© Copyright 2003-2019 Dive Lab® Inc. All rights reserve .

This Gui e is ma e available for the express use of owners an users of the Dive Lab XLDS systems.

This information is subject to perio ic up ates an changes. Always check the Dive Lab web site for the latest versions.

Document XLDS Gui e – Section Two

Revise July 17, 2019

SECTION TWO: CONCEPT AND INTENDED USE

Intermediate Surface Supply

Concept

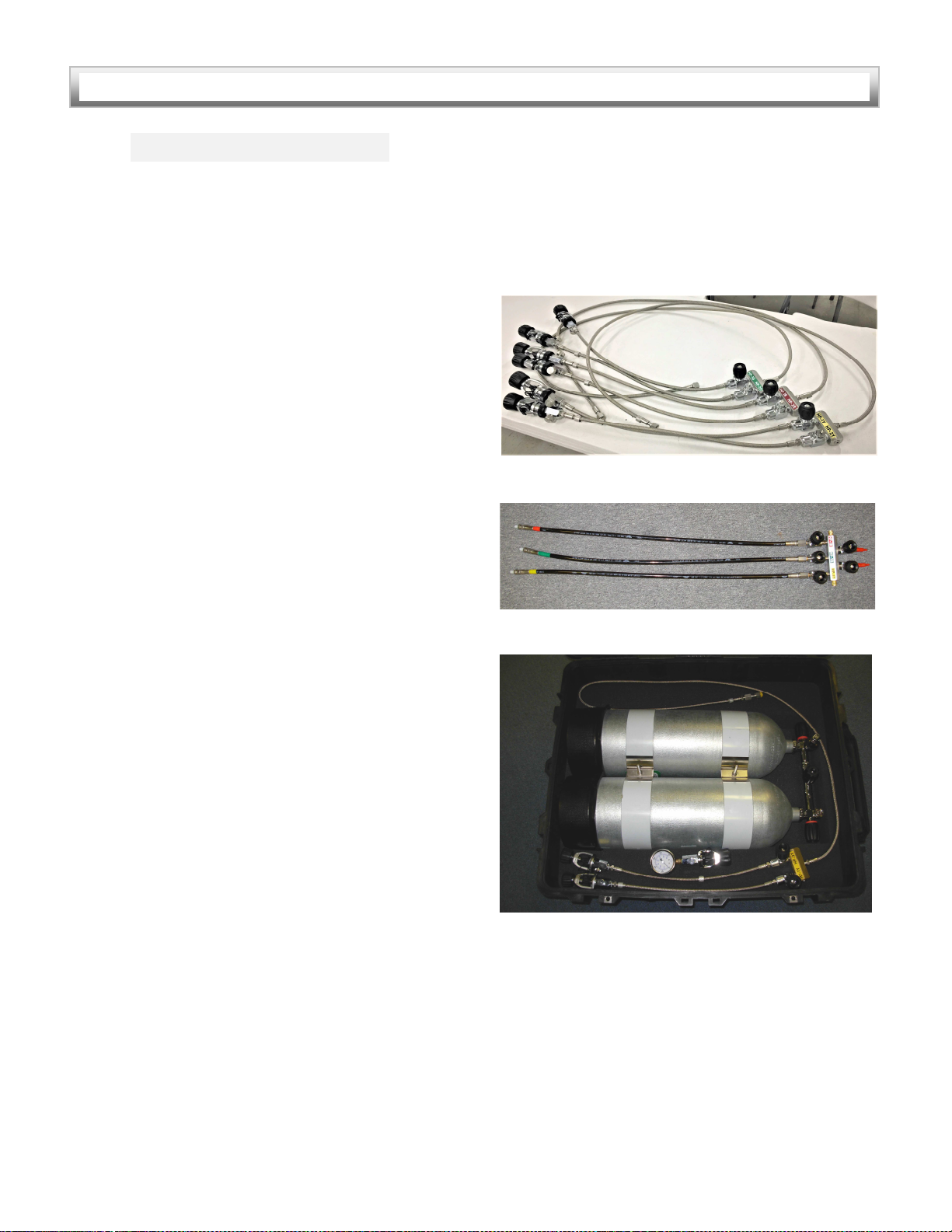

XLDS operates as an interme iate compensate

system. The XLDS system uses a specially

esigne 1/4" main gas umbilical assembly, that

re uces the weight an bulk of the umbilicals to

approximately half that of the lightest assemblies

normally use for surface supply iving. The

umbilicals are supplie air from the console, at

pressures between 350-375 PSIG (24-26 bar), to a

volume compensate pressure control system,

worn by the iver, known as the iver worn

interme iate manifol compensating regulator

system (ICS). The manifol is integrate with a 0.8

liter accumulator an manifol regulator system,

which re uces high velocity me ium pressure

breathing air (350 PSIG), from the umbilical, to

between 150-170 PSIG an supplies it to the

helmet or full face mask being use .

During inhalation, the ICS elivers breathing air to

the eman helmet or full-face mask with

minimal pressure rop, allowing for low

inhalation effort. During the exhalation cycle, the

system quickly buil s pressure for the next

inhalation cycle. Breathing performance of the

system allows breathing rates of up to 90 RMV to

epths of 100 FSW, an up to 75 RMV to epths

of 132 FSW, with most mo el KMDSI helmets an

ban masks, an at 75 RMV to 165 FSW when

using the KMDSI EXO- 26 BR. Both the positive

an non-positive pressure AGA

TM

FFM,

can be

use at work rates of 75 RMV, to epths of 150

FSW.

Conventional Surface Supplied

Diving

The surface air control consoles (RDC-2 an RDC-

3) can also be use as conventional air control

console, for eman mo e surface supplie

iving, with eman mo e Helmets an Masks.

When reference to conventional surface supplie

iving is given, it refers to the RDC-2 or RDC-3

console use with stan ar umbilicals an over

bottom tracking of supply pressures, no more

than 200-250 PSIG OB. When the RDC-2 or RDC-3

consoles are use for conventional air iving,

supply pressure can be regulate to each iver,

IAW the operational pressure an supply

requirements, ictate by the UBA being use ,

an IAW the recommen e performance

specifications as outline in this user gui e.

When using with conventional 3/8” umbilicals,

the RDC relief valves, shoul be reset to relieve

between 290-300 psig, verse the 390-400 psig

setting, when using with the XLDS system.

Currently the RDC-2 an RDC-3, are certifie by

Dive Lab, for use with all properly maintaine

current pro uction mo els of KMDSI Ban Masks,

Helmets, an Full Face Masks properly configure

for conventional surface supplie iving. Other

equipment may be use , contact Dive Lab for

a itional information.