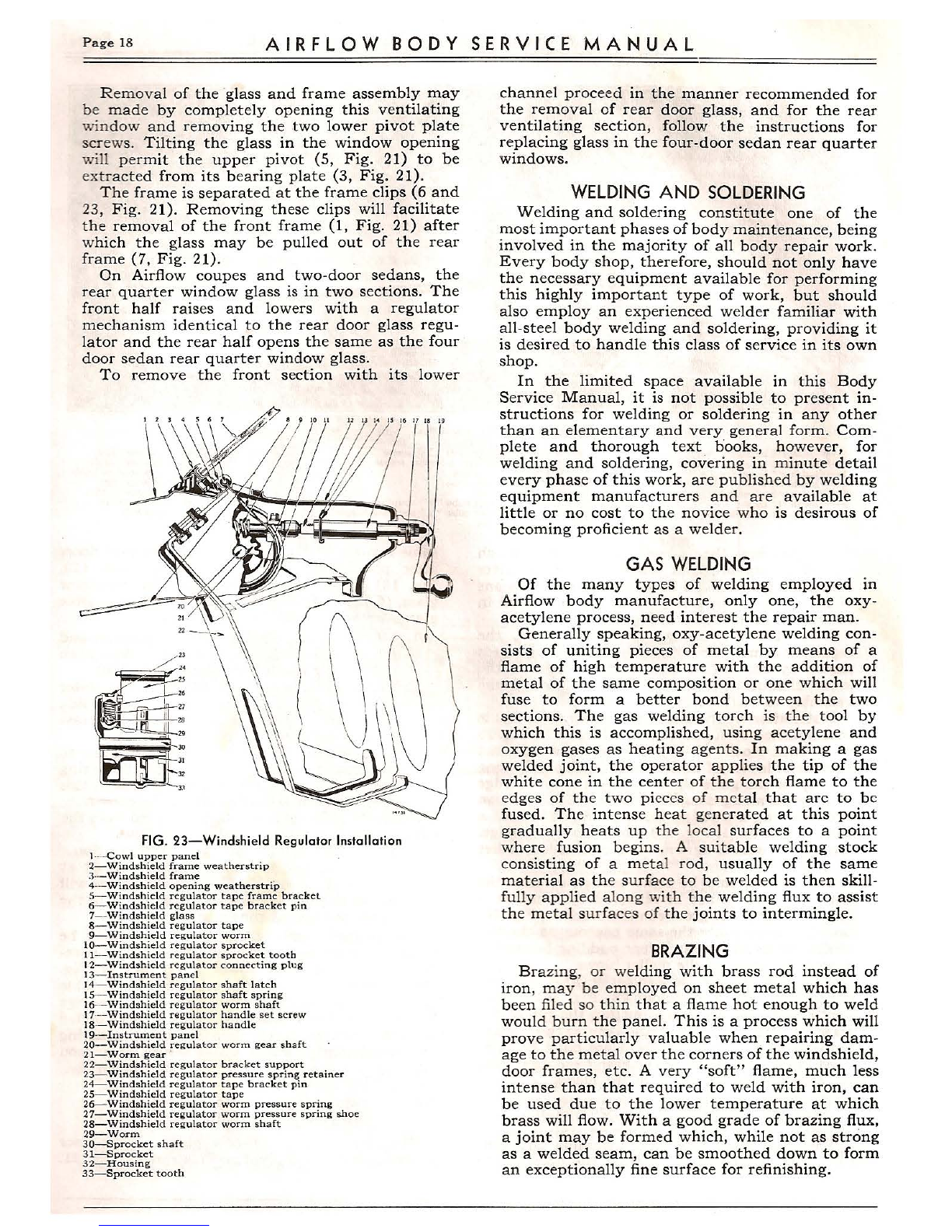

WINDSHIELD CONTROLS

Each windshield on the Airflow body is con -

trolled by an independent operating crank, or

handle (17 and 20, Fig. 22, and 18, Fig. 23),

mounted on the instrument panel. Turning the

regulator handle operates a drum-like sprocket

(10, Fig. 23) the teeth (11, Fig. 23) of which engage

with holes cut in the windshield regulator tape

(16 and 19, Fig. 22, and 8, Fig. 23). This tape, the

free-end of which is secured to the base of the

windshi eld frame by means of a yoke, or bracket

(5, Fig . 23), and pin (6, Fig. 23) is curved in cross-

section. This curvature imparts ample strength

to the tape to force the windshield open.

