Eco Angus Evo Multi Fuel Boiler User manual

Angus Evo Multi Fuel Boiler

Installation, Operation and Maintenance Manual

Index

Information on the boiler plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Boiler dimensions, boiler packaging dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Technical parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

A table of the Angus Evo Heating Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Ensuring safety of equipment and people . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Head loses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operating Instructions

Angus Evo Series Boiler – general features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Recommended fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Control and safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Temperature safety valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Hydraulic connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Putting the boiler into service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Checking the boiler before turning it on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Filling and draining the heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation and controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Starting a fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting outlet water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Stoking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Overnight heating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Removing solid combustion residuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dewing and tarring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Boiler shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Short term shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Long term shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Important information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Boiler cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Boiler repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Warranty and warranty conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Boiler delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation Instructions

Boiler installation – general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Heating water requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Boiler location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Minimum distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Boiler room disposition layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Angus Evo boiler parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Spare parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Accumulator tank capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Transportation and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Flue pipe installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chimney and chimney connection warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 1

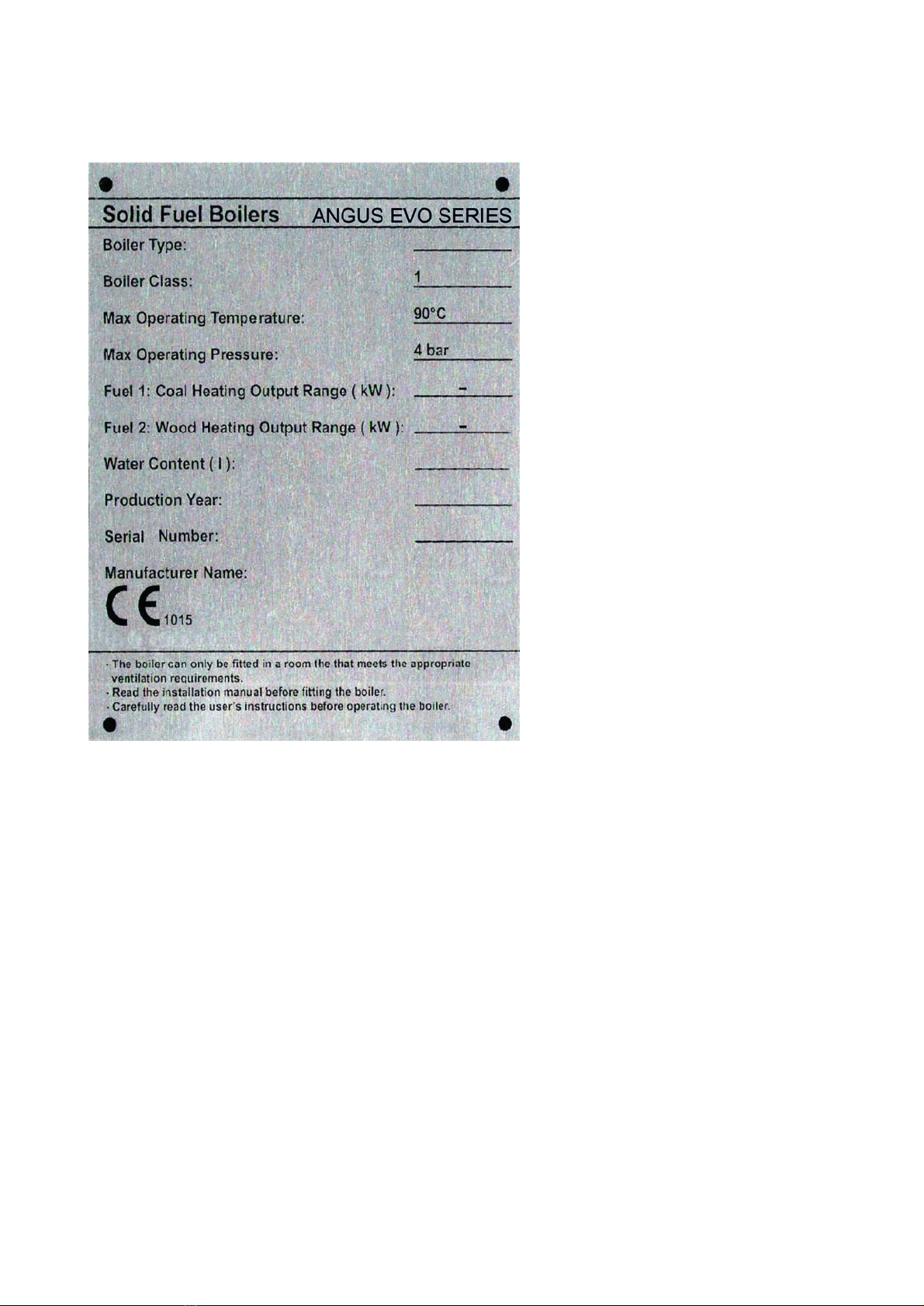

Information on the boiler plate

The boiler Serial No. is shown on the plate which is attached to the cover panel of the cast iron body.

fig.01

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 2

Boiler dimensions

fig.02

Boiler packaging dimensions

fig.03

EV-03 EV-04 EV-05 EV-06

L (mm) 609 709 809 909

EV-03 EV-04 EV-05 EV-06

L (mm) 665 765 865 965

Notice: Please obey to the meanings of the symbols on packaging for health care

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 3

Technical parameters

Series Name EV-03 EV-04 EV-05 EV-06

Number of Elements Pcs. 3 4 5 6

Nominal Heat Output (Black Coal – Walnut) kW 15-17 24-27 31-34 38-41

Nominal Heat Output (Hardwood – Split Logs) kW 12-14 18-20 25-27 30-33

Minimum Heat Output kW 9.2 12.1 14.6 18.5

Heating Water Maximum Temperature ˚C 90

Heating Return Water Minimum Temperature ˚C 50

Burning Time for Nominal Output (B. Coal) hr >4

Burning Time for Nominal Output (H. Wood) hr >2

Range of Temperature Control ˚C 30-90

Maximum Pressure of System bar 4

Minimum Pressure of System bar 0.4

Boiler Water Content L 16.33 20.30 24.27 28.24

m30.01633 0.0203 0.02427 0.02824

Exit Flue Connection Diameter mm 180

Combustion Chamber Dimensions (WxH) mm 300 x 380

Combustion Chamber Dimensions (L) mm 245 345 445 545

Water Inlet-Outlet Connection (") G1 1/2"

Inlet-Outlet Safety Cooling Loop Connection (") G 3/8"

Minimum Chimney Depression mbar 0.12 0.14 0.17 0.20

Safety Value Temperature Limit ˚C 95

Boiler Category (according to EN 303-5) Class 1

Boiler Dimensions (WxH) mm 450 x 947

(L) mm 609 709 809 909

Exit Flue Gas Temperature ˚C 190-260

Maximum Noise Level acc. to Valid Norms dB 45-60 (A)

Boiler Net Weight kg 177 207 237 267

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 4

A table of the Angus Evo Heating Area

*** For cold climate and low insulation houses, Max Heating Area should be decreased approximately 10%

*** For mild climate and strong insulation houses, Max Heating Area should be increased approximately 10%

FOR COAL

MODEL HEAT OUTPUT (kW) HEAT OUTPUT (kCAL) MAX HEATING AREA

(UNC) (M2)

Solid Fuel – 03 17 14,617 146

Solid Fuel – 04 27 23,216 232

Solid Fuel – 05 34 29,235 292

Solid Fuel – 06 41 35,254 353

FOR WOOD

MODEL HEAT OUTPUT (kW) HEAT OUTPUT (kCAL) MAX HEATING AREA

(UNC) (M2)

Solid Fuel – 03 14 12,038 120

Solid Fuel – 04 20 17,197 172

Solid Fuel – 05 27 23,216 232

Solid Fuel – 06 33 28,375 284

SOLID FUEL BOILERS HEAT OUTPUT AND MAX HEATING AREA (M2)

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 5

Introduction

1. The boiler and all associated equipment must be installed and used in accordance with the installation design, all applicable

legal regulations and technical standards and with the manufacturer’s instructions. The boiler may be used only for the purpose

for which it is intended.

