WARNING

Brake performance and features must be carefully matched to the

requirements of the application.

Consideration must be given to torque requirements, especially

where an overhauling condition exists, as well as thermal capaci-

ty, ambient temperature, atmospheric explosion hazards, type of

enclosure and any other unusual conditions.

Improper selection and installation of a brake and/or lack of main-

tenance may cause brake failure which could result in damage to

property and/or injury to personnel.

If injury to personnel could be caused by brake failure, additional

means must be provided to insure safety of personnel.

GENERAL SAFETY INFORMATION

NOTE: These brakes are not intended for accurate positioning applica-

tions. They are designed for applications that require rapid stopping

and holding power, such as on conveyors, door openers, etc.

1. For applications with high inertia-type loads or rapid cycling, the

thermal capacity of the brake must be considered.

2. Observe all local electrical and safety codes, as well as the

National Electrical Code (NEC) and the Occupational Safety and

Health Act (OSHA).

3. Brake motors and brake gearmotors must be securely and

adequately grounded. This can be accomplished by wiring with a

grounded metal-clad raceway system, by using a separate ground

wire connected to the bare metal of the motor frame, or other

suitable means. Refer to NEC Article 250 (Grounding) for addition-

al information. All wiring should be done by a qualified electrician.

4. Always disconnect power before working on or near a brake

motor, a brake gearmotor, or its connected load. If the power dis-

connect point is out of sight, lock it in the open position and tag it

to prevent unexpected application of power.

5. When working on the brake, be sure the load is completely

removed, secured or blocked to prevent injury or property damage.

6. Provide guarding for all moving parts.

7. Be careful when touching the exterior of an operating motor,

gearmotor or brake. It may be hot enough to cause injury or to be

painful. This condition is normal for modern motors, which operate

at higher temperatures when running at rated load and voltage.

8. Protect all electrical lead wires and power cables against contact

with sharp objects or moving parts.

9. Do not kink electrical lead wires and power cables, and never

allow them to touch oil, grease, hot surfaces or chemicals.

10. Upon usage, the inside surfaces of the brake will contain friction

material dust. This dust must be removed before servicing or

adjusting the brake. It is important to avoid dispersing dust into

the air or inhaling it, as this may be dangerous to your health. To

avoid dispersing the dust into the air, DO NOT blow the dust off

the brake. Remove dust with a vacuum. Avoid breathing dust.

Wear a respirator if dust becomes airborne.

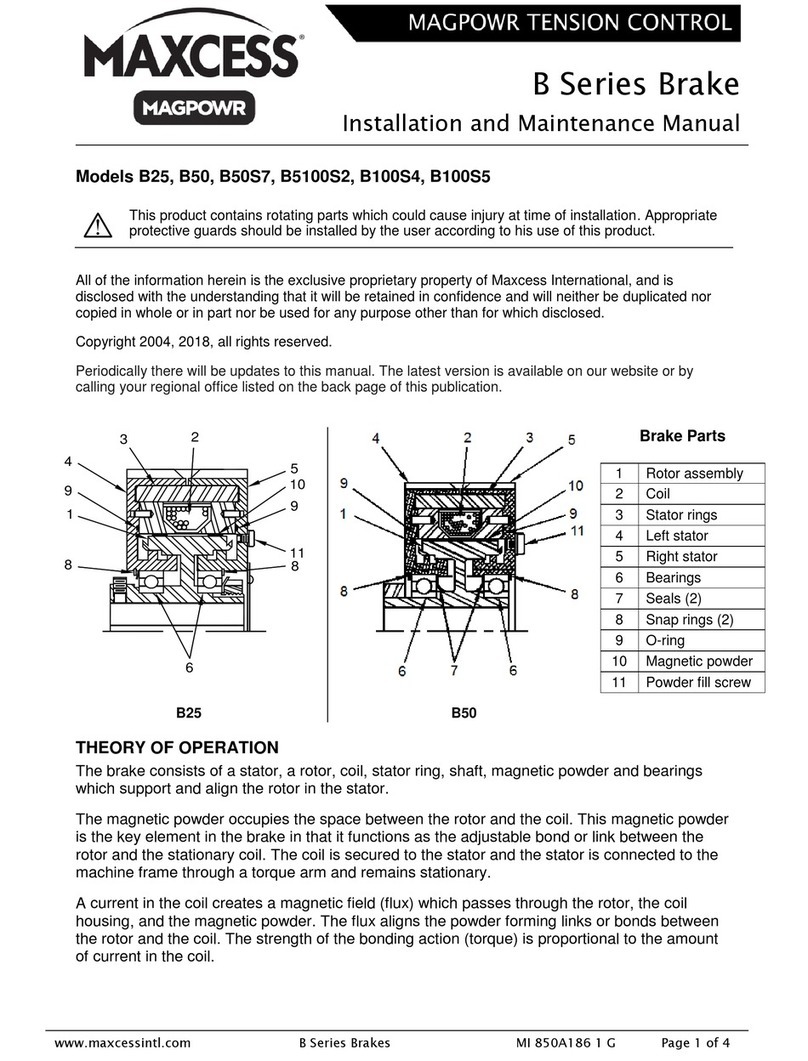

INSTALLATION AND OPERATION (See Figures 2, 3, 4 & 5)

1. Install 3/16” square key (31) in motor shaft keyway.

2. Install brake hub (30) onto motor shaft. Tighten two hub (30) set

screws to 94 lb-in. of torque or until long arm of allen wrench flexes.

3. Remove cover nuts (19) and cover (29).

4. Install brake assembly over brake hub (30).

5. Install and tighten two mounting screws (provided by customer).

6. Connect coil (21) wire leads as indicated in Figure 3.

7. Reattach cover (29) and secure by fastening cover nuts (19).

MANUAL RELEASE (See Figure 4)

Manually release the brake by rotating the release lever (24) until it has

moved approximately 90°. The brake will remain in the released

position until the lever is moved back to reset by hand or until the

brake is activated electrically.

MAINTENANCE AND SERVICE

FRICTION DISC REPLACEMENT (See Figure 4)

When total wear on rotating disc (11) reaches 1/16” (or total disc thick-

ness is less than 1/8”), replace disc as follows:

1. Remove the two cover nuts (19) and cover (29).

2. While holding pivot nut (15), loosen and remove lock nut (16).

3. Remove pivot nut (16).

4. Lift and move pressure arm (14) to remove the spacer bar (13)

and stationary disc (12).

5. With pressure arm (14) still moved, slide the friction disc (11) off the

hub and pull it out of the side of the brake.

6. Insert new rotating disc (11) in opposite fashion of disc removal.

7. Reassemble all other parts in reverse order.

8. Readjust magnet air gap as described under WEAR ADJUSTMENT.

Figure 4. Brake Gap Adjustment

Figure 3. Wiring Diagram

2

www.dingsbrakes.com