ECU ECU-57N User manual

ECU-57N

/ ECU-88L

/ ECU-88N

INSTRUCTION MANUAL

LOW

OIL

PRESSURE

HIGHWATER

TEMPERATURE

OVERCRANK

OVERSPEED

ENGINE STARTED

FRONT

VIEW

SIDE

VIEW

BACK VIEW SIDE VIEW

These

units

are

the

most

advanced,

rugged

and

compact

engine

control

modules

we

have

ever

built. They are simple to use

but

this

manual

will

assist

both

engineer

and

mechanic

alike in the installation

and

operation

of

these controls.

The

following

pages

have

in order:

wiring

and

operation, expansion, adjustment,

specifications,

physical

drawing, drilling guide

and

warranty

information.

•

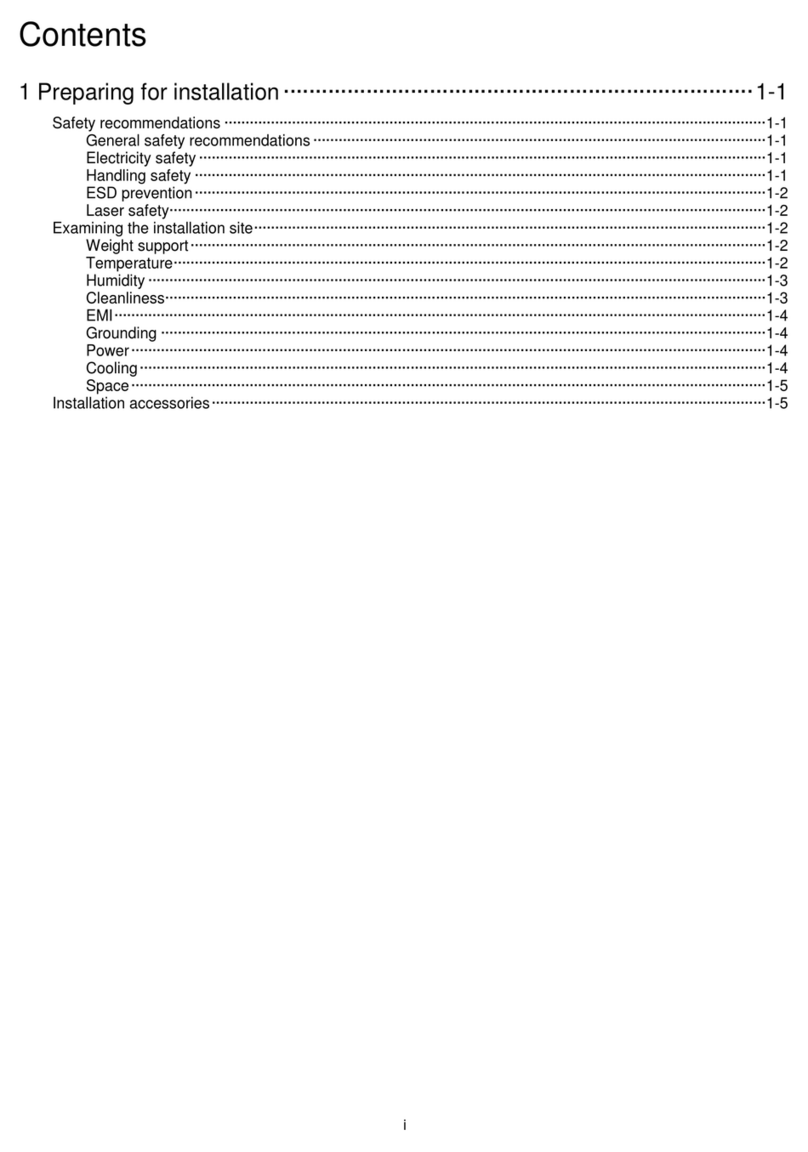

SPECIFICATIONS

Temperature Range

Voltage Range

Vibration

Standby Current

Operating Current

Maximum life cycles

Starter and

Fuel

Cutout

Signal outputs (total)

Speed input voltage range

Input Impedance

Weight

Crank Cycle Time Single

Crank Cycle Time Multi

Crank attempts

Low

oil

pressure delay

Crank disconnect trip

Overspeed trip

Verify mode

-40

TO

+85

C

9 to

28

VDC

10

G's

0 Amps

200

mA

50

000

5

Amps

1

Amp

2

to

15

Volts

5 kohms

12

oz.

