7

2.O1 Preliminary Tasks

It is highly recommended to visit the site well before installation, to familiarize yourself with the physical layout of the laundry,

the machines present and their characteristics, the laundry products in use, and how any current laundry dosing system is

being employed.

Pay attention to the entire laundry system, its requirements and its schedules, to ensure a smooth transition to, and

installation of, your Dositec laundry dosing system.

Learn the operations of all the washers, as well as the products they use, and why. Determine the capacities of the machines

and what is involved in programming their signals.

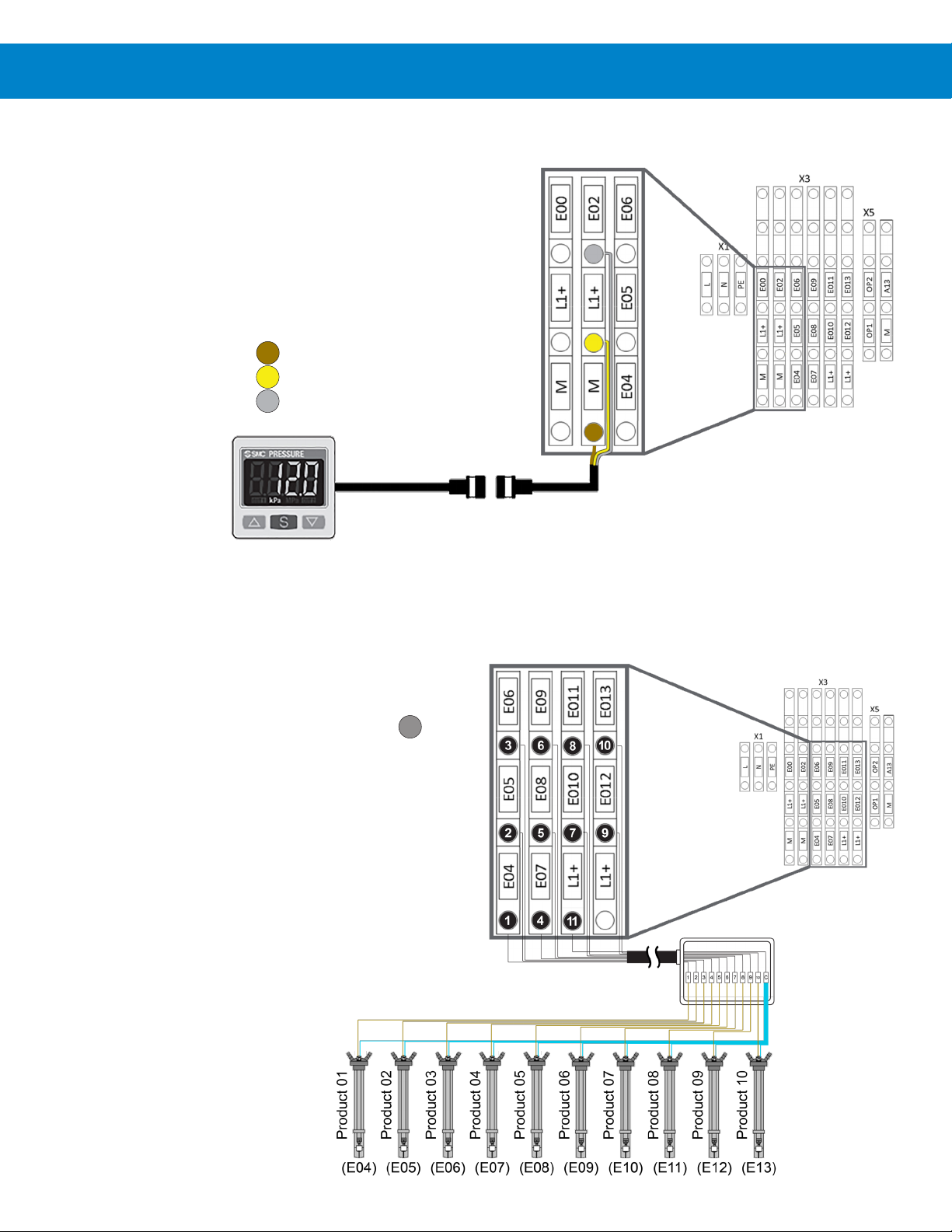

Measure the distance between where the Dositec main panel will be installed and the location of the Distribution Manifold(s).

Determine where the communication boxes will be installed for each washer, as well as the lengths of 4-conductor cable

needed to daisy-chain them back to the main panel, and the lengths of 10-conductor cable from each communication box to

each washer’s signal terminals. Identify the voltage each washer is using for it’s signals. Determine how many conductors you

need for connecting the main panel and the distribution manifold(s) and the distance for that connection.

Measure the lengths of chemical delivery hose that will be needed to run from the main panel to the distribution manifold(s),

from the distribution manifold(s) to the washers, and back to the Calibration vase. Identify how the hoses will be routed, and

what hardware will be required to accomplish that scheme. Identify where the bulk chemicals will be placed and the lengths

of hose needed to connect them to the Collection Manifold of the main panel. Calculate how many hose clamps will be

necessary to complete the installation.

It is recommended to order the specific installation kit for the system being installed, which is available from Hydro Systems. If

the mounting hardware is obtained from local providers, all items should be the same as the ones listed in the kit.

