-3-

SPECIFICATIONS

Input Impedance 1MW

Input Overload Protection 50V DC continuous

Thresholds Logic 1 Logic 0

TTL 2.3 + .25V 0.80V + .1V

CMOS 70% Vcc 30% Vcc

Response better than 25 nanoseconds

Pulse Detector 1.5 millisecond pulse stretcher

Power Requirements 5V Vcc @ 30mA

15V Vcc @ 40mA

Operating Temperature –40OC to +85OC

CIRCUIT DESCRIPTION

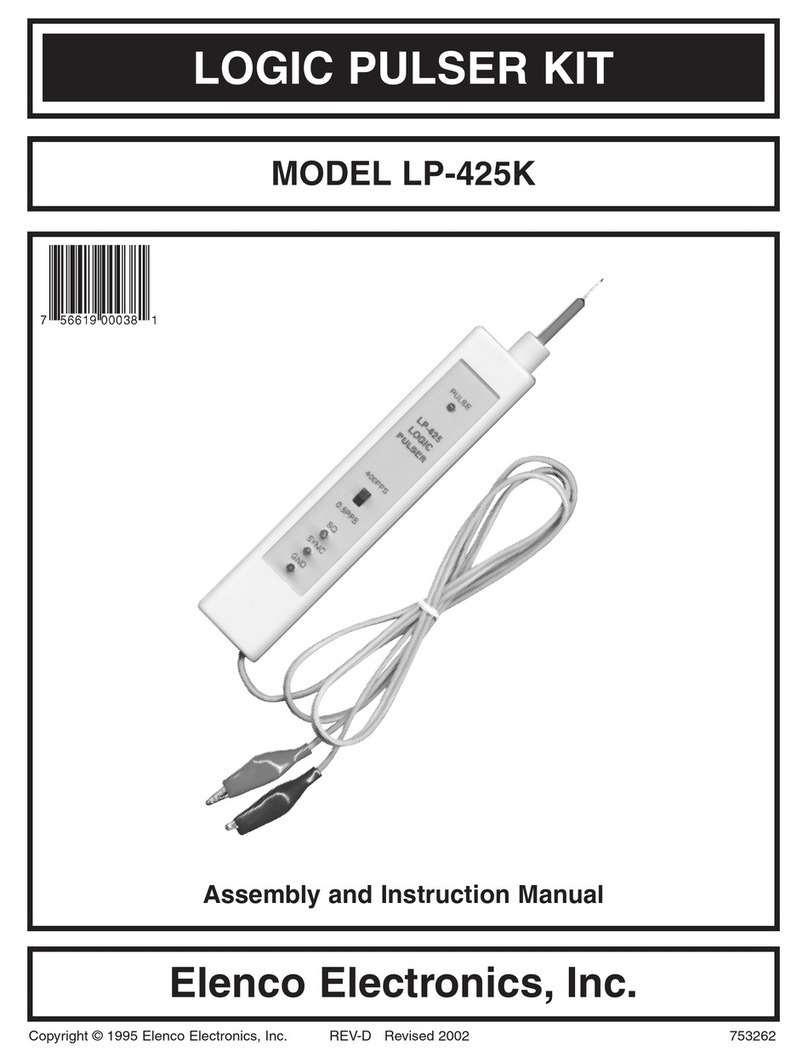

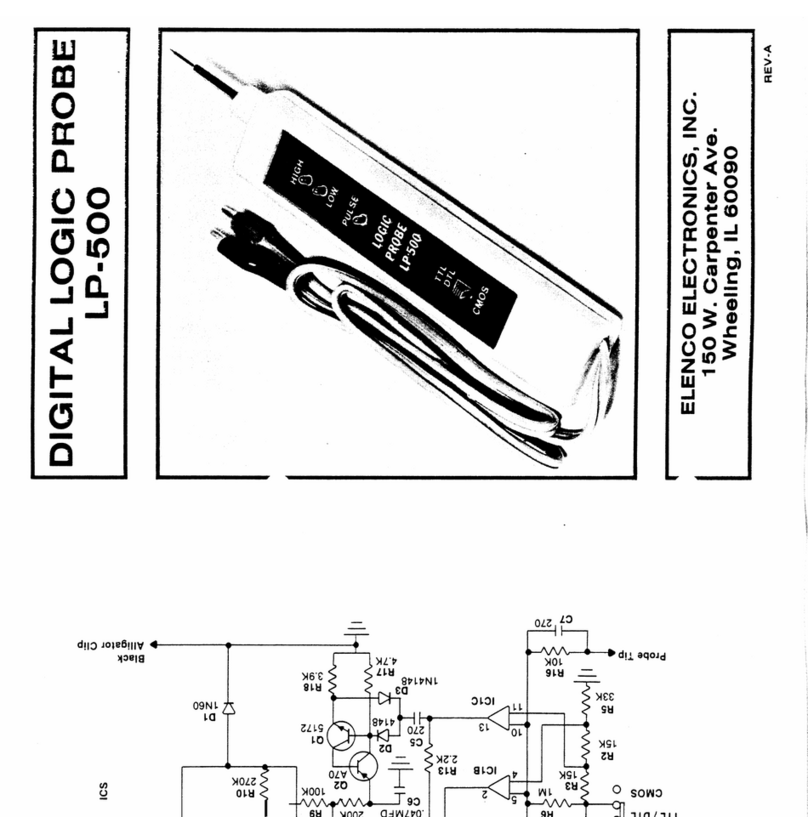

The Elenco™ Model LP-525K Logic Probe kit is a

convenient and precise instrument for use in the

measurement of logic circuits. It displays logic

levels (high or low), and voltage transients down to

25 nanoseconds. The LED readouts provide instant

response to the logic state.

To detect the high and low logic levels, the LP-525

uses two comparators of a Quad Comparator

LM2901 Integrated Circuit (see schematic diagram).

One comparator drives the HI LED and the other

drives the LOW LED. The comparator output goes

low, lighting the LED, when the (–) input is more

positive than the (+) input. To measure TTL circuits,

the TTL-CMOS switch is set to TTL and the red and

black alligator clips are connected to +5VDC and

ground. The (+) input (pin 5) of the HI comparator is

then biased to 2.3VDC by resistor network R9

through R15. Thus, the LED lights when the probe

tip is more positive than 2.3VDC. To measure

CMOS circuits, the HI comparator changes to

3.5VDC or 70% of the supply voltage.

The (–) input of the LOW comparator is biased to

.8VDC for TTL operation and 1.5VDC or 30% of the

supply voltage for CMOS operation. The LOW LED

thus lights when the probe tip is connected to

voltages less than .8 or 1.5VDC.

The pulse LED is controlled by a bipolar edge

detector circuit which responds to both positive and

negative transients. This circuit is made up of

capacitors C2 and C3, transistors Q1 through Q4,

and the associated resistors. When the circuit is

activated by pulses as short as 25 nanoseconds, a