2. The boiler may be installed only in an environment which it is designed for.If the boiler is delivered to the client by the same

person who installs it, he must give the user also all accompanying boiler documentation (in particular User Guide, Service Book,

etc.). Until the boiler is put into service, the original packaging must be kept in case the boiler has to be transported again.

3. After installation, the boiler must be put into operation by a service organisation authorised by the manufacturer.

4. The boiler complies with regulations applicable in the European Union. When used in the conditions of countries outside at

EU, any deviations from local regulations must be identified and rectified.

5. In the event of a defect, call an authorised manufacturer’s service organisation–any unauthorised interference may damage

the boiler (and possibly also associated equipment!).

6. The service technician putting the boiler into operation for the first time must show the user the various parts of the boiler and

how to control the boiler, with the boiler safety elements, their signals and appropriate user reaction to them, with fundamental

parts of the boiler and their controls. If the boiler is delivered to the client by the same person who installs it,he must make

sure that the original packaging is available in case the boiler has to be transported again.

7. Check the delivery for completeness.

8. Check whether the model and type supplied is suitable for the required use.

9. Whenever you are not certain how to control the boiler, study appropriate instructions in this Operation and Installation Guide

carefully and proceed accordingly.

10. Never remove or damage any markings and signs on the boiler. Keep the original packaging until the boiler has been put

into service, in case the boiler has to be transported again.

11. When making any repairs, only original parts must always be used. It is forbidden to make any changes to the boiler’s internal

installation, or to interfere with it in any way.

12. At the end of its life cycle, the boiler its package and its parts must be disposed of in a way avoiding harm to the environment.

13. The manufacturer disclaims any responsibility for damages caused by the failure to abide by:

■ The conditions stipulated in this Operation and Installation Guide;

■ Applicable regulations and standards;

■ Sound installation and operation procedures; and

■ Conditions stated in the Warranty Certificate and the Service Book.

Situations might occur in practice, when the following essential precautions must be taken:

■ Shut the boiler down every time when there are any (even temporary) flammable or explosive fumes present on the premises

from which combustion air is supplied to the boiler (e.g. from paint when painting, laying and spraying molten substances,

from gas leakage, etc.);

■ If it is necessary to drain water from the boiler or from the whole system, the water must not be dangerously hot; and

■ If there is any leakage from the boiler’s heat exchanger, or when the exchanger is clogged up with ice, do not attempt to

start up the boiler until normal operating conditions have been restored.

Ensuring safety of equipment and people

■The boiler (and all accessories) complies with the requirements of EN 303-5 its updates and all relevant European standards.

■In order to run and operate the boiler in accordance with the purpose for which it is designed in actual conditions of use

(hereafter referred to only as use), it is necessary to abide also by additional requirements the most essential ones of which

(i.e. those which must not be omitted) are found in the related regulatory documents.

■In addition to the above mentioned documents, it is necessary when using the boiler to proceed in accordance with this

Operation and Installation guide and the accompanying boiler manufacturer’s documentation.

■Any interference by children, persons under the influence of narcotic drugs, certified persons, etc., when using the boiler, must

be prevented.

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 6

Head loses

fig.04

Operating instructions

Angus Evo Series Boiler – general features

■Angus Evo Series solid fuel fired boiler is designed for heating both residential and industrial buildings.

■Besides professional installation, precondition for correct functioning of the boiler is the required chimney thrust and

correct operation.

■Angus Evo Series solid fuel fired boiler is designed for heating systems which are suitable for forced circulation systems only.

■Angus Evo Series boilers are available in four output series (determined by the number of segments 3, 4, 5, 6) from 17 to 41 kW.

■The cast iron boiler body comprises of segments and serves as a combustion chamber (including combustion gases routes),

and at the same time as a water reservoir (including water routes). Segments are of three types – front and rear, inserted

between which are 1 to 8 middle segments (of the same kind). By assembling and joining together an appropriate number of

segments, a boiler body of the required size is constructed (both the combustion chamber and the water reservoir). Assembled

boiler body is equipped with necessary pipe sections for water connection. It also has brackets for fitting thermostat sensors

and brackets on feet for fastening the boiler to the base. Attached to the cast iron boiler body are sheet metal covers which

are fitted on the inside with thermal insulation.

■To ensure that the boiler functions correctly and runs economically, it is important that its nominal output is equal to the thermal

losses of the heated premises.

■Choosing a boiler of insufficient output will result in inadequate heating of the premises, and thus failure to provide a

heating comfort.

■Choosing a boiler of unnecessarily high output will result in the boiler not running in full output, and as a consequence in

tarring and dewing.

Recommended fuel

■Recommended fuels for Angus Evo boilers are coal, coke and firewood.

■Optimal coal and coke granularity is 24-60mm.

■Optimal firewood size is logs of diameter 40-100mm. Their length will depend on how many segments the boiler have.

■Fuel must be stored in a dry place. To reach the boiler nominal output, water content in firewood must not exceed 20%.

■Approximate stoking intervals (referred to as Burning Time) are shown in the Technical Data Table on page 3.

■The boiler is stoked manually.

Please note

The boiler is not intended for burning any type of waste.

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 7

Control and safety devices

Angus Evo boilers are equipped with three main control elements:

