Elekta CTR1498 User manual

CONTENTS

X-RAY RADIATION PRECAUTION 2

SAFETY PRECAUTION 2

OPERATIONCONTROLS 3

GENERAL ADJUSTMENT INSTRUCTION 4-8

COLOR PURITY AND CONVERGENCE ADJUSTMENT 9-10

COMPONENT AND BOTTOM VIEW 11-13

WIRING DIAGRAM 14

SCHEMATIC DIAGRAM 15

BLOCK DIAGRAM 16

ELECTRICAL PARTS LIST 17-25

EXPLODED VIEW 25

MECHANICAL PARTS LIST 27-28

SPECIFICATIONS 28

CAUTION: BEFORE SERVICING THE CHASSIS, READ THE' SAFETY PRECAUTION ",'X-RAY RADIA-

TION PRECAUTION " AND ' PROOUCT SAFETY NOTICE " ON PAGE 2 OF THIS MANUAL.

NOTICE: THE POWER SUPPLY ClRCUIT OF THIS RECEIVER IS A " HOT " CHASSIS, THE REST ARE

" COLD " CHASSIS.

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can produce potentially hazardous-X-RAY RADIATION. To avoid such hazards, the high voltage

must not be above the specified limit. The normal value of th high voltaga of this receiver is 25kV at zero beam current

( minimum brightness ) under 220V AC power source. The high voltage must not, under any ciraurtstancss, exceed 26kV.

2. Each time a receiver requires servicing, the high voltage should be checked following the HIGH VOLTAGE CHECK PROCEDURE

in this manual. It is recommended the reading of the high voltage be recorded as a part of the service record.

It is important to use an accurate and reliable high voltage meter.

3. The primary source of X-RAY RADIATION in this TV receiver is the picture tube. For continued

X-RAY RADIATION protection, the replacement tuba must be exactly the same type tube as specfied in the parts list,

4. Some parts in this receiverhave special-safety-related charaderistics for X-RAY RADIATION protection. For continued

safety, parts replacement should be undertaken only after referrfng to the PRODUCT SAFETY NOTICE below.

5. The receiver is equipped with X-RAY RADIATION circuit. When the high voltage reach a set value, the circuit will set the

receiver to STAND BY mode to prevent the receiver from producing excessive amount of X-RAY RADIATION.

SAFETY PRECAUTION

WARNING:

Service should not be attempted by anyone unfamiliar with the necessary precaution on this receiver. The following are the

necessary precautions to the observed before servicing this chassis.

1. Since the power suppfy circuit of this receiver is directly connected to the AC power line, an isolation transformer should

be used during any dynamic service to avoid possible shock hazard.

2. Always discharged the picture tube anode to the CRT conductive coating before handling the picture tube. The picture tube

is highly evacuated and if broken, glass fragments will be violently expeIied. Use shatter proof goggles and keep picture

tube away from the unprotected body while handling.

3. When replacing a chassis in the cabinet. always be certain that all the protective devices ara put back in place, such as:

non-metallic control knobs, Insulating covers, shields, isolation resistor-capacitor network etc,

4. When replacing parts or cirduit boards, disconnect the power cord.

5. When replacing a high voltage ressistor ( oxide metal film resistor ) on the circuit board. keep ihe resistor l0mm (1 / 2in)

away from circuit board.

6. Connection wires must be kept away from components with high voltage or high temperature.

7. If any fuse in this TV receiver is blown, replace it with the FUSE specified in the chassis parts list.

8. The receiver is designed to operate with 220V ( 50Hz ) AC mains.

9. Replace any components according to the requirement after reading the parts list in this manual.

PRODUCT SAFETY NOTICE

Many electrical und mechanical parts in the chassis have special safety-related characteristics. These characteristics are otten passed

unnoticed by a visual inspecson and the X-RAY RADIATION protection afforded by them cannot necessarily be obtained by using

replacement components rated for higher wattage, etc. Repladement parts which have tese special safety characteristics are identified

in this manual and its supplements electrical components having such features are shaded on the schematic diagram and the parts Iist.

Before replacing any of these components, read the parts list in this rnanual carefully. The use of substitute replacement parts which do

not have the same safety characteristic as specified in the parts list may create shock, fire, X-RAY RADIATION other or hazards.

