10

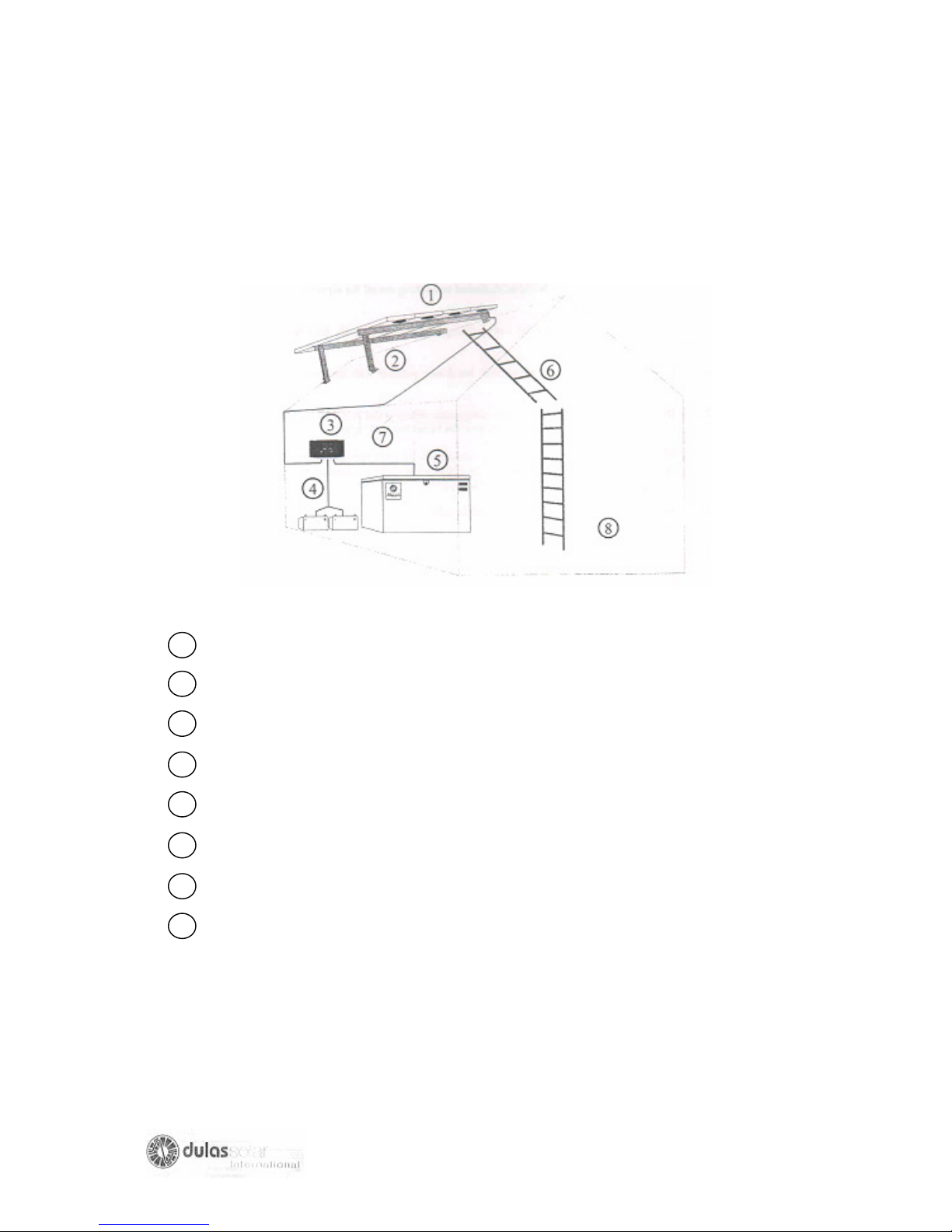

SOLAR ARRAY

KYOCERA MODULE ASSEMBLY

PLEASE READ ALL INSTRUCTIONS THOROUGHLY BEFORE COMMENCING

(FOR 12V WIRING LAYOUTS SEE ‘JUNCTION BOX WIRING DIAGRAMS’)

After insuring that all the components are present, remove the

solar (module a.1) from their cardboard boxes and lay them next

to each other on top of the cardboard, with glass facing down.

Do not step on the glass module. BROKEN MODULE CANNOT

BE USED. Arrange the solar modules so that the junction boxes

are all on the same side.

Interconnected the modules with the cables provided (a.3). The

interconnected cable has a crimped ring terminal at each end

which are easily connected to the Kyocera junction boxes as

illustrated below in figure1, (remove plastic unit, screw gland in

place, replace plastic nut and connect cable.)

The array output cable (a.2) must then be connected to the

nearest module (see system wiring diagram), brown or red wire

to +, blue or black wire to -. Ensure that there is sufficient cable

to meet the necessary distance then insert into the junction

boxes as performed previously.

Note: Due to New cable color regulations brown or red can be

used for + ve and blue or black for – ve until 1/4/06 after which

time only brown and blue will be permissible.

Lift the cover of the junction box by removing the four screws.

Place the ring terminal into position and tighten up the terminal

screw until it is gripped securely. Replace the cover of the

junction box with the screw provided ensuring a moisture proof

seal.