Digital Combo DK20S User manual

1

Digital Combo

Multi-Purpose press

2

Table of Contents .............................................................2

Introduction .....................................................................3

Setup & Suggestions ........................................................ 4

BasicUse ..........................................................................4

SettingTime .....................................................................4

Setting Temperature ......................................................... 5

Setting Height / Pressure ..................................................6

Guidelines & Standard Settings .......................................7

Removing a heat platen....................................................8

InterchangeableHeat Platens............................................8

Attaching a heat platen ..................................................... 9

Aligning the pedestal...................................................... 10

Cap Holddown Device ................................................... 10

(included with cap attachment only)................................................................................................... 10

Interchangeable Tables................................................... 10

Programmable Presets.................................................... 11

User Options Menu ........................................................ 12

Fahrenheit / Celsius........................................................ 12

Timer Counter................................................................ 12

Recorded Pressings ........................................................ 12

Pressure / Height Gauge Calibration .............................. 13

Height Gauge - High Point ............................................. 13

Height Gauge - Low Point.............................................. 13

Pressure / Height Gauge Sensitivity ............................... 14

Drop Sense..................................................................... 14

Beep ............................................................................... 15

Alarms............................................................................ 15

Maintenance ................................................................... 16

Troubleshooting ............................................................. 17

Troubleshooting (cont.) ................................................. 18

LimitedWarranty............................................................ 19

Table of Contents

3

Introduction

CongratulationsonyourpurchaseoftheDigitalComboswinger!

This heat press machine has many exciting features, all of which are

meanttohelpmakeyourheat transfer pressing endeavorsassuccessful

and easy as possible. Please take the time now to thoroughly read

through this manual to become acquainted with them. It will explain

some key features, concepts and methods that will save much time

and effort in using this press and in your heat pressing applications.

Throughout this manual, many areas and components of this

machine will be referred to by specific names. Please refer to the

illustrations below in order to become familiar with some of the

terminology used in this manual.

Handle

Pressure Knob

Top Head

Power Inlet

Clamp / Linkage

Heat Platen

Stop Collar

Height Sensor

Lower Table

Silicone Pad

Pedestal

Cap Holddown

Gibb Plates

Base

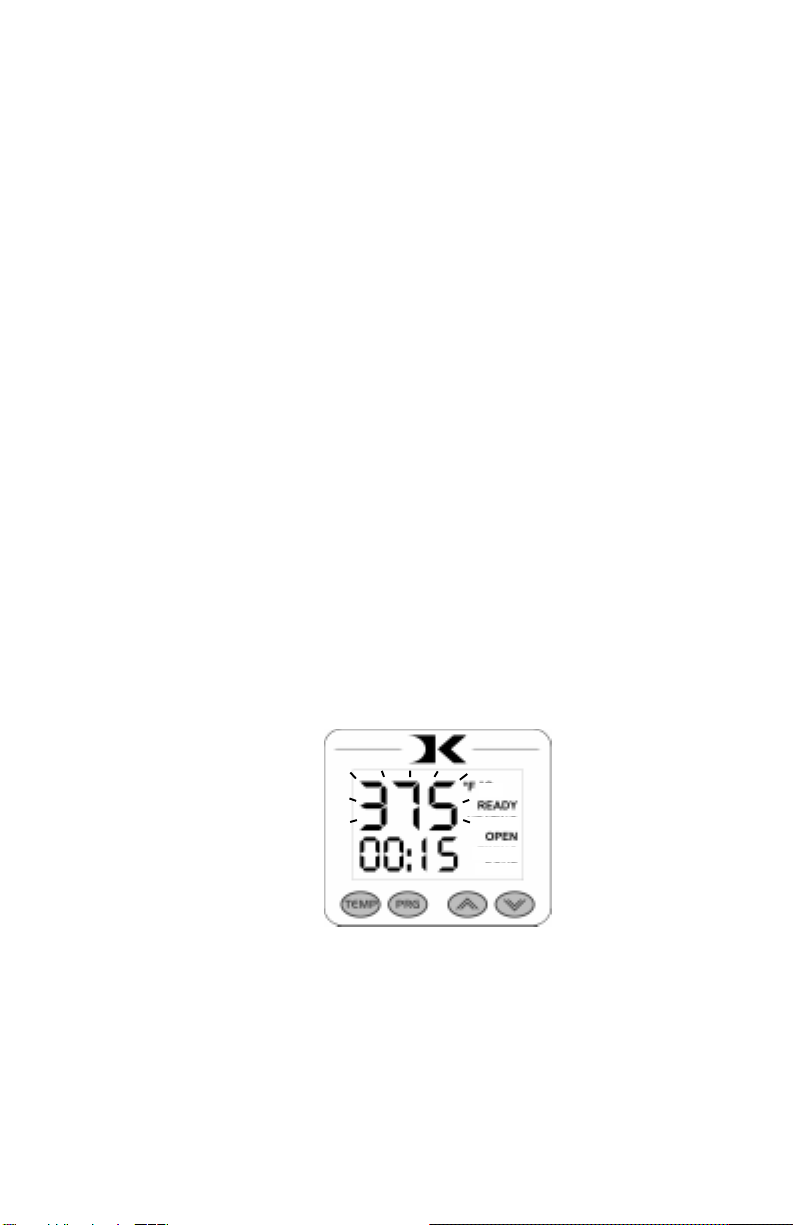

Temperature

°Far/°Cel Indicator

Ready Indicator

Heating Indicator

Open Indicator

Timing Indicator

Done Indicator

Time

TEMP Button

PRG Button

Up/Down Arrows

Default Operating Mode of Controller

4

Setup & Suggestions

• Locate the press on a firm, sturdy work surface.