2 sec

to

15

min

2

to

60

sec

1

to

8

1

to

60

sec

250

Hz

to

8500

Hz

250

Hz

to

8500

Hz

87

%

of

set

point

PHYSICAL DRAWING

INCH

MM

BACK VIEW

.260

1.50

6.6

38.1

SIDE VIEW

Mounting holes will accept No. 8 or No. 6 screws.

All specifications are subject

to

change

without

notice.

This

information

front

and back is protected

by

copyright

1996

and

ECU® is

a registered trademark

of

Engineering Concepts Unlimited Inc.

8950

Technology Drive Fishers, IN.

46038

Phone

317-849-8470

Need Replacement Parts?

Shop Online by Clicking Here

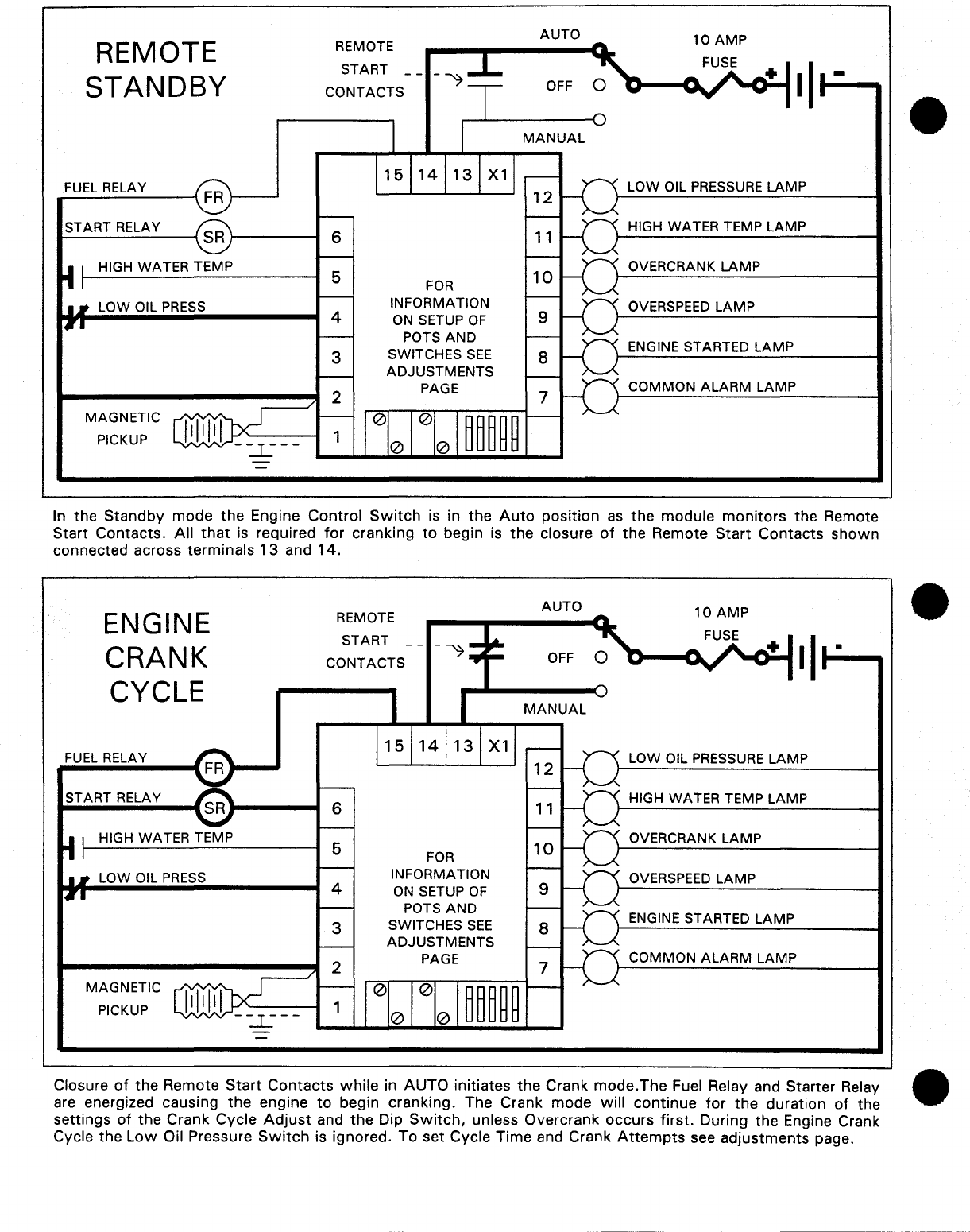

REMOTE

STANDBY

FUEL

RELAY

START RELAY

HIGH WATER TEMP

LOW OIL

PRESS

MAGNETIC

PICKUP

REMOTE

START

CONTACTS

6

5

4

3

1

15

14

13

X1

FOR

INFORMATION

ON

SETUP

OF

POTS

AND

SWITCHES

SEE

ADJUSTMENTS

PAGE

AUTO

OFF

MANUAL

LOW OIL

PRESSURE

LAMP

HIGH WATER TEMP LAMP

OVERCRANK

LAMP

OVERSPEED

LAMP

ENGINE STARTED LAMP

COMMON

ALARM

LAMP

In

the

Standby

mode

the

Engine

Control

Switch

is in the

Auto

