3- ENG D24152

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN SERIOUS

INJURY AND PROPERTY DAMAGE. READ AND UNDERSTAND ALL WARNINGS AND OPERAT-

ING INSTRUCTIONS BEFORE USING THIS EQUIPMENT.WHEN USING AIR TOOLS, BASIC

SAFETY PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO REDUCE THE RISK OF

PERSONAL INJURY.

SAVE! IMPORTANT SAFETY INSTRUCTIONS SAVE!

HAZARD WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF EYE OR HEAD

INJURY

• Air powered equipment and

power tools are capable of

propelling materials such as

metal chips, saw dust, and

other debris at high speed,

which could result in serious

eye injury.

• Compressed air can be haz-

ardous. The air stream can

cause injury to soft tissue areas

such as eyes, ears, etc.

Particles or objects propelled

by the stream can cause injury.

• Tool attachments can be come

loose or break and fly apart

propelling particles at the

operator and others in the work

area.

• Always wear ANSI approved

Z87.1 safety glasses with side

shields.

• Never leave operating tool

unattended. Disconnect air

hose when tool is not in use.

• For additional protection use

an approved face shield in

addition to safety glasses.

RISK OF FIRE OR

EXPLOSION • Abrasive tools such as sanders

and grinders, rotating tools

such as drills, and impact tools

such as wrenches, hammers,

and reciprocating saws are

capable of generating sparks

which could result in ignition of

flammable materials.

• Exceeding the maximum pres-

sure rating of tools or

accessories could cause an

explosion resulting in serious

injury.