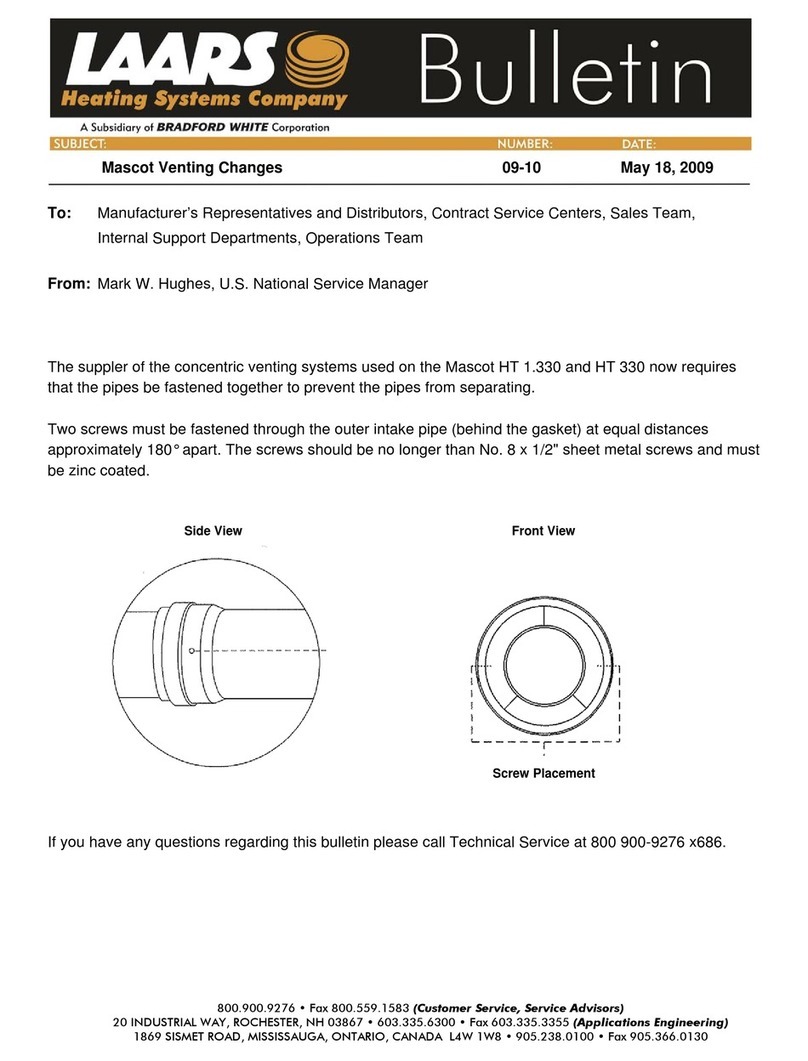

A chimney flap (Fig. 05), by means of which the chimney thrust can be controlled, i.e. the discharge of combustion fumes into

the chimney. The flap is situated in the flue neck of the boiler, and is controlled manually.

fig.05

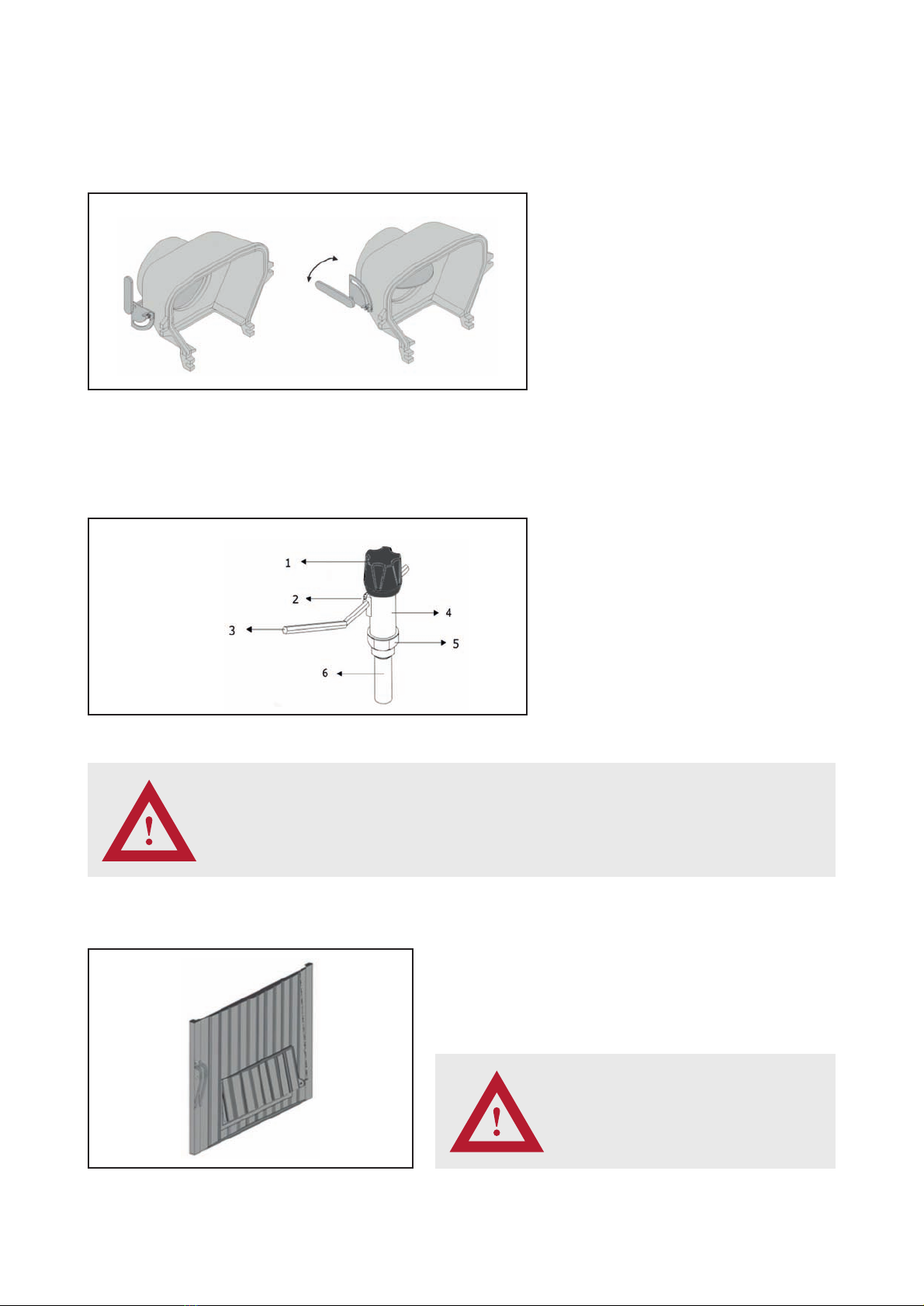

Another thrust control element is a thermo-mechanical output regulator (Fig. 06). It is situated on the outlet from the boiler

cast iron body. It detects temperature of the hot water and regulates the supply of primary combustion air to underneath the boiler

stoker, by opening or shutting a flap situated in the ashtray door.

fig.06

■When fitting the safety and the control elements remember to meet the principles of work safety.

■If replacing of safety device and of thermo-mechanical output regulator is necessary, please use

recommended devices in case of using any other type of the device negotiate with Eco Angus Ltd.

■Functionality of thermo-mechanical output regulator (satrom) must be checked or inspected by

authorised person once in a year.

Changing the hatch position controls the combustion intensity and thus the boiler output. The thermo mechanical output regulator is

connected with the regulating hatch by chain. The chain is connected to the hatch in such a way that its tension can be set (Fig. 07).

fig.07

Chimney flap

Thermo-mechanical regulator

1. Regulation head

2. Arm holder

3. Arm

4. Regulator body

5. Hexagon

6. Pit

Regulation hatch

Keep object’s away from regulation hatch’s front

and channels for allowing primary air transfer.