• The height of the bench/work space the press is located on would be

ideally 27” to 32” high.

• Attach the power cord from the rear to the underside of the top head.

• There is a power inlet under the top head that the modular cord will

plug into.

• Make sure the cord does no interfere with the lower table pressing

area, or the height sensor.

• The press should remain in the unclamped position when not in use.

Do not leave the heater block closed on the table surface when hot if

not using.

• The top head should be swung over and above the pressing table when

not in use.

Basic Use

Setting Time

Thetime setting is always editable in the default operatingmode

of the controller. The left two digits of the time display are minutes.

The right two digits are seconds. This can be changed to Hours/

Minutes in the User Options Menu.

• Use the Up & Down arrow keys to change the time.

• Hold the Up or Down arrow key down to increment the values quickly.

After a brief pause, the values will accelerate.

• Press the Up & Down arrow keys together to clear the setting to 00:00

• When the press is closed, the timing cycle starts. The “TIMING”

indicator will appear.

• When the timing cycle is finished, the “DONE” indicator will appear.

• Dependingonthe timer alarmchosen, the alarmmay continue tosound

at the end of the timing cycle until the press is opened.

• When the press is opened up, the “OPEN” indicator will appear.

5

Setting Temperature

• The control will regulate the heat platen temperature based on the set

point temperature. When the temperature falls below the Set Point,

the “HEATING” indicator will appear.

• Whenthetemperature reachestheSet Point,the“HEATING” indicator

will disappear and the “READY” indicator will appear.

• If the Set Point temperature is set to a temperature below the Current

temperature, the press will wait to cool down to that Set Point. At that

time, neither the “READY” or “HEATING” indicators will appear.

In the default operating mode of the controller, the displayed

temperatureistheCurrenttemperature.Thisistheactualtemperature

of the heat platen surface. Please note that the operating range of the

controller is from 150°F to 550°F (65°C to 288°C). During the first

heat up cycle of the press, the controller will display 150°F (65°C)

until the heat platen temperature rises above that temperature.

The Set Point temperature is the temperature the operator sets

the press for. This is the value the press will regulate the Current

temperature based on. The set point temperature may be changed

whenever necessary:

• When in the default operating mode, press the TEMP button.

• The Current temperature will be replaced by the blinking Set Point

temperature.

• Use the Up & Down arrow keys to change the Set Point temperature.

• Hold the Up or Down arrow key down to increment the values quickly.

After a brief pause, the values will accelerate.

• Press the Up & Down arrow keys together to set the temperature to

350.

• Whenfinishedsetting thetemperature,press theTEMPbutton toreturn

to the default operating mode.

6

Setting Height / Pressure

The Digital Height/Pressure gauge is a helpful indicator of the

current height of the top head as the operator adjusts the pressure.

• To decrease the pressure, turn the

pressure knob to the left,

counterclockwise.

• The top head will rise away from

the lower table.

• To increase the pressure, turn the

pressure knob to the right,

clockwise.

• The top head will lower toward the

pressing table.

• If the pressure knob is turned

rapidly enough, the display will

change to the pressure gauge

display. The units of measure are

arelativescale from 0:00to 10:00,

with :02 increments.

• To view the current pressure display value without changing it, simply

pull the pin up on the pressure gauge device on the pack post and let

it drop back down. This will force the PRS display to appear.

The gauge displays a reference value based on the height of the

heat platen in relation to the lower table. The closer the heat platen is

to the substrate on the table, the heavier the pressure. The further

away, the lighter the pressure. The amount of actual force exerted

depends on the thickness of the item being pressed and the distance

from the heat platen to the table. The digital height/pressure gauge

simply shows a relative value from 0:00 to 10:00 in fine resolution

increments as to the current height of the platen.

This helps the user return to an exact pressure setting without

the need of multiple experimentations to find the proper pressure

setting. By simply changing the pressure until the correct value

appears, previous heights and pressure settings for different thickness

substrates can be quickly reset without error.

7

Guidelines & Standard Settings

The following information covers some basic guidelines for

pressing, as well as some generic parameters for basic heat transfer

applications.

• When pressing shirts, it is often recommended that the shirts be quickly

pressed for 2 seconds before transferring to remove wrinkles and water

content. Make sure the plate template (3 sided aluminum tray) is NOT on

the pressing table when pressing fabrics. Only the silicone pad should be

on the table.

• When pressing two sides of a garment, pull the garment over the table so

that the printed side drapes underneath the table. This will avoid reheating

previously transferred designs on opposite sides of garments. It will also

avoid any bleed-through of inks on lighter fabrics.