position

as

the

module

monitors

the Remote

Start

Contacts.

All

that

is required

for

cranking

to

begin is

the

closure

of

the Remote

Start

Contacts

shown

connected across terminals

13

and

14.

ENGINE

CRANK

CYCLE

FUEL

RELAY

START RELAY

HIGH WATER TEMP

LOW OIL

PRESS

MAGNETIC

PICKUP

REMOTE

START

CONTACTS

15

14

13

X1

6

5

FOR

INFORMATION

4

ON

SETUP

OF

POTS

AND

3 SWITCHES

SEE

ADJUSTMENTS

2 PAGE

1

AUTO

OFF

MANUAL

LOW OIL PRESSURE LAMP

HIGH WATER TEMP LAMP

OVERCRANK

LAMP

OVERSPEED LAMP

ENGINE STARTED LAMP

COMMON

ALARM

LAMP

Closure

of

the

Remote

Start

Contacts

while

in

AUTO

initiates

the

Crank

mode.The

Fuel Relay and Starter Relay

are energized causing

the

engine

to

begin cranking. The Crank mode will

continue

for

the duration

of

the

settings

of

the

Crank Cycle

Adjust

and

the

Dip

Switch,

unless Overcrank occurs

first.

During

the

Engine Crank

Cycle

the

Low

Oil Pressure

Switch

is ignored. To set Cycle Time and Crank

Attempts

see

adjustments

page.

