ELGO-PLUS SpringerMAX User manual

Mini digger

SpringerMAX

INSTRUCTION

1

Contact:

P.H.U. ELGO-PLUS

ul. Przemysłowa 1

87-880 Brześć Kujawski POLAND

Tel.: +48 602 841 094

www.elgoplus.pl

e-mail: kontakt@elgoplus.pl

1. INTRODUCTION

This instruction contains basic informations of usage and terms of use mini digger SpringerMAX.

Proper maintenance and the correct way to use the machine condition the safe and reliable

operation. The procedures described in this manual are the optimal methods of working with the

machine and perform maintenance. In order to reduce the likelihood of an accident and prevention

of incidents as a result of which the machine could be damaged or cause to make it dangerous to be

thoroughly familiar with the content of warnings and comments given in the instructions for the

machinery.

Operators should carefully read all of this manual and observe all its recommendations.

Warning!

Do not operate the machine, do not start work and do not perform any of the actions

before reading the instructions for the machine.

Failure to follow these recommendations could be the basis for the withdrawal of the manufacturer's

warranty for the product.

This manual must be readily available and always kept near the mini digger!

ELGO-PLUS reserves the right to change specifications, construction, instruction, and extension or

modernization of the product without prior notice. ELGO-PLUS Company is not obligated to make

such changes to previously manufactured machines.

2

Description of signs used in instruction:

Warns that failure to follow instructions may result in serious injury, possibly death

and/or destruction of equipment.

Warns that failure to follow instructions will result in serious injury and / or

equipment damage.

Symbol draws attention to important informations.

2. MACHINE FEATURES

2.1. General description

The machine is designed for earthworks carried out in normal daylight conditions. If the machine is to

be used for other purposes or have to work in a potentially hazardous environment, then follow the

special safety regulations, and the machine itself should be equipped according to the working

conditions. For further information, please contact the manufacturer.

3

PIC.2.1 General construction

A

Steering levers

B

Rubber track chassis

C

Engine

D

Rotatable body

E

Seat

F

Support

G

Arm

H

Jib (Boom)

I

Bucket –changable equipment

J

Hydraulic pump

K

Overweight (removable equipment)

2.2. Technical data

Engine

Gasoline Briggs & Stratton Vanguard 10 HP 19L2

Engine power

10 HP

Battery

12 V, 24 Ah with electrolyte

Hydraulic pump

CASAPPA 6,61 cm³/rev

Hydraulic tank capacity

21 L

Weigh

680 kg (without counterweight)

Rotation

360˚

Maximum digging depth

1,65 m

Noise

No more than 85 dB(A)

J

K

4

Important:

Detailed information about drive unit located in the Briggs&Stratton engine manual.

5

PIC.2.MACHINES DIMENSIONS

6

2.3. Equipment

Grading bucket (70 cm wide)

Bucket (20cm wide)

Bucket (30cm wide)

Teeth ripper tool

2.4. Removable equipment

Overweight (110 kg)

7

2.5. Name plate

PIC. 2.3 NAME PLATE

1.Name plate

Contains information such as:

- CE marking

- The name and address of the manufacturer

- Machines model

- Serial number

- Year of production

- Weight of machine

8

3. SAFETY INSTRUCTIONS

The mini diggers user duties are knowledge of and compliance with applicable laws, therefore,

included safety instructions are only recommendations.

•The operator must be healthy and be at least 18 years of age.

•Mini digger must be maintained in good condition.

•Inspection and repairs can be carried out only after the machine is turned off

•It is forbidden to make unauthorized modifications to the machine without the

manufacturer's consent

•It is forbidden to work the machine in explosive atmospheres and confined spaces without

adequate ventilation

•Mini digger is not intended for public roads, it can only moves beyond them.

•It is forbidden to smoking and approaching other sources of ignition while refueling.

•The operator should exercise extreme caution when working, all people nearby mini digger

should still be within his sight.

•Do not fill fuel other than what is recommended for the engine. Detailed recommendations

are contained in the engine manual.

•Mini digger can be operated at the appropriate level of engine and hydraulic oil.

•Mini digger is designed to work in the daytime, in the case of work in conditions of limited

visibility, it should be provided appropriate lighting equipment to the work area on Your

own.

•It is forbidden to use the machine in clothing unsuitable for this or another that can cause

danger (eg. long dangling pieces of clothing).

•It is forbidden to use the machine if the operator contamination with substances such as oil,

grease, etc. that may cause a slip hazard.

•

Warning:

Before operating the machine, the operator of mini digger must have sufficient

knowledge and read the instructions.

