Kendrion Binder Magnete GmbH Operating Instructions 76 ..P..B00 Last updated: 30 Dec. 2009 Page 2

Contents

1. General information .............................................................................................................................. 3

1.1 Introduction ............................................................................................................................................ 3

1.2 Standards and directives ....................................................................................................................... 3

1.3 EC Declaration of Conformity ................................................................................................................ 3

1.4 Declaration of Incorporation

(in accordance with Annex II, part 1, Section B of Machinery Directive 2006/42/EC)........................... 4

1.5 Manufacturer's liability ........................................................................................................................... 4

2. Product description .............................................................................................................................. 5

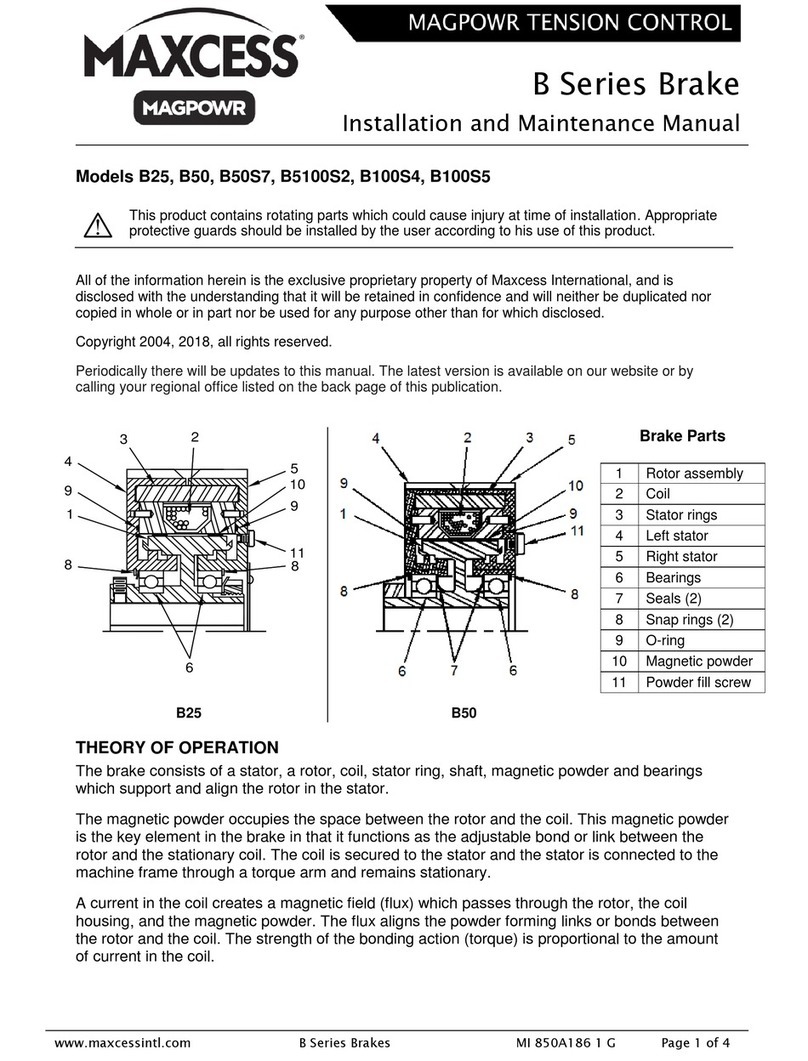

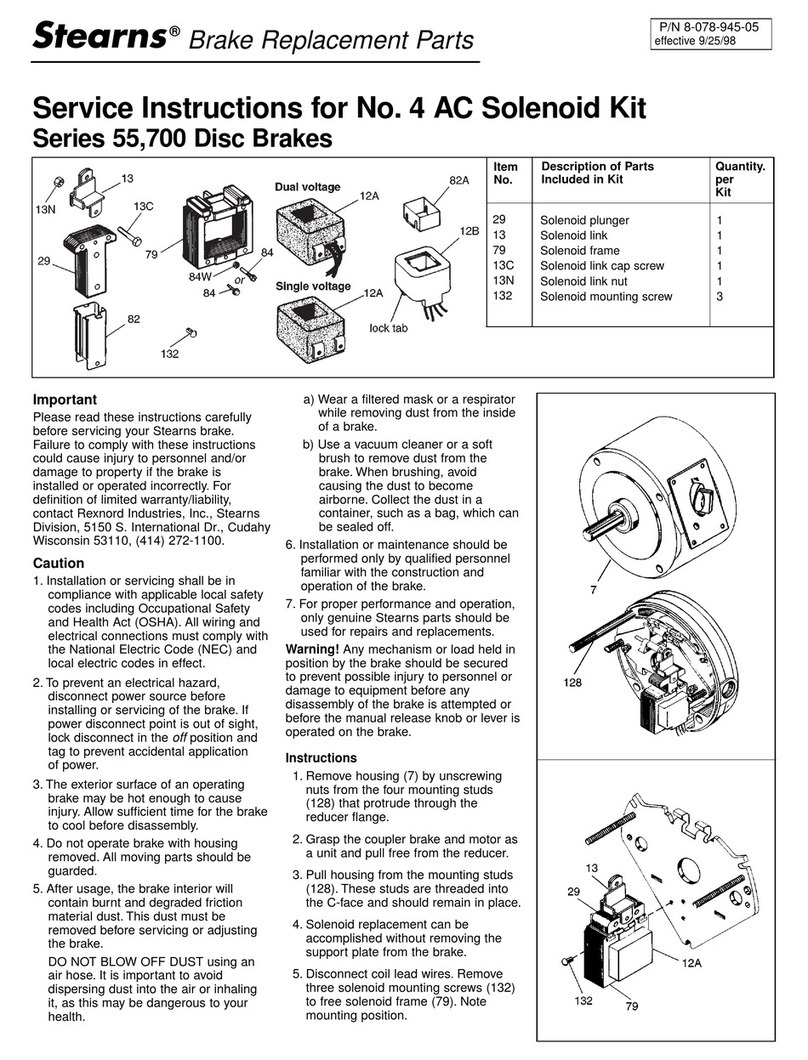

2.1 Operating principle................................................................................................................................. 5

2.2 Structure ................................................................................................................................................ 5

3. Installation.............................................................................................................................................. 7

3.1 Mechanical installation........................................................................................................................... 7

3.2 Installation of the hand release (29) (brakes types with hand release)................................................. 8

3.3 Electrical connection and operation....................................................................................................... 9

3.3.1 AC power supply ......................................................................................................................... 10

3.3.2 Microswitch (13) and thermoswitch (11 and 12) connection....................................................... 12

3.4 Electromagnetic compatibility .............................................................................................................. 14

3.5 Set-up and start-up .............................................................................................................................. 16

3.6 M2 rated torque adjustments ................................................................................................................ 17

4. Maintenance......................................................................................................................................... 18

4.1 Checks and service ............................................................................................................................. 18

4.2 Spare parts and accessories ............................................................................................................... 21

5. Condition at delivery........................................................................................................................... 21

6. Emissions............................................................................................................................................. 21

6.1 Noise.................................................................................................................................................... 21

6.2 Heat ..................................................................................................................................................... 21

7. Troubleshooting.................................................................................................................................. 22

8. Safety.................................................................................................................................................... 23

8.1 Intended use ........................................................................................................................................ 23

8.2 General safety information................................................................................................................... 23

8.2.1 Set-up.......................................................................................................................................... 23

8.2.2 Set-up and start-up ..................................................................................................................... 24

8.2.3 Installation ................................................................................................................................... 24

8.2.4 Operation..................................................................................................................................... 24

8.2.5 Maintenance and repair .............................................................................................................. 24

8.3 Warning symbols ................................................................................................................................. 25

9. Definitions............................................................................................................................................ 26

10. Technical specifications..................................................................................................................... 28

11. Product versions (types).................................................................................................................... 30

12. Authorised repair shops for maintenance work .............................................................................. 30

Issued by: Kendrion Binder Magnete GmbH

Industrial Drive Systems

Replaces the issue dated: 10 June 2008

Translation of original German operating instructions issue dated: 30 December 2009