The windshield control assemblies are bolted to

brackets welded to the back of the instrument

panel and may be removed readily by discon-

necting the tape at the point where it is secured to

the windshield frame and removing the two cap

screws by which it is mounte cr on the bracket .

Removal of the speedometer head from the

instrument panel will, on certain body types,

greatly facilitate replacement of the control as-

sembly by permitting the cap screws on one side

to be removed through the speedometer head

cut-out in the panel.

Each regulator handle is provided with ser-

rations which mesh with like serrations on the

end of the regulator worm shaft (16, Fig. 23).

A set screw (17, Fig. 23) permits the handle to

be removed and adjusted to any angle when the

windshields are closed so as to not obstruct .the

operator's vision of the instruments or road.

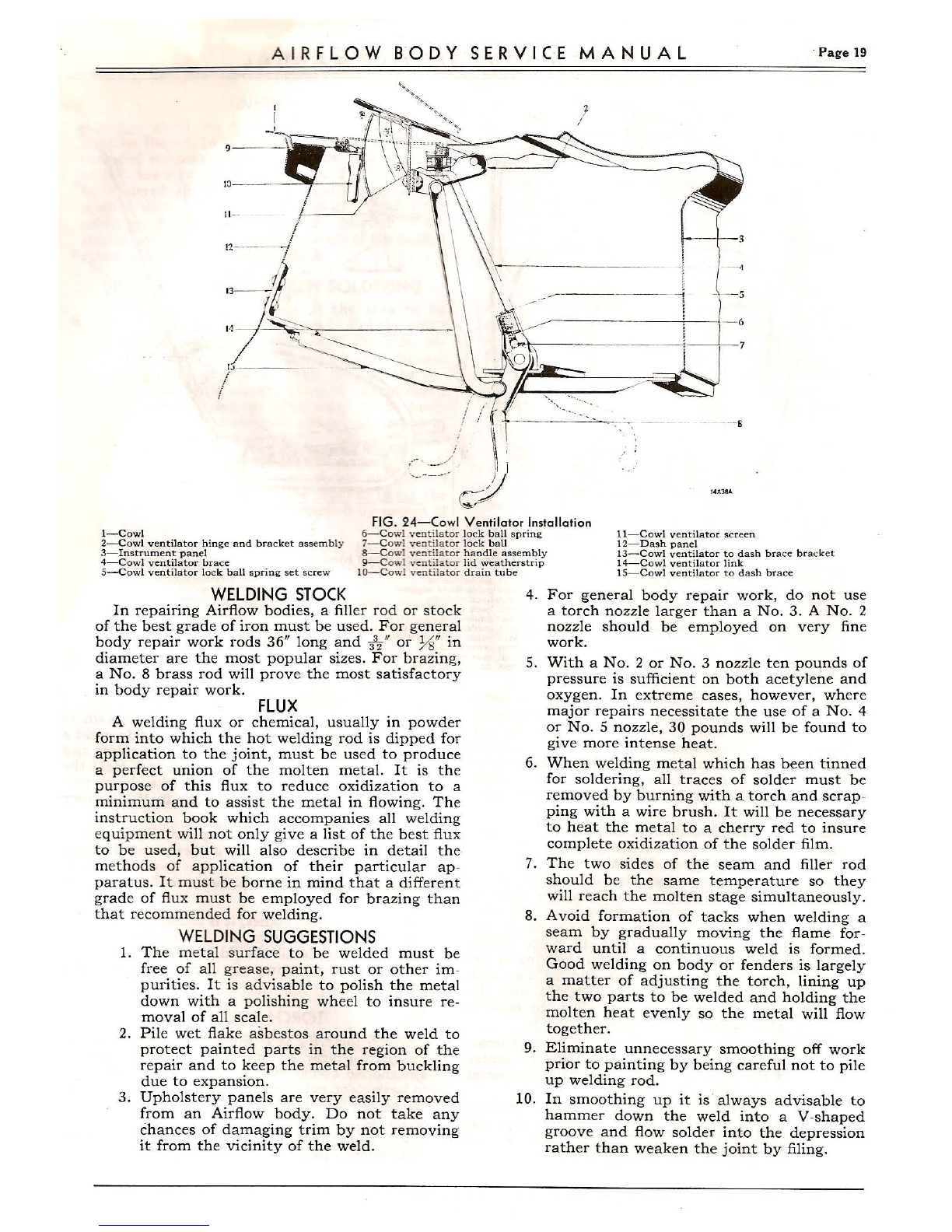

COWL VENTILATORS

Cowl ventilators are fitted into the body cowl

on each side of the center line of the windshield

with independent control handles (8, Fig. 24)

extending back into the driver's compartment in

an accessible position below the edge of the instru-

ment panel (3, Fig. 24). These ventilators control

the circulation of air around the toe and floor-

boards, dissipating any excess heat which might

accumulate at this point . The ventilator door is

adjustable to two open positions, as indicated in

Fig. 24, the lock ball (7) seating in the grooves in

the top of the handle to hold it in the desired

position.