• Avoid laying collars, cuffs, zippers, and other bulky parts of garments on

the lower table, as these can adversely affect pressing conditions, and reduce

the life of the silicone pad.

• Always check that the transfer image is face down against the material, to

avoid sealing the image against the heat platen instead of the substrate.

• When pressing rigid substrates (plastics, metals, woods, etc.), be sure

that any protective films or laminates are removed before heating.

• When pressing tiles, and other hard inconsistent shaped materials with

beveled edges, it is often necessary to use a heat conductive pad. This heat

conductive mat is included with the Digital Combo and is only used for tile

and related surfaces, and requires an additional 35°F to be added to the

temperature. Woods, metals, and plastics usually do not require the heat

conductive rubber mat.

• When pressing plates, the plate template (3 sided aluminum tray) should

be fitted over the table to protect the silicone pad. The grey circular rubber

pad should be adhered to the center of the template to center and cushion

the plate. Use the largest green rubber circle on top of the transfer, and

press between 4-5 minutes at 435°F with firm pressure.

Always follow the transfer media suppliers instructions when pressing. The

information below is for general reference only, and may not be as accurate as the

instructions provided by the transfer media & imprintable substrate supplier.

• Hot Split Supplier Transfers 350-375°F, 8-10 secs

• Puff Transfers 350-375°, 5-7 secs (extra heavy pressure)

• Ink-Jet Transfer Papers 360°, 15-18 secs

• ColorCopy/Laser Transfer Papers 375°, 20-25 secs

• Sublimation Inks (Polyester Fabrics) 400°, 35 secs

• Sublimation Inks (Plastics) 400°, 1 min, 15 secs

• Sublimation Inks (Metals) 400°, 1 min

• Sublimation Inks (Woods) 400°, 1 min, 15 secs

• Sublimation Inks (Ceramics) 435°, 4-5 min

8

Interchangeable Heat Platens

The main feature that makes the Digital Combo so versatile is

theinterchangeability of the heat platens. Because the heat platensare

modular in their method of connection, one platen can be unplugged

and another plugged in, in its place. The mechanical connection to the

clamp is no more than a simple quick release pin.

The following instructions apply to the 14x16, 12x14, cap, plate

&mug heat platen attachments. All of them disconnect and connect in

thesamemanner.

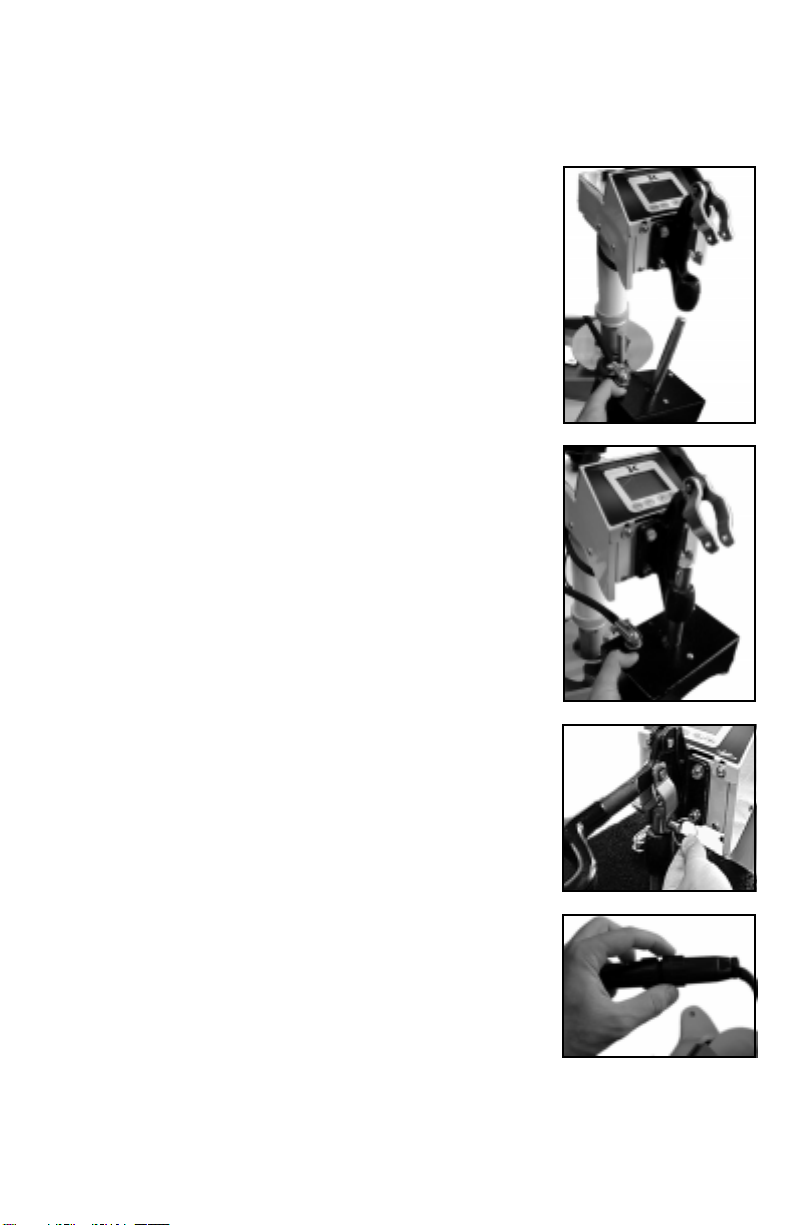

Removing a heat platen

• The heat platen can be safely disconnected

withthe machineon.However,thermalgloves

or oven mitts must be used when handling

hot heat platens.

