1

Water consumption is reduced by using the power of the laundry falling (free-fall) created when rotating

the drum. With temperature control system, this drum washing machine saves energy and improves

washing performance at the same time.

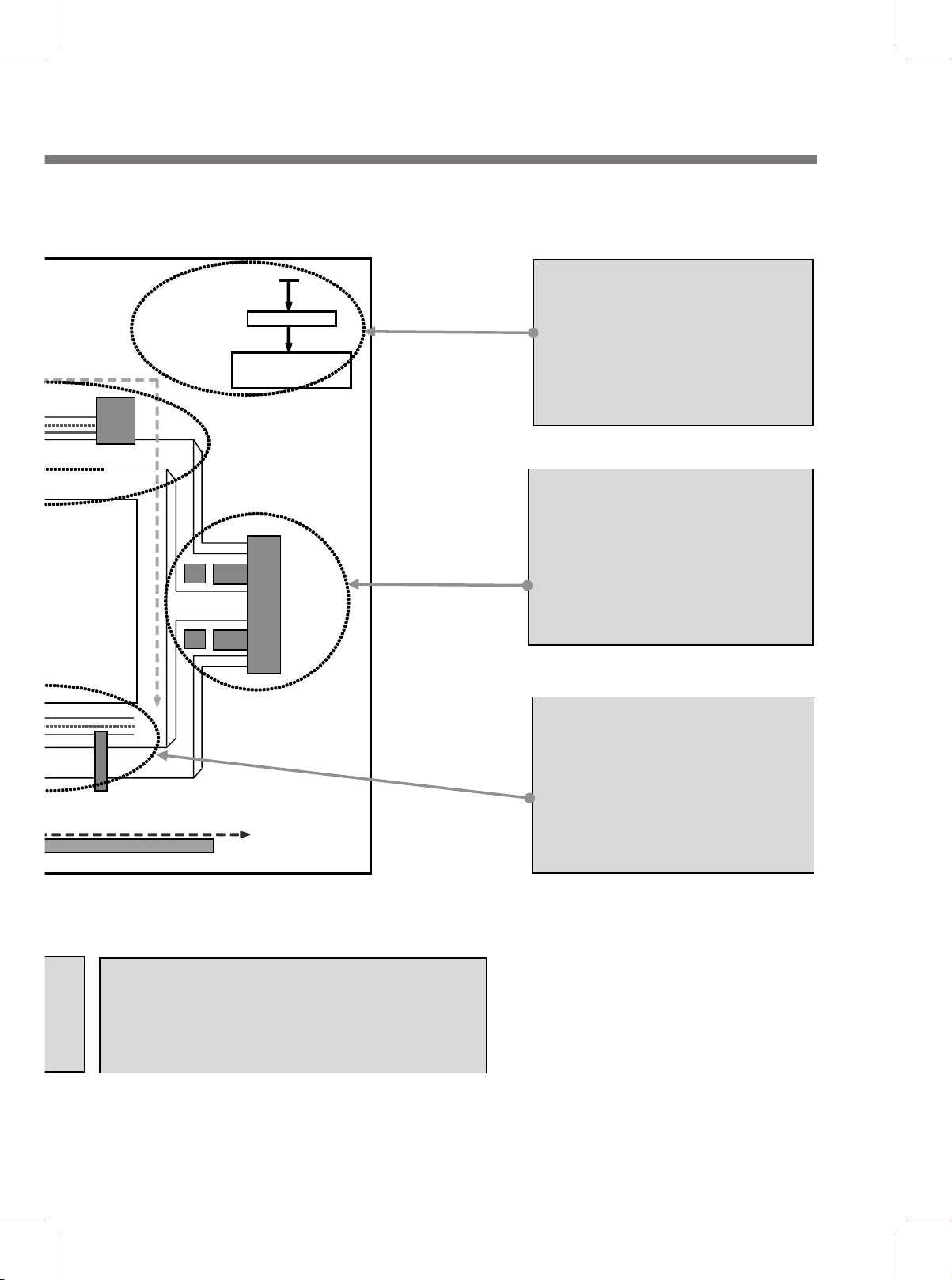

1. Drum Washing Machine

◆Waist Care

Designed by the waist, and the most comfortable

angle eject into the laundry is convenient and easy

to manipulate.

◆The World's First Steam White Course

The Steam White Course save more 50 percent of

Electricity, Water, Time than previous White

Course.

◆Star Drum

Using Star Drum is able to higher Washing

Performance and Minimal damage of laundry,

water consumption.

◆The biggest capacity with compact size

15 Kg Capacity enable to wash bigger laundry.

◆Sumultaneous supply of cold and hot water

As cold and hot water is supplied at the same time

heating time and energy is saved.

◆Luxury Audio Dial

Using the advanced Audio Dial is luxury design of

exterior.

◆The World's First Shoes Course Enable to wash

shoes.

◆DD inverter motor

The direct-drive type of which motor is directly

connected to drum without an interim chuth,

significantly reduces noise and vibration.

◆Self-Cleaning Course of Drum.

Enable to Self-Cleaning of Drum.

◆Digital Condensing Dry System.

Condensing Dry System with saveing energy.

◆For pump drainage, the powerful pump speeds up

drainage process.

◆AUTO DETERGENT SYSTEM

No more prepare detergent before every washing

(only liquid detergent and fabric softener)

◆SMART WASH

you can wash easily like stocking,lingerie use

smart wash system

2. Key Features

1. WHAT IS DRUM Washing Machine?

WFC3V11ZDNH01D2GW(DWC-PS1512X)_칠레향(SM).indd 1 2017-10-26 오후 4:17:28