Eaton is a registered trademark.

All other trademarks are property

of their respective owners.

Eaton

1000 Eaton Boulevard

Cleveland, OH 44122

United States

Eaton.com

© 2017 Eaton

All Rights Reserved

Printed in USA

Publication No. SA210009EN

June 2017 ACCQG-17R

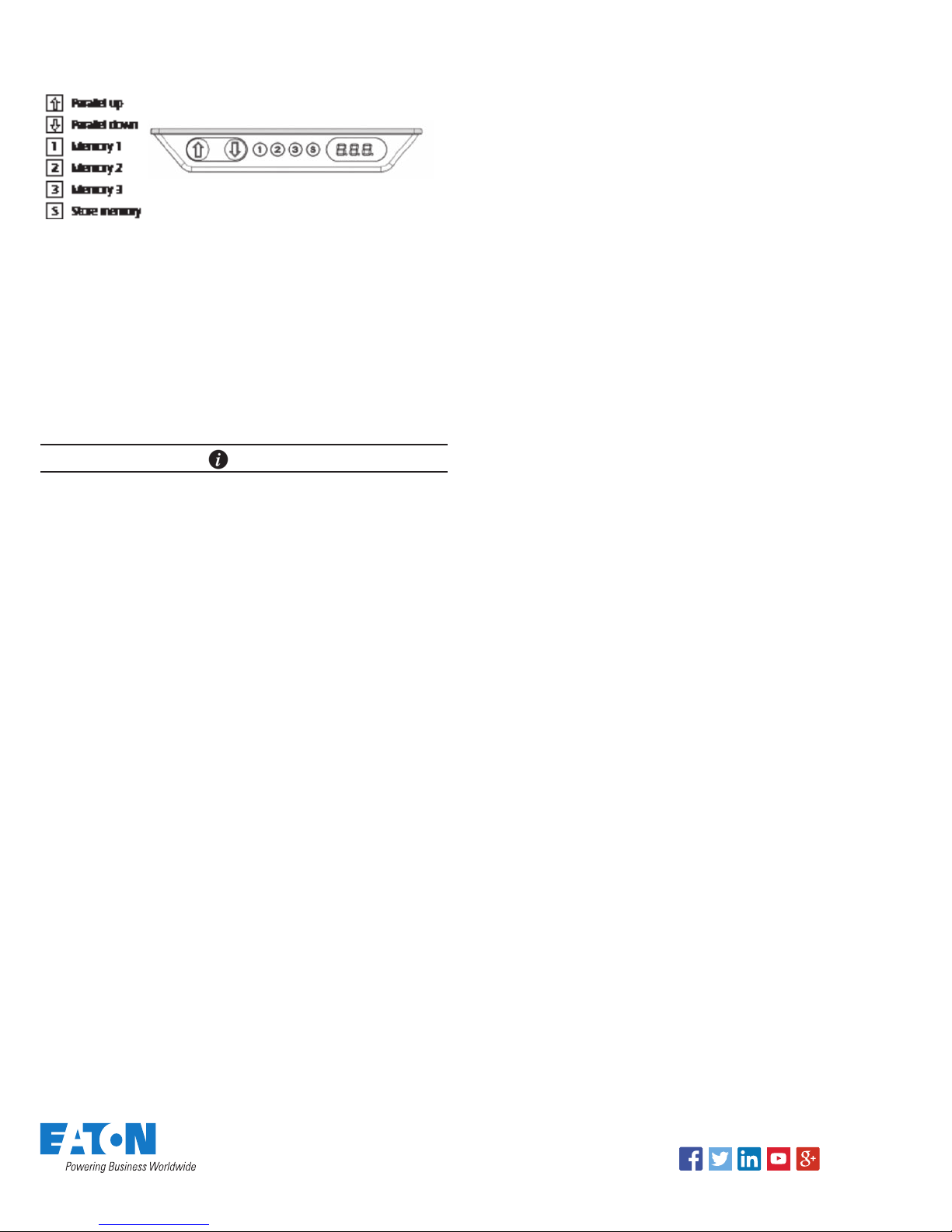

Operating the Height Adjustable Worksurface

Your command console is equipped with a DP1CS control pad.

Normal operation:

To run the desk up or down press the UP or DOWN arrow button

(/\ or \/), and keep it pressed until the desk reaches the desired

height. The display will count up or down while running, and after

stopping it will continually show the current height of the desk.

As a safety precaution, your Eaton’s command console is pre-

programmed to “single reference” mode. In “single reference”

mode, the controller requires the presence of four healthy lift

motors. In the event of a lift motor fault condition, the controller

will disable the signal to the remaining motors, preventing the

movement of the worksurface.

NOTE

The console’s lift motors have sensors that will detect an

obstruction when moving. If the worksurface is jarred during

operation or an obstruction is sensed, the worksurface will stop

movement and automatically begin to move in the opposite

direction.

Store a memory position:

The four small buttons are used for storing memory.

•Press the “S” button; the display will flash “S” for two seconds

•Within these two seconds press one of the small buttons

with numbers “1”, “2” or “3” and the position will be stored

at this button.

•The panel will acknowledge the setting by showing “1”, “2” or

“3” in the display, depending on the chosen position

Memory Drive

Press and hold one of the memory buttons and the system will

start driving to the pre-programmed memory position. Keep the

button pushed until the position is reached.

Display Function

Shows the actual height either in inches or cm. The display also

shows error codes.

Adjust the display to show the correct height:

It may be necessary to adjust the height display after the initial

set up of the console. Simultaneously press the “UP” and

“DOWN” arrow buttons (/\ or \/) and keep them pressed for

five seconds. This allows the initial height to be reset. Until the

initial height is reset, the display will show three minuses (- - -).

Thereafter the display will revert to showing the height. The

height can then be adjusted by pressing either /\ or \/ until the

correct height has been set. The system will return to normal

operation (and give a short blink) after five seconds of inactivity

on the buttons. The feature can be disabled via configuration

after which pressing the /\ and \/ buttons at the same time will

be considered an illegal keypress.

Switch between cm and inches:

Your DP1CS control pad is pre-configured to display in inches.

Switching between cm and inch can only be done via the DPF

configurator.

Adjusting the light intensity of the LED display

Possible light settings are off, 6%, 12%, 19%, 25%, 37%, 50%,

75% and 100%.

The adjustment can only be done via the DPF configurator

Adjusting the light timeout

Possible light timeouts are: 0-15 sec and off.

The adjustment can only be done via the DPF configurator.

Error Code Information

Possible error codes are shown below. The errors will only be

displayed when a button is pressed. The display blinks while

showing the error. E16 overrules any other error as the detection

is registered only in the display and no message is sent to the

control box.

E01 The console has an unknown position and needs to be

initialized (see section III.D.)

E02 Overload upwards has occurred

E03 Overload downwards has occurred

E16 Illegal keys pressed

Other diagnostic error codes may get displayed. When calling

your customer service representative for technical assistance,

please take note of all displayed error codes.

Using the Personal Environment System

Refer to the instructions provided with the personal environment

system.

Follow us on social media to get the

latest product and support information.