• Unplug the modular connector (1st figure above).

This is done by unscrewing the safety lock

and pulling the connectors apart.

• Lowertheheat platensoit restsonthe bottom

table, and do not clamp it.

• Pulloutthequickrelease pinfrom thelinkage.

It is easiest to remove when there is no

pressureonthe side linksor on theheat platen

shaft.

• Once the quick release pin is removed, lift the

handle away, exposing the heat platen shaft

now disconnected from the linkage.

• Lift up on the heat platen slightly, enough to

swing it out away from the bottom table.

Lower the heat platen down and out of the

clamplinkage.

9

Attaching a heat platen

• The heat platen can be safely connected with

the machine on. However, thermal gloves or

oven mitts must be used when handling hot

heat platens.

• Lift the heat platen into the clamp linkage.

Make sure the rear guide fork holds onto the

guide pin in the back post of the frame. This

holds the heat platen in a straight position and

keeps it from rotating.

• Reattach the quick release pin through the

linkage and the heat platen shaft.

• Reconnect the modular connector. An Err

display might read on the controller if in the

Normal operating mode. If this is the case,

once the heat platen is reconnected, turn the

machine off and then on again.

10

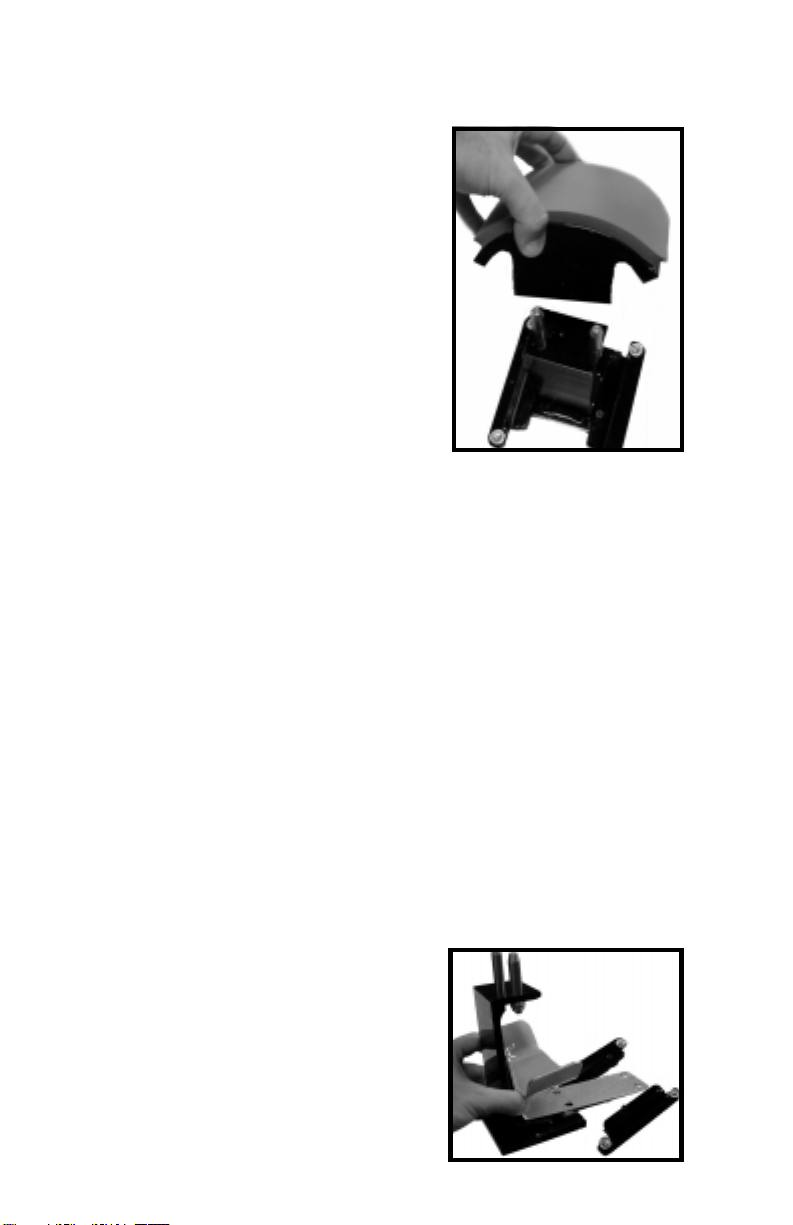

Interchangeable Tables

The lower table on the machine is

interchangeable. Different sized optional

tables can be obtained for various

materials & handling requirements.

The tables simply fit right onto the

pedestal.The 2 holes in the drop on tables

& curved forms fit onto the 2 steel pins

onthepedestal.Oftentimesit is beneficial

toleaveoneofthesteelpinsslightlyloose

to make changing out tables easier. This

will not effect evenness of pressing or

table stability.

