EGS Appleton Powertite 200 Series User manual

EGS Electrical Group • www.appletonelec.com • 800-621-1506 Rev. F 09/18/09 Page 1

330087

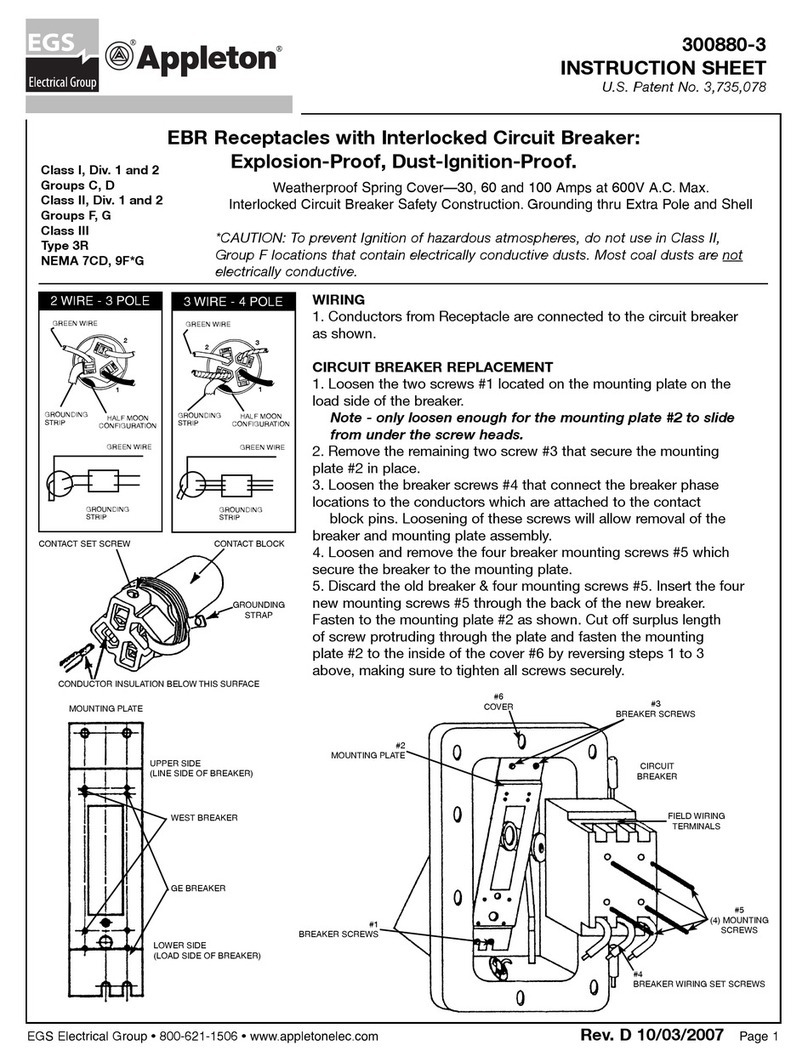

Instruction Sheet for Powertite®

Plug, Connector and Receptacle

Powertite®200 AmP Pin & Sleeve recePtAcleS,

cAble connectorS And PlugS: nemA 4X.

600 volt Ac, 250 volt dc. wire receSS diAmeter: .687”. wire Size rAnge: 250mcm - 4/0 And 3/0 - #4.

Applications

• Designed to supply power to portable or xed

electrical equipment such as motor generator

units, welders, pumps, compressors and similar

apparatus.

• Ideal for use on shipping docks, ports, and

other “ship to shore” applications.

• Suitable for use in locations where a NEMA 4X

enclosure is required.

• Rough usage construction

• Available in two grounding styles:

Style 1 (3W, 3P and 4W, 4P) shell grounding only.

Style 2 (2W, 3P and 3W, 4P) Shell and extra pole

grounding.

Compliances

• UL Standards 1682.

• CSA Specications C22.2 No 42.

* Plug is NEMA 4X when clamp is fully tightened.

Powertite®technicAl dAtA:

reverSe Service, PolArizAtion, Pin And Sleeve deSign.

Applications

• Designed to supply power to portable or

xed electrical equipment such as motor

generators units, welders, pumps, compressors

and similar apparatus.

• Ideal for use on shipping docks, ports,

and other “ship to shore” applications.

• Suitable for use in locations where a

weatherproof enclosure is required.

• Rough usage construction

• Available in two grounding styles:

Style 1 (3W, 3P and 4W, 4P) shell grounding only.

Style 2 (2W, 3P and 3W, 4P) Shell and extra pole

grounding.

Compliances

• UL Standards 1682.

• CSA Specications C22.2 No 42.

