EG&G ORTEC 416 User manual

INSTRUCTION

MANUAL

416

GATE

AND

DELAY

GENERATOR

Serial

No.

Purchaser

Date

Issued

COMPANY

100

MIDLAND

RDAD

OAK

RIDGE,

TENN.

37B30

PHONE—(615)

482-1QDB

TWX

810

-

572

-

1078

©ORTEC

Incorporated

1966

Printed

In

U.S.A.

TABLE

OF

CONTENTS

Page

WARRANTY

PHOTOGRAPH

1.

DESCRIPTION

1-1

2.

SPECIFICATIONS

2-1

3.

INSTALLATION

INSTRUCTIONS

3-1

3.1

General

3

-

1

3.2

Connection

to

Power

-

AEC

Standard

Nuclear

Instrument

Module,

ORTEC,

401A/402A

3

-

1

4.

OPERATING

INSTRUCTIONS

4-1

5.

CIRCUIT

DESCRIPTION

5-1

6.

MAINTENANCE

INSTRUCTIONS

6-1

6.1

Testing

Performance

6-

1

6.2

Calibration

Adjustments

6

-

1

7.

DC

VOLTAGE

MEASUREMENTS

7

-

1

8.

BIN/MODULE

CONNECTOR

PIN

ASSIGNMENTS

BLOCK

DIAGRAM

AND

SCHEMATIC

416-001-Bl

ORTEC

416

Block

Diagram

416-001-Sl

ORTEC

416

Schematic

LIST

OF

FIGURES

AND

ILLUSTRATIONS

Page

Figure

6-1.

Gate

and

Delay

Generator

-

Block

Diagram

6

-

1

Figure

6-2.

Delay

Stability

Versus

Temperature

Curves

6-2

F

w

A

NEW

STANDARD

TWO-YEAR

WARRANTY

FOR

ORTEC

ELECTRONIC

INSTRUMENTS

ORTEC

warrants

its

nuclear

instrument

products

to

be

free

from

defects

in

workmanship

and

materials,

other

than

vacuum

tubes

and

semiconductors,

for

a

period

of

twenty-four

months

from

date

of

shipment,

provided

that

the

equipment

has

been

used

in

a

proper

manner

and

not

subjected

to

abuse.

Repairs

or

replacement,

at

ORTEC

option,

will

be

made

without

charge

at

the

ORTEC

factory.

Shipping

expense

will

be

to

the

account

of

the

customer

except

in

cases

of

defects

discovered

upon

initial

operation.

Warranties

of

vacuum

tubes

and

semiconductors,

as

made

by

their

manufacturers,

will

be

extended

to

our

customers

only

to

the

extent

of

the

manufacturers'

liability

to

ORTEC.

Specially

selected

vacuum

tubes

or

semiconductors

cannot

be

warranted.

ORTEC

reserves

the

right

to

modify

the

design

of

its

products

without

incurring

responsibility

for

modification

of

previously

manufactured

units.

Since

installation

conditions

are

beyond

our

control,

ORTEC

does

not

assume

any

risks

or

liabilities

associated

with

methods

of

installation

other

than

specified

in

the

instructions,

or

installation

results.

QUALITY

CONTROL

Before

being

approved

for

shipment,

each

ORTEC

instrument

must

pass

a

stringent

set

of

quality

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warranty

repair

and

as

a

source

of

statistical

information

for

design

improvements.

REPAIR

SERVICE

ORTEC

instruments

not

in

warranty

may

be

returned

to

the

factory

for

repairs

or

checkout

at

modest

expense

to

the

customer.

Standard

procedure

requires

that

returned

instruments

pass

the

same

quality

control

tests

as

those

used

for

new

production

instruments.

Please

contact

the

factory

for

instructions

before

shipping

equipment.

DAMAGE

IN

TRANSIT

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

concealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normally

liable

for

damage

in

shipment.

Packing

materials,

waybills,

and

other

such

documentation

should

be

preserved

in

order

to

establish

claims.

After

such

notification

to

the

carrier,

please

notify

ORTEC

of

the

circumstances

so

that

we

may

assist

in

damage

claims

and

in

providing

replacement

equipment

if

necessary.