Unqualified user can cause serious injury or even death.

The contents of this chapter contains instructions and precautions that must be followed to ensure

proper and safe operation and maintenance.

These rules do not exempt the operator from the obligation to comply with the law or other

applicable rules regarding safety and health.

Users duties

The user is obliged to pay attention to the specific requirements and hazards during work as well as

personal safety. This is necessary to prevent serious injury or damage, and even deaths

Responsibility for other

It should work with the machine so as to avoid the risk of accidents and injuries. You have the right

and obligation to prevent this. No one is allowed to enter the working area of the machine during its

operation without prior notice to the operator. If someone must enter into the working area of the

machine to perform a specific job, that person must exercise extreme caution and without the need

not to move from the back of the machine or remain in a dangerous area

9

If someone is in the area of machine operation the operator must keep extra care. The operator

can operate the machine only when you see this person, or if this person comprehensible signals to

the operator, where it is located

Warning:

Do not sit or stand on the machine on site suitable for this operator which would

prevent safe operation of the machine.

Damages

User duty is to report any damage or wear that could affect safety. During the inspection,

maintenance and repairs, on-site operator allowed to stay only person with the required knowledge

of operating the machine and knowledge of controls.

Safety information when using and operating the battery

While use battery, observe the safety instructions and relevant national regulations. Before carrying

out any battery operation (including battery charging and starter battery use), you should familiarize

yourself with safe methods for working with batteries with an electrolyte.

Warning:

Batteries may emit explosive gases. Do not smoke, set fire or use high energy sources

(welding machines, etc.) in the vicinity of batteries.

Warning:

Do not connect the discharged battery with the fully charged battery. A current shock

may cause the battery to explode.

Warning:

Make sure that metal objects (such as tools, jewelery, etc.) do not touch the battery

terminals. This poses a health risk and a risk of fire. Always place the covers on the

place of the battery terminals and the cable clamps.

10

Warning:

When starting the engine from the battery of the other machine, do not allow the

machine to touch. It could damage the electrical system of one of the machines.

Warning:

Do not start the machine with the starter battery, in which:

•the battery freezes,

•The battery status indicator is in yellow color or bright,

•the battery's electrolyte level is below the top of the battery panel.

This can lead to personal injury.

Warning:

Do not allow the battery or the surrounding area to become contaminated with fuel or

oil. This can create fire hazards.

Warning:

Before cleaning the machine, all electrical components must be protected against

water, and after drying, dry them thoroughly. Failure to do so may result in accident or

damage to the machine.

11

Description of the marks on the machine

Warns that before using, the operator must read the instruction

manual.

Warns against hot surfaces nearby engine and hydraulic pump.

Symbol draws attention to take special care in time staying close to

working mini digger.

Symbol informs about the location where the hydraulic oil drain valve is

located.