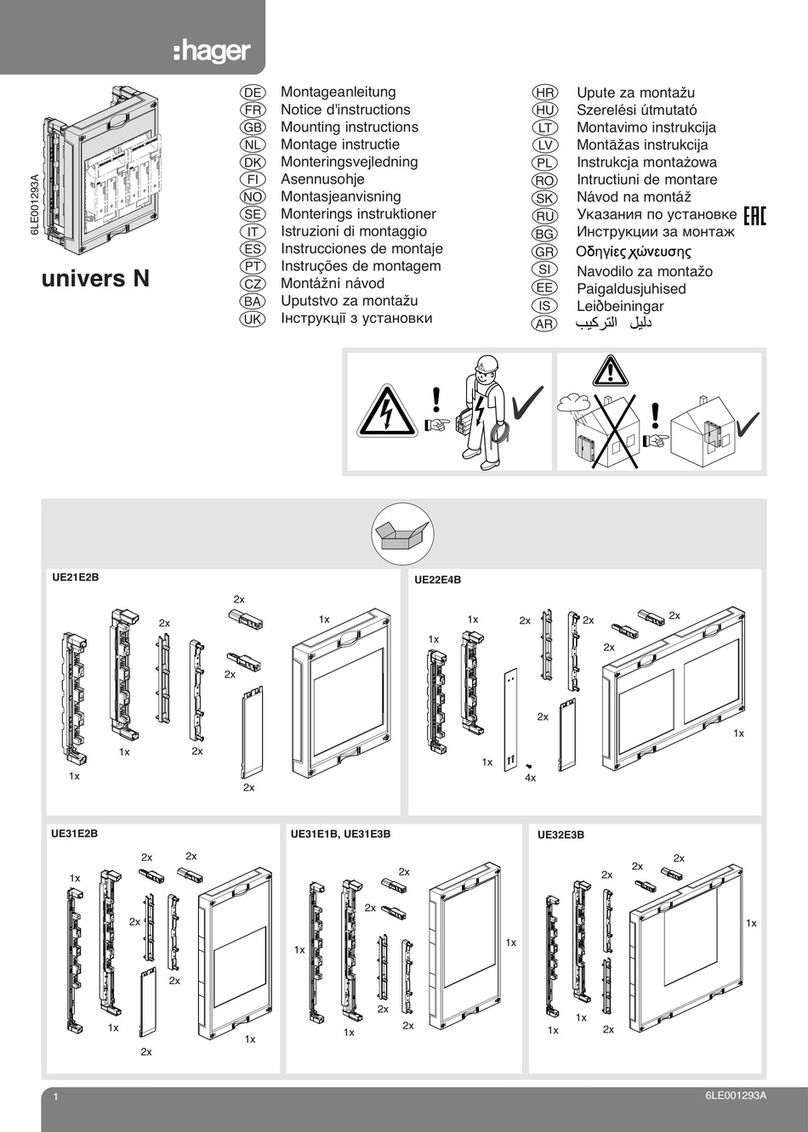

AJA Mounting Box

with Clamp Door

Receptacle

AJA Mounting Box

with Spring Cover

Receptacle

Plug Only*

Connector

Body Only*

Complete

Connector*

Ground Male

Terminal Assembly

Split Type

Contacts

Note: When ordering Reverse Service add - RS after catalog number.

Front Terminal

Block

Male Terminal

Ground Bar

Ground

Screw

Bushing

Crown

Style 1 (Only)

Ground Wire

Assembly

Plug Retaining

Ring

Retaining

Ring

Plug HousingHousing Cap Rear Terminal

Block

(Style 1)

330087 Rev. G 10/16

EGS Electrical Group • www.appletonelec.com • 800-621-1506Page 2 330087 Rev. G 10/16

Powertite®200 AmP Pin & Sleeve PlugS: nemA 4X.

600 volt Ac, 250 volt dc. wire receSS diAmeter: .687”. wire Size rAnge: 250mcm - 4/0 And 3/0 - #4.

Plug and

Connector Cable

Dia. Range

Cable Dia. Grommet

I.D.

Clamp

Position Clamp No.

.875 to 1.906

.875 to 1.062 1-1/32 -1- 304350

1.062 to 1.281 1-9/32

1.281 to 1.561 1-19/32 -2- 304350

1.562 to 1.906 1-29/32

1.875 to 2.500 1.875 to 2.187 2-3/16 -3- 304045

2.187 to 2.500 2-1/2

Terminal Recess Conductor Size Type Conductor

0.687 Dia.

250 MCM General wires

4/0 Flexible & extra

exible cable

* 0.687 Dia. with Stainless

Pressure Plate Included

(see page 5)

3/0 to 1/0 Flexible & extra

exible cable

* Option: Cat. No. PTK200WA3 and PTK200WA4 (see page 5)

0.687 Dia. with Copper

Pressure Plate #1 to #4 Flexible & extra

exible cable

WARNING: A wire schematic must

be followed so the same color wire is

always put into the same numbered

contact openings in all plugs, connectors

and receptacles in the system. This will

insure the correct polarity for the system

and eliminates possibilities for equip-

ment damage and/or personal injuries.

1. Disassemble as shown by removing screw (1),

loosen setscrew (2) and unscrew cap (4), remove

retaining ring (3) and terminal block (9).

2. Strip the proper cable as shown: (also applies to

connector and receptacle).

3. Prepare cable clamp (5) and select the proper

grommet (6) as shown:

Reversible cable clamp (just loosen screws and ip

over) permits wide cable range.

4. Slide cap (4) with clamps (5), steel ring (7), proper

grommet (6) and housing (8) over the cable.

5. Insert Wires into the proper terminals and tighten

For disconnect use only - not for current rupture

Phase

Motor Wire/Pole

Motor Horsepower

120 VAC 240 VAC 480 VAC 600 VAC

1-Phase 2W, 3P 60 120 160

3-Phase 3W, 3P; 3W, 4P or 4W, 4P 60 120 160

For emergency interrupting - maximum horsepower

1-Phase 2W, 3P 15 30 40 40

3-Phase 3W, 3P; 3W, 4P or 4W, 4P 20 40 50 50

set screws securely.

6. Slide terminal block assembly (9) into the

housing (8) aligning the hole in the ground

bar with the hole in the housing. Replace the

at head screw (1) and tighten securely.

7. Place the grommet (6) and steel ring

(7) in the back of the housing and tighten

the cap (4) until grommet (6) is tightened

around the cable and tighten the setscrew

(2). Tighten the clamps (5) screw securely.