•

•

•

•

•

•

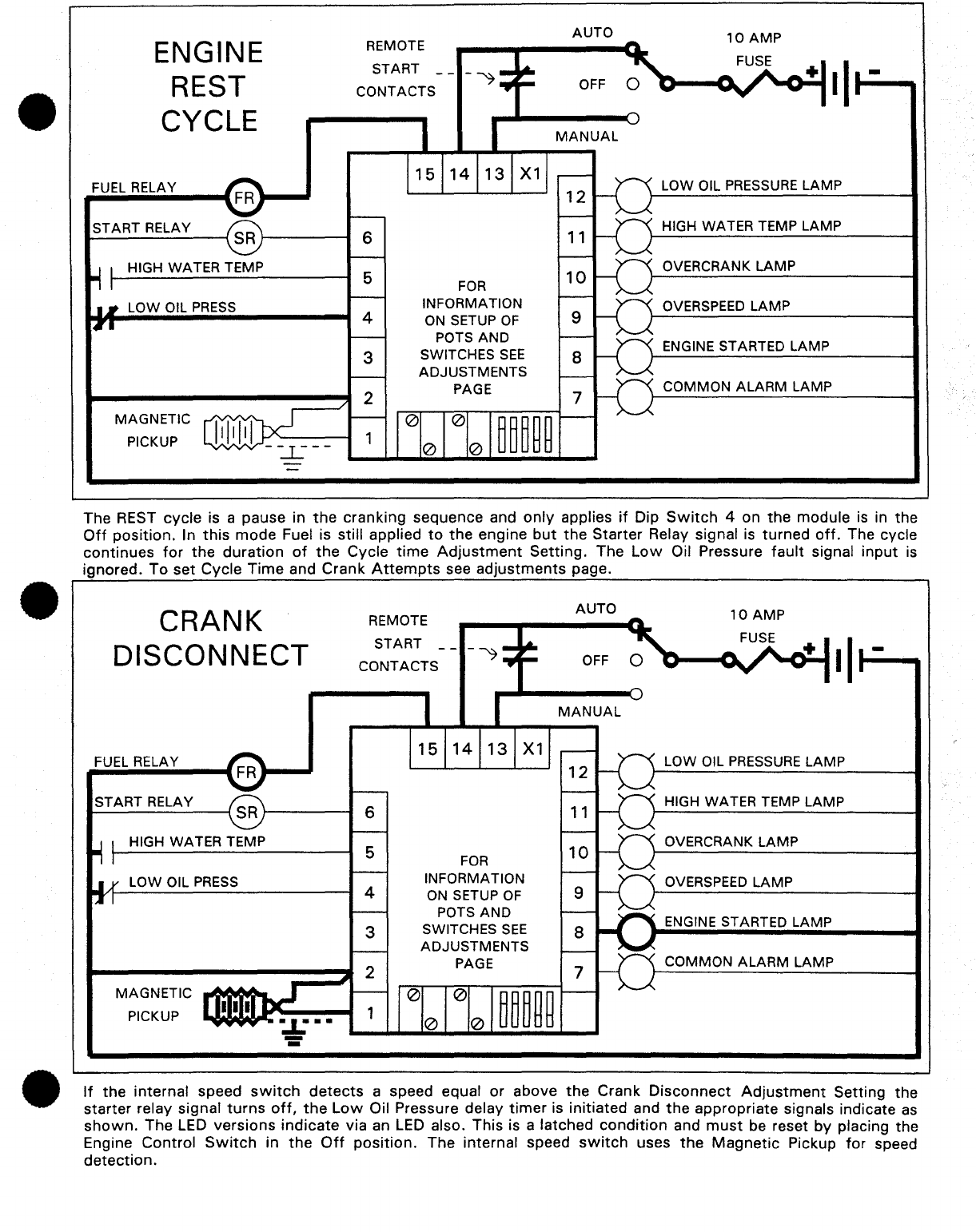

ENGINE

REST

CYCLE

FUEL RELAY

START

RELAY

HIGH WATER TEMP

LOW OIL

PRESS

MAGNETIC

PICKUP

REMOTE

START

CONTACTS

6

5

4

3

1

15

14

13

X1

FOR

INFORMATION

ON SETUP

OF

POTS

AND

SWITCHES

SEE

ADJUSTMENTS

PAGE

AUTO

OFF

MANUAL

LOW OIL PRESSURE LAMP

HIGH WATER TEMP LAMP

OVERCRANK LAMP

OVERSPEED

LAMP

ENGINE STARTED LAMP

COMMON

ALARM

LAMP

The REST cycle is a pause in

the

cranking sequence and

only

applies

if

Dip

Switch

4 on

the

module

is

in the

Off

position. In

this

mode

Fuel is still applied

to

the

engine

but

the

Starter Relay signal

is

turned

off.

The cycle

continues

for

the

duration

of

the

Cycle

time

Adjustment

Setting. The

Low

Oil Pressure

fault

signal

input

is

ignored. To set Cycle

Time

and Crank

Attempts

see

adjustments

page.

CRANK

DISCONNECT

FUEL RELAY

START

RELAY

HIGH WATER TEMP

LOW OIL

PRESS

MAGNETIC

PICKUP

REMOTE

START

CONTACTS

6

5

4

3

1

15

14

13

X1

FOR

INFORMATION

ON SETUP

OF

POTS

AND

SWITCHES

SEE

ADJUSTMENTS

PAGE

AUTO

OFF

MANUAL

LOW OIL

PRESSURE

LAMP

HIGH WATER TEMP LAMP

OVERCRANK

LAMP

OVERSPEED

LAMP

ENGINE STARTED LAMP

COMMON

ALARM

LAMP

If

the internal speed

switch

detects

a speed equal

or

above

the

Crank

Disconnect

Adjustment

Setting the

starter relay signal

turns

off,

the

Low

Oil Pressure delay

timer

is initiated and

the

appropriate signals indicate

as

shown.

The

LED

versions

indicate

via an

LED

also. This is a latched

condition

and

must

be reset by placing the

Engine Control

Switch

in

the

Off

position.