Cap Holddown Device

(included with cap attachment only)

Aligning the pedestal

There is a 1/2-moon cap holddown

device for stretching the cap over the

curved bottom table.

Simply pull the back strap of the cap

behind the pedestal and under the 1/2-

moon shaped bracket. This will hold the

cap in place for proper printing.

The table can be easily adjusted in a straight position if the heat

platendoesnotcorrectlyline up withthepressingsurface.Thepedestal

the table rests on can slide front to back on the base of the machine.

Loosen the screw in the gibb plates that holds the pedestal in place in

order to adjust its position.

The pedestal can also be slightly rotated in order to align with

the upper platen. Loosen all (4) screws holding the gibb plates in

place, position/rotate the pedestal to the desired place, and retighten

the gibb plates.

11

Programmable Presets

This feature is ideal for recalling previously saved settings from

various different applications. The presets are extremely easy to use,

and bring a powerful level of accuracy to heat transfer pressing.

Forexample,theusermayhaveSetting00for Hot-Split T-Shirts.

Whentheuserneedsto perform thatparticularapplication,theysimply

select Setting 00, and the Current temperature & time parameters are

updated. A pressure reference is also displayed, telling the user what

pressure to set the press to. The user can then rotate the pressure

knob until the gauge displays the same value that was stored and

displayed by the preset.

This allows the user to quickly change from one application to

another with extreme accuracy. Over time, the user will save many

different settings in the presets based on the best results for every

application. When those presets are selected, the user is immediately

returned to the proper settings, without time consuming

experimentation and risk of unsuccessful applications.

•From the default operating mode, to select a

preset, press PRG.

• Use the Up & Down arrow keys to select a preset

(00 - 70).

• Press PRG to update the current settings and return

to the default operating mode.

• To edit or add a new preset, select the preset to be

added/updated.

• Press TEMP to cycle through Temperature, Time

& Pressure values.

• The editable value will flash indicating it may be

changed.

• Use the Up & Down arrow keys to change values.

Pressing Up & Down together when editing the

temperature value resets it to 350, and 00 for time.

• After setting the pressure value, pressing PRG

again will bring the user back to the preset

selection screen.

• The user may press PRG to update the current

settings and return to the default operating mode,

or select another preset for editing/adding.

12

User Options Menu

Theuser options menu is a set of features andcalibrationoptions

that are programmable and adjustable by the user. It consists of a set

of menu items that can be scrolled through. Each menu item is a

feature whose values can be viewed and /or changed. To enter the

user options menu:

• From the default operating mode, press the TEMP & PRG keys

simultaneously.

• If the keys are not pressed exactly at the same time, you may enter the

temperature edit mode, or the presets mode. Exit either of those modes

and try again.

• To cycle from one menu item to the next, press PRG.