Ground Screw

Cable Clamps (5)

Cable

Steel Ring (7)

Grommet (6)

Flat Heat Screw (1)

Style 1 (only)

Ground Wire

Assembly

Cap (4) Set Screw (2) Housing (8)

Terminal Block Assy (9)

Retaining

Ring (3)

Grounding Bar

(Style 2 only)

Reference Guide Of Horsepower Ratings

For Use With Single Motor Application

EGS Electrical Group • www.appletonelec.com • 800-621-1506 330087 Rev. G 10/16 Page 3

Powertite®200 AmP Pin & Sleeve recePtAcleS: nemA 4X.

600 volt Ac, 250 volt dc. wire receSS diAmeter: .687”. wire Size rAnge: 250mcm - 4/0 And 3/0 - #4.

Powertite®200 AmP Pin & Sleeve connector: nemA 4X.

250 volt dc, 600 volt Ac. wire receSS diAmeter: .687”. wire Size rAnge: 250mcm - 4/0 And 3/0 - #4.

1. Remove the rear polarizing ring (1). Slide out the terminal block (2).

2. Follow paragraphs No. 2 and No. 5 for the plugs.

3. After wiring, slide terminal block assembly (2) in the back of housing (3). Replace the polarizing ring (1).

4. Tighten the angle adapter mounting bolts (4) to 50 to 70 in.-lbs. torque.

5. Tighten the receptacle mounting bolts (5) to 120 to 150 in.-lbs. torque.

1. Disassemble, as shown by loosening setscrews (1) and (2),

unscrew clamp cap (4) and housing cap (9), remove polarizing

plate (8), at head screw (12) and terminal block assembly (10).

2. Follow instructions shown on paragraphs No. 2 and No. 3 for the

plugs.

3. Slide clamp cap (4), steel ring (7), proper grommet (6), housing

cap (9) and polarizing plate (8) over the cable.

4. Follow instructions shown on paragraph No. 5 for the plugs.

5. Slide terminal block assembly (10) into the housing (11) aligning

the hole in the ground bar with hole in the housing, Put in at head

screw (12), tighten securely and put in polarizing plate (8).

6. Tighten housing cap (9) on the housing (11) and tighten

setscrew (1) securely.

7. Place the grommet (6) and steel ring (7) on the back of housing

cap (9), tighten the clamp cap (4) until the grommet (6) is tightened

around the cable and tighten the setscrew (2) and cable clamps (5)

securely.

Ground Male

Terminal Assembly

(Style 2 only)

Rear Polarizing

Ring (1)

Ground

Screw

Terminal Block

Assy (2)

Housing (3)

AJA

Mounting Box

Receptacle

Only*

Terminal Block

Assy (10)

Grommet (6)

Housing Cap (9)

Clamp Cap (4) Style 1 (only)

Ground Wire

Assembly

Style 2

Ground Screw

Ground Male

Terminal Assembly

Flat Head

Screw (12)

Housing (11)

Cable

Clamps (5)

Set Screw (2)

Steel

Ring (7) Set Screw (1) Polarizing Plate (8)

Complete

Connector

Connector

Body Only

EGS Electrical Group • www.appletonelec.com • 800-621-1506

Powertite®technicAl dAtA:

grounding StyleS, mAXimum wire SizeS.

PLUG – Equipment grounding

conductor is wired directly to

a solderless lug which is con-

nected to the plug housing with a

pressure connector. All terminals

are “current carrying.”

RECEPTACLE - Two detent

spring clips engage the ground-

ed plug housing on plug inser-

tion - grounded plug shell makes

contact with receptacle ground

spring before line and load poles

are engaged. Grounding path

is maintained until after current-

carrying contacts disengage. All

terminals are “current carrying.”

Standard Service

PLUG - Equipment grounding

conductor is not only connected

to the solderless lug in the plug

housing, but also to an extra

grounding pole. Grounding pole

has copper alloy grounding

jumper strap that connects to

plug housing.

RECEPTACLE - Two detent

spring clips engage the ground-

ed plug housing on plug inser-

tion. Jumper from extra ground-

ing pole is electronically con-

nected to a screw on receptacle

housing. Longer grounding pole

“makes rst and breaks last.”

Reverse Service

Receptacles Mounted on AJA and AJC Boxes

A B C D E F G H

8.00 10.75 6.75 9.50 14.00 15.25 3.75 1.88

dimenSionS:

Powertite®200 AmP Pin & Sleeve recePtAcleS,

PlugS, cAble connectorS, And mounting boXeS.

Receptacle

No. Poles A B C D E F

3 3.25 5.63 4.19 8.00 6.63 6.56

4 3.63 5.63 4.56 8.00 6.63 6.56

Connector Body

No. Poles A B C

3 13.00 4.19 5.38

4 13.00 4.56 5.75

Plug

No. Poles A B C D E

3 11.94 7.81 3.81 3.75 6.44

4 11.94 7.81 4.19 4.13 6.81

Style 2

Shell and Extra

Pole Grounding

Page 4 330087 Rev. G 10/16

Option

for AJB

EGS Electrical Group • www.appletonelec.com • 800-621-1506 330087 Rev. G 10/16 Page 5

Powertite®200 AmP PreSSure PlAte.