The internal speed

switch

uses

the

Magnetic

Pickup

for

speed

detection.

OVERCRANK

FAULT

FUEL

RELAY

START RELAY

HIGH WATER TEMP

LOW OIL

PRESS

MAGNETIC

PICKUP

REMOTE

START

CONTACTS

6

5

4

3

1

15

14

13

X1

FOR

INFORMATION

ON

SETUP

OF

POTS

AND

SWITCHES

SEE

ADJUSTMENTS

PAGE

AUTO

OFF

MANUAL

LOW OIL

PRESSURE

LAMP

HIGH WATER TEMP LAMP

OVERCRANK LAMP

OVERSPEED

LAMP

ENGINE STARTED LAMP

COMMON

ALARM

LAMP

If

the

engine does

not

start

in

the

allotted

time,

as

determined

by

the Crank Cycle

Adjust

and the Dip

Switch

settings,

the

Overcrank Fault

occurs.

The

Fuel and

Start

relays are

turned

off

and the appropriate signals

indicate

as

shown.

The

LED

versions indicate via

an

LED

also. The Overcrank

condition

is a latched condition

and

must

be reset via

the

Engine

Control

Switch.

See

Adjustments

page

for

proper

settings

of

adjustments.

OVERS

PEED

FAULT

FUEL

RELAY

START RELAY

HIGH WATER TEMP

LOW OIL

PRESS

MAGNETIC

PICKUP

REMOTE

START

CONTACTS

15

14

13

X1

6

5

FOR

INFORMATION

4

ON

SETUP

OF

POTS

AND

3 SWITCHES

SEE

ADJUSTMENTS

PAGE

1

AUTO

OFF

MANUAL

LOW OIL

PRESSURE

LAMP

HIGH WATER TEMP LAMP

OVERCRANK

LAMP

OVERSPEED LAMP

ENGINE STARTED

LAMP

COMMON

ALARM

LAMP

The Overspeed

fault

is armed

at

engine cranking.

If

the

internal speed

switch

detects

a speed equal or above

the Overspeed

Adjustment

Setting

the

engine is

shutdown

immediately. The internal speed

switch

uses the

Magnetic

Pickup

for

speed

detection.

The Fuel Relay is turned

off,

the

Low

Oil Pressure

switch

is locked

out

and the appropriate signals indicate

as

shown.

The

LED

versions indicate via

an

LED

also. The Engine

Switch

must

be placed in OFF

for

reset. See

Adjustments

page

for

speed adjustments.

