5

2.0 General instructions

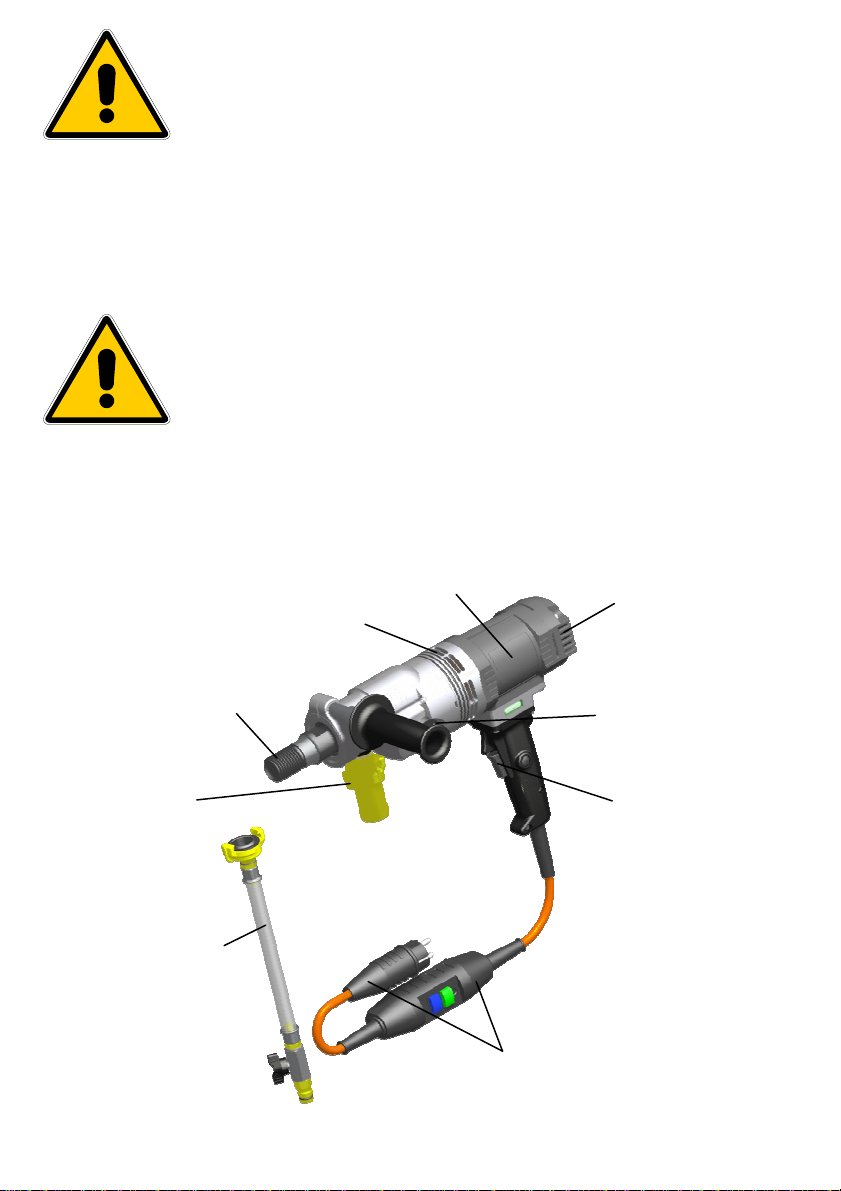

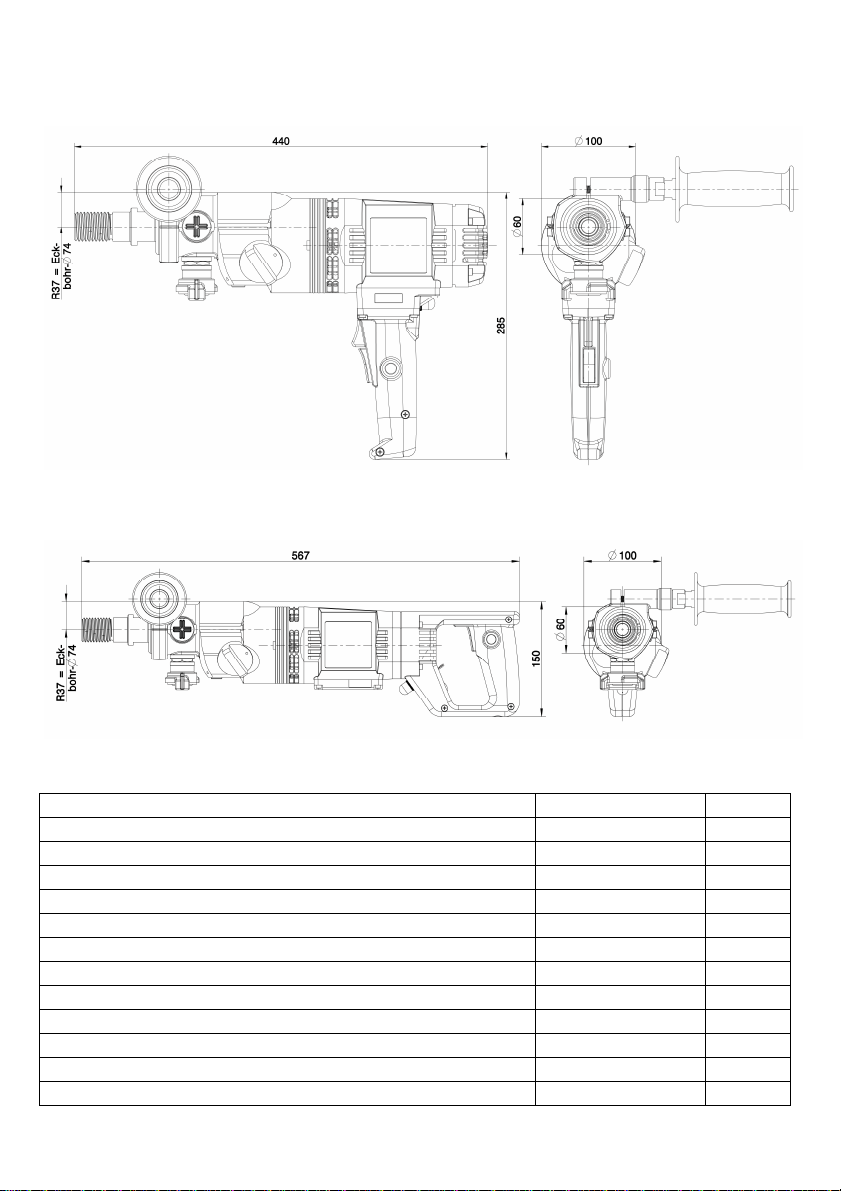

2.1 Application

The core drills can be used for the purposes outlined by the data on the model plate. If you are using spe-

cial machines, the details in the quotation and order confirmation also apply.

The core drills are supplied as standard in protection class I, only this can guarantee the full high quality

production of the residual current-operated circuit-breaker or PRCD switch.

If you use suitable core bits, you will be able to drill holes in the most diverse material types:

- Concrete (even if it contains thick reinforcement steel)

- Sandstone and limestone

- All building materials for solid walls

- Asphalt floors

Warning

The core drills comply with the regulations issued by the ”Stone and Earth” Profes-

sional Association issued in July 1989. They are machines of category II, which means

that they must be placed on stands and be stable (pursuant to DIN 57100 or VDE

0100), the stand must be equipped with

- a reversing block, and

- a water suction device.

The machine must be connected to the 230 V mains

- direct using a personal safety switch (residual current-operated circuit-breaker or PRCD), or

- using a coded (1h) plug to a safety box (IP 44) with a residual current-operated circuit-breaker.

2.2 Safety

Warning

Before using the machine for the first time, check that the conformity of the

data on the model plate with the mains voltage and frequency. Voltage devia-

tions of ± 5 % and/or voltage deviations of ± 2 % are permissible. Repairs must

only be completed by quality persons who have suitable training and qualifica-

tions.

The following points are to be given special attention:

- the technical data and details of the permitted use of the machine (commissioning, ambient and

operating conditions) which are set out in the catalogue, the operating manual, the model plate

data and other product information,

- the relevant accident prevention regulations

- the correct use of tools

- the use of personal safety equipment