For 3/0, 2/0 And 1/0 wire Size* with receSSed terminAl only

oPtionAl AcceSSorieS For wire Size* #1 to #4 - SPeciAl APPlicAtion

cAtAlog number PtK200wA3 (3 PlAteS) And PtK200wA4 (4 PlAteS)

1. Prepare components as shown in gure 1.

2. Insert stripped end of wire into terminal.

3. Insert pressure plate into terminal so that set screws, pressure plate and wire are aligned (gure 2).

4. Tighten set screw securely (80-100 in-Ibs).

1. Prepare components as shown in gure 3.

2. Insert copper plate into terminal.

3. Insert stripped end of wire into terminal so that set screws, wire and copper plate are aligned (gure 4).

4. Tighten set screw securely (50-60 in-Ibs).

* Caution: Check National Electrical Code for proper wire size and application.

1. Pressure Plate

4. Hex Set Screw

4. Hex Set Screw

2. Stripped Wire

Recessed Terminal

3. Terminal

2. Stripped Wire

1. Copper Plate

3. Terminal

Figure 3

Figure 1

Figure 4

Figure 2

EGS Electrical Group • www.appletonelec.com • 800-621-1506Page 6 330087 Rev. G 10/16

1. With both wing nuts fully tightened, loosen the RIGHT

wing nut that secures the receptacle cover ¼ turn and

position both wing nuts as shown in Figure 1.

Figure 1

2. Slide the locking bar to the right and slip the locking

bracket under the left wing nut and over the at washer.

3. Slide the locking bar to the left side.

Figure 2

4. Slip the locking bracket under the right wing nut and

over the at washer as shown in Figure 2. Tighten

the wing nut ¼ turn until it is parallel with the locking

bracket

5. Slide the locking bar in place until it is ush with both

ends of the locking bracket as shown in Figure 3.

Figure 3

6. Install padlock(s) in one or more of the ve 11/32”

(8.9mm) padlock holes provided.

oPtionAl AcceSSorieS For Powertite®200 And 400 AmP Pin & Sleeve recePtAcleS

inStAllAtion inStructionS For cAtAlog numberS:

PtlocK2004 - Powertite 200 AmP 3 & 4 Pole locKing Kit

PtlocK4004 - Powertite 400 AmP 4 Pole locKing Kit

EGS Electrical Group • www.appletonelec.com • 800-621-1506 330087 Rev. G 10/16 Page 7

200 AmP ground lug For Style 1 recePtAcle

To Assemble Grounding Lug

1. Locate threaded hole on polarizing plate (1).

2. Insert the brass screw (3) through the top of lug (2).

3. Line-up edge of plate (1) with at on lug (2).

4. Thread screw into plate until tight.

5. Thread set screw (4) into lug (2).

To Connect Ground Wire To Lug

1. Prepare wire by stripping 3/4”from the end of the wire (wire size range: #2-4/0).

2. Loosen the set screw enough to t the wire in the lug.

3. Tighten set screw securely (50-60 in-lbs).

EGS Electrical Group • www.appletonelec.com • 800-621-1506Page 8 330087 Rev. G 10/16