•

•

•

•

•

•

HIGH

WATER

TEMPERATURE

FAULT

FUEL RELAY

START RELAY

HIGH WATER TEMP

LOW OIL

PRESS

MAGNETIC

PICKUP

REMOTE

START

CONTACTS

6

5

4

3

1

15

14

13

X1

FOR

INFORMATION

ON

SETUP

OF

POTS

AND

SWITCHES

SEE

ADJUSTMENTS

PAGE

AUTO

OFF

MANUAL

LOW OIL PRESSURE LAMP

HIGH WATER TEMP LAMP

OVERCRANK LAMP

OVERSPEED

LAMP

ENGINE STARTED LAMP

COMMON ALARM LAMP

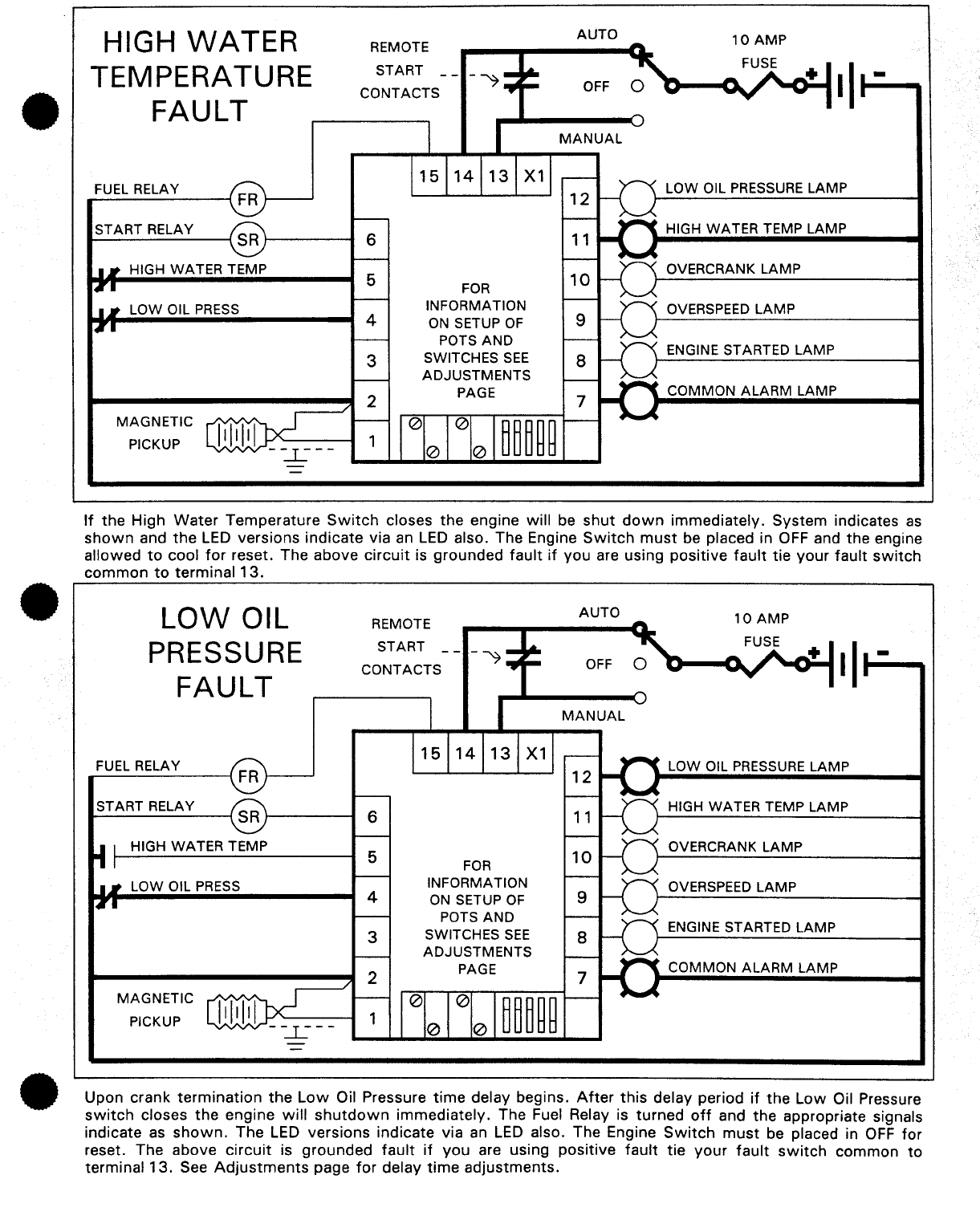

If

the High

Water

Temperature

Switch

closes

the

engine will be

shut

down

immediately. System indicates

as

shown

and

the

LED

versions indicate via

an

LED

also. The Engine

Switch

must

be placed in

OFF

and the engine

allowed

to

cool

for

reset. The above

circuit

is grounded

fault

if

you

are using

positive

fault

tie

your

fault

switch

common

to

terminal

13

.

LOW

OIL

PRESSURE

FAULT

FUEL RELAY

START RELAY

HIGH WATER TEMP

LOW OIL

PRESS

MAGNETIC

PICKUP

REMOTE

START

CONTACTS

6

5

4

3

1

15

14

13

X1

FOR

INFORMATION

ON SETUP

OF

POTS

AND

SWITCHES

SEE

ADJUSTMENTS

PAGE

AUTO

OFF

MANUAL

LOW OIL

PRESSURE

LAMP

HIGH WATER TEMP LAMP

OVERCRANK

LAMP

OVERSPEED LAMP

ENGINE STARTED LAMP

COMMON

ALARM

LAMP

Upon crank

termination

the

Low

Oil Pressure

time

delay begins.

After

this

delay period

if

the

Low

Oil Pressure

switch

closes

the

engine

will

shutdown

immediately. The Fuel Relay is

turned

off

and

the

appropriate signals

indicate

as

shown.

The

LED

versions indicate via

an

LED

also. The Engine

Switch

must

be placed in

OFF

for

reset. The above

circuit

is

grounded

fault

if

you

are using positive

fault

tie

your

fault

switch

common

to

terminal

13.

See

Adjustments

page

for

delay

time

adjustments.