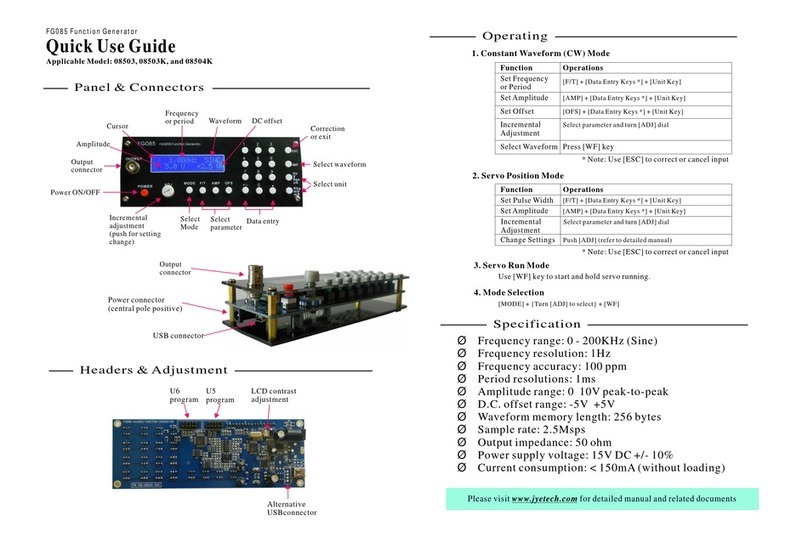

MODEL

416

GATE

AND

DELAY

GENERATOR

DELAY

RANGE

0.1-1.1

DELAY

1.0-11

■

(jlSEC

■

u

WIDTH

AMPLITUDE

0.4

4.0

2.5

10

/xSEC

VOLTS

INPUT

DELAY

DLY'D

PERIOD

MARKER

O

4t

■OUTPUT-

POS—

DLY'D

GATE—NEG

OUTPUT-

-fI2V

85mA

-I2V

50mA

-P24V

45mA

~24V

35mA

1

-

1

ORTEC

416

GATE

AND

DELAY

GENERATOR

1.

DESCRIPTION

The

416

Gate

and

Delay

Generator

is

one

in

a

series

of

modular

instruments

com

plying

with

the

AEG

Nuclear

Instrument

Module

Standards.

This

module

is

de

signed

to

provide

the

interface

functions

for

logic

pulses

between

the

logic

pulse

generation

and

its

end

use.

These

necessary

functions

ore:

variable

delay,

vari

able

pulse

amplitude,

variable

pulse

width,

and

a

selection

of

output

polarity.

The

uses

for

the

unit

will

include

such

applications

as

analyzer

gating

and

coinci

dence

trigger

circuits,

and

others.

Due

to

its

unique

design,

it

also

provides

timing

signals

which

are

suitable

for

driving

time

to

pulse

height

converters

or

coincidence

circuits

in

delayed

coincidence

applications

such

as

pulse

shape

dis

crimination,

etc.

I

2-

1

2.

SPECIFICATIONS

Delay

Ranges

Delay

Adjustmenl-

Delay

Readout

Delay

Linearity

Delay

Temperature

Stability

Delay

Generator

Dead

Time

Gate

Generator

Dead

Time

Count

Rote

Delay

Jitter

Input

Input

Impedance

Output

Impedance

Delay

Period

Delay

Marker

Delayed

Gate

Power

Requirements

0.1

psec

to

1,1

psec

1.0

psec

to

11

psec

Continuously

variable

within

the

selected

range

by

means

of

a

10-turn

potentiometer

Direct

reading

via

a

10-turn

dial

±2%

sO.03%

of

selected

range

Delay+0.1

range

Gate

pulse

width

+0.2

psec

l/dead

time

^0.02%

of

range

at

average

dead

time

<20%

Pos.,

2V

min.,

protected

to±100Vmax.,

dc-coupled,

non-critical

to

rise

time,

25

nsec

minimum

width

s

1

K

ohm

Less

than

10

ohms

for

all

outputs

Tp

<50

nsec,

positive,

4V,

width

equal

to

delay

time

Tp

<10

nsec,

negative,

0.6V,

width

<25

nsec

Positive

and

negative

simultaneously;

amplitude

variable

2.5V

to

lOV,

width

variable

0.4

psec

to

4

psec;

T^.