Table of contents

Other EGS Industrial Electrical manuals

Popular Industrial Electrical manuals by other brands

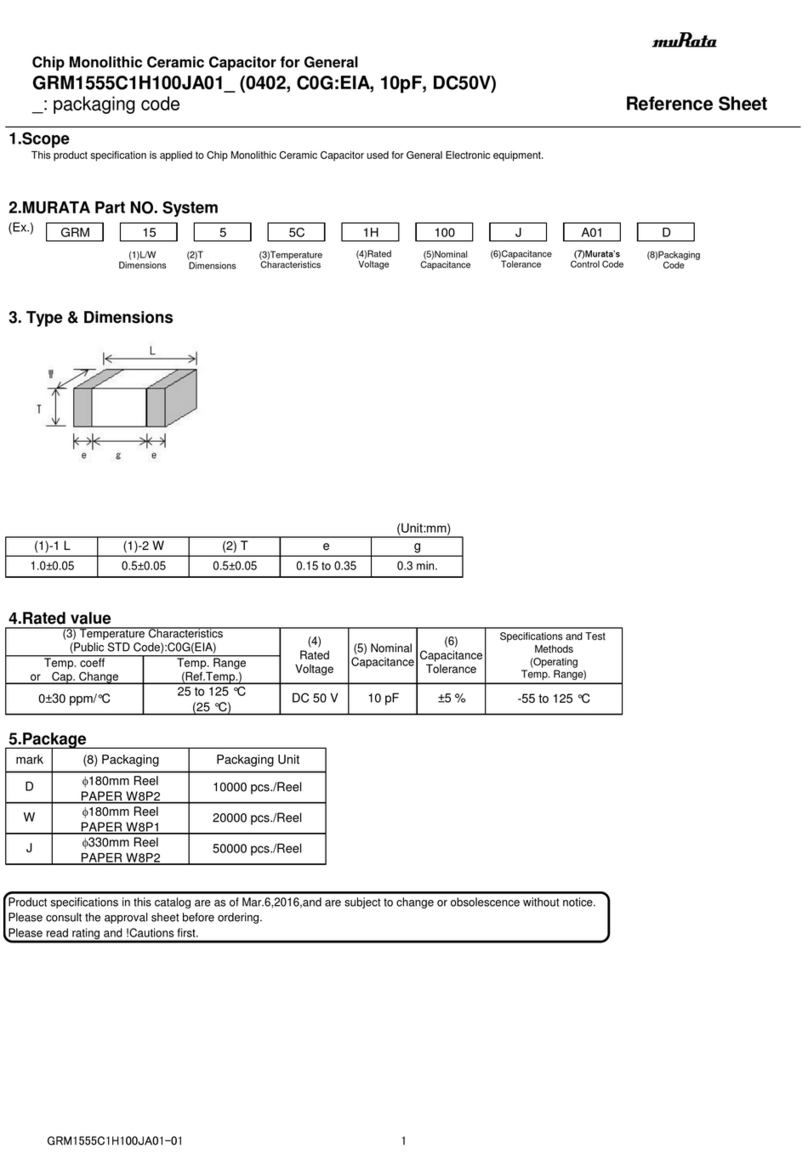

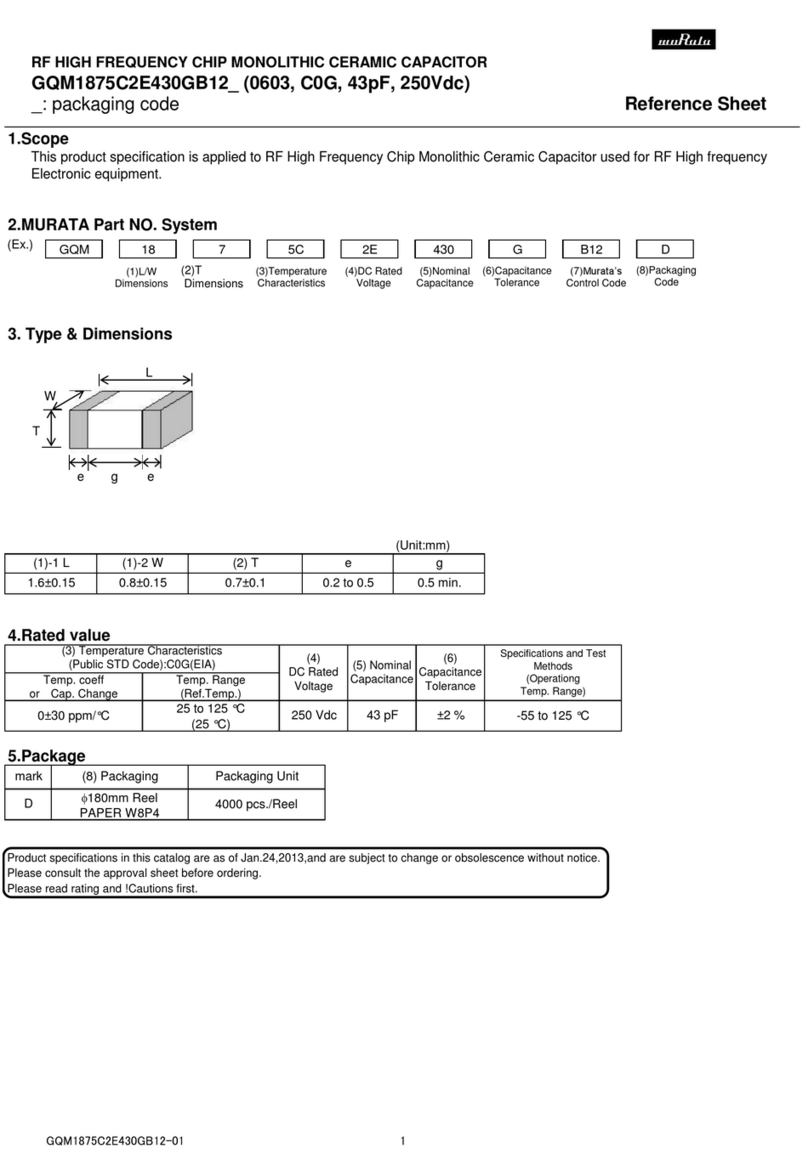

