5

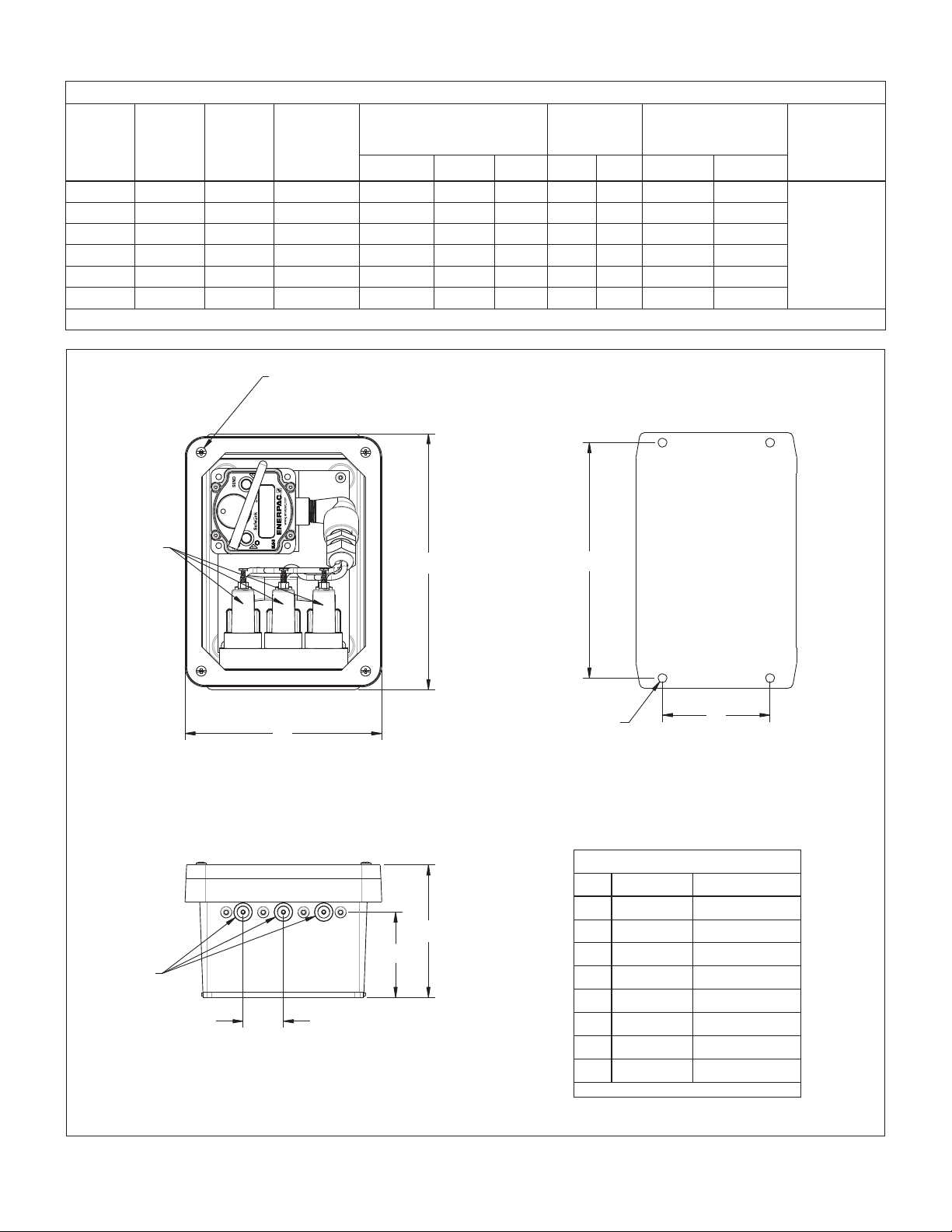

Adjustment

Screw

Lock Nut

Figure 5, Pressure Switch Setting Adjustment

NOTICE Two 10 mm wrenches are required to complete the

pressure setting adjustment described in steps 6 thorough 12.

6. Loosen the pressure switch lock nut by turning it counter-

clockwise. See Figure 5.

