2/ 84 SM-SG-2 Ev3/25062014

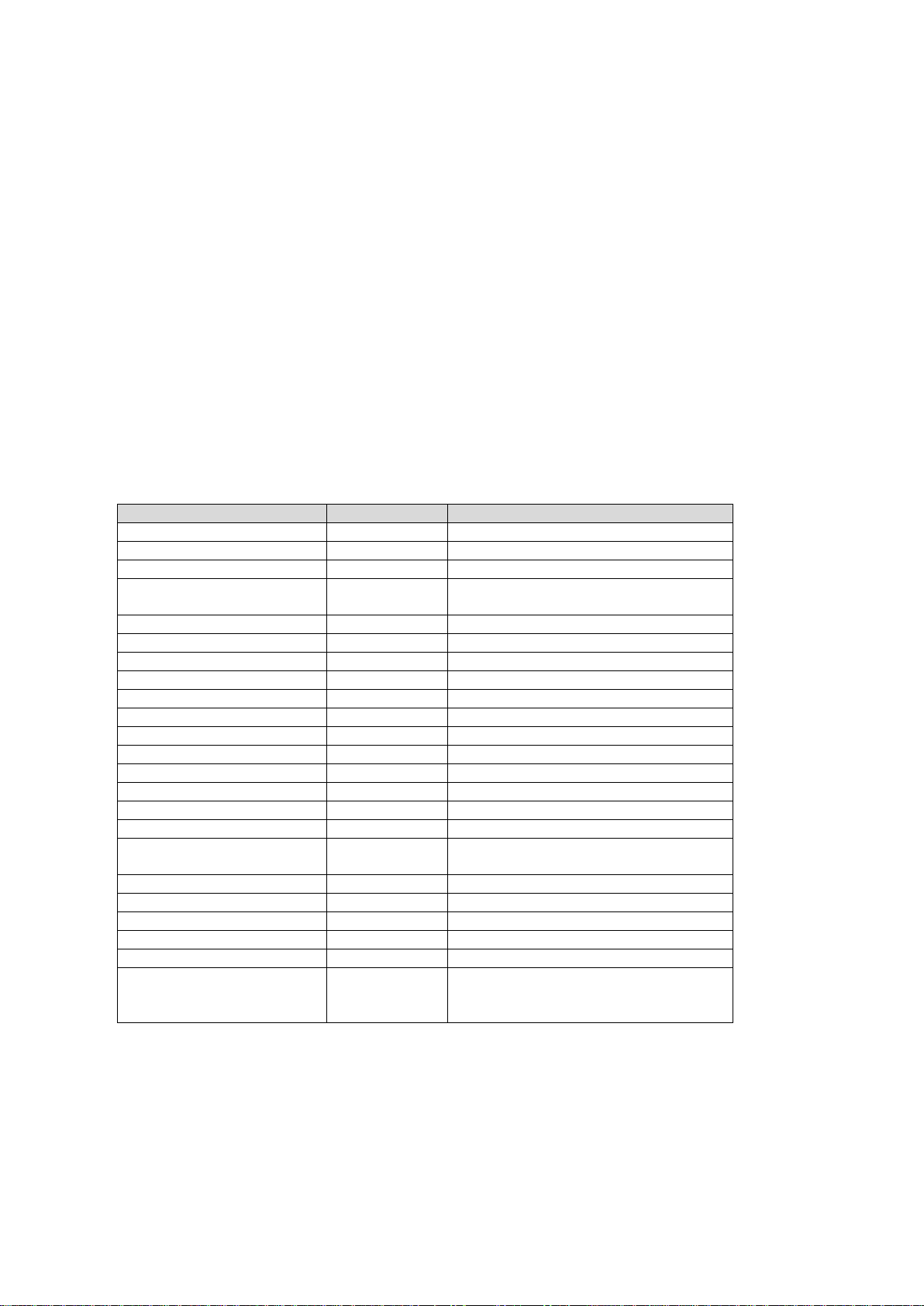

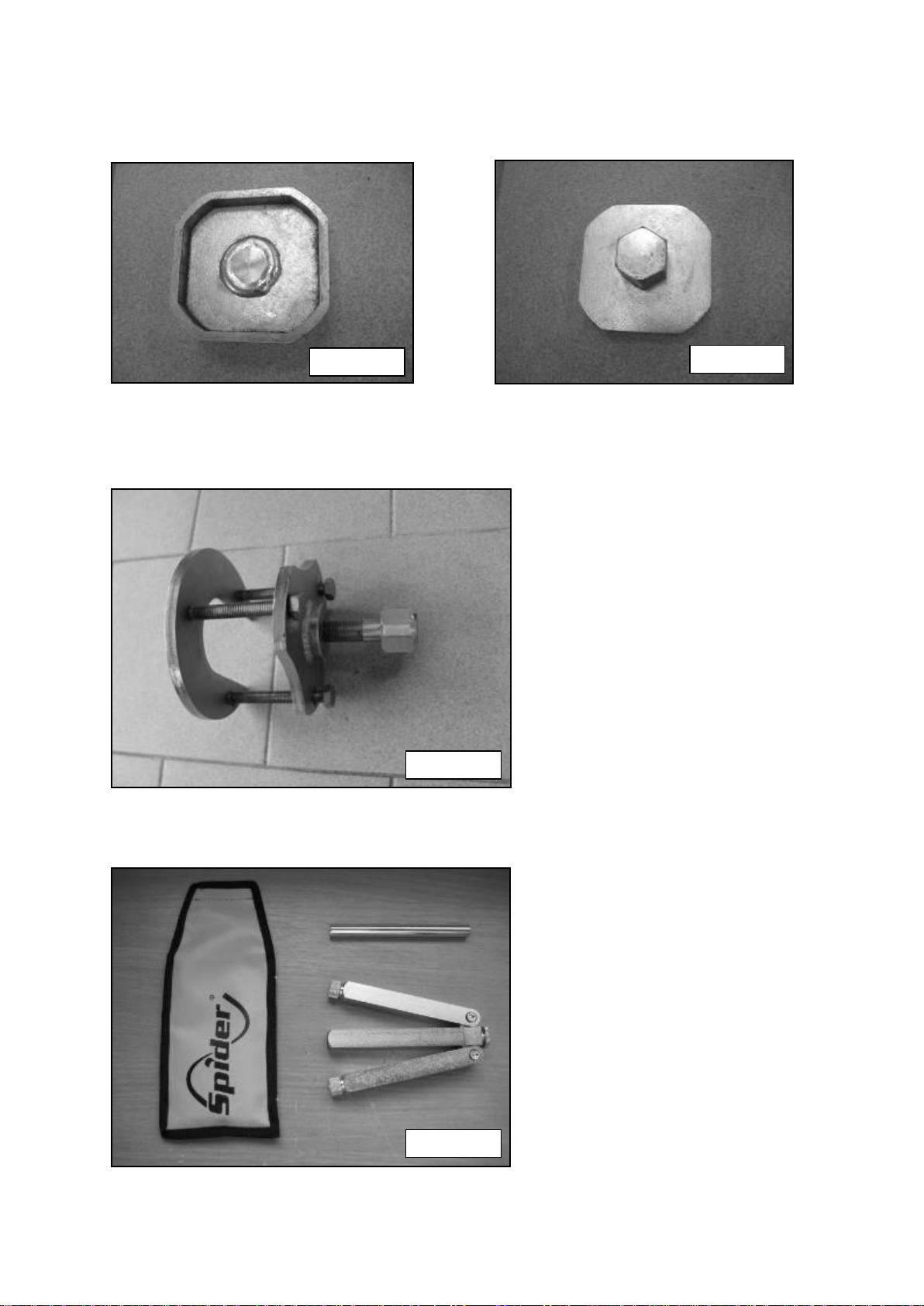

SPIDER ILD02 SG

TECHNICAL DESCRIPTION ............................................................................... 4

TECHNICAL SPECIFICATIONS ......................................................................... 4

1 Special service tools............................................................................................ 5

2Troubleshooting................................................................................................... 8

2Basic technical specifications........................................................................... 10

4 Regular maintenance SPIDER .......................................................................... 11

4.1 Daily......................................................................................................................................11

4.2 After first 8 hours..................................................................................................................12

4.3 After 25 hours .......................................................................................................................12

4.4 After 50 hours .......................................................................................................................13

4.5 After 100 hours .....................................................................................................................14

4.6 After 200 hours .....................................................................................................................14

4.7 Seasonal period .....................................................................................................................16

4.8 After 800 hours .....................................................................................................................16

5 Engine maintenance chart ................................................................................. 17

6 Instruction Manual SPIDER.............................................................................. 18

6.1 Tilting of the mower for maintenance...................................................................................18

6.2 Replacement of the engine oil filter ......................................................................................19

6.3 Replacement of the hydraulic oil filter..................................................................................20

6.4 Replacement of the hydraulic pump.....................................................................................21

6.5 Replacement of the auxiliary drive brake from S/N151........................................................24

6.6 Replacement of the hydraulic motor .....................................................................................32

6.7 Replacement of the clutch driving belt B 1160.....................................................................34

6.8 Replacement of the blade driving belt SPB 2410..................................................................36

6.9 Replacement of the pump driving belt Good Year BX 17x960 ............................................37

6.10 Replacement of the bearing boxes-driven, driving, tightening............................................40

6.11 Replacement of the clutch...................................................................................................41

6.12 Sharpening and replacement of the blade............................................................................42

6.13 Replacement of the steering chain.......................................................................................43