<100

nsec

+24V

~

45mA

-24V

~

35mA

+12V

~

85mA

-12V

~

50mA

p

3

-

1

3.

INSTALLATION

INSTRUCTIONS

3.1

General

The

ORTEC

416,

used

in

conjunction

with

the

ORTEC

401A/402A

Bin

and

Power

Supply,

is

intended

for

rock

mounting;

therefore,

it

is

necessary

to

ensure

that

vacuum

tube

equipment

operating

in

the

same

rack

has

sufficient

cooling

air

circulating

to

prevent

any

localized

heating

of

the

oM-tronsistor

circuitry

used

throughout

the

416.

The

temperature

of

equipment

mounted

in

rocks

can

easily

exceed

the

recommended

maximum

unless

precautions

ore

token.

The

416

should

not

be

subjected

to

temperatures

in

excess

of

120°F

(50®C).

3.2

Connection

to

Power

—

AEC

Standard

Nuclear

Instrument

Module,

ORTEC

401iV402A

The

416

contains

no

internal

power

supply;

therefore,

it

must

obtain

power

from

a

Nuclear

Standard

Bin

and

Power

Supply

such

as

the

401A/402A.

It

is

recommended

that

the

Bin

power

supply

be

turned

off

when

inserting

or

re

moving

modules.

The

ORTEC

400

Series

is

designed

so

that

it

is

not

possible

to

overload

the

Bin

power

supply

with

a

full

complement

of

modules

in

the

Bin;

however,

this

may

not

be

true

when

the

Bin

contains

modules

other

than

those

of

ORTEC

design.

In

this

cose,

power

supply

voltages

should

be

checked

after

the

insertion

of

modules.

The

401A/402A

has

test

points

on

the

power

supply

control

panel

to

monitor

the

dc

voltages.

4-

1

4.

OPERATING

INSTRUCTIONS

The

operation

of

the

416

should

be

very

simple

and

straightforward.

Once

it

is

plugged

in

and

the

power

turned

on,

it

is

necessary

only

to

furnish

a

trigger

pulse

of

sufficient

amplitude

to

trigger

it,

select

the

desired

range

of

delay,

then

dial

in

the

approximate

delay

wanted,

and

connect

the

desired

output

to

the

input

of

the

circuit

that

it

is

to

drive.

For

instance,

if

one

wishes

to

gate

an

analyzer

which

requires

an

0.8-microsecond

delay

and

a

negative

4-volt

signal

2

microsec

onds

wide,

connect

the

negative

delayed

output

to

the

gating

input

to

the

analyzer,

set

the

delay

range

to

the

0.1

psec

to

1.0

psec

position,

and

dial

the

delay

poten

tiometer

to

800

on

the

10-turn

dial.

Set

the

width

potentiometer,

R28,

at

approxi

mately

midrange

and

the

amplitude

potentiometer,

R24,

at

approximately

one-third

range.

Of

course,

to

set

the

width

and

amplitude

precisely

one

must

view

these

with

an

oscilloscope.

Also,

the

real

time

delay

is

not

meant

to

be

correlated

close

ly

enough

with

the

dial

reading

to

be

believed

better

than

±5

percent;

however,

the

reproducibility

of

the

delay

should

be

very

good.

Therefore,

if

one

wishes

to

plot

the

delay

function

versus

dial

reading,

he

should

be

able

to

determine

his

delay

precisely

at

any

time

thereafter.

In

almost

all

instances,

care

should

be

taken

to

see

that

the

connecting

cables

used

are

terminated

in

their

characteristic

impedances.

In

the

case

of

the

DELAYED

GATE

output,

this

is

not

quite

so

critical

as

it

is

in

the

case

of

the

DELAY

PERIOD

and

the

DELAYED

MARKER;

however,

if

pulse

fidelity

is

a

requirement,

this

precaution

should

be

observed

also

on

the

DELAYED

GATE

outputs.

5

-

1

5.

CIRCUIT

DESCRIPTION

Diodes

D6

and

D7

form

o

current

limiting

protection

circuit

to

protect

against

large

amplitude

signals.

Q13,

Q14,

and

Q15

form

a

dc-coupled

Schmitt

trigger

which

has

fast

rise-time

and

a

width

equal

to

the

width

of

the

input

signal.

The

current

pulse

at

the

collector

of

Q14

is

differentiated

by

L2.

