3.6.3 Gauge and Pump Tubing Installation – EL Tank .................................................................18

3.7 Metering Pump Installation – Non-EL Tank (skip if you have EL tank)........................................19

4. Installation of Furnace Components................................................................................................20

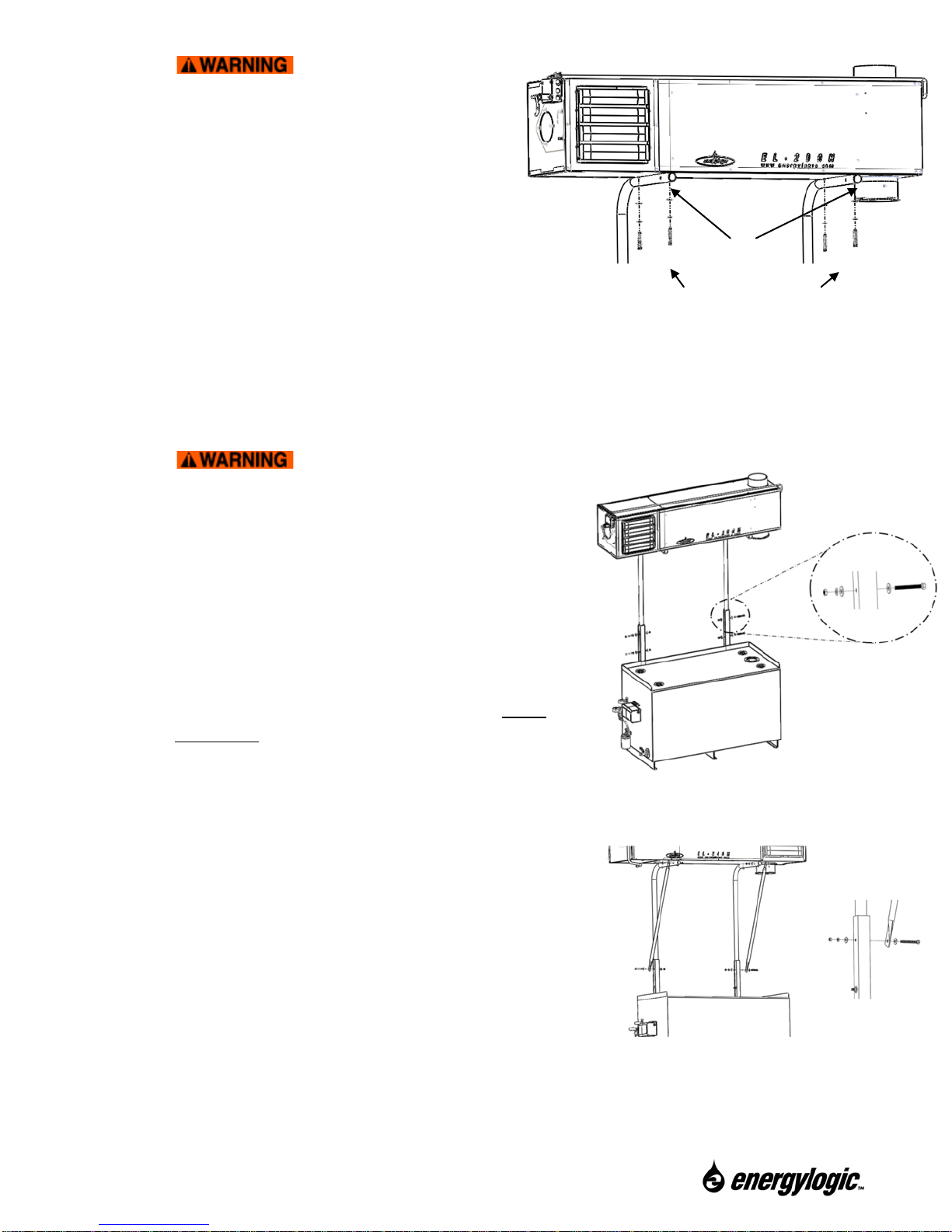

4.1 Blower Assembly Installation.....................................................................................................20

4.2 Burner/Preheater Assembly.......................................................................................................22

4.3 Burner/Cabinet Assembly..........................................................................................................23

4.4 Pump Outlet Tubing Installation.................................................................................................24

4.4.1 Pump Outlet Tubing Installation ...........................................................................................24

4.4.2 Pump Outlet Tubing Installation – Ceiling or Wall Mounted Furnace (skip if you have a tank

mounted furnace)..........................................................................................................................25

5. Exhaust Flue System Installation ....................................................................................................26

5.1 Barometric Damper Tee Installation...........................................................................................26

5.2 Flue Piping Installation...............................................................................................................26

5.3 Draft Gauge Installation (included with some packages)............................................................29

6. Electrical System Installation...........................................................................................................30

6.1 Wall Thermostat ........................................................................................................................30

6.2 Fuel Pump Power Connection...................................................................................................32

6.3 Main Electrical Connection ........................................................................................................33

7. Startup and Operation.....................................................................................................................34

7.1 Do’s and Don’ts/Tech Tips.........................................................................................................34

7.2 Burner Primary Control Operation..............................................................................................34

7.3 Safety Systems and Warnings...................................................................................................35

7.4 Furnace Startup.........................................................................................................................36

7.4.1 Fuel System Priming...........................................................................................................36

7.4.2Starting the Furnace............................................................................................................38

7.4.3Burner System Checkout ....................................................................................................39

7.5 Everyday Operation of Your EnergyLogic Used Oil Furnace......................................................42

8. Maintenance ...................................................................................................................................43

8.1 Service Contracts......................................................................................................................44

8.2 Safety Warnings – Lockout/Tagout............................................................................................44

8.3 Monitoring System Performance over Time...............................................................................44

8.4 Maintenance Schedule and Parts..............................................................................................44

8.5 Maintenance Procedures...........................................................................................................46

8.5.1 Heat Exchanger Cleaning ...................................................................................................46

8.5.2 Blower Cleaning..................................................................................................................50

iii

Call 1-615-471-5290 for Technical Support