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 8

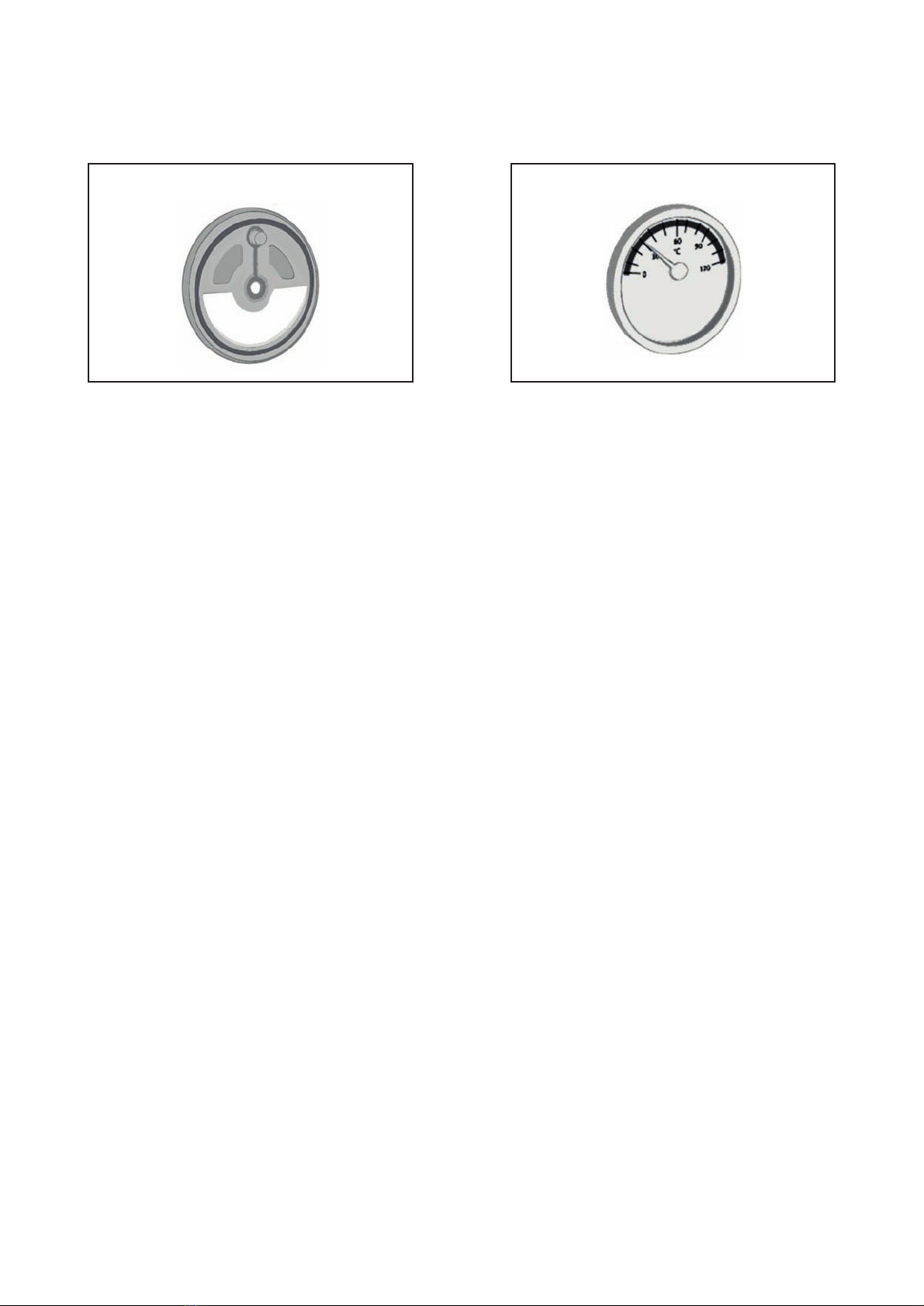

Supply of secondary combustion air is controlled by an air rosette (Fig. 08), situated in the boiler’s stoking door, which has a direct

effect on the level of emission.

Hot water temperature can be checked on a thermometer (Fig. 09), which is situated in the front boiler cover above the stoking door.

fig.08 fig.09

Temperature safety valve

The Angus Evo boilers can be equipped with a safety heat exchanger with thermal safety valve as an optional which ensures

dissipation of excessive heat without additional device and supply of external energy in such a way that the maximum permissible

boiler temperature of 95°C is not exceeded.

For more information on the safety heat exchanger with thermal safety valve please see http://www.ecoangus.co.uk/

ecoangus_images/Test_Reports_and_Instruction%20Manuals/1958_Safety_Heat_Exchanger_Manual_FINAL.pdf

