DMW Dispenser Operations Manual 8

SETUP AND OPERATION

Initial Startup Instructions

To us e th e di sp ens er f or th e fi rst

time or t o re sta rt the u ni t aft er

clean in g, ob serv e t he f ollowin g

procedu re s:

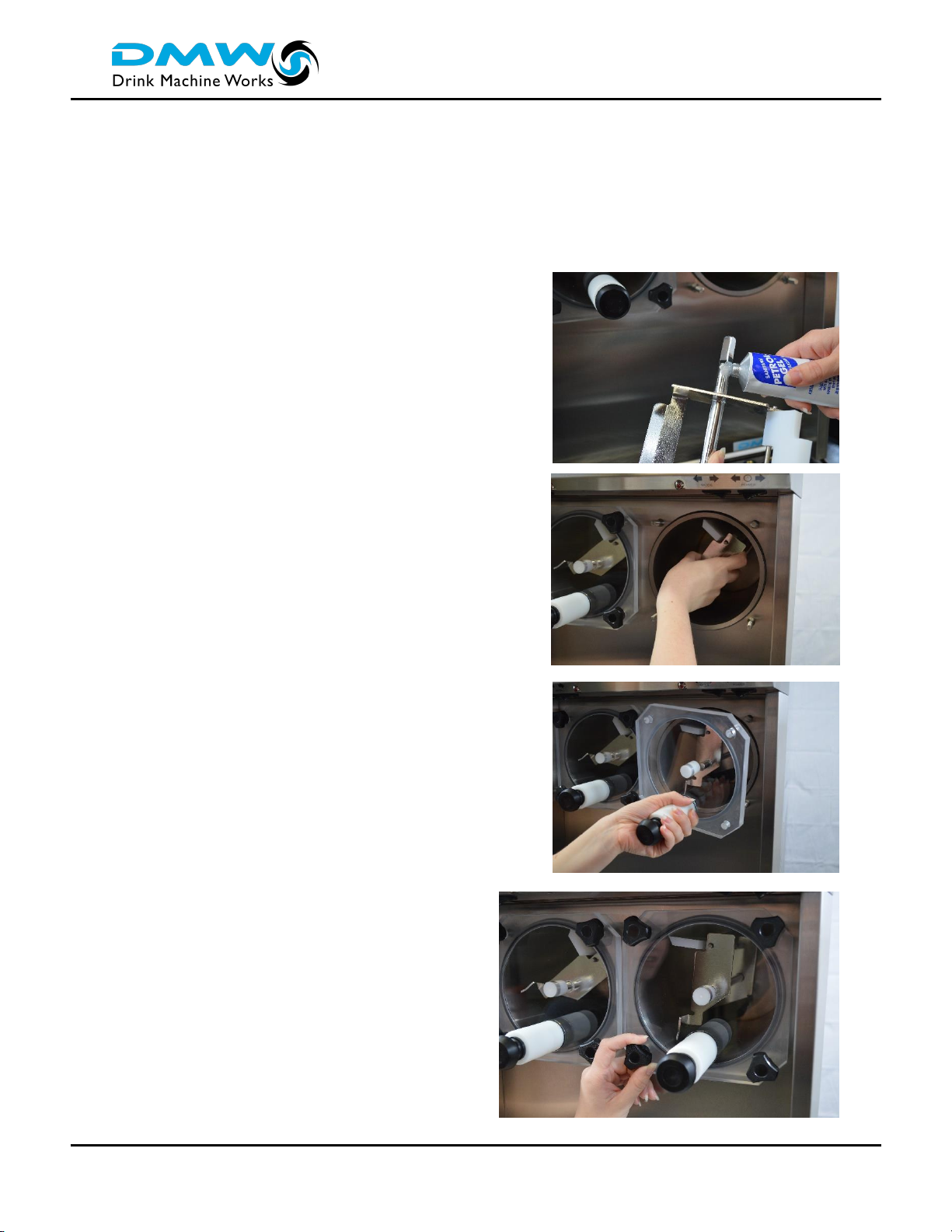

1. Remov e th e di spen s er li d s and

set th em aside.

2. Ma ke su re tha t a ll c ont rol

swit che s are i n th e cent er p osition

(OFF)

3. Pou r produ ct i nt o th e h opp er s.

4. Pl ace t he li d s on t he m achin e.

5. Te st th e cont rol switch i n the

CLEA N po sition.

NOTE: Wi th t he c ont rol s set i n th e

CLEA N p osi ti on, th e driv e mot or

turn s th e b eat er ba r and th e

comp ressor rem ai ns off.

6. Pl ace t he con trol swi tch i n th e

AUTO p osition. Al low th e unit t o

run i n FR EEZE m ode until the

comp ressor st ops .

7. Sam pl e th e pr od uct f or ta st e

and thickn ess.

8. If n ec ess ary , us e th e thi ckn es s

adjustm ent screw to adjust th e

mach in e fo r optimal p roduct

thi ckn ess. The product sh oul d be

slushy —neithe r as th in as jui ce,

nor as t hi ck as i ce cream.

NOTE : CH ILL i s an extended

defrost m od e that al l ows th e un it

to remain un at tende d for more

than 12 h ou rs . It w il l mai nt ain the

produ ct a t a ref rigerat ed

temp erature. This m od e is en ergy

effi cien t an d retai ns th e pr odu ct

freshne ss .

NOTE : You r di sp enser wil l be

equi pp ed wi th a l ow -l evel i ndicato r

light . Design ed t o activate th e li ght

when produ ct i n th e h op p er falls

belo w a ce rtain l evel. However,

addi ng mix b ef ore the l i ght goes

off will i ncreas e producti on a nd th e

rec overy rate o f you r un it.

9. When th e resul ts o f all tests an d

checks a re s ati sfa ct ory, th e unit i s

read y for operat ion.

10. Pe rform a fi nal check , ret urn

the switche s to AU TO, and wi p e

down the ou tsi d e of t he uni t.