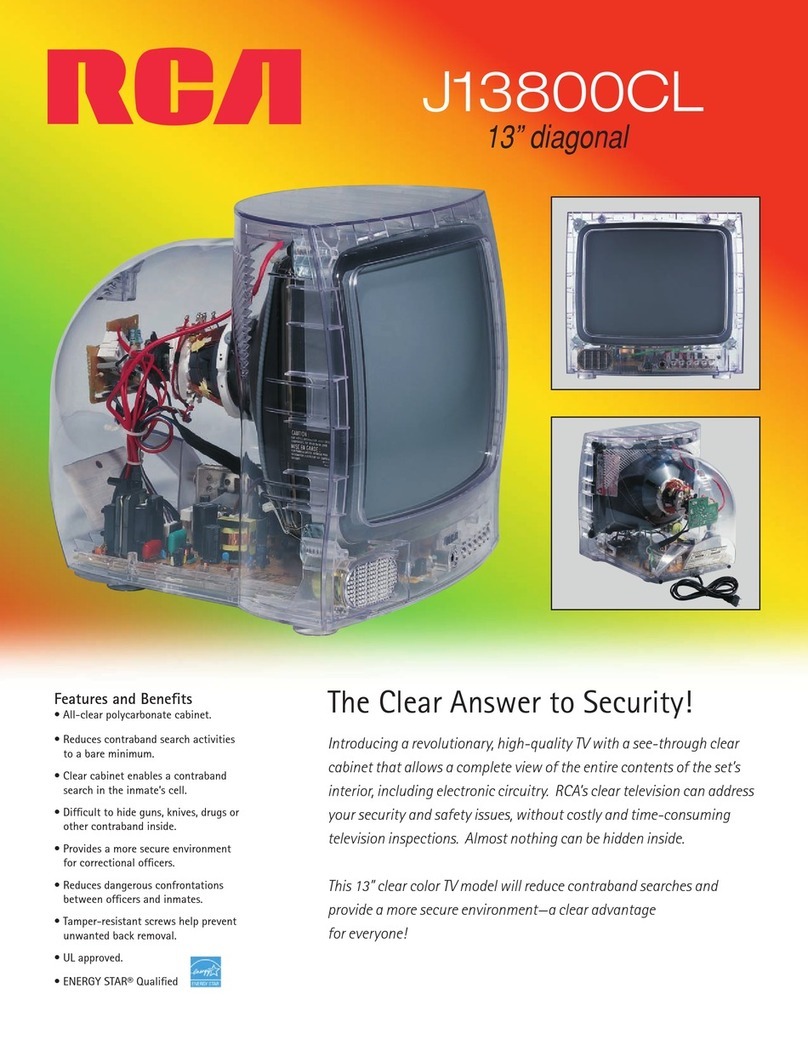

OPERATION CONTROLS

VOLUME CONTROL

( UP / DOWN )

CHANNEL SELECTOR

(

UP /

DOWN )

POWER SWITCH

LED

INFRARED REMOTE

SENSOR

SPEAKER

CONTROL DOOR

MANUAL TUNING AUTO PRESET STAND BY

PRESET ON/OFF SKIP

AUDIO IN

VIDEO IN

AC CORD

ANTENNA TERMINALS

GENERAL ADJUSTMENT INSTRUCTION

This receiver is transistorized and special care should be taken when servicing. Read the following matters that demand

special attention before attempting adjustment.

1. Adjustment requires and exact procedure and should be under taken only when necessary.

2. An isolation transformer should be used during any dynamic service to avoid possible shock hazard.

3. The test equipment specified or its equvalent is required to perform the alignment property. Use of equipment which does

not meet these requirements may result in improper alignment.

4. Correct matching of the equipment is essential. Failure to use proper matching will result in responses which can not

repressent the lure operation of receiver.

5. The AC power line voltage should be kept 215 to 225 volts 50Hz during alignment

6. Do not attempt to connect or disconnect any wire while the receiver is in operation.Make sure the power cord is

disconnected before replacing parts in the receiver.

7. Unless otherwise noted, do not perform arty adjustment until the receiver has been turned on for at least 10 minutes.

Note: For safety sake, the following adjustment should be conducted with the low voltage DC supply to avoid shock hazard.