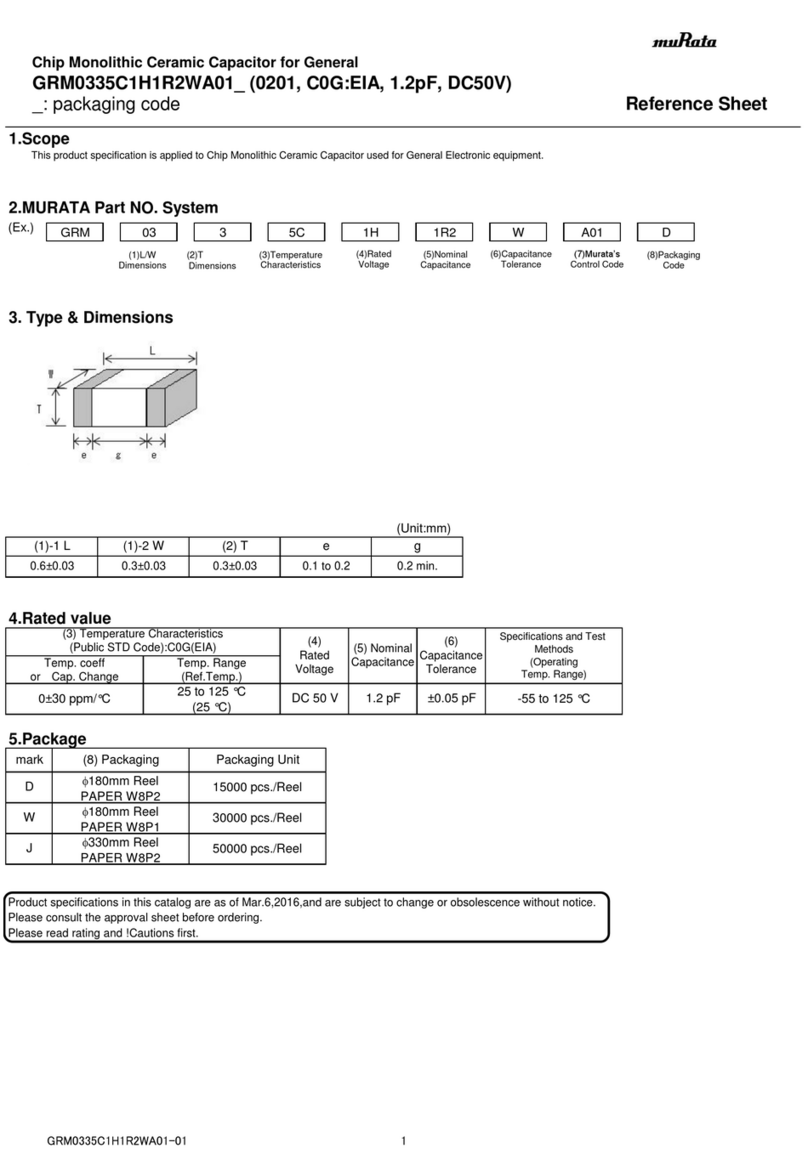

Murata

Murata GQM1875C2E430GB12 Series Reference sheet

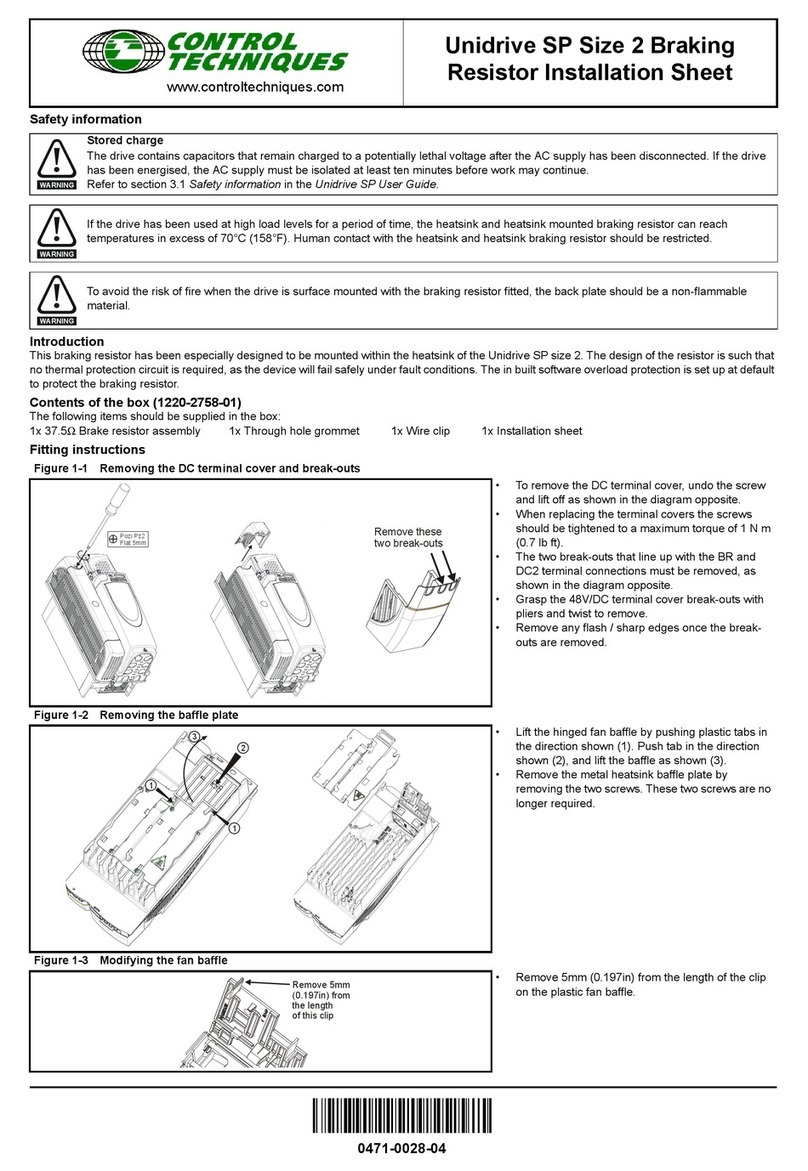

Control Techniques

Control Techniques Unidrive Size 2 Installation sheet