Air rosette Thermometer

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 9

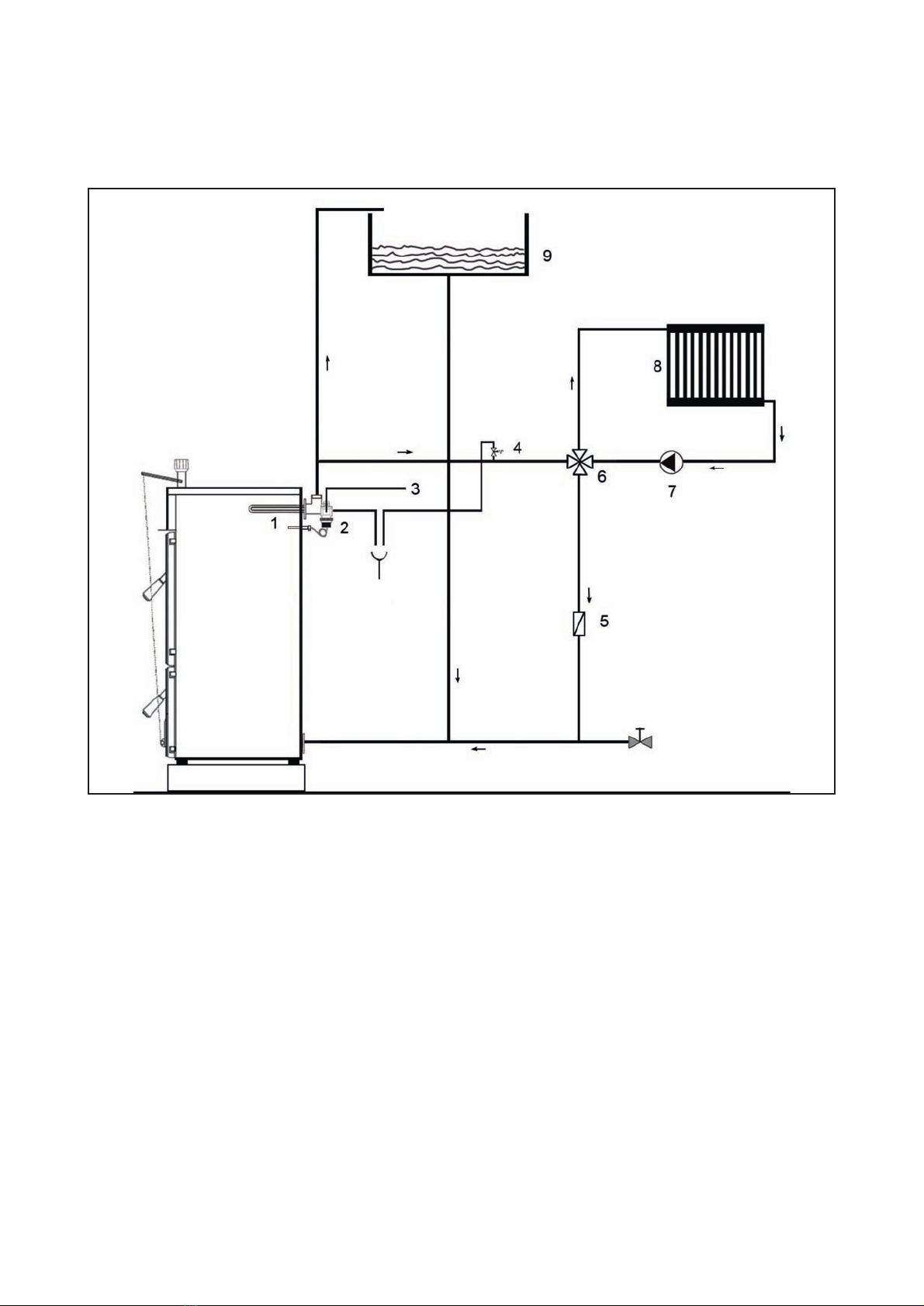

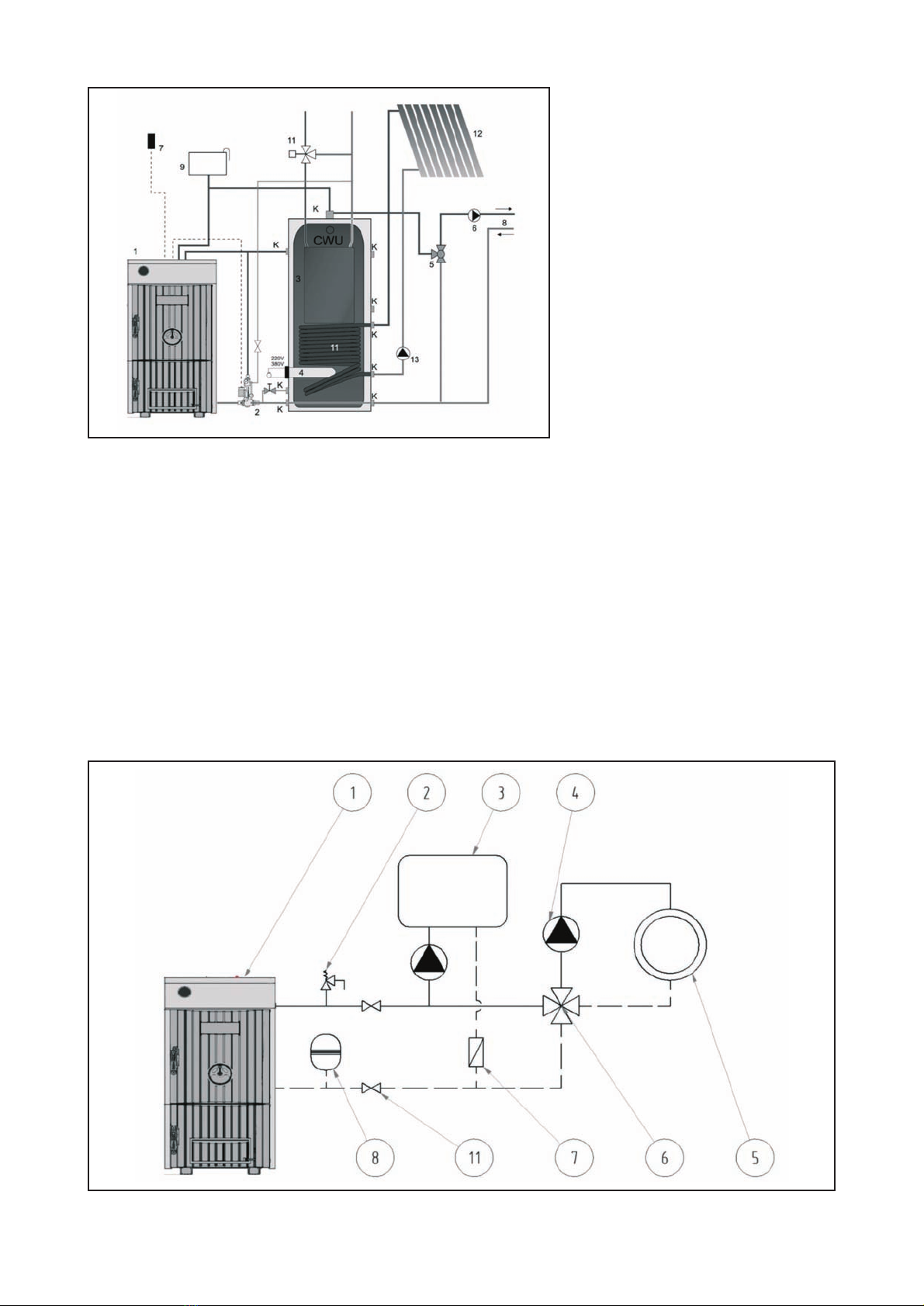

Hydraulic connection diagram

It is suggested hydraulic system should be installed according to following schemes.

Open expansion tank system

fig. 10

1. Safety Heat Exchanger (SHT) 6. Mixing Valve

2. Safety Valve (TS 131, STS 20) 7. CH Pump

3. Cold Water Feed 8. Heating System

4. System Safety Valve (3 bar – 1/2") 9. Open Expansion Tank

5. NRV

■Open-type expansion tank must be equipped with the highest level in the entire hydraulic system.

■The expansion tank must be selected properly against the changes in water volume resulting from heating and cooling.

■The expansion tanks and their connecting pipes must be protected against to freezing.

■Diameter of drainage pipe must be selected properly against to overflow into tank.