TEST EQUIPMENTS

1. AM / FM signal generator ( 4.5MHz-6.5MHz )

2. Sweep / Marker signal operator ( 30MHz~60MHz )

3. Sync. oscilloscope

4. Oscilloscope ( volt sensitivity over 10mV and input impedance having 1MO, below 10PF )

5. Probe ( Low capacitance )

6. High impedance electronic voltmeter on VTTM ( Input impedance having 100kO/ V at leasti )

7. DC power supply ( Source such as a battery or a well regulated and isolated DC bias supply )

8. Frequency counter.

PICTURE AND SOUND I. F. ADJUSTMENT

1. Picture I. F. Alignment

(a) Connect the signal output of sweep / marker generator to the Test Point of tuner through 1 kO resistor and 1 OOOPF capaci-

tor ( See Fig. 1 ).

(b) Connect the vertical input terminal of an sync oscilloscope in series with a 100kO resistor to TP4.

(c) Apply a + 12V DC across C120 on Main Board.

(d) Apply a + 8V DC dummy AGC bias to Pin 5 of IC101.

(e) Tune L105 and L109 to obtain a waveform as show in Fig. 2.

2. AFC OVERALL RESPONSE ALIGNMENT

(a) Act the step (a), (c) and (d) of Picture I. F. Alignment.

(b) Reconnect oscilloscope to TP5through a 1 MO resistor.

(c) Adjust coil L110 that 38.9MHz, Markeris set at the center position as shown in Fig. 3.

3. SIF ALIGNMENT ( 5.5MHz )

(a) Set signal generator output to 5.5MHz with AF 1 kHz, 75kHz FM modulation output level 60dB. Apply the signal to TP6

through a 1kO resistor and a 1OOOPF capacitor. As show in Fig. 4.

(b) Connect the oscilloscope input in series with a 100kO resistor to TP7

(c) Apply a + 12V DC across C120.

(d) Fine adjust L108 to abtain a maximum amplitude signal output with minimum distortion.

Note: In case of the D / K system, sound carrier frequency should be at the point of 6.5MHz and video carrier frequency at the point of

38.0MHz.

Fig.4.

GENERAL ADJUSTMENT

1. AUTOMATIC DEGAUSSING

An automatic degaussing coil is attached around the picture tube, degaussing the tube property in about one second after the set is

switched on. If the receiver is moved or faced in a different direction, the power must be switched off at least 15 minutes in order that

the automatic degaussing circuit operates property. External degaussing is necessary íf Use automatic degaussing proves ineffective

offer the set is moved. External degaussing is done by moving a degaussing coil circlewise in front of the face plate and then moving it

away step by step until it is about two meters from the screen, then switch off the degaussing coil If residual color spots are still found

on the screen, adjust the color purity and convergence.

2. B + ( 110V ) ADJUSTMENT

CAUTION: To avoid X-ray hazards, B + voltage must be set correctly at + 110V position.

(a) Make sure the AC power supply is 220V, 50Hz

(b) Switch on the TV receiver tune in an active channel and adjust brightness, color and contrast for maximum

(c) On Main PCB check the B+ voltage at C518 with a reliable DC voltmeter.

(d) Adjust VR501 on Power Supply PCB for B + 110V voltage reading.

3. HIGH VOLTAGE CHECK

CAUTION: There is no high voltage adjustment in this chassis, B + 110V voltage directly relates to the high voltage, it must be property

adjusted to insure the correct high voltage. The high voltage must not exceed 26kV under any conditions.

(a) Connect an accurate high voltage meter to the second anode cap or the picture tube.

(b) Turn on the receiver, set brightness and contrast controls to minimum, then observe its voltage Zerobean Current )

(c) Make sure the high voltage does not exceed 26kV.

(d) No matter whether the luminance, contrast and chrominance controls are set to maximum or minimum, the high voltage must be

kept under 24kV.

4. HORIZONTAL OSCILLATOR ADJUSTMENT

Adjust the HORIZONTAL HOLD control VR203 to the center of the pull-in range

5. VERTICAL OSCILLATOR ADJUSTMENT

If the picture moves up or down on the screen, adjust the VERTICAL HOLD control ( VR204 ).