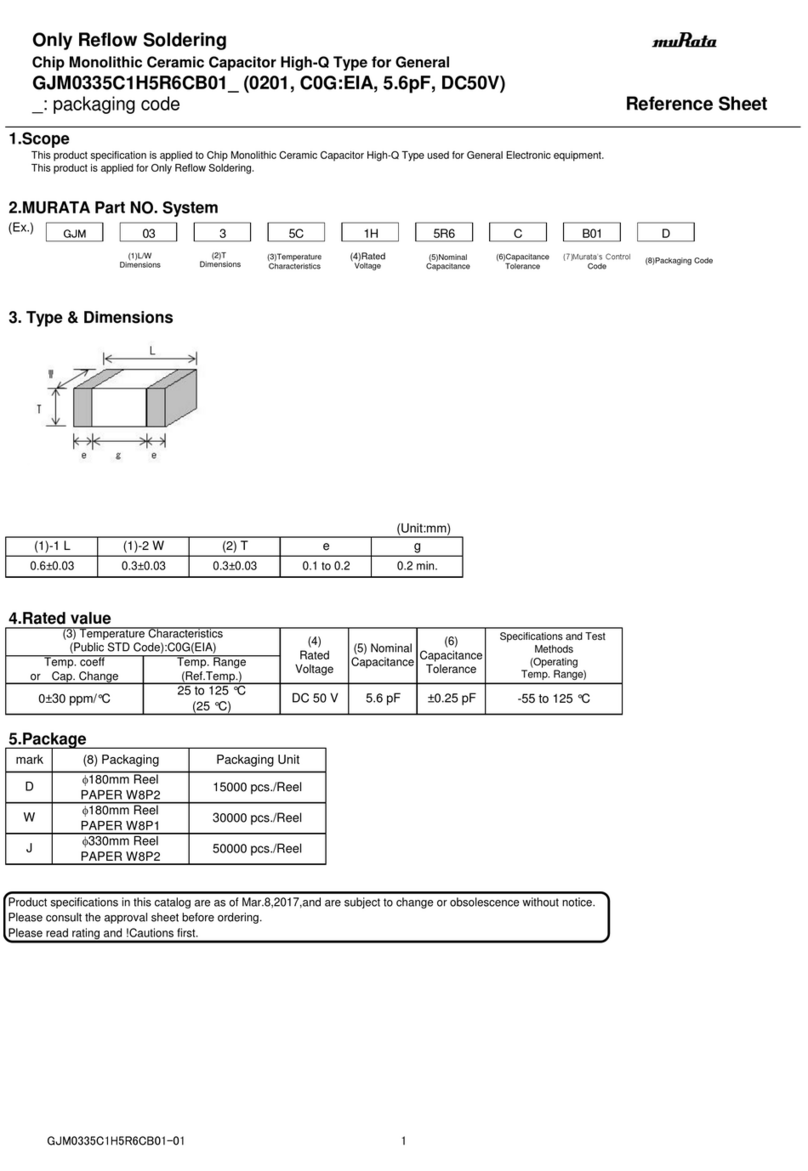

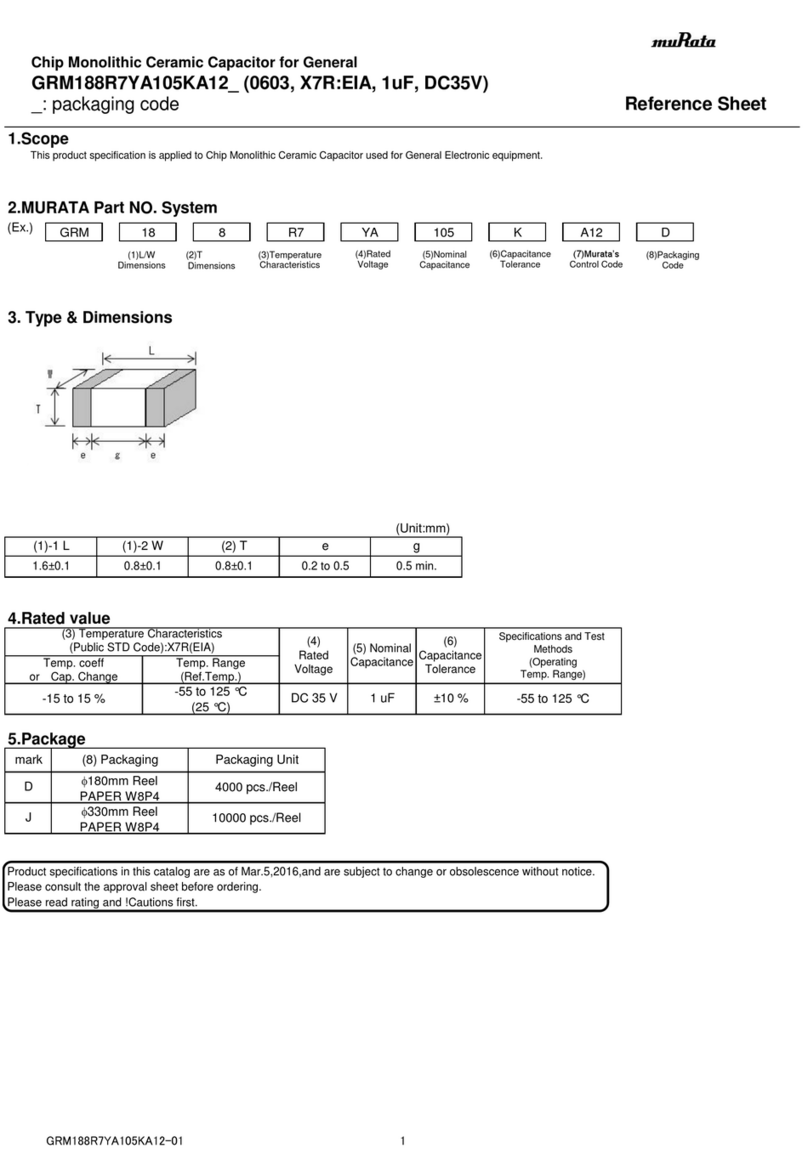

Murata

Murata GRM188R7YA105KA12 Series Reference sheet

hager

hager univers N UE21E2B Mounting instructions

