EnerPro FCRO4100 User manual

http://www.enerpro-inc.com

99 Aero Camino

Goleta, California 93117

Operating Manual: OP-0106

August 2019

Enerpro Document No: OP-0106, Rev. B Page 1 of 14 ECO #19-11089; Release Date: 08/02/2019

Operating Manual: Four-SCR General Purpose Gate Firing Board

FCRO4100 Revision L

Introduction

This manual describes the salient features and specifications of the FCRO4100 firing board, including

typical firing circuit signal waveforms and a checkout procedure.

Product Description

1.0 Application

The FCRO4100 board is a four-SCR firing board suitable for use with single-phase AC

controllers, center-tap or full wave rectifiers. The firing board responds to a voltage or current

delay angle command signal (SIG HI) to produce four delayed, isolated, 180°-spaced high-

current SCR gate firing pulses. An optional regulator circuit provides voltage or current regulation

and optional plug-in regulator boards provide voltage/current limiting or polarity transition

functionality for four-quadrant rectifiers.

2.0 ASIC-Based Firing Circuit

All firing circuit logic is contained in a custom 20-pin ASIC. Additional detail on the firing circuit

theory is contained in a separate engineering society paper1.

3.0 Board Mounted Connectors

3.1. Gate/Cathode and Control Power Connector

Six-position header J1 provides the connections for the +X1 SCR (load connected cathode) at

positions 1 and 2 and for the -X1 SCR (line connected cathode) at positions 5 and 6.

Five-position header J2 provides the connections for the +X2 SCR (load connected cathode) at

positions 1 and 2 and for the –X2 SCR (line connected cathode) at positions 4 and 5.

The board-mounted 24 VA power supply transformer (T1) is normally energized by connecting

the mains voltage at J3. The gate firing signals are locked to the mains waveform through the

power control transformer, hence, the board power must be in phase with the mains voltage.

3.2. Control Signal Connector

The delay angle command (SIG HI), instant and soft inhibit controls, voltage and current feedback

signal, and auxiliary power connections are available through J4, a 12-position Mate-N-Lok™

connector. The pinout of this connector is detailed in drawing E168 Rev L.

3.3. Feedback Signal Connector and Plug-In Regulator Board Connector

The FCRO4100 board can accept voltage and current feedback in certain configurations.

Ground-referenced voltage feedback and current limit command signals enter on J5 pins 4 and 5

respectively. Current feedback signals from CTs enter on J5 pins 1 and 2 and connect to the

associated bridge rectifier and burden resistor. A 14-position connector J6 provides an interface

for plug-in regulator boards; see section 7.0 for operational information regarding regulation

capabilities.

3.4. Auxiliary Firing Board Connector

Six-position MTA header J7 provides board power, circuit common, and SCR gate signals that

connect to the FCOAUX60 auxiliary firing board to provide four-quadrant operation. See section

6.0 for operational information regarding four-quadrant applications.

1 Bourbeau, F. J., “Phase Control Thyristor Firing Circuit: Theory and Applications”, Power Quality ’89, Long Beach, California.

Enerpro Document No: OP-0106, Rev. B Page 2 of 14 ECO #19-11089; Release Date: 08/02/2019

3.5. Operating Frequency Selection

The FCRO4100 board may be set for operation at 50 or 60 Hz by making the appropriate jumper

selection at J8. VCO timing resistor R12 is set by the factory; the addition or omission of R13 by

J8 ensures the correct closed-loop PLL response.

4.0 Gate Delay Command

The SIG HI delay angle command signal is inversely proportional to the delay angle. When SIG

HI is at a maximum, the delay angle is at a minimum value, corresponding to maximum rectifier or

controller output. When SIG HI is at a minimum, the delay angle is at a maximum value,

corresponding to a minimum rectifier or controller output.

The delay command signal, SIG HI, may be configured as a voltage (0 to 5 Vdc) or current signal.

When SIG HI is a current signal, R11 is selected to provide 5.0 Vdc at the maximum delay angle

command signal current, typically 249 ohms for a 4 to 20 mA or 0 to 20 mA range.

5.0 Bias and Span Potentiometers

Two 5.0 kΩ potentiometers are used to control the bias (R6) and span (R7) of the delay angle

command signal. These controls allow the customer to change the delay angle range for a

specific application. Note that the maximum effective full-scale delay angle command range is

limited to approximately 10° ≤ α ≤ 170°.