NORMAL

SHUTDOWN

LAMP

TEST

88L/88N

ONLY

FUEL RELAY

START RELAY

HIGH WATER TEMP

LOW OIL

PRESS

MAGNETIC

PICKUP

REMOTE

START

CONTACTS

6

5

4

3

1

15

14

13

X1

FOR

INFORMATION

ON

SETUP

OF

POTS

AND

SWITCHES

SEE

ADJUSTMENTS

PAGE

AUTO

OFF

MANUAL

LOW OIL PRESSURE LAMP

HIGH WATER TEMP LAMP

OVERCRANK

LAMP

OVERSPEED

LAMP

ENGINE STARTED

LAMP

COMMON

ALARM

LAMP

To

stop

engine place

switch

in

the

OFF

position

and engine will

shut

down

immediately. The Fuel Relay

is

turned

off

and

the

unit

draws

no

power.

If

the

unit

is

an

LED

version lamp

test

may

be applied

as

shown

and

all LEDS

will

light. Since

the

output

system

is

totally

independent

of

the

signal

system

Lamp Test can

be

actuated at any

time

with

no

possibility

of

backfeed.

ADJUSTMENTS PAGE

TURN POTS CLOCKWISE

TO

INCREASE SETTING

POTS ARE

25

TURN

AND

CAN

NOT

BE

DAMAGED

BY EXCESS TURNS

1 2 3 4 5

1 2 3 4 5

SWITCH

5 ON FOR

OVERSPEED VERIFY

REDUCES TRIP SPEED

BY

13

PERCENT

CYCLES

SW1

SW2

SW3

1

OFF OFF OFF

SWITCH

4

2

OFF

ON

OFF

OFF -CYCLE

CRANK

3

ON

OFF OFF

4

ON ON

OFF

ON -SINGLE

CRANK

5

OFF

OFF

ON

6

OFF

ON ON

7

ON

OFF

ON

8

ON

ON

ON

DRILLING TEMPLATE

----------

2.65

.65

16.51

.35

8.89

.35

8.89

.35

8.89

.35

8.89

.35

8.89

.3

7.62

DRILLING

TEMPLATE 7.62

CENTER

PUNCH

2.8

DIRECTLY

--

THROUGH

71

·12

PAPER

1.3

33.02

ALL

HOLES

.25

6.35

DIA.