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 10

1. Boiler 4. Safety Valve (TS 131, STS 20)

2. Open Expansion Tank 5. Four Way Mixing Valve

3. Radiator

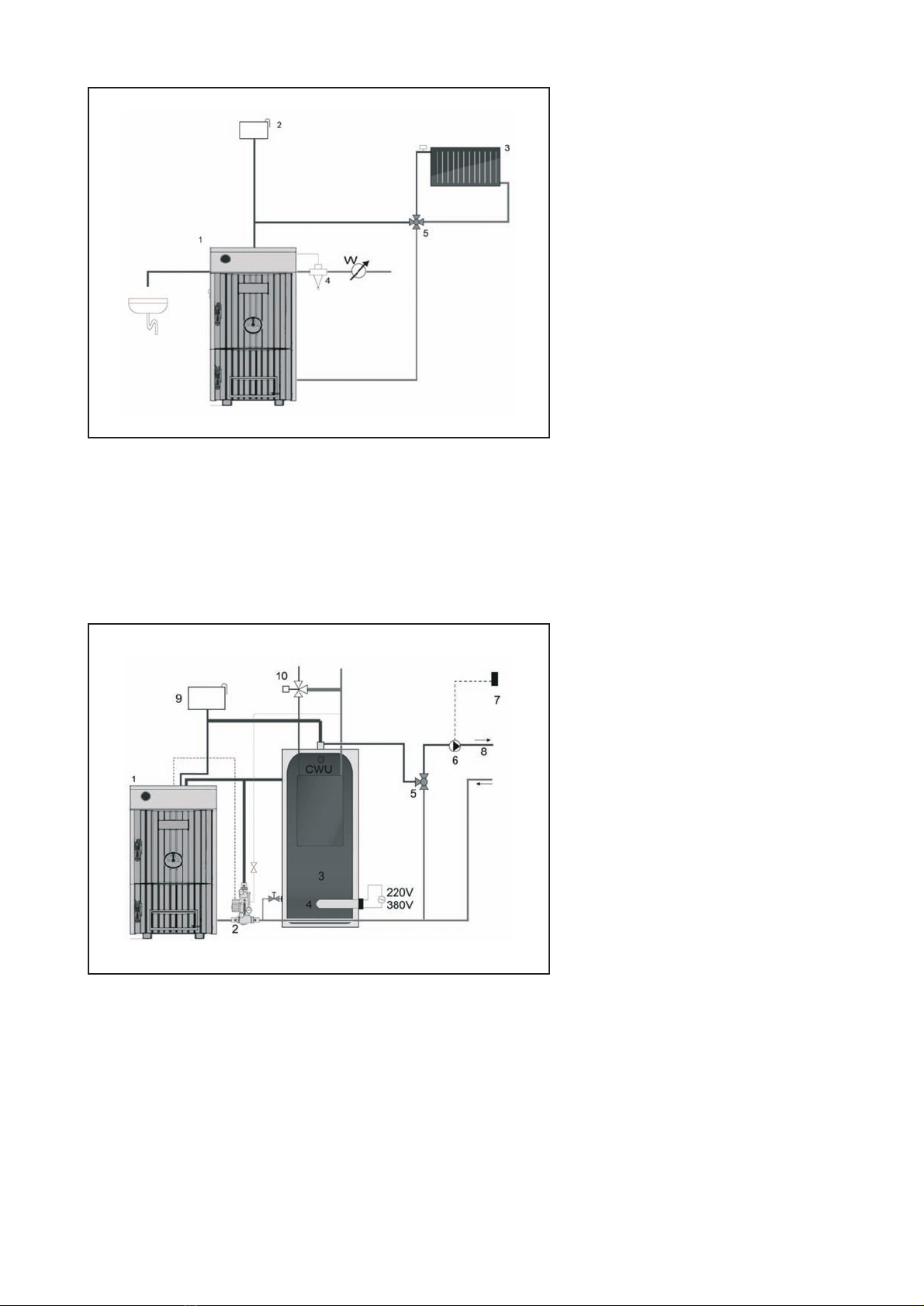

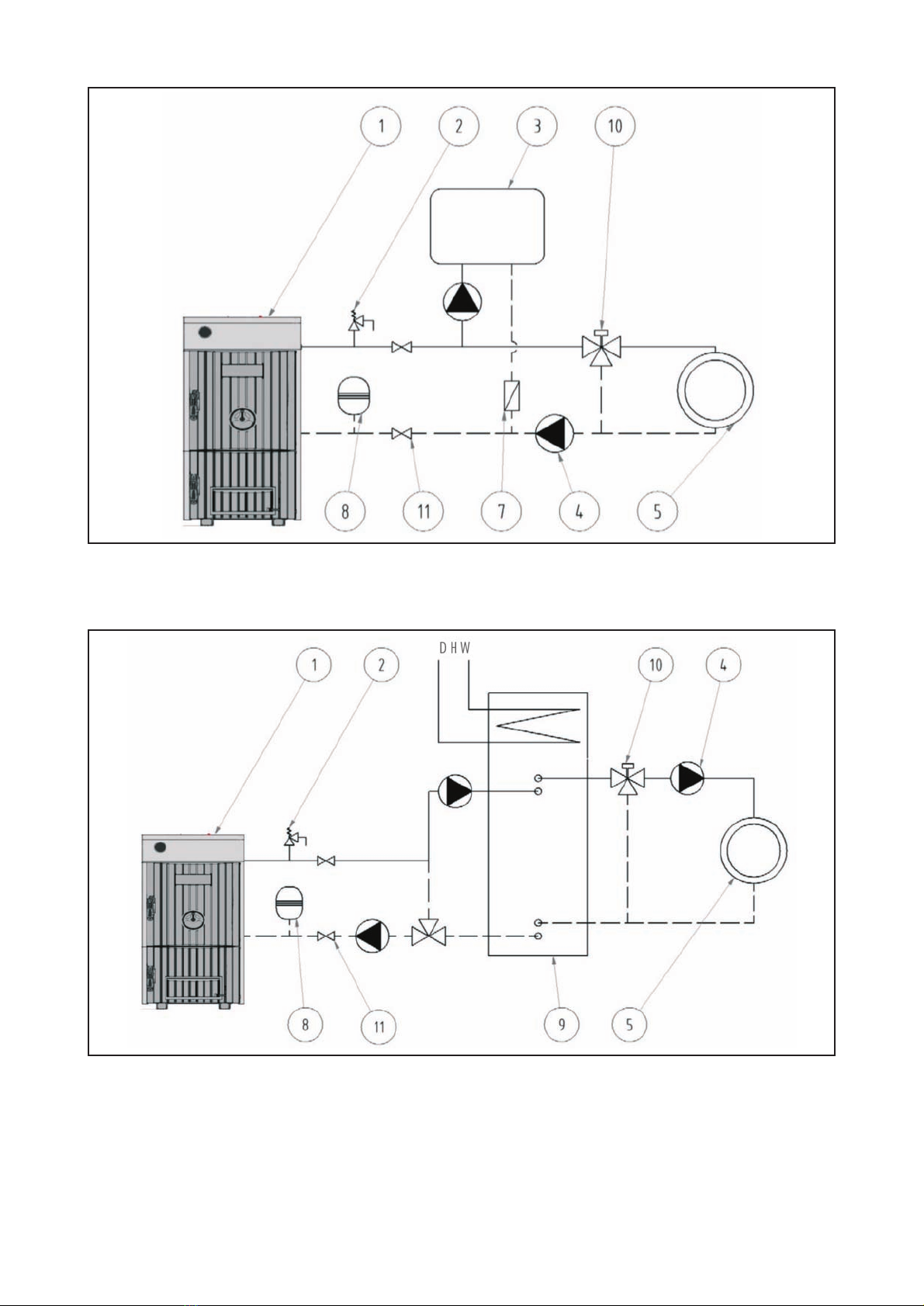

fig. 11

1. Boiler

2. Laddomat 21-60 operated by Flue

Thermostat – 50-300°C

3. NAD or NADO Accumulator Tank

4. Immersion Heater

5. Three Way Mixing Valve

6. Circulating Pump

7. Room Thermostat

8. Heating System Outlet

9. Open Expansion Tank

10. DHW Mixing Valve

fig. 12

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 11

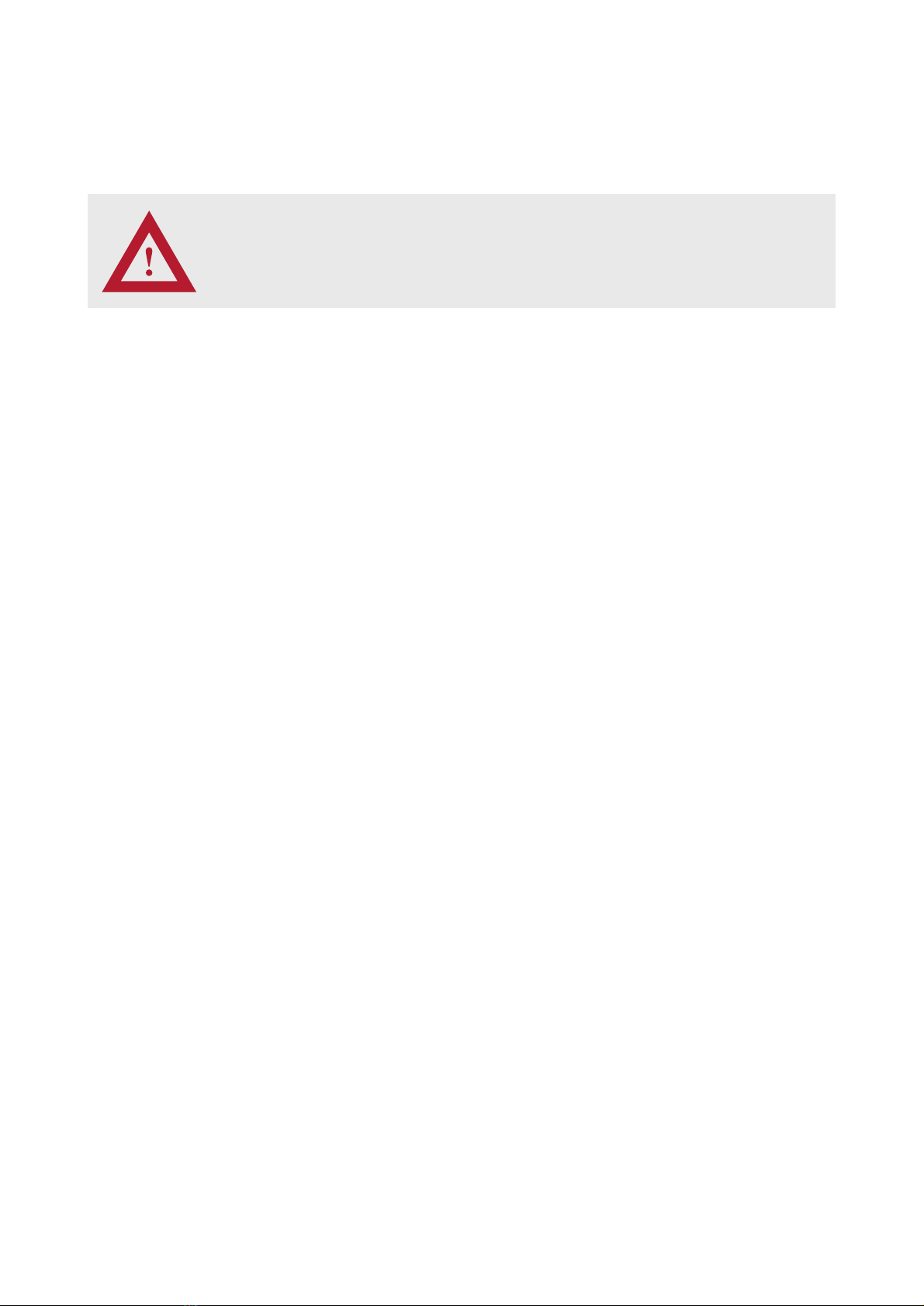

fig. 13

fig. 14

1. Boiler

2. Laddomat 21-60 operated by Flue

Thermostat – 50-300°C

3. NAD or NADO Accumulator Tank

4. Immersion Heater

5. Three Way Mixing Valve

6. Circulating pump

7. Room Thermostat

8. Heating System Outlet

9. Open Expansion Tank

10. DHW Mixing Valve

11. Solar Coil

12. Solar

13. Solar Circulation Pump

Systems for Pressurised Tank

In a pressurized system consideration should be given for an appropriately sized expansion vessel on the central heating circuit

before the return to the boiler and a safety group on the primary flow. It is essential to ensure that the expansion vessel is sized

accordingly to your system. It is recommended to use an expansion vessel that is 15% of the volume of water in your system including

the primary water in the accumulator tank if applicable. An appropriately rated pressure relief valve should also be used in the

safety group. It is also recommended to use a safety heat exchanger with a thermal safety valve that we offer to ensure the boiler

has overheat protection installed.

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 12

fig. 15

fig. 16

1. Boiler

2. Safety Group (automatic air vent, pressure

reducing valve and pressure gauge)

3. DHW Cylinder

4. CH Pump

5. Heating System

6. Four Way Mixing Valve

7. NRV

8. Expansion Vessel

9. Accumulator Tank

10. Three Way Valve

11. Valve

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 13

Putting the boiler into service

Checking the boiler before turning it on

Before putting the boiler into operation, the service technician must check:

■Whether the installation conforms with the design;

■Whether the boiler has been filled in and is under pressure (on the thermo-manometer), and whether there are any leakage

in the heating system;

■Connection to the chimney – connection must be approved by an authorised chimney sweep (chimney inspection);

■Functioning of the heating controls.

Please note

The service technician must show the user how to control the boiler and enter the date when the boiler was put into service into the

Warranty Certificate.

Filling up and draining the heating system

The system can only been filled up or topped up with water which meets the parameters specified by EN standards. The water must

be clear, colourless, free of suspended particles, oil and chemically corrosive substances, and must not be acidic (pH factor must

be greater than 7.2). First of all, the heating system must be thoroughly flushed and all dirt washed out.

Please note

Water in system must not be reduced or put out unless the boilers is in service or under freezing danger.

Against freezing anti-freeze liquid can be added in to system water at the rate of 15%.

The failure to meet this requirement may lead to the heat exchanger getting clogged up, and the cast iron block may crack as a result.