6. HEIGHT ADJUSTMENT

(a) Receive the Philips Pattern signal.

(b) Adjust the height control ( VR205 ) to slightly overscan the screen.

7. PICTURE CENTER POSITION ADJUSTMENT

If the picture is on the left or right side of the screen, adjust the HORIZONTAL CENTER control VR207 until it is satisfactory.

8. FOCUSING ADJUSTMENT

(a) Receive a TV signal.

(b) Set the contrast control to the normal position.

(c) Adjust the FOCUS control ( on· T302 ) for a well-defined, sharpest display on the screen.

9. WHITE BALANCE ADJUSTMENT

(a) Set TV brightness control to miniumum and switch to AV mode. Warm up the set for 15 minutes.

(b) Set the R.G.B. cut off controls VR403 VR404, VR405 and the B.G. drive control ( VR401, VR402 ) to center position.

(c) Rotate the screen control on the FBT fully counter clokwise.

(d) Disconnect the luminance output terminal connector ( socket-Y ).

(e) Connect TP9 and TP10 with a jumper wire.

(f) Rotate the screen control gradually clockwise until the first horizontal line appears on the screen.

(g) It the first horizontal line is in blue, adjust VR403, VR404 to increase the redand green component level to get a white horizontal

líne.

(h) Remove the jumper wire and connect back the luminance output connector ( socket-Y ). Adjust VR401, VR402 to maintaina good

white balance at the brightest part of the screen.

(i) Observe the screen white balance, if it is not proper ire high brightness or low brightness condition, adjust R.G.B. cut off controls or

G.B. drive controls respectively to maintain a good white balance in both low and high luminance.

10. DELAY AGC ADJUSTMENT

(a) Switch on the TV receiver, set input signal level at 60dB.

(b) Adjust the AGC control ( VR101 ) fully clockwise, then turn it counter clockwise until snow noise just disappears from me screen.

Now AGC voltage should be 6. 2V.

11. ABL ADJUSTMENT

(a) Tune in a color bar pattern signal.

(b) Set the brightness, contrast and color to minimum.

(c) Turn VR802 counter clockwise until two black-white burs just appear on the left of the screen.

(d) The voltage on R139 should be below 1.0V if it is tested by DVM.

12. OSD POSITION ADJUSTMENAT

(a) Set the RECALL on the remote control.

(b) Adjust OSD control C816 until the caption display appears on the upper right corner of the screen.

13. COLOR SYNC ADJUSTMENT

(a) Tune in a color bar pattern signal.

(b) Set the contrast control to minimum, and the color control to maximum.

(c) Set VR801 to the center position.

(d) Connect a resistor 10kO between TP11 and TP15.

(e) Short L203 to GND by jumper wire.

(f) Adjust the color sync, variable capacitor C246 so that the color bar pattern stands still.

14. PAL MATRIX ADJUSTMENT

(a) Tune in a color bar signal.

(b) Use oscilloscope with 2 channels input and set to the " X-Y ' mode.

(c) Channel 1 ( X ) connected to TP28 ( Pin 1 of IC1401 ) ( R-Y ).

(d) Channel 2 (Y) connected to TP29 (Pin 3 of IC1401) (B-Y).

(e) Adjust amplitude balance VR202 until the center points of the two waveforms coincided (as shown in Fig. 5).

(f) Adjust L203 and 1204 until all other points of the two waveforms coincided (as shown in Fig. 5).

15. COLOR DECODER ADJUSTMENT FOR SECAM SYSTEM

A. IDENT FILTER ADJUSTMENT

(a) Apply a SECAM color bar signal ( 60dB level ) to the input

(b) Connect a high impedance DC voltmeter to TP31 ( Pin 10 of IC1401 ).

(c) Adjust L210 of the ident filter for minimum voltage at Pin 10 ( 3V ).

B. BELL FILTER ADJUSTMENT

(a) Apply a SECAM color bar signal ( 60dB level ) to the antenna input.

(b) Connect an oscilloscope to TP30 ( Pin t4 of IC1401 ).

(c) Adjust L206 to make the envelop of color bar signal into flat response ( Fig. 6 ).

Fig. 6 SECAM Color Bar Signal

C. B-Y DEMODULATION

(a) Apply a SECAM color bar signal to the input.