negative pulse is applied to the (+) input (pin 11) of

the pulse stretcher comparator. The comparator

then turns on and is held by the feedback resistor

R8. The ground level on the output (pin 13) causes

C5 to discharge through R17. In approximately 1.5

milliseconds, the voltage on the (–) input (pin 10)

becomes more negative than the (+) input and the

comparator turns off. The short pulse on the input is

thus stretched to 1.5 milliseconds.

The (–) input (pin 8) of the PULSE LED driver is

biased to +2.5VDC by resistors R19 and R20. The

(+) input is biased to +3VDC by resistors R6 and

R18. The 1.5 milliseconds pulse from the pulse

stretcher grounds the (+) input through diode D5

turning the comparator on and lighting the PULSE

LED. When the PULSE-MEM switch is in MEM, Q5

is also turned on, causing the (–) input of the

comparator to go to +5VDC. This keeps the

comparator on even after the (+) input returns to

+3VDC. When the PULSE-MEM switch is in

PULSE, the feedback path to the (–) input is broken

and the LED is lit only for the duration of the 1.5

milliseconds pulse.

Thus, each time the input signal changes state, the

PULSE LED is activated for 1.5 milliseconds. When

observing low frequency signals, the PULSE LED

provides an immediate indication of this pulse

activity. By observing the HI and LOW LEDs, the

polarity of the pulse train can be determined. Low

frequencies cause the PULSE LED to blink once for

each transition. High frequencies cause the LED to

flash at a rate that makes it appear to be on

continuously. When the PULSE-MEM switch is in

MEM, a single input pulse will cause the PULSE

LED to come on and stay on until the switch is

returned to the PULSE position.

The input impedance of the LP-525 is 1MW. This

eliminates any loading effect on the circuit under

test.

CAUTION: Do not connect the alligator clips to any

AC power source or to a DC power source greater

than 35VDC. Failure to comply with this warning

may result in damage to this instrument.