During the heating season, a constant volume of water must be maintained inside the heating system. When topping up water,

care must be taken that no air is sucked into the system. Water must never be let out of the boiler or the heating system, unless it

is absolutely essential, such as before repairs, etc. Draining water and refilling the system with new water increases the risk of

corrosion and formation of incrustation.

Filling or topping up water to the heating system must always be done with the boiler cold or cooled down; otherwise the boiler

segments may crack!

Operation and controls

Starting a fire

Check on the thermo-manometer whether there is enough water in the heating system. Open the shutting valve between the boiler

and the heating system. Spread paper on top of the clean stoker and then enough finely chopped wood. Open the flue flap in the

chimney adapter and shut the stoking door. Light the paper through the open ashtray door and fully open the regulating flap in the

ashtray door. The fire has caught up enough, stoke a layer of main fuel on top of the burning firewood. When the fire is powerful

enough, stoke more fuel right up to the bottom edge of the stoking door and level it into.

Provide an even layer throughout the entire boiler depth. If the fuel suddenly turns into dark red blaze, open partially the secondary air

supply rosette in the stoking door. When the flame turns yellow, shut the secondary air supply rosette again. When the boiler has reached

the required output, it is suitable to partially shut the flue thrust flap to prevent heat from unnecessarily escaping into the chimney.

■Do not start the boiler without connecting the boiler to the chimney.

■Control chimney connections before starting the boiler.

■Adjust the chimney blow as requested level. If chimney blow is under mentioned levels try not to

use the boiler.

Setting the outlet water temperature

When the required outlet water temperature is say 60°C, heat up the boiler to a temperature for instance 5°C higher than the

required temperature of 60°C (measured on the thermometer on the boiler outlet pipe). Then turn the control knob to 65°C and

check whether the chain is stretched and the regulating hatch completely shut. This position of the chain and regulating hatch is

fine-adjusted by turning the control knob.Then let the regulation process work. When the water temperature drops, the regulating

hatch will start opening by the tension applied by the regulator on the chain. When the water temperature suddenly rises, the

regulating hatch will start opening. And the hot water temperature on the boiler outlet is controlled.

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 14

Stoking

First shut the regulating hatch; this will shut supply of combustion air into the boiler. Then open the chimney flap completely. Partially

open the stoking door and wait until all combustion gases have been sucked from the combustion chamber into the chimney. Only

then open the stoking door completely and start stoking the boiler. After shutting the stoking door, set the chimney flap again and

restore the functioning of the regulating hatch.

■Boiler doors must not be held open as the boiler is continously working.

■Provide a minimum 5 cm gap to be between top point of the fuel and ceiling of stoking chamber

when boiler is stoked.

