To order parts and supplies: 800.345.1178 >> eastwood.com 3

ASSEMBLY

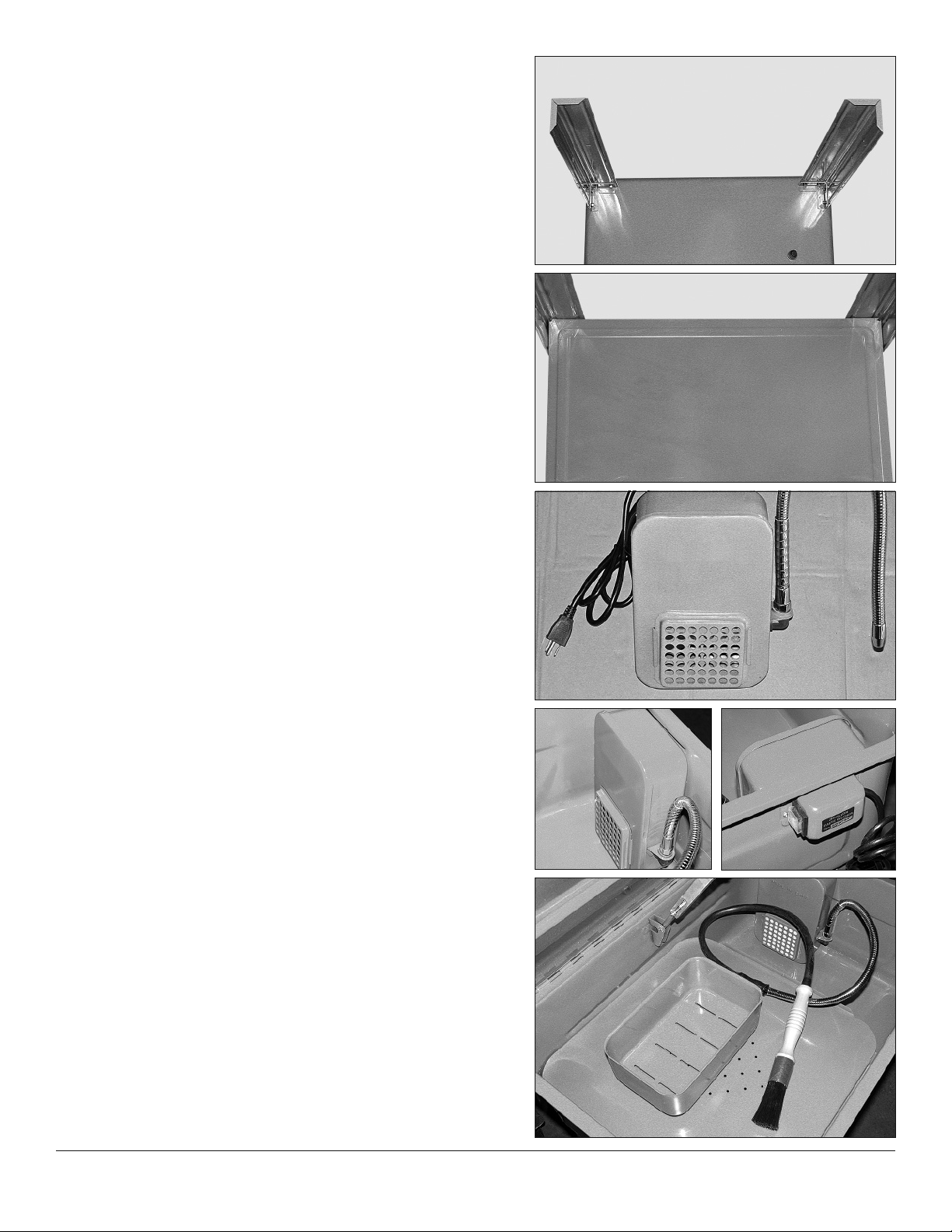

1. With spring loaded lid closed, place Tub unit upside down on a non-scratching surface

(cardboard, carpet etc.).

2. Attach each of the 4 legs with 4 sets each of 6mm screws, lockwashers and nuts to the

brackets on the Tub unit (Fig 1).

3. Attach Storage Tray to holes located mid-way of 4 legs with 2 sets each of

6mm screws, lockwashers and nuts (Fig 2).

4. Thread the fitting of the Flexible Metal “Gooseneck” fluid outlet tube onto the Pump outlet

(Fig 3).

5. Place the Pump Box Lid over the open Pump Box with fluid intake perforations and raised

ribs downward and over pump. Snap into place (Fig 3).

6. Place white fibrous 4” x 4” Filter Media pad into the perforated Filter Media Cover and

slide into place under raised-ribs of the Pump Box Lid (Fig 3).

7. Return the Tub unit to the upright position on its legs and open the spring-

tensioned lid.

8. Route the power cord of the Pump Box Assembly through the rectangular opening on the

side of the Tub Unit with the Inlet Filter downward and facing inward.

The Power Switch is visible through the rectangular opening. Hook the raised offset tab

on the rear of the Pump Box Assembly over the bottom edge of the rectangular opening

(Figs 4-5).

9. Check to see that the Tub drain plug is tightly installed.

10. Place the Parts Cleaning Tray over the ledges on the walls of the tub (Fig 3).

11. Make sure the Nozzle of the Flexible Metal “Gooseneck” Fluid Outlet Tube is

facing in toward the center of the Tub and downward (Fig 3).

12. The installation of the included Flow-through Parts Cleaning Brush and hose extension is

optional. The molded fitting on the hose end opposite the brush

may be slipped into place over the Fluid Outlet Tube Nozzle (Fig 3).

13. Be sure the Nozzle or Brush outlet is facing in toward the center of the Tub

and downward.

14. Fill unit with suitable, water-based degreasing solution sufficiently to cover the entire Inlet

Filter (approx. 12 gallons). Important Note: Follow degreasing solution mixing, usage and

safety label instructions carefully before using.

15. Plug power cord into an approved, grounded and GFI equipped 120 Volt AC,

60hz. Outlet.

16. Turn Power Switch to the “On” position. The Parts Washer is now ready for use.

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6