2/ 102 SM-8 Ev3/08072015

SPIDER MINI

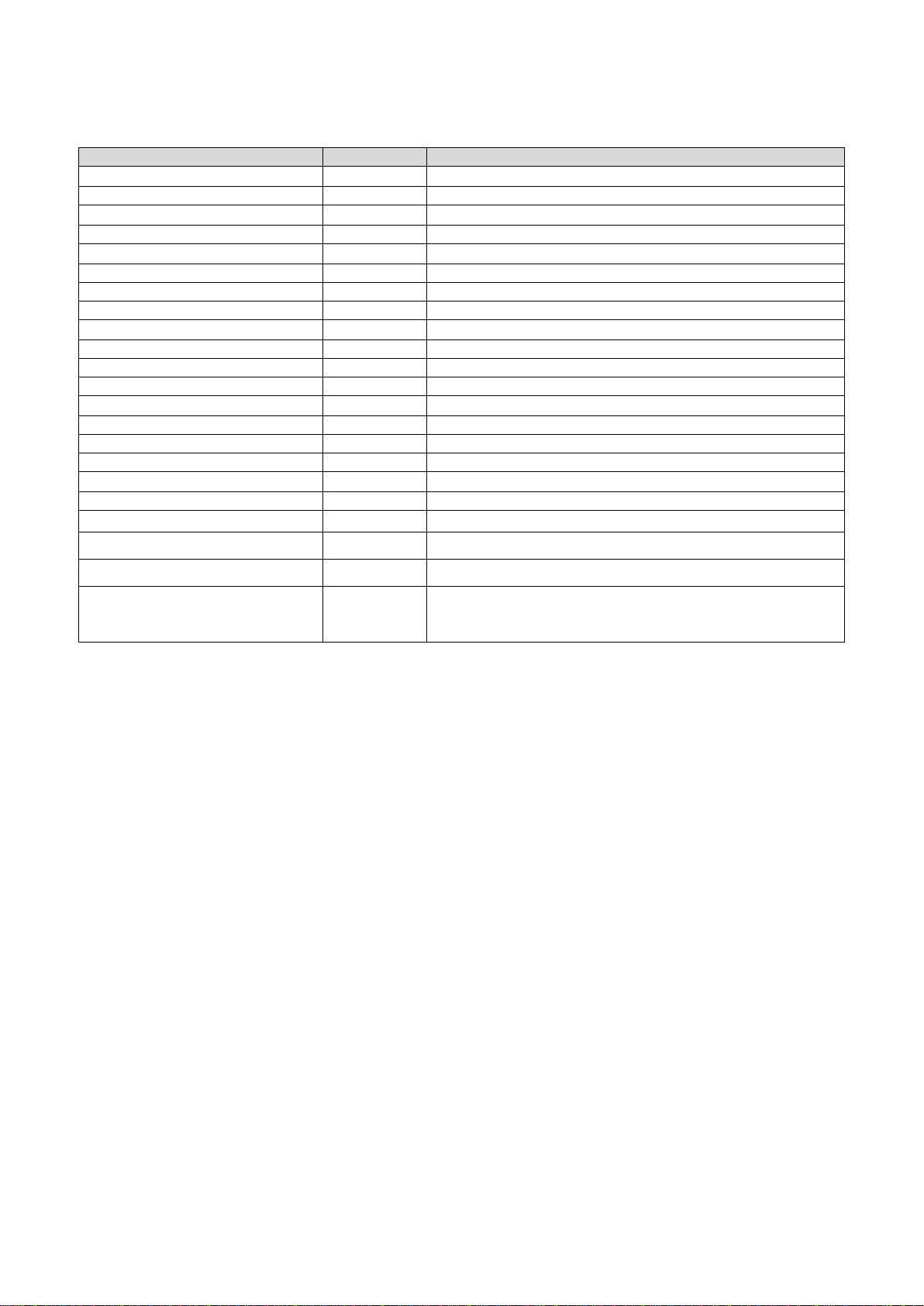

TECHNICAL SPECIFICATIONS ...................................................................................................3

1 SPECIAL SERVICE TOOLS..........................................................................................................4