(b) Connect an oscilloscope to TP17 ( Pin 3 of IC1401 ).

(c) Adjust L209 to obtain a B-Y signal will, correct chrominance output ( Fig. 7 )

D. R-Y DEMODULATION

(a) Apply a SECAM color bar signal.

(b) Conned an oscilloscope to TP18 ( Pin 1 of IC1401 ).

(c) Adjust L211 to obtain an R-Y signal with correct chrominance output ( Fig. 8 ).

16. SUB-COLOR ADJUSTMENT

(a) Receive Philips signal.

(b) Set the contrast, brightness to the normal position, set the color to minimum.

(c) Turn VR801 clockwise until the color is not overflow.

COLOR PURITY AND CONVERGENCE ADJUSTMENT

1. COLOR PURITY ADJUSTMENT

Note: Before attempting any purity adjustments, the receiver should be operated for at least fifteen minutes.

(a) Demagnetize the picture tube and cabinet using a degaussing coil.

(b) Turn the contrast and brightness controls to maximum.

(c) Adjust Red and Blue Controls ( VR403 ) and ( VR405 ); to provide only green raster. Advance the Green Bias Control ( VR404 ) if

necessary.

(d) Loosen the clamp screw holding the yoke backward to provide vertical green belt ( ZONE ) in the picture screen.

(e) Remove the Rubber Wedges.

(f) Rotate and spread the tabs of the purity magnet ( See Fig. 9 ) around the neck of the picture tube until the green beil is in the

center of the screen. At the same time, center the raster vertically.

(g) Move the yoke slowly forward or backward until a uniform green is obtained. Tighten the clamp screw of the yoke temporarily.

(h) Check the purity of the red and blue raster by adjusting the bias controls.

(i) Obtain a white raster, referring to white balance adjustment.

(j) Proceed with convergence adjustment.

2. CONVERGENCE MAGNET ASSEMBLY POSITIONING

Convergence Magnet Assembly and Rubber Wedges need mechanical positioning following Fig. 9.

3. CENTER CONVERGENCE ADJUSTMENT

Note: Before attempting any convergence adjustments, the receiver should be operated for at least fifteen minutes.

(a) Receive crosshatch pattern with a color bar signal generator.

(b) Adjust the brightness and contrast controls for well defined pattern.

(c) Adjust two tabes of the 4 Pole Magnets to change the angle between them ( See Fig. 10 ) and superimpose red and blue vertical

lines in the center area of the picture screen. ( See Fig. 11 )

(d) Turn both tabs at the same tiem keeping the contrast angle to superimpose red and blue horizontal lines at the center of screen. (

See Fig. 11 )

(e) Adjust two tabes of 6 Pole Magnets to superimpose red /blue line with green one. Adjusting the angle affects the vertical lines and

rotating both magnets affects the horizontal lines.

(f) Repeat adjustments 3, 4, 5keeping in mind red, green and blue movement, because 4 pole Magnets and 6 pole magnets interact

and make dot movement complex.

4. CIRCUMFERENCE CONVERGENCE ADJUSTMENT

Note: This adjustment requires Rubber Wedges and Grass Cloth Tapes.

(a) Loosen the clampling screws of deflection yoke to allow the yoke to tilt.

(b) Place a wedge as shown in Fig 14 temporarily.( Do not remove cover paper on adhesive pant of the wedge. )

(c) Tilt front of the deflection yoke up or down to obtain better convergence in circumference ( See Fig. 11 ). Push the mounted wedge

into the space between picture tube and the yoke to hold the yoke temporarily.

(d) Place othter wedge intro bottom space and remove the cover part to stick.

(e) Tilt front of the yoke right or left to obtain better convergence in circumference. ( See Fig.11 ).

(f) Hold the yoke position and put another wedge in either upper space. remove ~ paper and stick the wedge on picture tube to hold

the yoke.

(g) Detach the temporarily mowed wedge and put it in another upper space. Stick in on picture tube to fix the yoke.

(h) After placing three wedges, recheck over all convergence. Tighten the screw firmly to hold the yoke tightly in place.

(i) Stick 3 grass cloth tapes on wedges as shown in Fig. 9.

Table of contents