Stahlwille Manoskop 721/5 User manual

This manual suits for next models

3

Table of contents

Other Stahlwille Power Tools manuals

Stahlwille

Stahlwille MANOSKOP 714 User manual

Stahlwille

Stahlwille Manoskop 71/80 User manual

Stahlwille

Stahlwille MANOSKOP 714 User manual

Stahlwille

Stahlwille MANOSKOP 730D How to use

Stahlwille

Stahlwille MANOSKOP 730a/10 Quick User manual

Stahlwille

Stahlwille MANOSKOP 721 Quick User manual

Stahlwille

Stahlwille Standard Manoskop 720 Nf/80 Parts list manual

Stahlwille

Stahlwille Standard Manoskop 720 Nf/80 User manual

Stahlwille

Stahlwille 701 User manual

Stahlwille

Stahlwille MANOSKOP 721 Quick User manual

Popular Power Tools manuals by other brands

Westfalia

Westfalia 90 00 01 instruction manual

Daewoo

Daewoo DAJS 400 user manual

Scheppach

Scheppach MPT3400-4PGE Translation from the original instruction manual

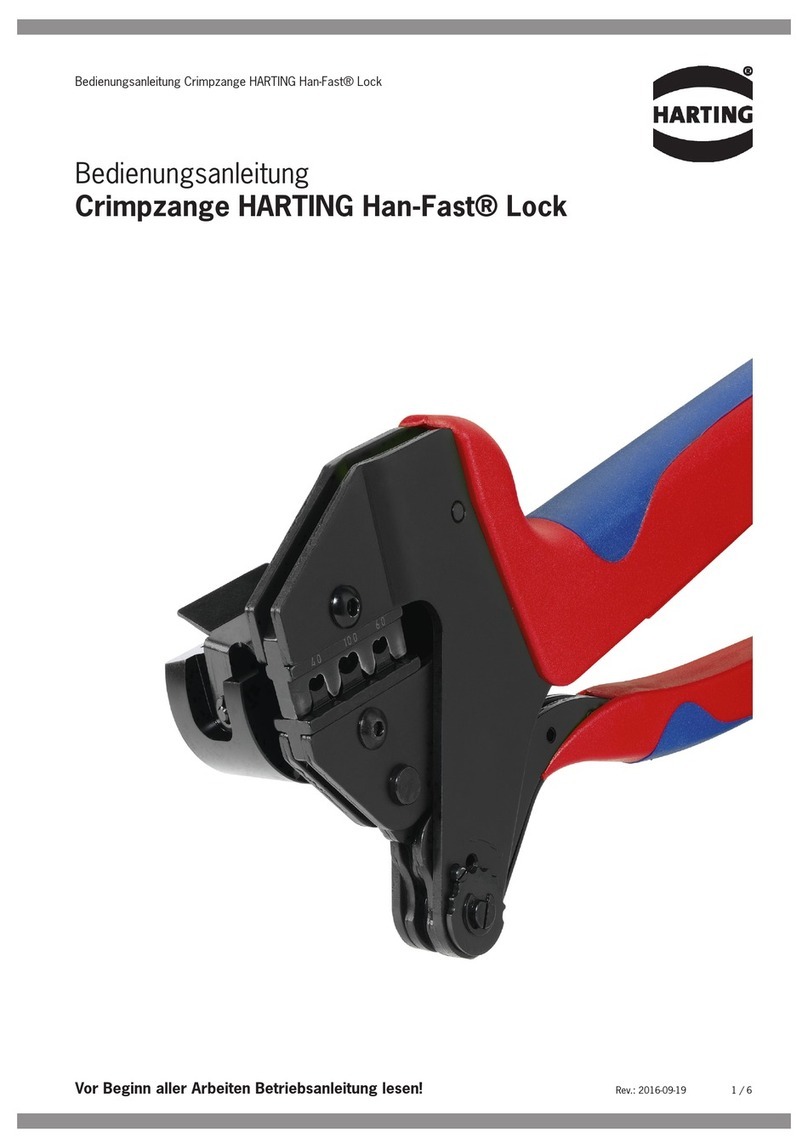

HARTING

HARTING Han-Fast Lock Series owner's manual

Vortex

Vortex CT503DC Original instructions

Omer

Omer RFID.25 Use, maintenance and spare parts manual