5ECOGENICA FR MODELS PRODUCT & INSTALLATION GUIDE

Warning: Safety Information

Please read all manuals carefully before installing and operating this unit.

The following safety warnings are very important, always read and obey all safety signs.

WARNING

• The device must be effectively grounded.

• RCBO circuit breaker must be installed.

• Do not remove, cover or damage any permanent

instructions or labels from the exterior or interior of the

unit panel.

• Only qualified personnel should install in accordance

with local and national regulations and this guide.

• Improper installation may cause water leakage, electric

shock or fire alarm.

• All electrical connections must comply with the

requirements of the local power company, the local

power company and this guide.

• Do not use rated fuse, otherwise it may malfunction and

cause electrical fire.

• Do not insert fingers, rods or other objects into the air

inlet or outlet. The fan is rotating at high speed, which

may cause injury.

• Do not use flammable sprays, such as hairspray or

paint, near the machine to avoid fire.

• Disposal: Do not dispose of electrical appliances as

unsorted municipal waste, A separate

collection facility should be used. Contact

your local government to find out information

about the collection system. If electrical

appliances are disposed of in landfills or

dump sites, hazardous substances

can seep into groundwater and cause health problems.

• The unit must be fixed firmly, otherwise noise and

vibration may be generated.

• Make sure there are no obstacles around the device.

• In places with strong wind (such as seaside areas),

the unit should be installed in a windproof place.

• The PTR valve should be operated every 6 months to

ensure that the valve does not have any restrictions.

The drain pipe should be well insulated to prevent the

water in the pipe from freezing in cold weather.

CAUTIONS

• The ground electrode must be well grounded.

Make sure all electrical sockets and plugs are

dry and tightly connected;

• Before cleaning, be sure to stop operation and

isolate the unit (ie, turn off the isolating switch

or circuit breaker). Otherwise, electric shock and

injury may occur;

• Water temperature over

50 degrees Celsius will cause

severe burns and even death.

Children, the disabled and the

elderly are at the highest risk

of burns. In the bath feel the

water temperature with your

hands before showering to avoid burns.

• Do not operate the machine with wet hands to

avoid electric shock.

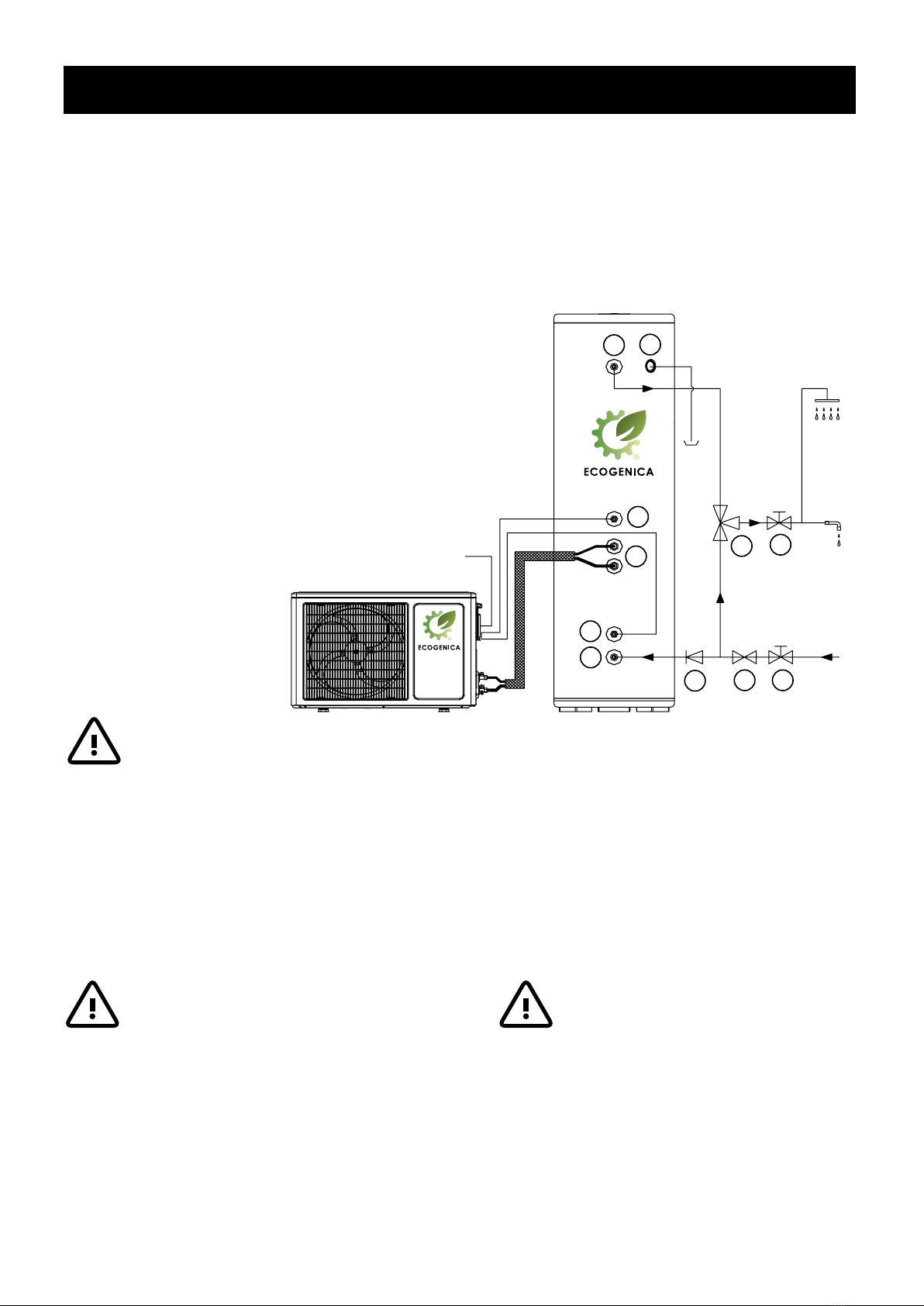

• A one-way check valve and a suitable isolation

valve must be installed on the water inlet side.

• It is normal for the one-way safety valve to

release some water during operation.

However, if there is a large amount of water,

please contact our service team. Improper

drainage can cause water damage to

surrounding areas such as buildings, furniture

etc. Except for repair and maintenance purposes,

do not turn off the power, especially in cold

weather, as it may freeze the machine when

the power is turned off. Continuously powered

heating water is necessary.