Each ventilating opening is fitted with a fine

wire mesh screen (11, Fig. 24) to filter foreign

particles, such as insects, etc., out of the air. When

FIG. 20-Removing Rear Ouarter Ventilating Window Adjustor

1-Quarter ventil ating window adjuster

2-Quarter ventilating wind ow adjustor studs

AIRFLOW BODY SERVICE MANUAL

~~:i::::. g :nextremely dusty localities or driving

:..::..-;::,::.s=. !:errito ries infested with flying insects ,

::.::_=s:=-sc:-eens should be thoroughly cleaned to

=-~-=-=-=:;i:-oper unobstructed air circulation.

:J:-a::..:::tro ughs, on the inside of the channel in

=~the sponge rubber weather strip seats

; _? :g. 24) are fitted with drain tubes (10, Fig. 24)

:::; ~=-o·,"lde an adequate safeguard against water

~:e7:.:i g the car interior under the most extreme

-·=- ,,,tic conditions.

:' ne dr ain troughs must be kept clean and the

::...-a:.ntubes (10, Fig. 24) free from kinks or

;:;::i:s:::-uctio ns.

7/a ter leakage around the ventilator is caused

::: :;i:-acti cally every instance by improper adjust -

==.e::t of the ventilator door on the weatherstrip

; . F :g. 24).

9,'

\

10

\

\

2

'\ 3 4

SEATREGULATORS

The front seat frame is adjustable for position

in relation to the s~ ering wheel and control pedals.

The seat cushion and back slide, as an assembly ,

on rollers (4 and 17, Fig. 25) in guides (15, 18

and 28, Fig. 25) and is locked in the desired posi -

tion by front seat lock (24, Fig. 25) meshing with

the teeth in the front seat lock retainer, or plate

(21, Fig. 25). Front seat lock spring (22 and 27)

holds the lock in engagement with the retainer

unless manually released by raising lock handle

(23 and 25).

The front seat guide compensating spring (16)

acts as an aid to the operator when moving the

seat forward on its guides.

A front seat guide tie rod (20) having a guide

gear (7) riveted to each end which mesh with the

)

/

/ /

FIG. 21-Rear Quarter Ventilating Window

1- Quarter ventilating window frame-front

2-Quarter ventilating window weatherstrip

3-Quarter ventilating window upper pivot plate

4-Quarter ventilating :window upper-pivot plate screw

5-Quarter ventilating window upper pivot

6-Quarter ventilat ing{window frame clip-upper

7-Quarter ventilating windowJrame-rear ·

8-Quarter ventilating ·window glass

9-Quarter ventilating window ·weatherstrip assembly

I a-Quarter ventilat ing~window lower pivot

11-Adjustor worm wheel collar

12-Adjustor handle shaft suppor _t

To align the door so that it will contact the

.....-eath erstrip evenly and simultaneously, as it is

:o-;,,·ered , at all four sides and corners, loosen the

;;cew s which secure the cover to the cowl venti-

:c.:o:- hinge and bracket assembly (2, Fig. 24) and

:::'.': ventil ator door on its slotted mountings until

::: ::ouche s the weatherstrip at all points evenly,

_;__:°:e:- which the screws must be tightened without

::.:_s::ar bing the position of the cover.

T::ie sponge rubber weatherstrip (9, Fig. 24) is

~ ::::.e:::ited to the channel around the ventilator

=9e::.:.:1g. When reinstalling or replacing these

- ~:.:.,ers tri ps, use Approved Rubber Cement, as

==.:::::-.::o::1ed on Page 7, to ensure a perfect bond

.:i.~een th e strip and metal channel.

13-A dj ustor handle set screw

14-Quarter window garnish mouldi;-ig

15- Adjustor worm wheel

16-Adjustor worm shaft pressure pl u g

17-Adjustor housing

18- Adjustor worm shaft pressure plu g

19- Adjustor handle

20-Adjust or worm wheel shaft

21-Adjustor worm wheel

22-Quarter ventilating window lower pivot shaft

23-Quarter ventilating window frame clip-lower

slots in the front seat guide gear racks (6), keeps

the front seat in perfect alignment at all times .