7. Turn the adjustment screw counter-clockwise until the

screw is backed-out completely. This will ensure that the

pressure setting is at its lowest level.

NOTICE Starting from the lowest possible setting will result in

a more accurate setting for the desired pressure.

8. Before pressurizing the hydraulic input line, view the SLS-3

send unit display and verify that I/O 1 is “OFF”. (I/O 2 for

second pressure switch, I/O 3 for third pressure switch).

9. Pressurize the hydraulic input line gradually to the machining

center’s minimum working pressure setting. In most cases,

this will be the operating pressure minus a user-determined

acceptable pressure drop.

10. View the SLS-3 send unit display and verify that I/O 1 has

changed from “OFF” to “ON” (I/O 2 for second pressure

switch, I/O 3 for third pressure switch).

11. While viewing the SLS-3 send unit display, slowly turn the

adjustment screw clockwise until I/O 1 changes from “ON”

to “OFF”. This will simulate a hydraulic pressure release at

the desired setting (I/O 2 for second pressure switch, I/O 3

for third pressure switch).

12. While holding the adjustment screw with a wrench (so that it

does not turn), use a second wrench to tighten the lock nut

clockwise to 3 ft-lb [4 Nm].

13. If the send unit enclosure contains additional pressure

switches, repeat steps 1 though 12 for each remaining

pressure switch.

14. Reinstall the enclosure cover after all pressure adjustments

have been completed. Torque the cover screws to

approximately 14-16 in-lb [1.6 to 1.8 Nm].

8.0 MAINTENANCE

8.1 Enclosure

The enclosure protects the SLS-3 send unit, pressure switches

and manifold against coolant spray and other harsh conditions

which may occur in the manufacturing environment. It is

maintenance free and corrosion resistant.

8.2 Removing and Installing the Enclosure Cover

To ensure that the components inside the enclosure remain

protected, always reinstall the enclosure cover and use all 4

cover screws (supplied with unit). Torque the cover screws to

14-16 in-lb [1.6 to 1.8 Nm].

NOTICE To prevent damage to components inside the

enclosure, always be sure that the cover is fully secured with

all four screws tightened to the proper torque. Never allow

machining center operation while the cover is loose or removed.

8.3 Desiccant Pack Replacement

The inside of the enclosure must remain condensation free.

Condensation could damage the SLS-3 send unit and the other

components inside the enclosure.

The use of a desiccant packet is recommended to absorb

any condensation which may form inside the enclosure. The

desiccant packet is a consumable and should be replaced

immediately if condensation is found inside the enclosure.

Frequency of desiccant packet replacement will vary, depending

on the operating environment.

Check the enclosure for condensation at initial start-up and

periodically during the following months to determine the proper

replacement interval for the desiccant pack. Desiccant packs

are readily available from many industrial supply sources and are

not offered by Enerpac.

8.4 Send Unit Battery Replacement

The SLS-3 send unit battery has a 2 to 3 year expected life.

Battery replacement procedures can be found in the SafeLink

Pallet Monitoring System Instruction Sheet (Enerpac document

L3080).

The SLS-3 send unit attaches to the enclosure back plate using

Velcro strips. This Velcro mounting allows the SLS-3 send unit to

be easily detached and re-attached to the enclosure back plate,

simplifying the battery replacement procedure.

9.0 PRODUCT WARRANTY

SafeLink products are warranted by Enerpac to be free from

defects in material and workmanship for 2 years following the

date of shipment. Enerpac will repair or replace, free of charge,

any SafeLink product which, at the time it is returned to the

factory, is found to have been defective during the warranty.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED

(INCLUDING, WITHOUT LIMITATION, ANY WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE), AND WHETHER ARISING UNDER COURSE OF

PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion

of Enerpac, replacement. IN NO EVENT SHALL ENERPAC BE

LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR

ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS,

OR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL

DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR

FROM THE USE OR INABILITY TO USE THE PRODUCT,

WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE,

TORT, STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Enerpac reserves the right to change, modify or improve the

design of the product without assuming any obligations or

liabilities relating to any product previously manufactured by

Enerpac.