With the FCRO4100 board connected to the SCRs, set the SIG HI command to its minimum

value (above 0.5 Vdc if the low signal inhibit circuit is connected via D6). Enable firing and

observe that the inhibit LED, PD1, extinguishes. Adjust the BIAS potentiometer, R6, to achieve

the desired minimum output voltage or current. Increase SIG HI to its maximum value and adjust

the SPAN potentiometer, R7, to obtain the maximum desired output. Decrease SIG HI again to

the level used to set the bias potentiometer and check that the desired minimum output voltage or

current has remained the same after adjusting R7. If necessary, incrementally adjust R6 and R7

in this manner several times to achieve the required range.

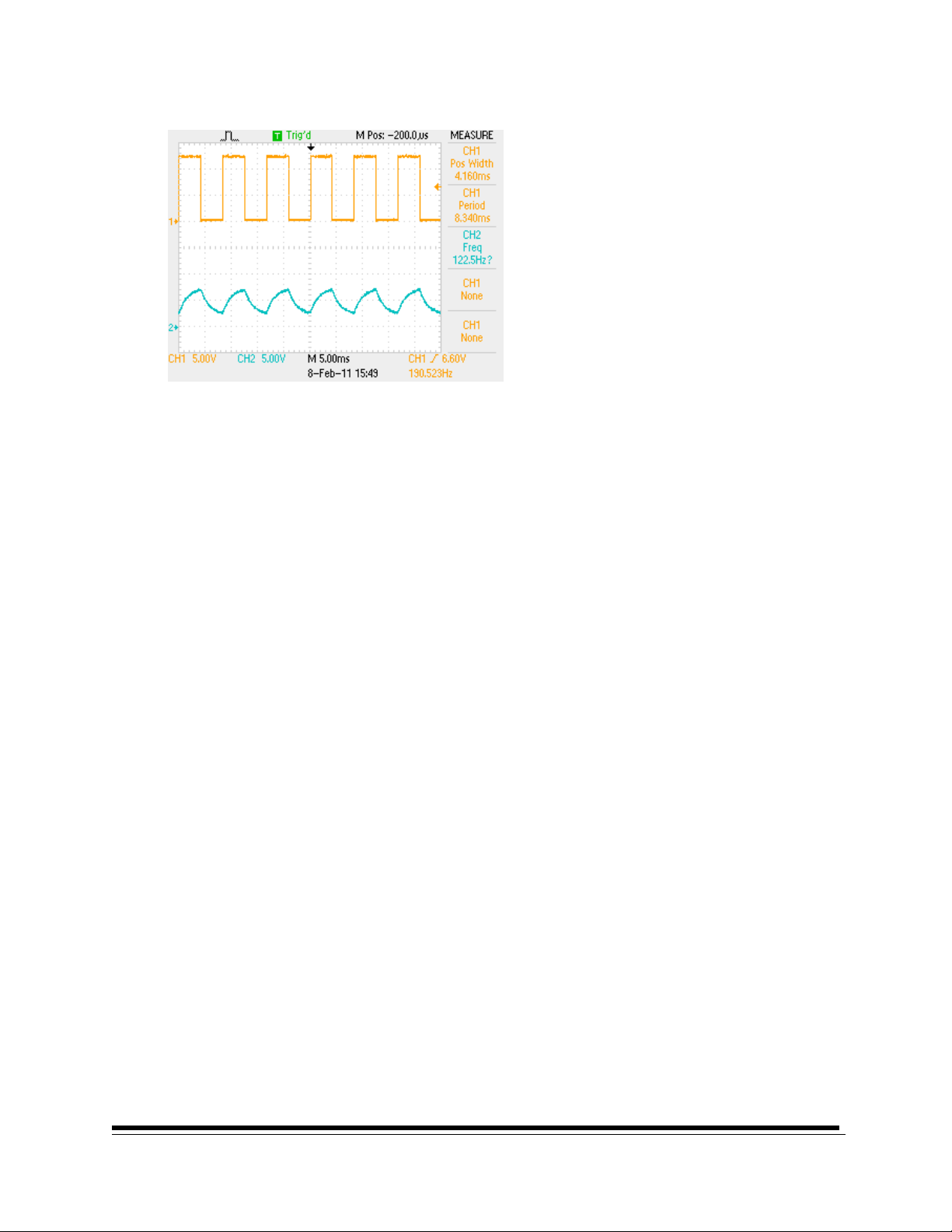

Figure 1 shows the phase detector (TP6) waveforms for maximum delay angle (SIG HI = 0.5 V)