D1,

in

turn,

clips

the

negative

portion

of

the

differentiated

pulse

and

passes

the

positive

portion

to

the

base

of

Q1

.

The

positive

portion

of

the

pulse

triggers

the

delay

multivibrator,

which

is

composed

of

Ql,

Q2,

Q3,

and

Q4.

When

triggered,

this

multivibrator

sets

a

voltage

step

onto

a

capacitor,

either

C4

or

C5,

and

then

this

capacitor

is

discharged

with

a

constant

current

which

is

furnished

by

way

of

Q4

and

is

con

trolled

by

the

delay

potentiometer,

R11

.

Since

it

is

a

constant

current

discharge,

the

delay

will

be

linear.

Diode

D2

provides

the

dc

bias

necessary

to

hold

Q2

in

the

conduction

state

until

the

multivibrator

is

triggered,

at

which

time

the

voltage

pulse

from

the

emitter

of

Q3

is

fed

over

to

cut

off

the

diode.

It

will

remain

off

until

the

multivibrator

recovers.

D3

provides

a

dc

restoration

for

the

capacity

coupling

by

C3

of

the

output

pulse

from

the

delay

multivibrator.

This

output

pulse

is

emitter-follower

buffered

through

Q5

and

is

called

the

DELAY

PERIOD

output.

The

DELAY

PERIOD

output

pulse

is

differentiated

by

means

of

LI,

and

the

differen

tiated

pulse

is

fed

to

the

base

of

Q6,

which

is

normally

off

emitter

follower,

but

the

negative

portion

which

occurs

at

the

trailing

edge

of

the

DELAY

PERIOD

pulse

will

be

fed

out

as

a

DELAY

MARKER

pulse.

When

06

conducts,

it

furnishes

the

DELAY

MARKER

pulse

at

the

output

and

an

inversion

of

the

DELAY

MARKER

pulse

at

its

collector

which

is

ac-coupled

to

the

base

of

07.

This

pulse

triggers

the

gate

pulse

generator

composed

of

Q7,

Q8,

and

Q9.

When

the

gate

pulse

generator

is

triggered,

the

constant

current

that

is

flowing

through

Q8

will

be

switched

through

07,

and

an

output

pulse

which

is

the

constant

current

multiplied

by

the

sum

of

R25

and

the

amplitude

control,

R24,

will

be

fed

to

the

base

of

OlO,

and

is

the

generation

of

the

gate

pulse.

Again,

D5

forms

a

dc

restoration

for

the

capacity

coupling

of

C12.

O10

is

a

phase

splitter

which

forms

two

pulses

of

equal

amplitude

but

opposite

polarity.

The

positive

pulse

is

fed

to

the

base

of

011

and

the

negative

to

the

base

of

Q12.

Ql

1

and

Q12

are

an

NPN

and

PNP

pair

that

are

both

in

the

cut-off

state

until

the

gate

pulse

arrives,

at

which

time

they

turn

on

for

the

period

of

the

gate

pulse

and

present

an

output

at

their

respective

output

connectors.

The

gate

pulse

width

is

controlled

by

the

RC

combination

composed

of

C11

and

the

series

resistance,

R29

and

R28.

R28

is

the

GATE

WIDTH

control.

W

6

-

1

6.

MAINTENANCE

INSTRUCTIONS

6.1

Testing

Performance

To

te

st

the

operation

of

this

unit,

first

test

the

operation

of

the

delay

multi

vibrator

section.

To

do

this,

merely

insert

on

input

trigger

pulse

and

check

for

on

output

from

the

DELAY

PERIOD

output.

Monitor

the

width

of

the

DELAY

PERIOD

output,

vary

the

delay

potentiometer,

R11,

through

its

range,

and

also

check

the

operation

of

the

RANGE

SELECTOR

switch,

SI

.

Of

course,

this

pulse

width

should

be

equal

to

the

desired

delay

time

except

for

a

small

propagation

delay

of

about

25

nanoseconds.

With

the

trigger

present,

if

there

is

no

DELAY

PERIOD

output,

the

trouble

is

immediately

isolated

to

the

delay

multivibrator.

Usually

the

first

test

to

perform

is

that

of

measuring

dc

voltages

and

comparing

them

with

the

voltages

given

in

Table

1.