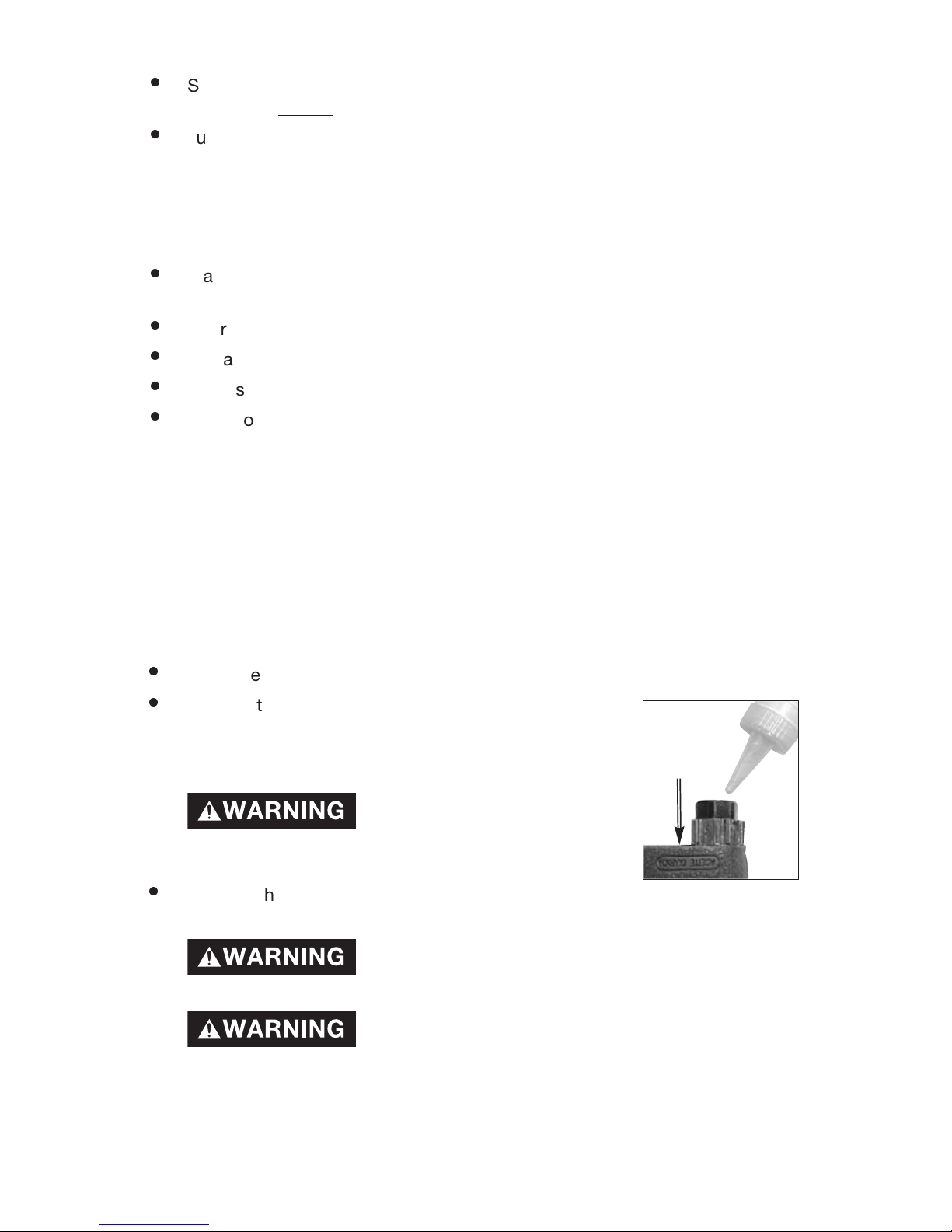

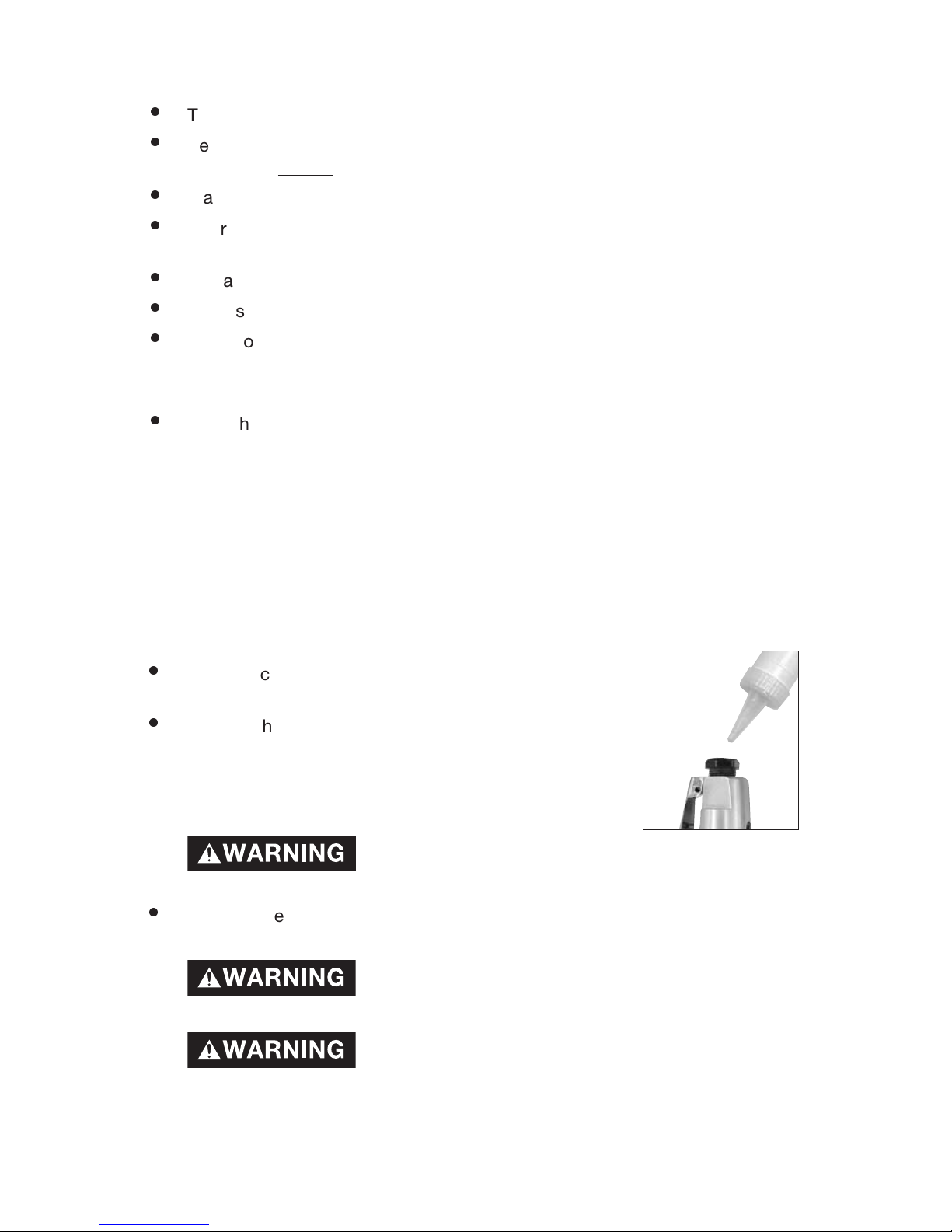

• Make sure that any attach-

ments are securely assembled.

• Never operate tools near

flammable substances such

as gasoline, naptha, cleaning

solvents, etc.

• Work in a clean, well ventilated

area free of combustible

materials.

• Never use oxygen, carbon

dioxide or other bottled gases

as a power source for air tools.

• Use compressed air regulated

to a maximum pressure at or

below the rated pressure of

any attachments.

RISK OF LOSS OF

HEARING • Long term exposure to noise

produced from the operation

of air tools can lead to

permanent hearing loss.

• Always wear ANSI S3.19

hearing protection.

RISK TO BREATHING

INHALATION HAZARD

• Abrasive tools, such as

grinders, sanders, and cut-off

tools generate dust and

abrasive materials which can

be harmful to human lungs and

respiratory system.

• Some materials such as

adhesives and tar, contain

chemicals whose vapors

could cause serious injury with

prolonged exposure.

• Always wear MSHA/NIOSH

approved, properly fitting face

mask or respirator when using

such tools.

• Always work in a clean, dry,

well ventilated area.