REPLACEMENTOF GLASS

IN REARDOORS

The lower ends of the window runways are held in

place by snap fasteners, the upper portion where it

follows the contour of the window frame by metal

screws and the garnish moulding. The runway

may be readily removed by extracting these metal

screws, removing the garnish mouldings, garnish

moulding supports and lifting upward, at the same

time tilting the top towards the inside of the door.

Rear door glass (and rear quarter window glass

which may be rais~d or lowered) is removed by

A I R FiL O W B O D Y SE RV I C E M A N U A L Page 17

FIG. 22-Complete Windshield Installation, with Trim Panels Removed

1-Windshield hinge bracke t

2-Windshield hinge male outer

3- Windsh ield hinge female

4-Windshield wiper

5-Windshield wiper tube

6- Windshield glass

7-Windshicld side channel

8-Wi ndsh ield hinge to bracket screw 16- Windshield regulator tape

17- Windshield regulator handle

18-Windshield wiper control knob

19-Windshield regulator tape

20-Windshield regulator handle

21-Windshield wiper bracket

22-Windshield wiper tube

J 9-Windsh icld bracket to header screw

IO-Win dshi eld hi nge pin

11- Win d sh icld w ipe r tube

12-Win d shi eld wi per

13- Win d sh ield wipe r tub e "Y" coupling

14-W ind shield wipe r tube "Y" coupling nipple

15-W ind shicl d glass

first removing the garnish mo ulding , garnish

moulding support and window run ways after

which the glass should be slowly raise d by means

of the regulator handle (7, Fig. 16) and tilted in

at the top, as indicated in Fig. 16.

When the window is completely raised , the

regulator arms (11 and 12, Fig. 16) will meet, as

shown by the dotted lines in the center of the

lower channel, permitting the glass and frame

assembly to be lifted out of the door.

Installation of the glass in the lower channel is

accomplished by supporting the channel (6, Fig. 26

on wooden blocks (7, Fig. 26), laying a sufficient

number of layers of anti-squeak (5, Fig. 26) along

the top of the glass channel. Lay the lower edge

of the glass along the groove in its proper position

and applying a wooden block (3, Fig. 26) with a

padded groove (1, Fig. 26) along the upper edge,

tap lightl y with a lignum vitae or wooden mallet

(2, Fig. 26).

The glass should be tight enough so that the

lower channel cannot be removed by hand. It is

important tha t the groove in the block (3, Fig . 26)

be of approxima tely the same contour as the top

of the glass, and that sufficient padding be used to

absorb the shock of the mallet blows.

It is also possible to drive the glass into the

channel by laying the block (3, Fig. 26) on the

bench with the groove up, putting the top of the

glass into the padded slot and driving the channel

onto the glass with a ~allet. Car e must be exer-

cised, however, in doing so to keep from damaging

the channel with the force of the blows.

REPLACEMENT OF GLASS

IN FRONT DOORS

The door glass assembly, including the ven-

tilator, should be removed from the door in the

same manner as the glass assembly for rear doors

after placing the ventilator locking lever (20,

Fig. 18) in a horizontal position. The ventilator

glass, (6,) is removed from the complete double

glass assembly, as follows:

1. Move locking lever to vertical position and

rotate ventilator glass to the wide open

position by turning the driven disc (10).

2. Remove two screws which attach the lower

pivot (9, Fig. 19), and spring the outside

glass frame slightly so as to release the glass

frame from the pivot plate.

3. Slide the glass frame off the glass, using care to

not break the frame at the corner~. Springing

the vertical portion of the frame aids in this

operation and relieve strain at the corners.

The large glass (21, Fig. 18) is removed from the

comp lete double glass assembly, as follows:

1. Move the locking lever to vertical position.

2.~ ull the upper an d lo-Ner channels apart at

t:he, joints , 9 and 22, Fig. 18). The glass will

follow the lower cha nnel and slide out of the

upper section, as shown tn Fig. 17.

The rubbe r weather st rip (2, Fig. 18) may be

removed, after the ventila t or glass has been re-

moved, by pressing the lower pivot shaft (4, Fig .

18) out of the gear (11, Fig. 1~). Use of a suitable

gear puller on this opera t ion will avoid damage

to th e parts. The weathers trip may then be pulled

out of the window frame channe l. When installing

this weatherstrip, soapy wat er serves as a good

lubricant for the rubber and fa cilitates assembly.

