6

29785 R3 3/10/2004

IF CLEANING RATHER THAN REPLACING THE

FILTER, UNLESS THE FILTER IS THOROUGHLY

WASHED AND DRIED, BE SURE THAT THE

FILTER IS RE-INSTALLED WITH THE AIRFLOW

DIRECTION IDENTICAL TO ITS PREVIOUS USE.

REVERSING THE FILTER WILL CAUSE DUST

TRAPPED WITHIN THE FILTER TO BREAK

FREE AND RECIRCULATE WITHIN THE DUCT

SYSTEM.

LUBRICATION

Minimal lubrication is required for your

furnace. The induced blower assembly

motors have sealed bearings. The

bearings contain permanent special

purpose lubricants. Attempting to force

common oil into the induced blower

motor bearings will deteriorate the

original lubricant and shorten bearing

life.

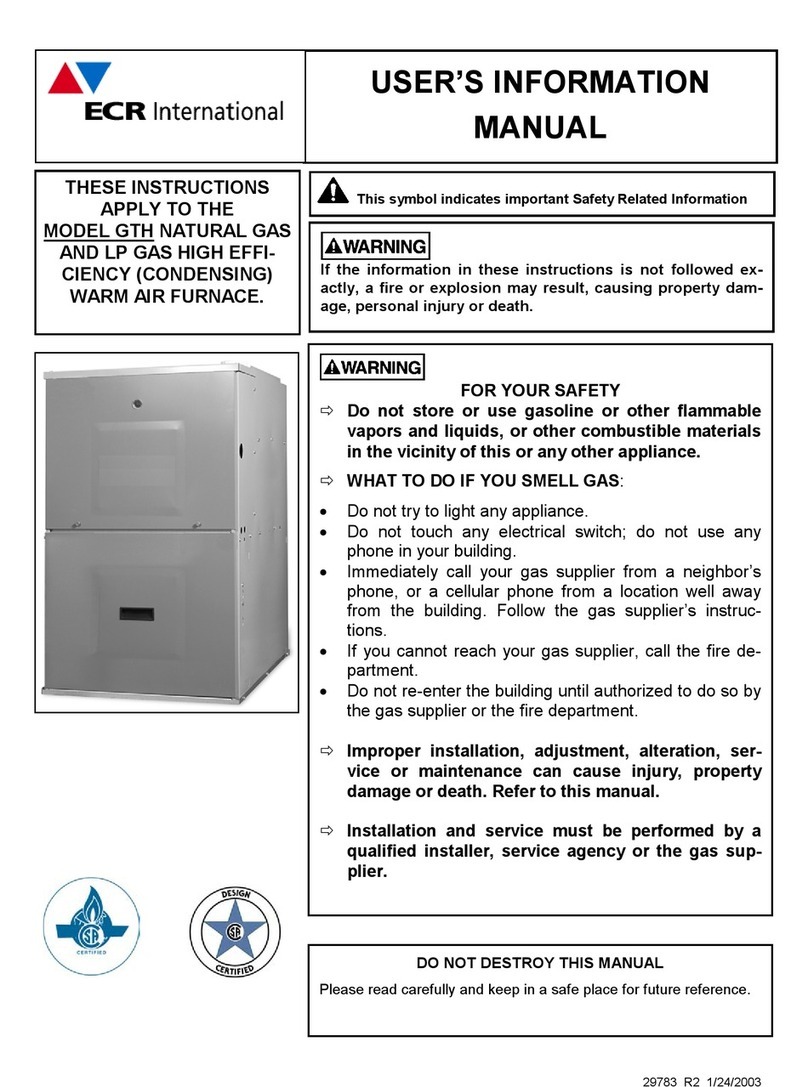

DISCONNECT ELECTRICAL POWER

TO THE FURNACE BEFORE

ATTEMPTING TO LUBRICATE THE

BLOWER MOTOR. FAILURE TO DO

SO COULD RESULT IN SEVERE

PERSONAL INJURY OR DEATH.

The circulating fan may have perma-

nently lubricated ball bearings or

sleeve bearings. If the blower motor is

equipped with sleeve bearings, peri-

odic oiling is required. If the fan motor

runs continuously, the bearings should

be oiled yearly. If the fan runs occa-

sionally, (automatically), the bearings

may be oiled after the second year. 4 -

6 drops of SAE 20 non-detergent oil is

ideal. The oiling ports are normally (but

not necessarily) located on the outside

edge of the motor end bells. The inner

oil port is difficult to reach without a

“tele-spout” or similar type oiler. If you

cannot see an oil port, we recommend

that you leave this part of the mainte-

nance to your service contractor.

DO NOT USE AUTOMOTIVE MOTOR OIL,

HOUSEHOLD OIL, GENERAL-PURPOSE OIL,

ETC. THESE OILS WILL SHORTEN THE LIFE

OF THE MOTOR.