12

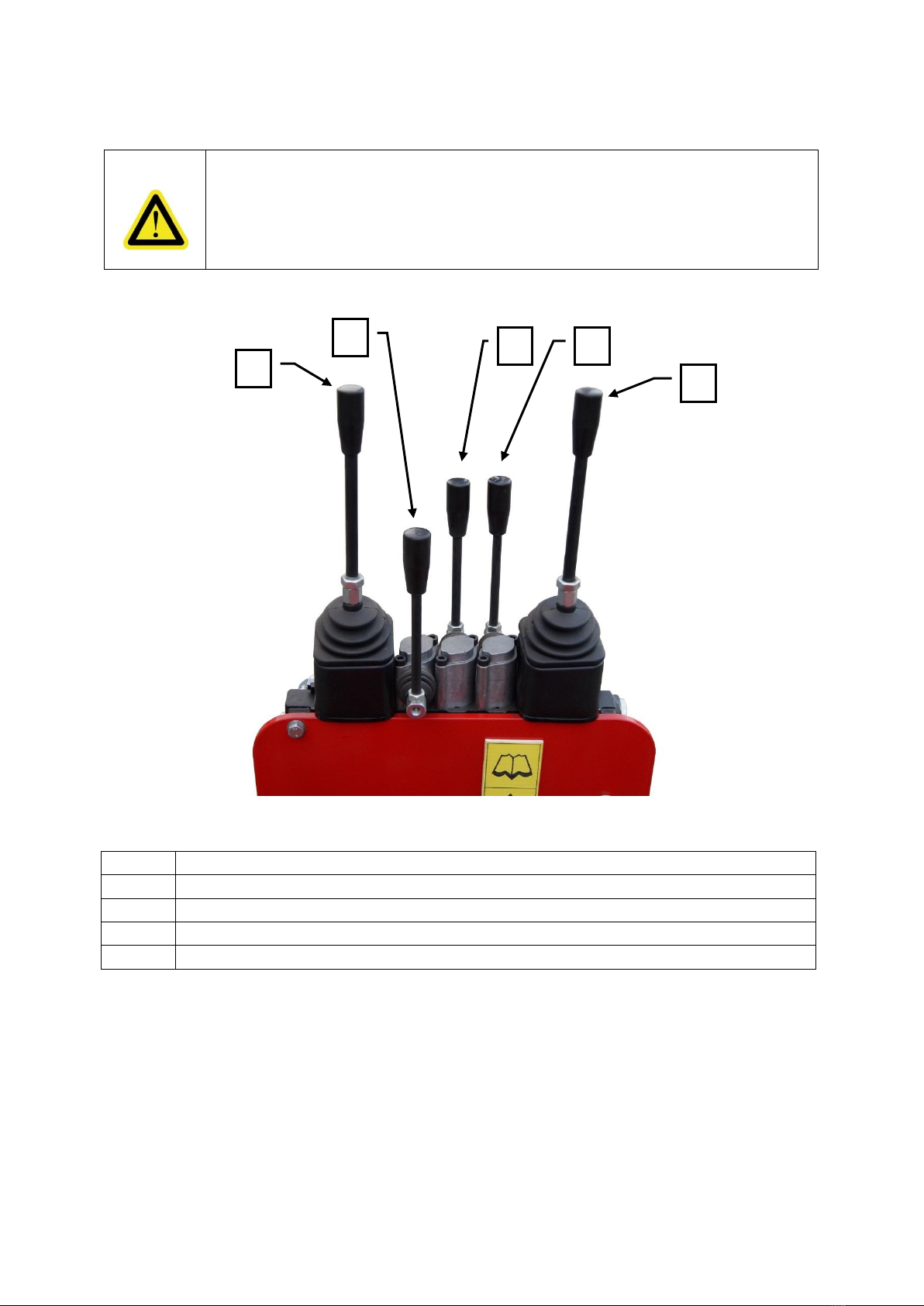

4. STEERING ELEMENTS

Warning:

Do not start the mini digger before reading the exact location and function of all

controls

PIC.4.1 STEERING ELEMENTS

A

Left track steering lever

B

Right track steering lever

C

Support position steering lever

D

Arm position and rotation steering lever

E

Jib position and bucket work steering lever

B

C

D

E

A

13

Left track steering ( A, Pic.4.1)

1- forward –in order to move track forward, push steering lever forward (A,

Pic.4.1)

N- neutral –track stops (the lever returns to this position automatically)

2- backward –in order to move track backwards push steering lever backwards

(A, Pic.4.1)

Right track steering ( B, Rys.4.1)

1- forward –in order to move track forward, push steering lever forward (B,

Pic.4.1)

N- neutral –track stops (the lever returns to this position automatically)

2- backward –in order to move track backwards push steering lever backwards

(B, Pic.4.1)

Moving forward

Push forward both steering levers (A and B, Pic.4.1), machine will go forward.

Moving backward

Pull back both steering levers (A and B, Pic.4.1), machine will go backward.

Turning left

Push forward the right steering lever (B, Pic.4.1), the right track starts to move forward, the machine

will go forward turning left.

Or:

Pull back left steering lever (A, Pic.4.1) the left track starts to move backward, the machine will go

back turning to the left.

Turning right

Push forward the left steering lever (A, Pic.4.1), the left track starts to move forward, the machine

will go forward turning right.

Or:

Pull back right steering lever (B, Pic.4.1) the right track starts to move backwards, the machine will go

back turning to the right.

N

N

1

1

2

2

14

Caution!

It is forbidden turning in opposite movement of the two tracks, doing so may cause

damage to the mini digger.

Support position steering ( C, Pic.4.1)

1–support lowering

N–neutral position –support stops (the lever returns to that position

automatically)

2–support lifting

Arm position steering ( D, Pic.4.1)

N- neutral position (arm stay in neutral

position)

1–arm lifting

2–arm lowering

3–turning left

4–turning right

N

N

1

2

3

4

4

1

2

15

Jib position steering ( E, Pic.4.1)

N- neutral position (jib and bucket stay in

neutral position)

1- jib lowering

2- jib lifting

3–bucket closing

4–bucket opening

5. USAGE

5.1. Before working

Warning:

Do not adapting these rules may result an accident, serious injury or death.

- Before starting the mini digger familiar with the contents of this manual.

- Defects and damages that affect safety must be removed before use.