and minimum delay angle (SIG HI = 5.0 V). Calculate the delay angle from the duty cycle of the

waveform at TP6 as )1(180 D

. The approximate minimum duty cycle of D = 0.06 corresponds

to a maximum delay angle of 169)06.01(180

max

. The approximate maximum duty cycle of D

= 0.96 corresponds to a minimum delay angle of 180°(1-0.96) ≈ 7.2°

Figure 1. Maximum and Minimum Delay Angle Calculation

Channel 1: Phase Detector (TP6), SIG HI = 0.5 Vdc, D = 0.06, = 169°

Channel 2: Phase Detector (TP6), SIG HI = 5.0 Vdc, D = 0.96, = 7.2°

Enerpro Document No: OP-0106, Rev. B Page 3 of 14 ECO #19-11089; Release Date: 08/02/2019

6.0 Bipolar Operation

The FCRO4100 is capable of firing four-quadrant converters in two- or four-pulse configurations.

For two-quadrant two-pulse converters, install jumper JU1, omit jumper JU2, and leave the “Cut

Trace” indication on J4 positions 5 and 6 intact. In this configuration, connector J1 provides the

gating signals for the positive bridge and J2 provides the gating signals for the negative bridge.

For four-quadrant four-pulse converters the FCOAUX60 connects to the FCRO4100 and provides

an additional set of four isolated gate outputs. A cable connects the FCRO4100’s auxiliary gate

outputs on J7 to the gate inputs on the FCOAUX60’s J3 or J4 connector. On the FCRO4100

board, omit jumper JU1, install jumper JU2, and cut the trace where indicated between J4

positions 5 and 6. The positive bridge gating signals are provided by J1 and J2 on the FCRO4100

board and the negative bridge gating signals are provided by J1 and J2 on the FCOAUX60. The

P signal on J4 pin 5 controls the rectifier polarity. This signal is normally pulled to +12 V through

resistor RN4D (1.50 kΩ) which sets the rectifier output to the positive polarity. Grounding this

signal instantly reverses the rectifier polarity. For timed polarity transition, the PTIR-1 timed

polarity transition inhibit board provides approximately 100 ms of dead time (i.e., SCR firing is

inhibited for 100 ms) between polarity transition with an optional voltage regulation feature.

7.0 Regulator Circuit

The FCRO4100 board includes an optional regulation circuit for ac current feedback as supplied

by a current transformer. Burden resistor R4, connected to the output of bridge rectifier BR1, is

selected to provide 1.0 Vdc at the desired full load current or voltage.

The VRCL1P-1 regulator board (sold separately) extends the FCRO4100’s functionality by

providing voltage regulation with an adjustable current limit from CT-derived current feedback.

Additionally, the PTIR-1 plug-in board can provide voltage regulation for bipolar SCR

configurations.

8.0 Gate Inhibits

SCR gating is enabled by pulling the instant inhibit, I1

¯ to 12 V. This signal is located at J4 pin 4 .

When enabled, the INHIBIT LED (PD1) extinguishes. An open-collector transistor (U4A) with

optional current-liming resistor (R5) provides enable status to an external relay coil, lamp, or other

customer-furnished monitoring system. This input can sink up to 500 mA.

The instant inhibit signal I1

¯ is normally pulled to ground through resistor RN4B (1.50 kΩ). The

user typically connects the I1

¯ signal to +12 Vdc to enable firing. This arrangement ensures that

SCR gating is inhibited if plug P4 is inadvertently disconnected. In applications where the instant

inhibit is not used, install a jumper between pins 4 and 6 of P4 to hold I1

¯ at +12 Vdc.