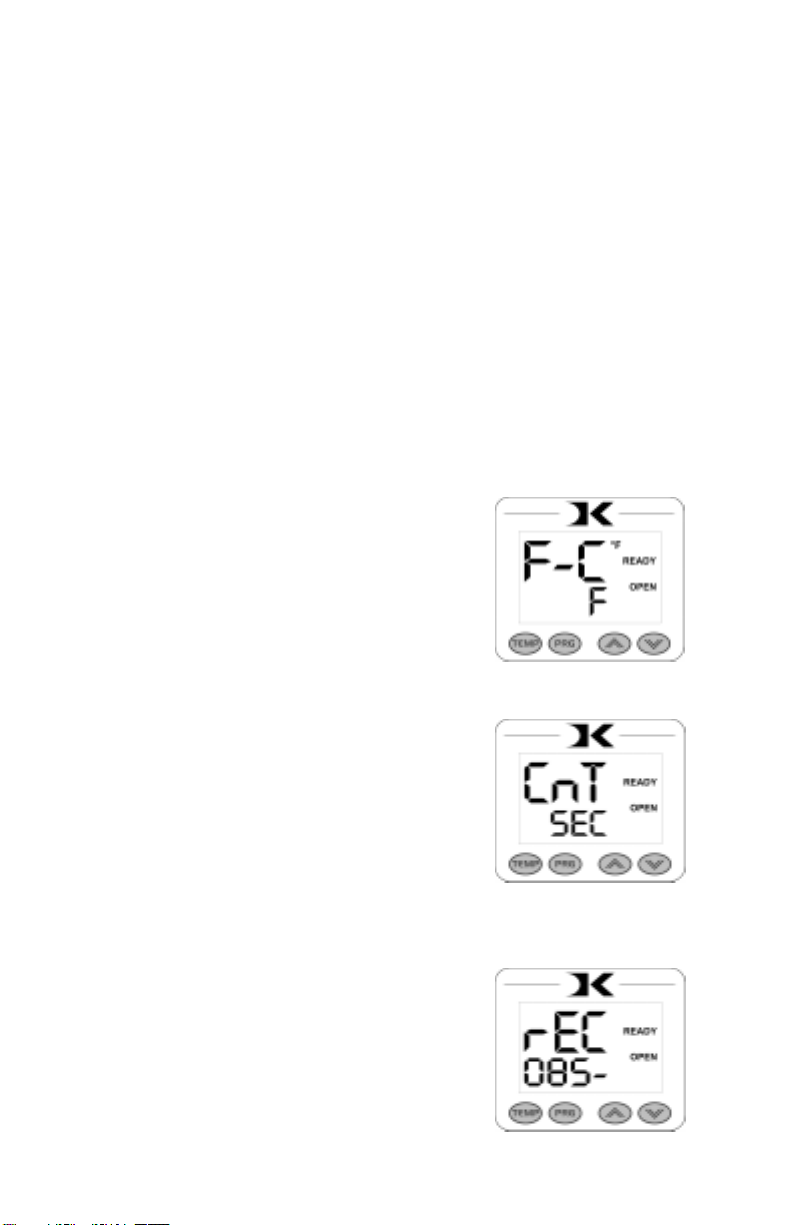

Fahrenheit / Celsius

The Current, Set Point, and Preset

temperature values can be displayed in

Fahrenheit or Celsius. To change the value to

F or C, use the arrow keys. Press PRG to move

tothenextmenuitem.

Timer Counter

The timer displays as factory default

Minutes:Seconds. This can be changed to

Hours:Minutes. To change to value to HR

(hours:mins)orMIN(mins:secs),usethe arrow

keys.PressPRGto move tothenextmenuitem.

Recorded Pressings

The digital control records the number of

pressing cycles completed. This can be very

helpful when counting the number of full

pressings that have been performed. The value

will scroll from left to right. A “-” sign will

separate the beginning and end of the number.

To reset the count to Zero, press an arrow key.

Press PRG to move to the next menu item.

13

Pressure / Height Gauge Calibration

Height Gauge - High Point

Turn the pressure knob to the left to raise

the top head. Do this until the highest level is

reached, without unscrewing the internal bolt

from the main post. Press an arrow key to lock

in that pressure value to PRH. The high point

of the pressure/height gauge is now defined.

Press PRG to move to the next menu item.

Height Gauge - Low Point

Turn the pressure knob to the right to

lower the top head. Do this until the lowest

level is reached. Press an arrow key to lock in

that pressure value to PRL. The low point of

thepressure/heightgaugeisnowdefined. Press

PRG to move to the next menu item.

The digital pressure/height gauge is calibrated from the factory

to recognize the lowest and highest pressure points settable on the

press. By defining the highest and lowest points of adjustment, the

controller is then able to accurately calculate and display the current

heat platen height & pressure as the operator turns the pressure knob.

Itmaybecomenecessarytorecalibratethedigitalpressure/height

gauge if the displayed values of 00 through 10:00 do not properly

correspond to the lowest and highest pressure adjustment levels. This

could happen if the stop collar is loosened to adjust the stopping

position of the heat platen over the lower table. Other factors may

also require the user to redefine the highest and lowest points of

pressure adjustment to the controller.

Thisisdonevery easilythroughthefollowingUser OptionsMenu

items:

14

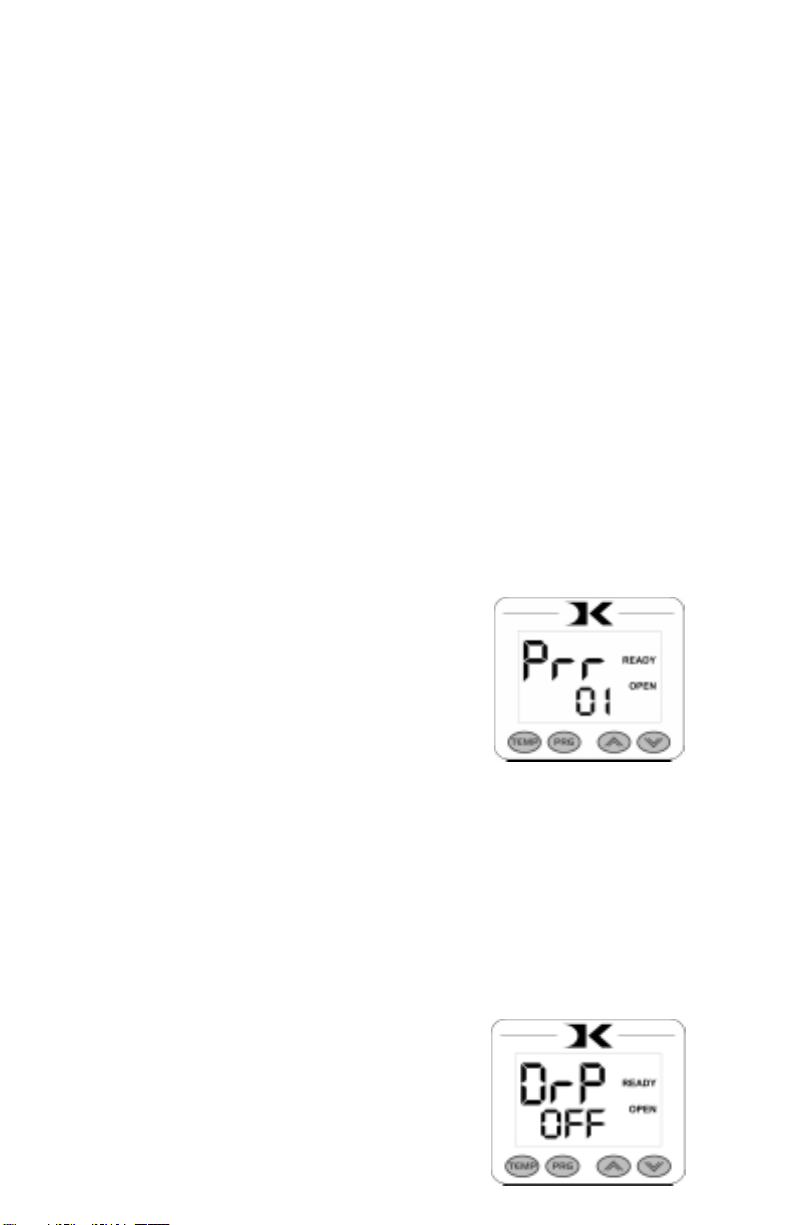

Pressure / Height Gauge Sensitivity

Drop Sense

The PRR menu item allows the user to define how sensitive the

height gauge is for displaying purposes. This setting defines how

quickly the pressure display will appear during normal operation.

The lower the sensitivity setting, the less the amount of change is

required when turning the pressure knob to cause the PRS display to

appear during the default operating mode. The higher the number, the

greater the amount of change in height is required to display the PRS

value.

Usually a setting of 02 is fine for normal operation. However,

sometimesmerelyclosingthepresscancausethe pressure/heightgauge

to register a reading and change the display to the PRS reading

undesirably. By increasing this value, the PRSdisplaywillnotactivate

from smaller changes to the pressure. Conversely, sometimes the

operator may adjust the pressure knob, but the PRS value does not

display unless the knob is turned very quickly. By lowering the value,

the display will activate based on smaller and slower changes to the

pressure setting.

Use the arrow keys to change the PRR

sensitivity setting. Press PRG to move to the

nextmenuitem.

A temperature alarm is available for warning the user of out-of-

range temperature conditions. The user can set this menu item to

soundanalarmiftheheat platen drops belowtheSetPointtemperature

bythe amount indicated. This can be helpful when pressing substrates

that absorb an unusually large amount of heat, causing the platen to

fall in temperature quickly. If the results of the transfer begin to

deteriorate, the Drop Sense feature can help the user avoid this.

Use the arrow keys to set the degrees or

to turn this feature off. If the Current

temperature drops below the Set Point by this

amount or more, an alarm will sound. The

default value is OFF.

15

Beep

Normally, all buttons on the keypad beep

when pressed. This can be turned off, so all

button keypresses are silent. Use the arrow

keys to turn this feature On or Off.

Alarms

There are 10 different alarms available to choose from. These

alarms are sounded at the end of the timing cycle, as well as if the

Drop Sense feature is enabled.

Use the arrow keys to change the values

ortoturnthealarmoff. Please note thedifferent

alarms below.

• denotes a short beep.

_ denotes a longer beep.

~ denotes infinite loop.

Alarm# AlarmPattern

Off No alarm

01 • • • _

02 • • • _ ~

03 • • _

04 • • _ ~

05 • • •

06 • • • ~

07 _ ~

08 _

09 •

10 • (shorter)

16

Maintenance

Themajorityofthepresshasbeendesigned to be as maintenance

free as possible. There are only a few aspects of the machine that

should be monitored to insure proper operation.

• The clamp/linkage assembly is the greatest area of wear and friction

on the press. The posts that connect to the heat platen should be

lubricated with SuperLube - a clear high-temperature lubricant. Do

not use grease, white lithium, or WD-40 to lubricate the clamp/linkage

assembly.

• Check the power cord and heat platen connector cords regularly to

make sure there are no visible signs of damage. Make sure the modular

cord does not come in contact with the underside of the heater. The

modular cords should travel from under the head back away from the

machine.

• The silicone pad on the lower table can degrade after much use and

over an extended period of time. This pad is replaceable. If the pad

becomes dried out, cracked, or there are chunks removed from the

silicone pad, this can result in inconsistent and poor quality transfers.

17

Troubleshooting

Thefollowinginformationattemptstoaddressthemostprobable

mechanical and user issues with the press. Most issues with heat

transfer presses are application related. That is, they have to do with

the results of a particular transfer application.

For technical support on problems having to do with the final

results of a particular transfer paper or media, please contact the

supplierofthattransfermedia.Generally,the machinery manufacturer

is unable to support the myriad of different transfer papers, inks and

imprintable items on the market from other resellers.

Q. The timer does not start when I close the heat platen, or the timer does

not reset when I open the press up.

A. There are several probable causes for this. The timer is activated by a

micro-switch under the head of the press. It is located on a sheet metal

bracketwithslots. When thehead of themachine is opened,thetimer’s

lever should be depressed and the small contact button under the lever

should click in. When the head for the machine is lowered, the lever

of the timer switch should move down and the contact button click

out. The timer switch may need to be loosened and moved along the

bracket to a position that allows for the heat platen cover to trigger the

switch. When tightening the switch against the bracket, do not

overtighten, the switch housing can crack very easily.