6.14 Replacement of the steering motor......................................................................................44

6.15 Replacement of the driving belts.........................................................................................45

6.16 Replacement of the angle gear UNI M8..............................................................................46

6.17 Replacement of the wheel suspension arm..........................................................................47

6.18 Adjustment and replacement of the wheel driving chain ....................................................48

6.19 Replacement of the wheel shaft...........................................................................................49

6.20 Replacement of the wheel housing......................................................................................50

6.21 Adjustment of the stabilizer length .....................................................................................51

6.22 Replacement of the stabilizer - pressed in...........................................................................52

6.23 Adjustment of the wheel geometry .....................................................................................53

6.24 Replacement of the elevation servomotor ...........................................................................54

6.25 Adjustment of the lift pull rods ...........................................................................................55

6.26 Replacement of the girder and cross ...................................................................................55

6.27 Replacement of the drive control servomotor NBB ............................................................57

6.28 Replacement of the starter switch relay .............................................................................58

6.29 Replacement of the main harness.......................................................................................59

6.30 Carburettor maintenance .....................................................................................................60

6.31 Fuel system .........................................................................................................................62

6.32 Hydraulic diagram...............................................................................................................63

6.33 Torque.................................................................................................................................65

6.34 Lubricators ..........................................................................................................................65

7 Electrical system ............................................................................................... 66

7.1 Electrical component location...............................................................................................66

7.2 Main switch –Emergency STOP..........................................................................................67

7.3 Horn ......................................................................................................................................67

7.4 Skid steering system..............................................................................................................68

7.5 Elevation servomotor connector...........................................................................................69

7.6 Elevation system ...................................................................................................................69

7.7 Engine rpm servomotor.........................................................................................................70