- Do not operate the machine while under the influence of alcohol, drugs or other intoxicants.

- Dress in appropriate clothing that allows for safe operation.

- To increase the safety of the head is recommended to use a protective helmet.

- Adjust the seat.

- Do not overload the machine. Overloading adversely affect safety.

- Before starting the mini see if there is someone in her immediate vicinity.

- Check for leaks.

- Check for damaged or loose parts that could cause damage.

- Check if there is fuel in the tank.

- Check the hydraulic oil tank.

- Check engine oil level.

- Before driving check that the machine is not near other people.

- When it is very cold do not direct the machine to work hard after starting.

- Check battery mounting.

- Check the battery cables mounting.

- Check the fuel tank for leaks or cracks.

N

2

3

4

4

1

16

5.2Starting and shutting down the machine

Mini digger can be started by pulling a starting rope or by a starter with key located next to the

engine.

Before starting, unlock the fuel / ignition lever.

To turn off the machine lock the fuel / ignition lever.

RYS.5.1 SILNIK

A

Rope pulling holder

B

Fuel/ignitation lever

C

Marking the position of the lever

A

B

C

17

PIC.5.2 KEY STARTER

A

Key

B

Marking of the direction of starting

Important:

For further information on the power unit, refer to the Briggs&Stratton engine

manual.

5.2. Driving

When driving on flat ground, set back attachments and lift it off the ground to avoid knocked out of

the terrain elements.

When driving on uneven terrain should move the machine so as not tilted to one side more than 10⁰.

Riding uphill

If the tracks are sliding on the slope, push the bucket into the ground and pull the arm backwards to

facilitate the uphill drive.

Riding downhill

In case of downhill riding, drive the mini digger as slow as possible.

Warning:

Do not change driving direction rapidly. Especially, in case of changing direction in

place, stop the machine.

A

B

18

5.3. Stopping

To park the machine choose flat terrain

1. Set steering levers in neutral position

2. Lower the bucket to the ground, keeping the bottom of the bucket parallel to the ground

5.4. Parking

Important

To park the machine choose flat terrain. If you can not avoid parking on a slope, under

each of the tracks to put a block of wood and push the bucket teeth into the ground.

Pay attention to weather conditions and take necessary steps to ensure that the machine is not

frozen to the ground, plunged into it, or suffered other consequences.

Long-term parking

Follow the instructions for parking and in addition:

-check the machine for leaks and if there is no damage to the working system and tracks.

-remove form the track accumulated soil

-recure the machine against the corrosion and thoroughly lubricate

-fill the fuel tank and oil to the maximum

-shut off the fuel supply to the engine, according to the recommendations in the engine manual

5.5. Bucket working

Mini digger is a multi-purpose machine that can be equipped with a variety of specialized work

equipment in order to perform many types of work. Below are described some operations

5.5.1. Digging ditches

Install a appropriate bucket for this kind of work. To work effectively set tracks in accordance with

the direction of the ditch.

In the case of a broad ditches first dig on both sides of the trench, and then select the material from

the central area.

.

5.5.2. Loading works

In order to increase the effectiveness of the trolley set it in order to obtain a small angle of the mini

diggers arm and good visibility for the operator.

19

Caution:

1. Do not use the work of inertia driving machine.

2. Do not dig, do not push the bucket teeth into the ground using the inertia of the

driving machine. This can overload the back of the machine and damage the drive

track.

3. Do not pull out completely the hydraulic cylinder piston rod. This results in a

shortening of the life of the machine. Leaving to work as much as possible backlash.

4. Do not use the work of inertia of the falling bucket.

5. Do not dig by dropping the boom or bucket to use as a pick. Digging combined with

stroke or continuous hitting can damage the operating system.

6. Do not perform lifting.

Caution!

During work, always leave the support to the ground, so that the machine received

appropriate support.

Warning:

Pay attention for diffrences in machines stabillity, depending on the angle of rotation

of the body.

5.6. Transport

While transporting the machine, follow the existing rules on weight, width, height, length and

anchoring loads.

Remove grease, oil, mud, ice, etc., from ramps or platform surface to prevent slipping off the

machine.

5.7. Loading

1. Turn on brakes of transporting vehicle

2. Put blocks under the wheels of transporting vehicle

3. Secure the ramps

- check the strength, width, length and thickness of the plank ramps is sufficiently safe for loading,

- pay attention to the angle of ramps was 15 ⁰ or less.

4. Check that the left and right ramp are the same height.

5. Ride slowly to the ramps.

Table of contents

Other ELGO-PLUS Excavator manuals