Q. The control displays Err when it first comes on, and I can not set the

temperature or use the press.

A. The Err message will display if the heating signal from the platen has

been cut off, interrupted, or the heating sensor has failed. Check that

the modular heat platen connector is properly plugged in and secured.

Then check the green heat connector that plugs into the digital control.

This is inside the top head. Unplug the power cord. Remove the two

screws in between the clamp/linkage that hold down the top panel, and

carefullyliftthe panelupand lookinsideat thedigitalcontroller. At the

top of the controller, there is a green connector that plugs in. This is the

temperature sensor wire. Check to make sure is it properly seated. Be

surenotto unplugany other connectors.The temperaturewireconnects

to the center of the rear half of the heat platen. Check this connection

as well to see if the connection is correct.

18

Troubleshooting (cont.)

Q. I press the keys on the keypad, and there is no sound or response from

the controller.

A. Check the connection of the keypad to the controller. This is inside

the top panel. Unplug the power cord. Remove the two screws in

between the clamp/linkage that hold down the top panel, and carefully

lift the panel up and look inside at the digital controller. The keypad

connector passes in through the top panel. It should wind around the

first circuit board and be seated fully into the connector. Check the

black keypad connector that plugs into the circuit board to see if it has

pulled apart. Also check the area where the keypad connects to the

front membrane to see if the leads have been damaged. The membrane

keypad may need to be replaced.

Q. The clamp becomes extremely difficult to open and close, and

sometimes binds up.

A. The linkage pins and the posts that connect to the heat platen must be

lubricated with SuperLube - a clear, high temperature lubricant. Lower

the heater but do not clamp the press. Remove the e-clips & linkage

pins and carefully drop the heat platen down from the clamp/linkage

assembly. Make sure there is no tension on the electrical connections

from the heat platen to the top head. Thoroughly clean the posts that

come out of the heat platen, as well as the pins, the holes the pins pass

through, and the holes the heat platen posts pass through. Relubricate

the posts, pins, and all holes & areas in the clamp assembly that receive

motion, and reconnect the assembly.

Q. The press has shut off, and will not come back on after checking the

power cord, on/off switch, etc.

A. Check the fuse. In the back panel of the control box, the power cord

socket has a built-in fuse-holder. Unplug the power cord, and gently

pry out the fuse-holder. If the fuse is burnt out or there is no continuity,

replaceit.If thefuseis fine,check the blackand white wireconnections

from the power socket to the on/off switch, and from the on/off switch

to the controller.

Q. I pressed a transfer upside down. The inks and transfer material have

burned onto the heat platen.

A. Coolthepressdown.Usinga nonabrasivedetergentorcleaner,thoroughly

scrub the heat platen surface. Do not use an abrasive scrubber, or a pad

that will scratch the Teflon coating of the platen. If you are still unable to

remove the transfer material, obtain teflon heater block cleaner from the

contact information located at the end of this manual.

19

Limited Warranty

Geo Knight & Co warrants that the press is free from defects in both material and

workmanship One Year from the date of invoice to the buyer. If any parts or workmanship are found to

bedefectiveinmanufacture, GeoKnight &Co willrepair orreplace thedefective partsor workmanship.

In addition, Geo Knight & Co warrants that the Digital Knight heat control is free from defects in both

material & workmanship and is covered under no-charge support for (3) years. Geo Knight & Co also

warrants that the heating element is warranted for the lifetime of the press, provided it is owned by the

original purchaser. This lifetime warranty on the heating element does not cover temperature sensor

failure, damage or disconnection. This warranty covers all parts to repair the defects, except when

damage results from accident, alteration, misuse or abuse, or when the machine has been improperly

installed, or modified in any way. If the press becomes defective during the limited warranty period of

one year for the entire press, three years for the control, or the lifetime of the heating element, Geo

Knight & Co reserves the right to recall the defective press to the factory for repairs if on site component

replacement is deemed not possible by Geo Knight & Co. A return authorization must be granted by

Geo Knight & Co prior to its return.

If a press covered by the one year limited warranty must be returned to the factory for

repairs, Geo Knight & Co shall make every effort to repair buyer’s press. However, Geo Knight & Co

reserves the exclusive right to determine whether to repair or replace a defective press. If Geo Knight

& Co authorizes a replacement press, the warranty of the replacement press shall expire on the

anniversary date of the original machine’s invoice to the buyer.

There are no warranties which extend beyond the description on the face hereof. Seller

disclaimsany impliedwarranty ofmerchantability and/orany implied warrantyof fitnessfor aparticular

purpose, and buyer agrees that the goods are sold “as is”. Geo Knight & Co does not warrant that the

functions of the press will meet the buyers requirements or expectations. The entire risk as to use,

quality and performance of the press lies with the buyer. In no event will Geo Knight & Co be liable

for any damages, including loss of profits, destruction of goods or any other special, incidental,

consequential or indirect damages arising from the use of the press or accompanying materials. This

limitation will apply even if Geo Knight & Co or its authorized agent has been advised of the possibility

of such damage.

20

Table of contents

Other Digital Combo Power Tools manuals