Schedule an orderly transition from any previous dosing system in use, and investigate if any portions of that system must

be removed before the installation of the Dositec system. In case a previous unit is already working in the site, all the existing

elements must never interfere with the new installation.

2.O2 Panel Mounting

• In order to make the unit work correctly, it must be placed on a clear

and flat wall.

• The system must be placed at such a height that the screen must be

easily manipulated.

• The panel’s mounting dimensions will be approximately 25.25 in by

35.25 in (642 mm by 895 mm), but may vary slightly, so use the actual

panel being installed as a template. To use the supplied mounting

hardware, drill four 5/16 in (8 mm) holes at the locations indicated.

• Insert the included fittings.

• Place the unit on the wall and use the included screws and mounting

hardware to hang the system.

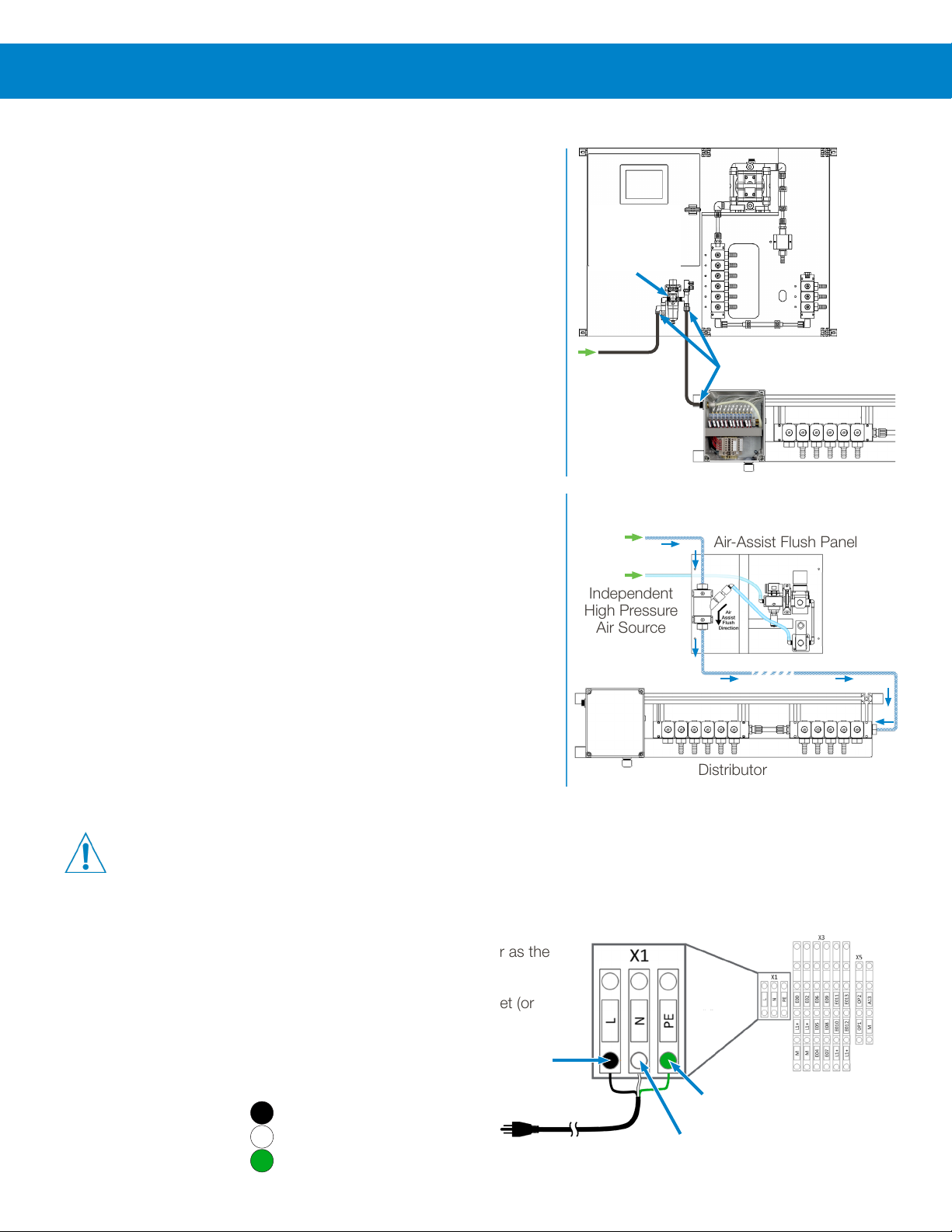

2.O3 Peripheral Elements

After placing the unit, it is necessary to mount the rest of the elements:

Distributor: This element is the responsible for diverting the products to the corresponding washer extractor. Only one

machine is attended while the others are queued. It is recommended to set the distributor at a position equidistant from the

washer extractors.

Calibration Vase: Since this vase is used for dosage calibration, it should be installed on the wall near the main panel.

Please note the vase is connected by a hose to the distribution manifold. Make provision for draining the calibration vase and

for overflow from the vent fitting.

Communication Boxes (machine signal interfaces): These elements are used to get the signals from the machines so they

can be acquired by the unit. There must be one box per washer extractor. The recommended position is a clear place on the

wall behind every machine.

2.OO installation

25.25”

35.25”

Note: Indicated Measurements are Approximate!