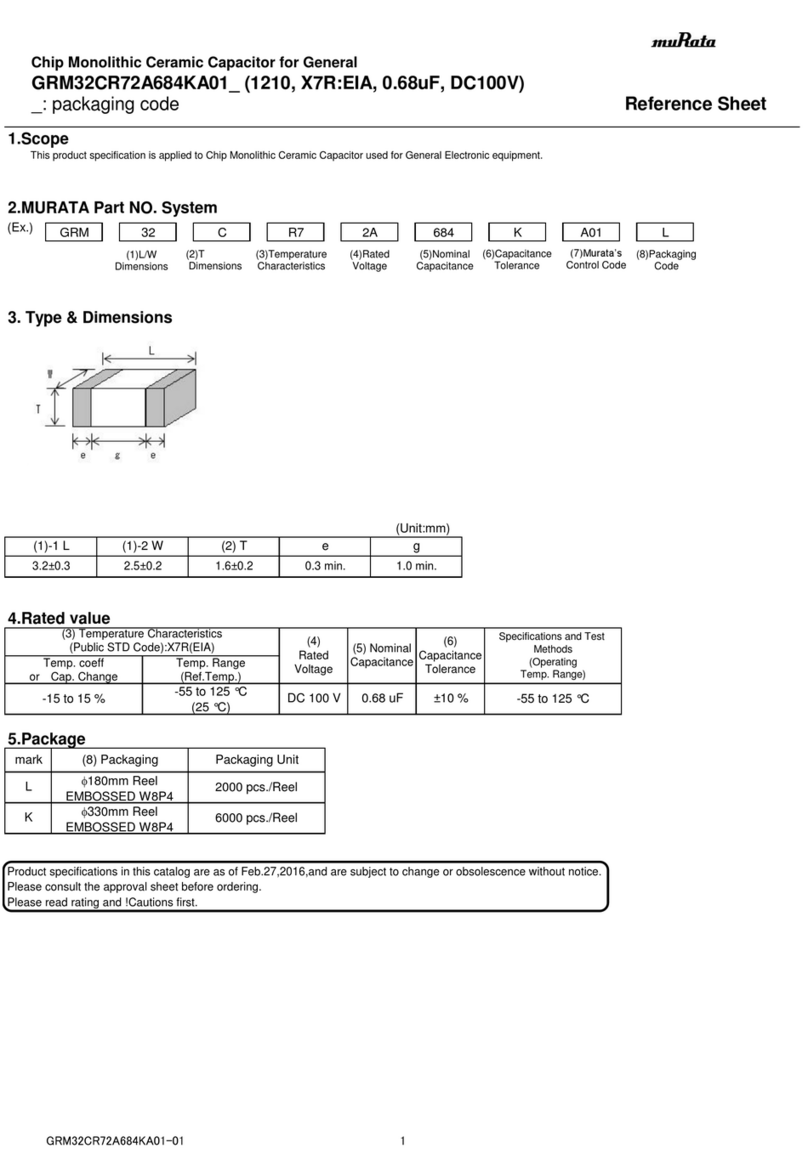

Murata

Murata GRM0335C1H1R2WA01 Series Reference sheet

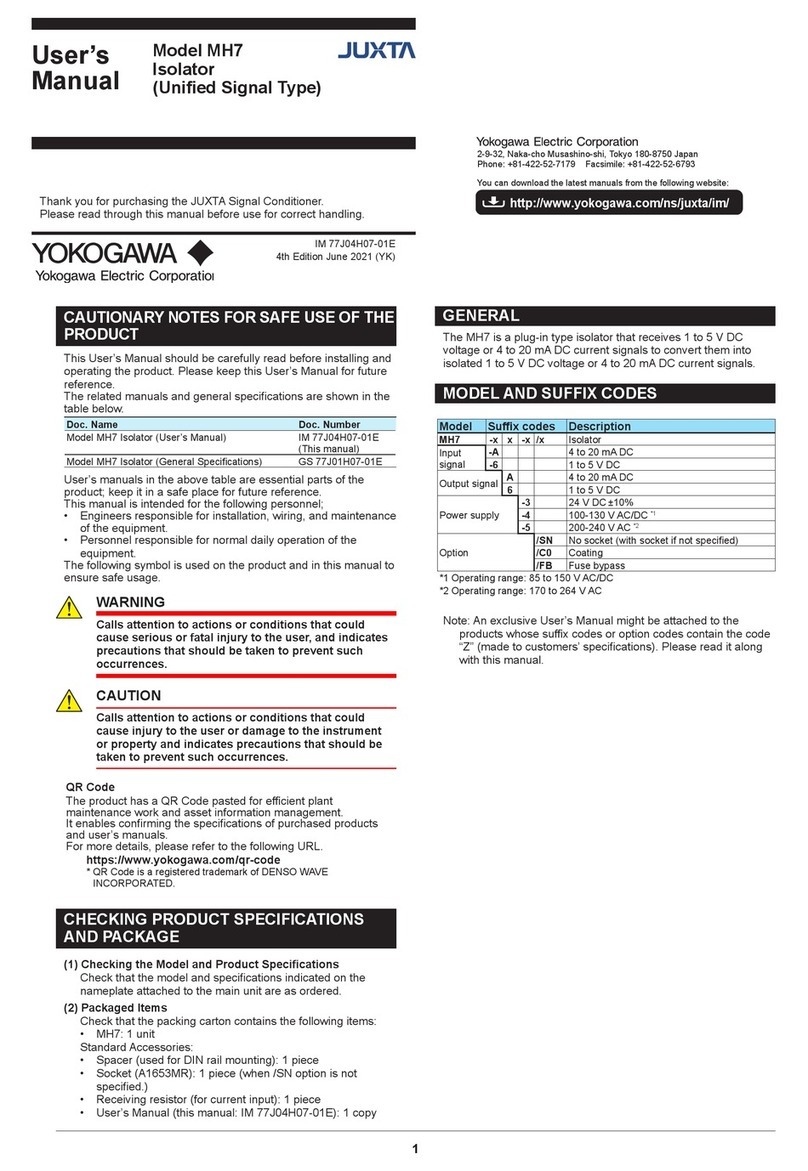

YOKOGAWA

YOKOGAWA Juxta MH7 user manual