'I,

REPLACEMENTOF GLASSIN

REARQUARTERWINDOWS

The rear quarter window glass in four-door

sedans operates on a pivot, as illustrated in Fig. 21.

Page 18 AIRFLOW BODY SERVICE MANUAL

Remova l of the ·glass and frame assembly may

be made by completely opening this ventilating

windo w and removing the two lower pivot plate

screws. Tilting the glass in the window opening

will permit the upper pivot (5, Fig . 21) to be

extracted from its bearing plate (3, Fig . 21) .

The frame is separated at the frame clips (6 and

23, Fig. 21). Removing these clips will facilitate

the removal of the front frame (1, Fig. 21) after

which the glass may be pulled out of the rear

frame (7, Fig. 21).

On Airflow coupes and two-door sedans, the

rear quarter window glass is in two sections. The

front half raises and lowers with a regulator

mechanism identical to the rear door glass regu-

lator and the rear half opens the same as the four

door sedan rear quarter window glass.

To remove the front section with its lower

FIG. 23-Windshield Regulator Installation

1-- -Cowl upper panel

2-W:indshield frame weatherstrip

3-- Windshield frame

4-Windshield opening weatherstrip

5-Windshield regulator tape frame bracket

6-Windshield regulat or tape bracket pin

7--Windshield glass

8- Windshield regulator t ape

9-Windshield regulator worm

10- Windshield regulator sprocket

I I-Windshield regulator sprocket tooth

12-Windshield regulator connecting plug

13-lnstrument panel

14-Windshield regulator shaft latch

15--Windshield regulator shaft spring

16- Windshield regulator worm shaft

17-- Windshield rogulator hand le set screw

18-Windshield regulator handle

19- Instrument panel

20- Windshiel d regulator worm gear shaft

21- Worm gear ·

22-Windshield regulator bracket support

23-Windshie ld regulator pressure spr ing retainer

24-Windshield regulator tape bracket pin

25-Windshield regulator tape

26-Windshield regulator worm pressure spring

27- Windshield regulator worm pressure spring shoe

28-Windshield regulator worm shaft

29-Worm

30---Sprocket shaft

31- Sprocket

32-Housing

33-Sprocket tooth

channel proceed in the manner recommended for

the removal of rear door glass, and for the rear

ventilating section, follow the instructions for

replacing glass in the four-door sedan rear quarter

windows.

WELDINGAND SOLDERING

Welding and soldering constitute one of the

most important phases of body maintenance, being

involved in the majority of all body repair work.

Every body shop, therefore, should not only have

the necessary equipment available for performing

this highly important type of work, but should

also employ an experienced welder familiar with

all-steel body welding and soldering, providing it

is desired to handle this class of service in its own

shop .

In the limited space available in this Body

Service Manual, it is not possible to present in-

structions for welding or soldering in any other

than an elementary and very general form. Com-

plete and thorough text books, however, for

welding and soldering, covering in minute detail

every phase of this work, are published by welding

equipment manufacturers and are available at

little or no cost to the novice who is desirous of

becoming proficient as a welder.

GAS WELDING

Of the many types of welding employed in

Airflow body manufacture, only one, the oxy-

acetylene process, need interest the repair man.

Generally speaking, oxy -acetylene welding con-

sists of uniting pieces of metal by means of a

flame of high temperature with the addition of

metal of the same composition or one which will

fuse to form a better bond between the two

sections. The gas welding torch is the tool by

which this is accomplished, using acetylene and

oxygen gases as heating agents. In making a gas

welded joint, the operator applies the tip of the

white cone in the center of the torch flame to the

edges of the two pieces of metal that arc to be

fused . The intense heat generated at this point

gradually heats up th e local surfaces to a point

where fusion begins. A suitable welding stock

consisting of a meta l rod, usually of the same

material as the surfac e to be welded is then skill-

fully applied along with the welding flux to assist

the metal surfac es of the joints to intermingle.

BRAZING

Braz ing, or welding with brass rod instead of

iron, ma y be employed on sheet metal which has

been filed so thin that a flame hot enough to weld

would burn the panel. This is a process which will

prove particularly valuable when repairing dam-

age to the metal over the corners of the windshield,

door frames, etc. A very "soft" flame, much less

intense than that required to weld with iron, can

be used due to the lower temperature at which

brass will flow. With a good grade of brazing flux,

a joint may be formed which, while not as strong

as a welded seam, can be smoothed down to form

an exceptionally fine surface for refinishing.