If

this

does

not

isolate

the

trouble,

then

one

must

resort

to

the

use

of

on

oscilloscope

and

waveform

checks.

Sufficient

waveforms

for

comparison

ore

given

on

the

schematic

diagram,

drawing

number

416-001-51,

in

the

back

of

the

manual.

If

the

DELAY

PERIOD

output

pulse

is

present,

check

for

on

output

from

the

DELAYED

MARKER

output

BNC.

If

the

DELAYED

MARKER

output

does

not

exist,

then

the

problem

is

immediately

isolated

to

the

circuit

surrounding

Q6.

If

a

DELAYED

AAARKER

output

exists

but

there

is

no

gate

pulse

output,

this

of

course

indicates

that

the

gate

multivibrator

is

not

being

correctly

triggered.

Again,

the

best

test

is

a

dc

voltage

measurement

test

and

comparison

against

the

tabulated

voltages.

6.2

Calibration

Adjustments

There

ore

no

calibration

adjustments

in

the

Gate

and

Delay

Generator

itself;

only

the

adjustments

which

are

available

at

the

front

panel

are

variable.

DELAY

PERIOD

J

\Z3-^y.

J

DELAY

J

MARKER

OATL

GEN.

'I

GEN.

PULSE

GEN.

^

(i)

delay

v.^-\

[

^marker

DELAYED

OA-4m

sec

®

i_jfp

Figure

6-1.

Gate

and

Delay

Generator

-

Block

Diagram

6-2

h-

Uj

ki

Qi

Q

k

O

k

S

o

tt

O.k

0.5

0.4

0.3

0.2

0.1

0

0.1

0.2

0.3

0.4

0.5

0.6

\

\

\

\

\

\

\

\

\

\

\

\

\

\

-

-

-

\

\

/

/

/

X/

y

\

\

N

//

/

/

/

/

>

//

/

/

/

-

DELAY

=

full

range

-DELAY

=

1/E

RANGE

-DELAY-

l/t).

RANGE

-DELAY

=

1/10

RANGE

5

10

15

20

25

30

35

40

45

50

55

GO

TEMPERATURE

(Degrees

Centigrade

)

Figure

6-2.

Delay

Stability

Versus

Temperature

Curves

7

-

1

Table

1,

DC

Voifoge

Measurements

Checkpoint

Average

Values

+

12

bus

+11.8

+

24

bus

+23.8

-24

bus

-23.6

-12

bus

-11.7

Q2-B

+

0.70

Q2-C

+

5.0

Q3-B

+11.5

Q4-B

+21.5

Q5-B

-

0.60

Q6-C

-11.8

Q8-B

+

0.60

Q8-C

Amp

Pot

Min

+9.4

Q8-C

Amp

Pot

Max

+

0.50

Q9-E

+12.4

QID-B

-

0.25

QIO-E

+

0.50

*Q10-C

-

0,45

Qll-E

+

0.1

Q12-E

-

0.1

Q13-B

+

0.1

Q14-B

'

+

1.8

Q15-E

+12.5

*

R

33

to

be

selected,

if

necessary.

Nominal

22

Q

Note:

All

voltages

are

read

with

respect

to

ground

with

a

vtvm,

with

no

signal

input,

and

with

all

front

panel

pots

in

the

zero

position.

BIN/MODULE

CONNECTOR

PIN

ASSIGNMENTS

FOR

AEC

STANDARD

NUCLEAR

INSTRUMENT

MODULES

PER

TID-20893

Pin

Function

Pin

Function

1

+3

volts

23

Reserved

2

—3

volts

24

Reserved

3

Spore

Bus

25

Reserved

4

Reserved

Bus

26

Spare

5

Coaxial

27

Spare

6

Coaxial

♦28

+24

volts

7

Coaxial

♦29

—24

volts

8

200

volts

dc

30

Spore

Bus

9

Spare

31

Carry

No.

2

♦10

+6

volts

32

Spore

*11

—6

volts

CO

CO

115

volts

ocC^^O

12

Reserved

Bus

♦34

Power

Return

Groundi

13

Carry

No.

1

35

Reset

14

Spare

36

Gate

15

Reserved

37

Spore

*16

+12

volts

38

Coaxial

♦17

—12

volts

39

Coaxial

18

Spore

Bus

40

Coaxial

19

Reserved

Bus

*41

115

volts

oc

(Neut.)