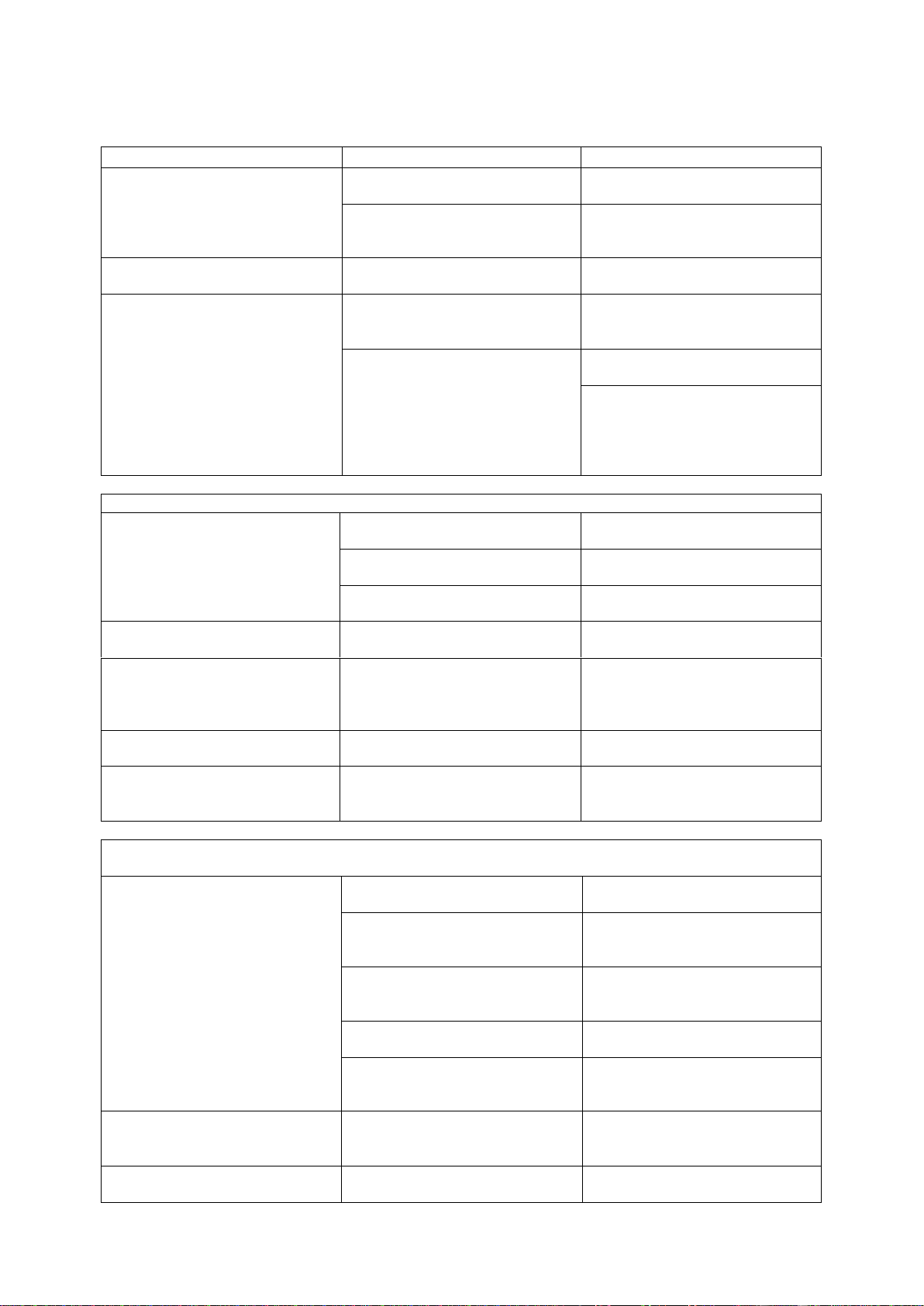

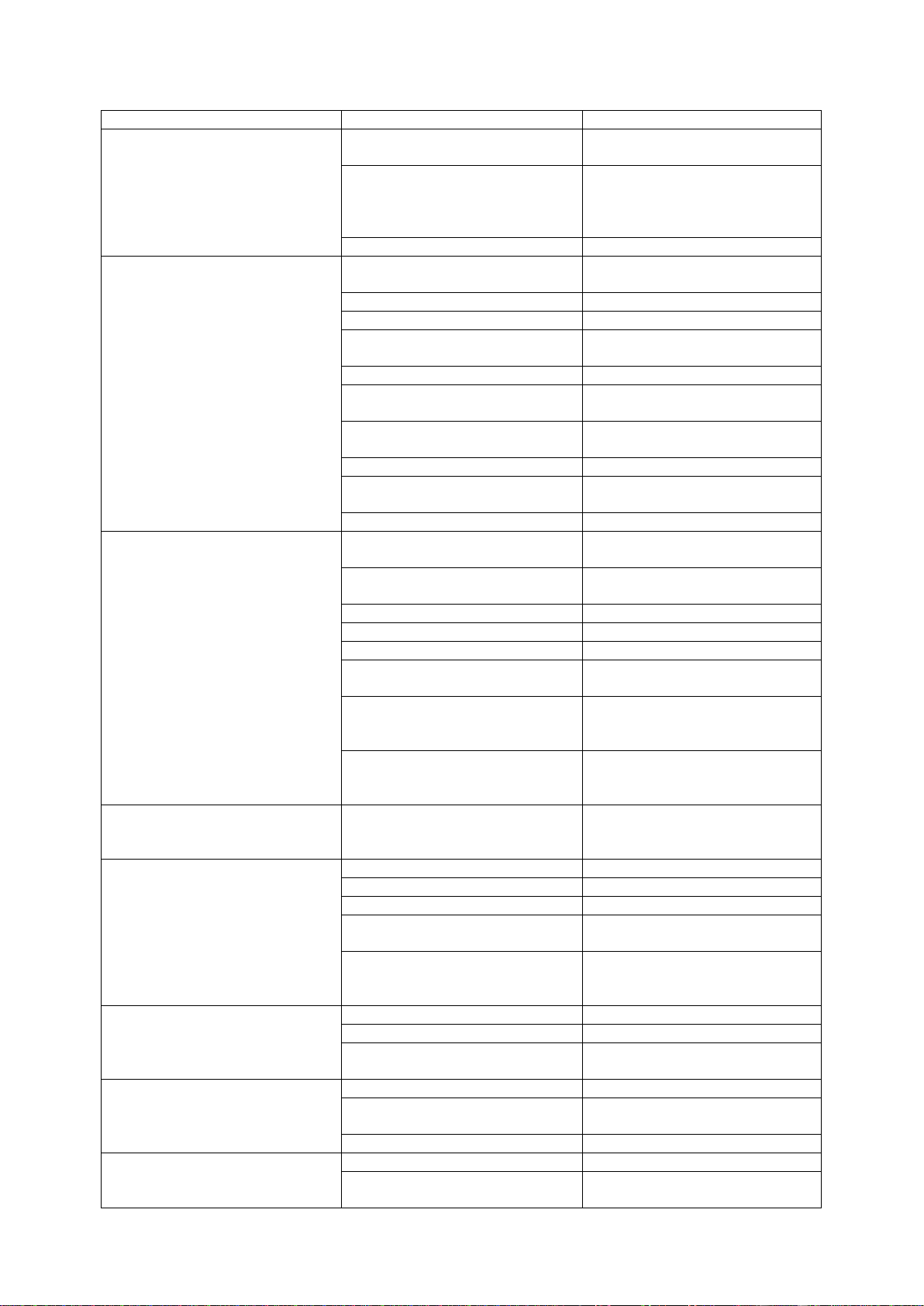

2 TROUBLESHOOTING ..................................................................................................................6

3 BASIC TECHNICAL SPECIFICATIONS.......................................................................................9

4 REGULAR MAINTENANCE OF SPIDER MINI .........................................................................10

4.1 DAILY OR EACH 8 mth......................................................................................................10

4.2 AFTER FIRST 5 HOURS.....................................................................................................13

4.3 AFTER 50 HOURS............................................................................................................... 13

4.4 AFTER 200 hours.................................................................................................................14

4.5 SEASONAL PERIOD .......................................................................................................... 16

5 ENGINE MAINTENANCE CHART .............................................................................................19

6 INSTRUCTION MANUAL SPIDER MINI ................................................................................... 20

6.1 Tilting of the mower for maintenance-service position.........................................................20

6.2 Replacement of engine oil and filter .....................................................................................21

6.3 Replacement of hydraulic oil and filter.................................................................................22

6.4 Replacement of hydraulic pump ........................................................................................... 24

6.5 Replacement of hydraulic motor...........................................................................................28

6.6 Replacement of the clutch, drive V-belt and engine pulley ..................................................33

6.7 Replacement of the blade hub and bearing ........................................................................... 37

6.8 Sharpening of the blade.........................................................................................................39

6.9 Replacement of the steering chain ........................................................................................40

6.10 Replacement of the steering servomotor............................................................................. 41

6.11 Replacement of the main drive chain..................................................................................43

6.12 Replacement of the wheel chain.......................................................................................... 46

6.13 Replacement of the wheel shaft, bearings and chain tensioners..........................................53

6.14 Replacement of the wheel suspension.................................................................................58

6.15 Wheel geometry alignment .................................................................................................62