A IR FLOW 8 0 DY SERVI CE MANUAL · Page 19

II -

'-···- -··

-3

~--------J J=:

~ - ---- 1----!I :

-- -- ~.- - - ---·-. ··- - ---s

1-Cowl FIG. 24-Cowl Ventilator Installation

6-C owl ventilator lock ball spring 11- Cowl ventilator scr een

12- Dash panel7-C owl venti lato r lock ball2-Cowl ventilator hinge and bra cket assemb ly

3- lnstrument panel

4-Cowl ventilator brac e

5-Cowl ventilator lock ball spring set screw

8-Cowl ventilat or handle assembl y

9-C owl ventilator lid weatherstrip

IO-C owl ventil ato r d rain tube

13- Cowl vent ilat or t o dash bra ce bra cket

14- Cowl ventilator link

15-Cowl ventilat or to d ash brace

WELDINGSTOCK

In repairing Airflow bodies, a filler rod or stock

of the best grade of iron must be used. For general

body repair work rods 36" long and 3\" or ½" in

diameter are the most popular sizes. For brazing,

a No. 8 brass rod will prove the most satisfacto ry

in body repair work. FLUX

A welding flux or chemical, usually in powder

form into which the hot welding rod is dipp ed for

application to th e joint, must be used to produce

a perfect union of the molten metal. It is the

purpose of this flux to reduce oxidization to a

minimum and to assist th e metal in flowing. The

instruction book which accompanies all welding

equipm ent will not only give a list of the best flux

to be used, but will also describe in detail the

method s of application of their particular ap -

paratus. It must be borne in mind that a different

grade of flux must be employ ed for brazing than

that recomm ended for welding.

WELDINGSUGGESTIONS

1. The meta l surface to be welded must be

free of all greas e, paint, rust or other im -

purities . It is advisable to polish the metal

down with a polish ing wheel to insure re-

moval of all scale.

2. Pile wet flake asbe stos around the weld to

protect paint ed parts in the region of th e

repair and to keep the meta l from bucklin g

due to expansion.

3. Upholstery panels are very easily removed

from an Airflow body. Do not tak e any

chances of damaging trim by not removing

it from the vicinity of the weld.

4. For general body repair work, do not use

a torch nozzle larger than a No. 3. A No. 2

nozzle should be employed on very fine

work.

5. With a No. 2 or No. 3 nozzle ten pounds of

pressure is sufficient on both acetylene and

oxygen. In extreme cases, however, where

major repairs necessitate the use of a No. 4

or No. 5 nozzle, 30 pounds will be found to

give more intense heat.

6. When welding metal which has been tinned

for soldering, all traces of solder must be

removed by burning with a torch and scrap -

ping with a wire brush. It will be necessary

to heat the metal to a cherry red to insure

complete oxidization of the solder film.

7. The two sides of the seam and filler rod

shou ld be the same temperature so they

will reach the molten stage simultaneously.

8. Avoid formation of tacks when welding a

seam by gradually moving the flame for -

ward until a continuous weld is formed .

Good welding on body or fenders is largely

a matter of adjusting the torch, lining up

the two parts to be welded and holding the

molten heat evenly so the metal will flow

together .

9. Eliminat e unnecessary smoothing off work

prior to painting by being careful not to pile

up welding rod.

10. In smoothing up it is always advisable to

hammer down the weld into a V-shaped

groove and flow solder into the depression

rather than weaken the joint by filing.

Pa.ge 20 AIRFLOW BODY SERVICE MANUAL

2 :3 4 G 7 8 13

I \ I /

Z? /

I \

I

I

I

/

FIG. 25- FrontSeat Frame and Adjustment Mechan ism

I-Front seat cushion sup port assembly

2- F ront seat frame

3- Front seat support rear

4--Fro nt seat gu ide roller assembly

11-Fron t seat guide-low er

12- Front sea t guide front support

13- Fro nt seat back cushion

21- ? = =t Joe.kin g reta iner

22- F==: seat lock spring

23- ? :=: 5eat lock handle

2-<- ? =. : seat lock

5 -Front seat guide te e rod assembl y

6 - Front seat guide gear rack assem bly

7- Fro nt seat gui de gear

· 14-Fr ont seat back frame

15- Front seat guide-u p per

16-Front seat guide compensating spring

17- Front seat guide roller assembly

18- Front seat lower guide