DO NOT OVER-OIL THE ELECTRIC MOTOR.

EXCESS OIL WILL SHORTEN THE LIFE OF THE

MOTOR.

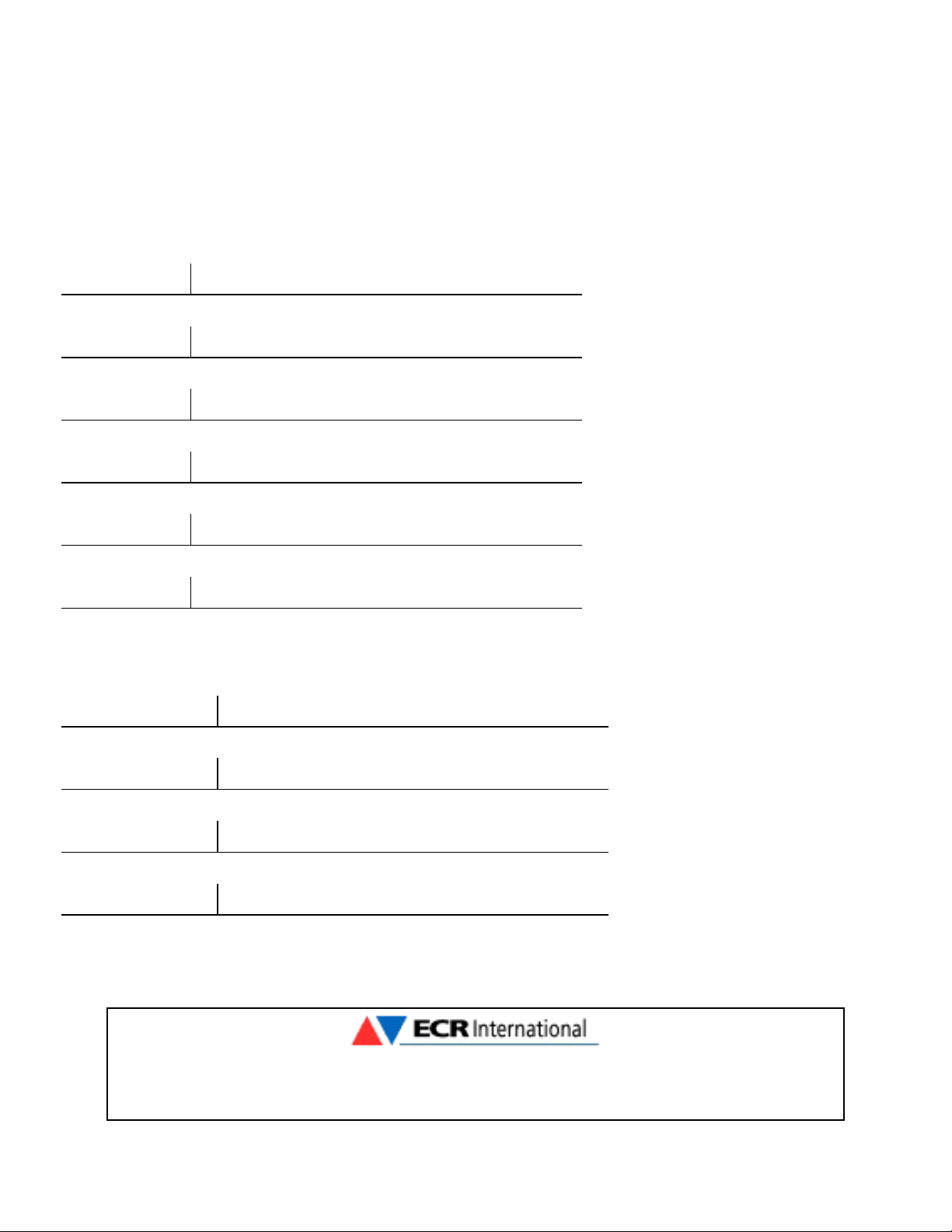

ROUTINE EXAMINATION

It is good practice to give a quick in-

spection of your furnace each time you

inspect or clean the air filter. Things to

check:

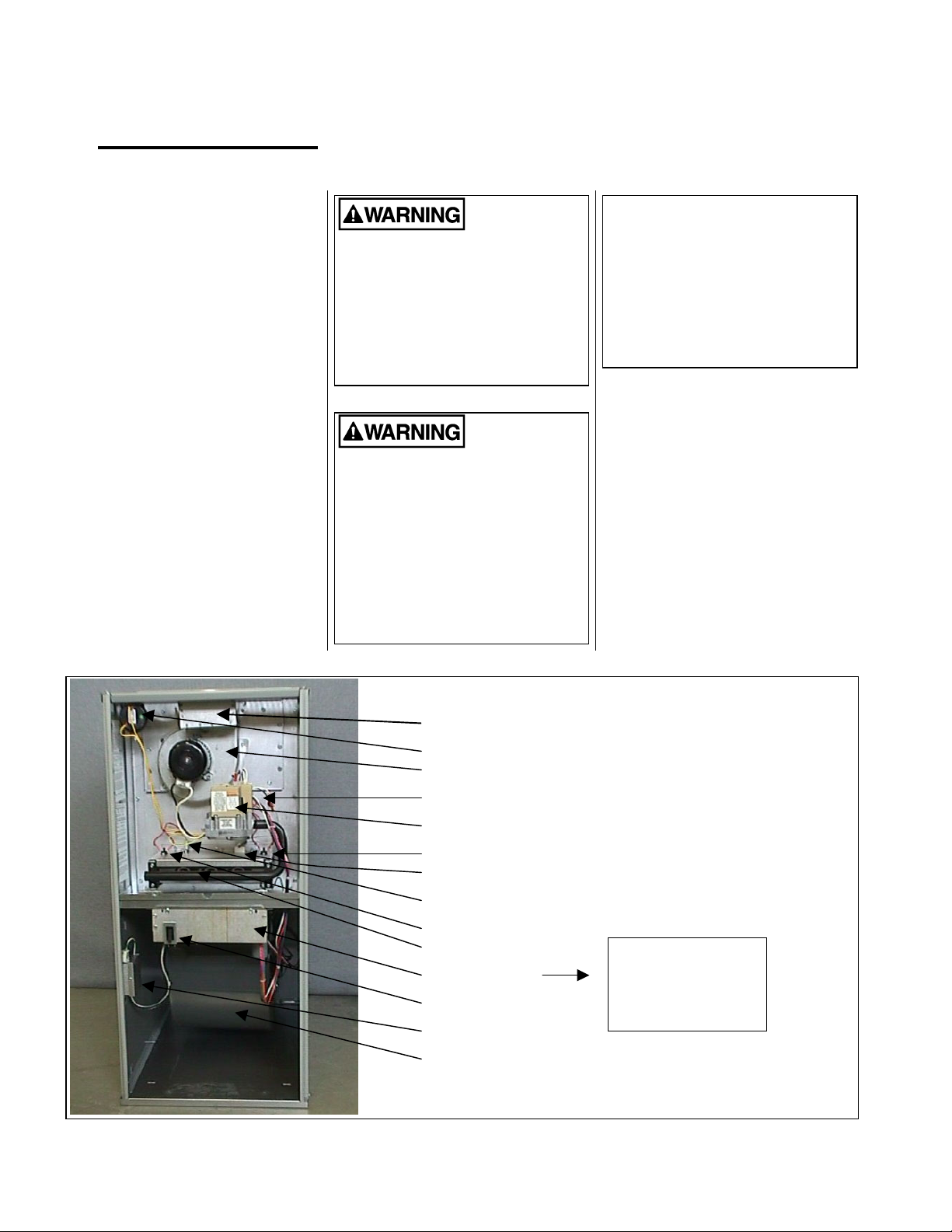

· All areas around the vent connec-

tor and chimney should be clear

and free of obstructions.

· Check the venting to ensure that it

is still fastened to the furnace. It

should not sag, and should have a

¼ inch to the foot slope upwards

to the chimney. It should be physi-

cally sound, without holes or ex-

cessive corrosion.

· The return air duct connection

must be sound and securely fas-

tened to the furnace casing. In

most cases, the filter rack provides

the means to connect the return

air to the furnace. There should be

no return air inlets in the vicinity of

the furnace.

· All ductwork should be secured to

the furnace, and all ductwork

should be solidly supported

throughout the heating system.

· The furnace should be well sup-

ported on a level floor, or, by the

means used to suspend the fur-

nace in a horizontal configuration.

Base support should be physically

sound without sagging, cracks,

gaps, etc. around the base so as

to provide a seal between the

support and the base.

· Check the furnace for obvious

signs of deterioration.