Overnight heating mode

This mode is used when you want to maintain the fire in the boiler for instance over night. First scrape all ash out of the combustion

chamber, with the chimney flap completely opened. Then stoke the boiler with fuel and shut the boiler up completely. Then shut the

chimney flap and also almost shut the regulating hatch. This will reduce the chimney thrust and restrict the supply of combustion

air.Shut also the secondary air supply rosette in the stoking door. To restore the boiler’s required output, just open the chimney flap

and partially open the regulating hatch to the required boiler output.

Removing solid combustion residuals

This is done by removing and emptying the ashtray situated underneath the stoker in the ash compartment. This must be done

on a regular basis to prevent ash from accumulating and blocking the supply of air to the combustion chamber from underneath

the stoker.

Dewing and tarring

When starting fire in a cold boiler, water condensates on the walls and runs down into the ash compartment, which may make an

impression that the boiler is leaking. This dewing will disappear after the astray has settled on the boilers inside walls. When running

the boiler with low water temperature usually below 65°C, or when using damp fuel, water condensates in combustion gases and

the condensate runs down the boiler’s cold walls. Low temperature heating also reduces the chimney life. Therefore it is

recommended to equip the boiler with for instance a four-way blending valve which will ensure that the temperature of return water

does not drop below 50°C. Boiler tarring occurs under similar conditions (lack of combustion air, the boiler is choking). To prevent

dewing and tarring, we recommend you run the boiler at temperatures higher than 65°C and choose a boiler to match the required

heating system output. An oversized boiler suffers unnecessarily, because it has to be run at low temperatures.

Boiler shutdown

We do not recommend that you try to speed up the boiler combustion process.The fuel must burn completely on its own on

the stoker.

Short term shutdown

After shutting the boiler down, clean it, remove all combustion residuals,empty the ashtray, clean the stoking door contact surfaces

and the ash compartment, and then shut the boiler’s stoking door and ash compartment door.

Long term shutdown

When shutting the boiler down for a protracted period of time (heating season end), the boiler must be thoroughly cleaned from

all soot and ash sediments in which dampness accumulates and causes excessive corrosion of the boiler body.

Important information

■The boiler may only be operated by an adult person familiar with these Operating Instructions.

■Shut the boiler down every time there are any (even temporary) flammable or explosive fumes present on the premises from

which combustion air is supplied to the boiler (e.g. From paint when painting, laying and spraying molten substances, from

gas leakage, etc.).

■It is forbidden to light the boiler with explosive substances.

■It is forbidden to overheat the boiler.

■At the end of the heating season the boiler, flue and flue adapter, must be thoroughly cleaned. Lubricate all hinges, the flue

flap mechanism and other moving.

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 15

Boiler cleaning

When the boiler is used, soot and fine ash accumulates on the boiler walls, mainly on heat exchanger ribs and in the flue neck,

which reduces heat transfer and the boiler output. The actual quantity of soot and fine ash will depend on the quality of the fuel

used and on the boiler operating conditions.

If the boiler is oversized or was for some reason run at low temperatures, more soot is generated. This may also result in inadequate

chimney thrust.

The boiler must be cleaned regularly, at least once a month, which is done with a steel brush through an open boiler door.

After taking front section plate off, all boiler walls inside the combustion chamber and combustion gases routes should be cleaned.

If a larger quantity of tar has accumulated on internal walls of the combustion chamber, it must be removed with a scraper or burnt

with hard wood (or coke), running the boiler at maximum operating temperature.

Please note

Ashes should be stored (by using proper glove) in a non-combustible container properly and transported outdoors. Other waste

must not be stored in this container.

fig.17 fig.18

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 16

fig.19 fig.20

fig.21 fig.22

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 17

Boiler repairs

The boiler may be repaired by an authorised service technician or organisation only. The user or owner may do only normal

maintenance and simple replacements of some parts – e.g. sealing cords.

Please note

When repairing the boiler, original parts must always be used.

Warranty and warranty conditions

Angus Evo boilers are covered by warranty specified in the Warranty Certificate, Service Book and User and Installation Guide

(chapter Introduction, Installing the boiler).

Boiler delivery

Angus Evo boilers are delivered completely assembled and functionally tested.

The delivery includes:

1. Boiler

2. Operating and installation instructions

3. Service book

4. List of service centres

5. Warranty certificate

6. Thermo-mechanical output regulator

7. Cleaning kit (brush, mixing rod)

INSTALLATION, OPERATION AND MAINTENANCE MANUAL 18

Installation Instructions

Boiler installation – general information

Angus Evo boilers must be put into service by an authorised services. A network of authorised service organisations which meet

these conditions is available for all boiler installations, putting them into service and for warranty repairs.

The boiler is designed to supply heating systems with gauge pressure up to 400 kPa which use water that meets the requirements

of related standards (under no circumstances may the water be acidic, i.e. it must have pH>7, and it should have minimum

carbon hardness).

The heating system must be designed in such a way that hot water can circulate all the time through at least some of the radiators.

Antifreeze fluids – because of their unsuitable properties, we do not recommend to use them.They have a reduced ability to transfer

heat, have large volumetric expansion, age and damage rubber components. If under concrete circumstances there is no other

option how to reliable prevent.

Before final installation, the heating system distribution piping must be flushed several times with pressurised water. In old,already

used systems,the flushing must be done in opposite direction to the hot water circulation. In new systems, all radiators must be

cleaned from conservation material. and rinsed with warm water under pressure.

We recommend installing a sludge trap upstream of the boiler (i.e. on hot water return pipe). The sludge trap design should allow

emptying in regular intervals, without the need to drain a lot of hot water. The sludge trap may be combined with a filter; however,

a filter alone will not provide an adequate protection.

Please note

System must be connected to open expansion tank for safety reasons.

Any valve must not be connected to safety input and safety output lines.

For increasing safety of the system, by-pass line must be installed on the line between input and output of circulation pumps, as

shown in diagrams.

By-Pass line’s valve must be kept closed as the boiler is working normally.

By-Pass line’s valve can be used in electricity problems and must be opened if there is a risk of overheating in system water caused

by an electricity cut or problem.

The pipe used in by-pass line must be at least in the diameter of plumbing systems pipe.

UPS (Power Supply Units) can be used for preventing electricity problems.

Any problems (malfunctions) caused by boiler clogging with dirt from the heating system and/or malfunctions induced by clogging,

are not covered by the boiler warranty.

The filter as well as the sludge trap must be checked and cleaned regularly.

Heating water requirements

Heating water requirements are specified in EN Standards. When the sum of concentrations of calcium and magnesium in the

water exceeds 1.8mmol/l, additional non-chemical treatments preventing lime deposition must be considered (e.g. magnetic or

electrostatic field treatment).

This manual suits for next models

4

Table of contents

Other Eco Angus Boiler manuals

Popular Boiler manuals by other brands

Ferroli

Ferroli KONA 12 operating instructions

TermoTeknik

TermoTeknik LOGIC Combi C26 Installation and servicing

CONCORD

CONCORD CXA 40 - 120 user guide

Slant/Fin

Slant/Fin VICTORY II VHS Series parts list

MASCOT

MASCOT HT 1.450 Installation and servicing instructions

Froling

Froling SP Dual compact operating instructions

Viessmann

Viessmann VITOLIGNO 300-C operating instructions

Baxi

Baxi Luna 3 Comfort Installation and servicing instructions

Infiniton

Infiniton GWN-12NG user manual

Laars

Laars MAGNATHERM MGH2000 Installation and operation instructions for

Varmeteknikk

Varmeteknikk SB 180 operating instructions

WarmFlow

WarmFlow GC29B User instructions