20

Spore

♦42

High

Quality

Ground

21

Spore

G

Ground

Guide

Pin

22

Reserved

*These

pins

are

installed

and

wired

in

parallel

in

the

ORTEC

401A

Modular

System

Bin.

u

The

transistor

types

instalied

in

your

instrument

may

differ

from

those

shown

in

the

schematic

diagram.

In

such

cases,

necessary

replace

ments

can

be

made

with

either

the

type

shown

in

the

diagram

or

the

type

actually

used

in

the

instrument.

Table of contents

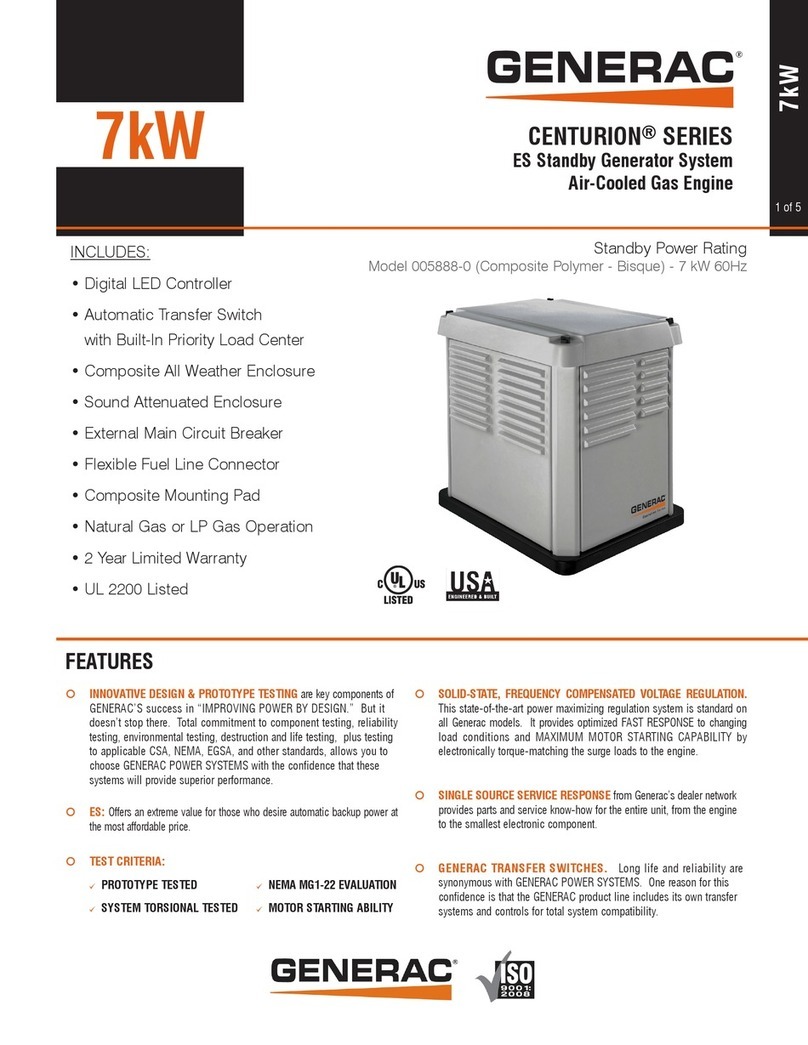

Popular Portable Generator manuals by other brands

Winco

Winco WL22000VE/B Installation & operator's manual

Coleman

Coleman Powermate PM Series Operator's manual

Stanley

Stanley SG 4200B Original instructions

Troy-Bilt

Troy-Bilt 30247 Operator's manual

Southwest Windpower

Southwest Windpower Whisper H-80 owner's manual

SDMO

SDMO Diesel 6000 E XL C Instruction and maintenance manual

Briggs & Stratton

Briggs & Stratton 030694-00 Operator's manual

Senci

Senci SCDE19i-YS user guide

Ribimex

Ribimex PRGE0800 User and maintenance manual

Smart Generators

Smart Generators Motorhead Plus SG13001 operating instructions

Stanley

Stanley SIG 1200S Original instructions

Troy-Bilt

Troy-Bilt 1923 owner's manual