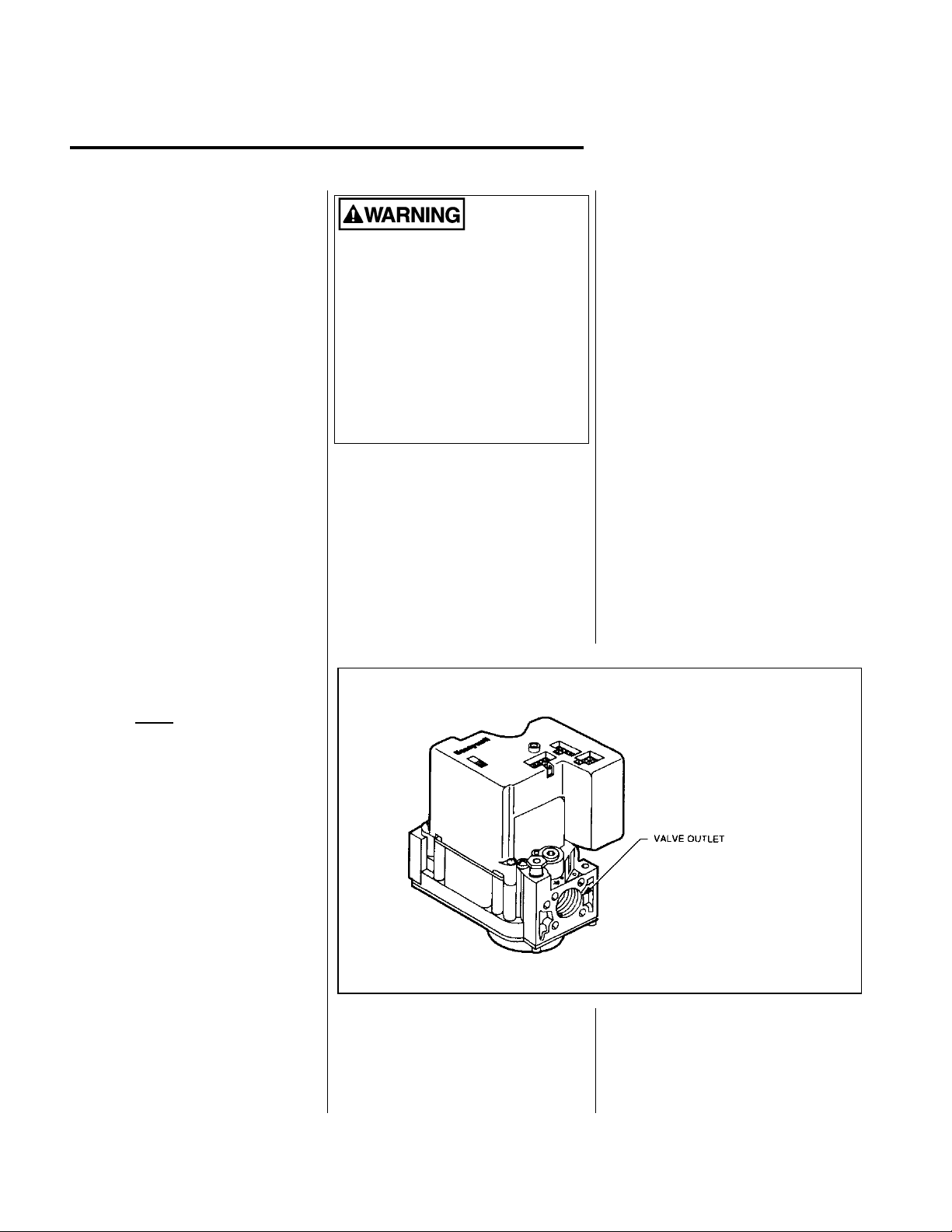

· The gas burner should be ob-

served from time to time during the

heating season to ensure that the

flames are clean and blue. A bit of

orange color in the flame is not

likely to be a problem and is

probably dust particles burning. If

you observe lazy yellow flames,

call your heating or service con-

tractor immediately. The yellow

flames inevitably lead to soot-ups.

FURNACE APPEARANCE

The furnace exterior finish is a durable

automotive like coating. It may be

washed with mild soap if necessary.

Galvanized metal surfaces require no

maintenance.

CLEANING

It is advisable to keep dust build-up on

warm surfaces to a minimum, since

dust, in some cases, can be a combus-

tible.

Dust build-up in the circulating fan can

impair blower performance; therefore,

reduce efficiency. Because the blower

wheel is fastened directly to the blower

motor, we recommend that major

cleaning be left to your service contrac-

tor.

DO NOT PERMIT WATER OR CLEANING SOLU-

TIONS TO ENTER THE ELECTRIC MOTOR.

The burner area should be inspected

and cleaned periodically. Be careful

when cleaning around the burner area.

The hot surface igniter is fragile and

will break easily. Do not touch the hot

surface igniter or flame rod

NEVER ATTEMPT TO CLEAN THE

BURNER AREA WHILE THE

BURNERS ARE OPERATING. DOING

SO MAY RESULT IN EXPLOSION OR

FIRE RESULTING IN SEVERE

PERSONAL INJURY OR DEATH.

ALWAYS DISCONNECT THE

ELECTRICAL SUPPLY TO THE

FURNACE BEFORE REMOVING THE

BURNER COMPARTMENT ACCESS

DOOR.