INCH

MM

•

•

•

•

•

•

EXTRA

FAULT

EXPANSION

FUEL RELAY

START RELAY

HIGH WATER TEMP

LOW OIL

PRESS

TIE FAULT

COMMONS TO

TERMINAL

13

MAG

PICKUP

EXTRA FAULT A

EXTRA FAULT B

REMOTE

START

CONTACTS

6

5

4

3

1

5

4

3

15

14

13

X1

FOR

INFORMATION

ON

SETUP

OF

POTS AND

SWITCHES

SEE

ADJUSTMENTS

PAGE

FEX3

2

AUTO

OFF

MANUAL

1

4

3

LOW OIL

PRESSURE

LAMP

HIGH WATER TEMP LAMP

OVERCRANK LAMP

OVERSPEED LAMP

ENGINE STARTED LAMP

COMMON

ALARM

LAMP

EXTRA FAULT A LAMP

EXTRA FAULT B LAMP

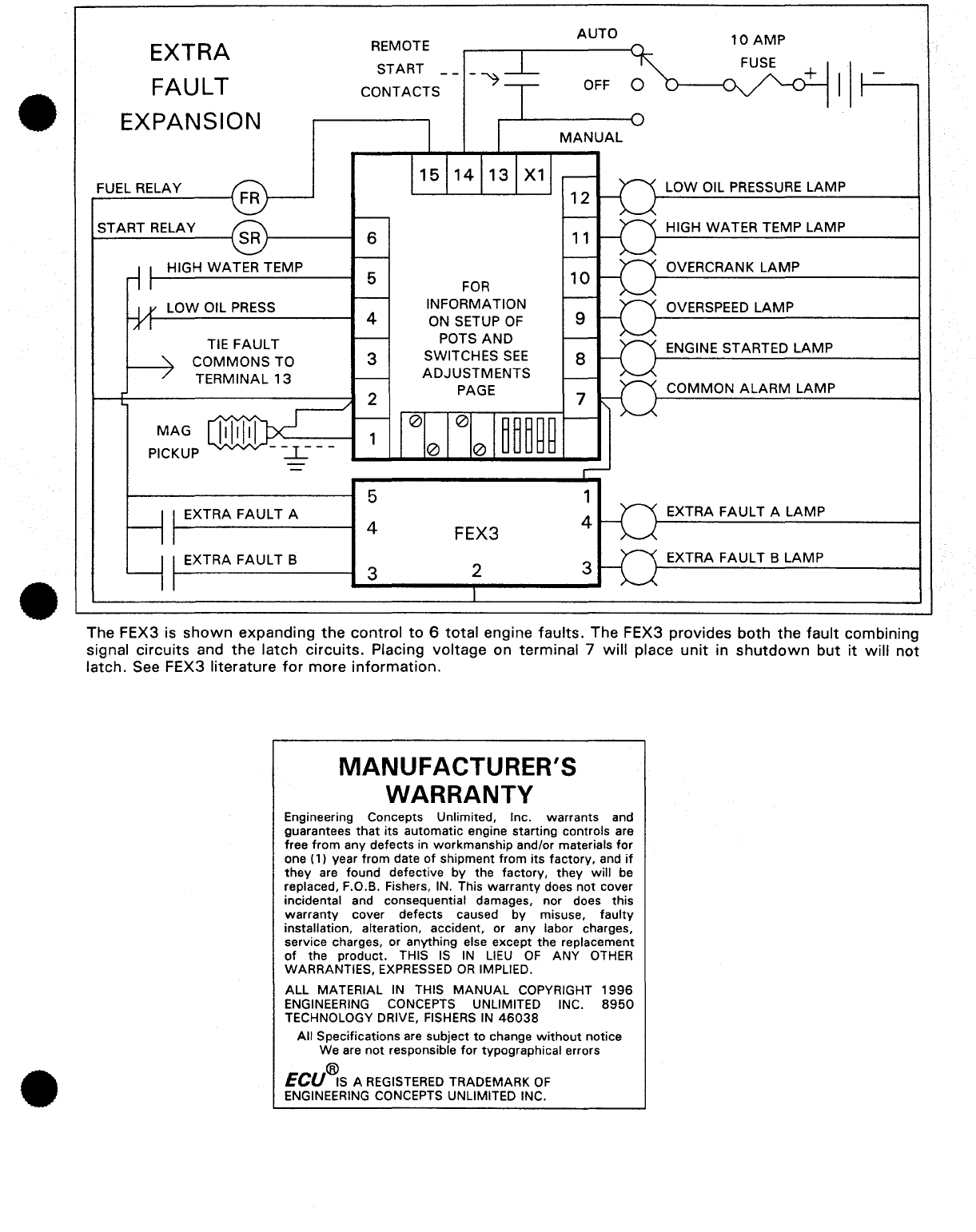

The FEX3 is

shown

expanding

the

control

to

6

total

engine

faults.

The FEX3 provides

both

the

fault

combining

signal

circuits

and

the

latch

circuits.

Placing

voltage

on terminal 7

will

place

unit

in

shutdown

but

it

will

not

latch. See FEX3 literature

for

more

information.

MANUFACTURER'S

WARRANTY

Engineering Concepts Unlimited, Inc. warrants and

guarantees

that

its automatic engine starting controls are

free

from

any defects in workmanship and/or materials for

one (1) year from date

of

shipment from its factory, and

if

they

are found defective

by

the factory, they will be

replaced, F.O.B. Fishers, IN. This

warranty

does

not

cover

incidental and consequential damages, nor does this

warranty

cover defects caused

by

misuse,

faulty

installation, alteration, accident, or any labor charges,

service charges, or anything else except the replacement

of

the product. THIS

IS

IN

LIEU

OF

ANY

OTHER

WARRANTIES,

EXPRESSED

OR

IMPLIED.

ALL MATERIAL

IN

THIS

MANUAL

COPYRIGHT

1996

ENGINEERING CONCEPTS UNLIMITED INC.

8950

TECHNOLOGY DRIVE,

FISHERS

IN

46038

All

Specifications are subject

to

change

without

notice

We are

not

responsible

for

typographical errors

®

ECU

IS

A REGISTERED TRADEMARK

OF

ENGINEERING CONCEPTS UNLIMITED INC.

This manual suits for next models

2

Table of contents