6.16 Replacement of the alternator .............................................................................................66

6.17 Replacement of the drive servomotor .................................................................................68

6.18 Replacement of the brake solenoid .....................................................................................73

6.19 Replacement of the main harness........................................................................................75

6.20 Carburetor of the engine Briggs &Stratton Professional 950.............................................. 80

6.21 Modification of the engine brake Briggs & Stratton...........................................................81

6.22 Replacement of the engine Briggs & Stratton Professional 950 .........................................82

6.23 Hydraulic circuit .................................................................................................................87

6.24 Torque chart........................................................................................................................88

6.25 Lubricators .......................................................................................................................... 88

7 ELECTRICAL SYSTEM ...............................................................................................................89

7.1 Electrical component location............................................................................................... 89

7.2 Electric circuit diagram......................................................................................................... 90

7.3 Fuse box................................................................................................................................ 91

7.4 Current measurement table...................................................................................................92

7.5 Main switch –Emergency STOP..........................................................................................92

7.6 Horn ......................................................................................................................................93

7.7 Brake solenoid.......................................................................................................................93

7.8 Light for neutral position ......................................................................................................94

7.9 Battery ..................................................................................................................................94

7.10 Steering servomotor PAL ................................................................................................... 95

7.11 Drive servomotor NBB ......................................................................................................95

7.12 Alternator - charging...........................................................................................................96

7.13 Control unit NBB................................................................................................................97

Programming of the control unit..................................................................................................... 98