The soft inhibit signal I2

¯ is normally pulled to +12 Vdc through resistor RN4C (1.50 kΩ). The user

then grounds I2

¯ to soft-stop SCR firing. In this mode, the delay angle ramps from the setpoint

value determined by SIG HI to the largest angle as determined by the span and bias settings,

after which firing is completely inhibited. This is termed the soft-stop shutdown mode. Opening

the connection at I2

¯ enables gating with the delay angle set to the maximum value; the delay

angle then ramps to the value determined by SIG HI.

Enerpro Document No: OP-0106, Rev. B Page 4 of 14 ECO #19-11089; Release Date: 08/02/2019

The soft-stop and soft-start time constants are independently configurable via two timing resistors

(R15 and R14 respectively) and a capacitor (C2). The soft-stop and soft-start times are as follows

(where R is in kΩ, C is in uF, and t is in milliseconds):

tsoft-stop = 1.84(R15)(C2)

tsoft-start = 0.58(1.5 + R14)(C2)

9.0 Power-On Reset

A power-on reset circuit inhibits SCR gating until the onboard regulator establishes the 12 Vdc rail

voltage. This circuit has the added benefit of inhibiting SCR gating during severe line voltage

transients or dropouts.

10.0 Low Signal Inhibit

A low-signal inhibit circuit instantly inhibits firing when the SIG HI voltage is less than

approximately 0.48 Vdc. Operational amplifier U2D functions as a comparator whose output

instantly inhibits the firing circuit through diode D6. Omit D6 to remove the low signal inhibit

function.

11.0 Gate Pulse Profile

The firing circuit uses a phase-locked loop (PLL) circuit locked to the single phase mains voltage.

A series of counters divide the PLL’s oscillator output and a decoder section then generates two

180°-wide delayed logic signals. These logic signals are modulated by the PLL’s voltage

controlled oscillator (VCO) output signal which operates at 256 times the line frequency.

The gate logic signals are amplified by a Darlington transistor array, which excites the primary

windings of two isolated pulse transformers. The primary winding of each pulse transformer is

also connected to a current-limiting resistor and a speed-up capacitor; this provides an initial

hard-firing gate pulse followed by sustaining, lower amplitude picket fence pulses. Figures 2 and

3 show a single gate pulse burst profile and the detail of the first hard-firing pulse.

Each pulse module consists of a 2:1 ratio pulse transformer tested for 3500 VRMS isolation, two

secondary diodes, noise suppression resistors across both the primary and gate drive output, and

a fusible link in series with the output. Each pulse module is potted in a silicone insulating

material.

The DDFO4100 (delay determinator fiber optic) is a version of the FCOG4100 with fiber optic

outputs replacing the pulse transformers. Four FO1024 modules are installed which feature

Avago HFBR-1412Z fiber optic transmitters in lieu of the EP1024 modules. The transmitters

feature ST (bayonet) style connectors, operate at 820 nm and are directly compatible with the

MVTB series of medium voltage trigger boards. Each module has an LED to indicate that the fiber

optic transmitter is operational. Please specify this configuration on your ordering documents or

contact Enerpro for additional information.

Enerpro Document No: OP-0106, Rev. B Page 5 of 14 ECO #19-11089; Release Date: 08/02/2019

Figure 2 Gate Pulse Profile (into 1Ω) 2.

Figure 3 Initial pulse profile detail (into 1Ω)

12.0 Installation and Checkout

The following procedure should be followed to ensure proper operation prior to the application of

mains power to the SCRs. The following equipment will be required:

Oscilloscope (100 MHz two-channel model or better)

Digital multimeter

DC supply or potentiometer for SIG HI input

Mate-N-Lok™ crimp tool (AMP Service Tool II #29004-1 or equivalent)

Mate-N-Lok™ extraction tool (AMP Extraction Tool 458994-2 or equivalent)

Wire strippers

12.1. Ensure that the mains are not energized. Wire plug P3 with the mains voltage connected

to the appropriate pins. With an EP1031 power control transformer installed, connect between

pins 5 and 3 for 120 V mains or pins 5 and 1 for 240 V mains. With an EP1032 power control

transformer, connect between pins 5 and 3 for 240 V mains or pins 5 and 1 for 480 V mains. Note

that the control power source must be in phase with the AC mains connected to the SCRs.

12.2. Install plug P4, prewired with the delay angle command signal, signal common, and

instant/soft inhibit controls.

12.3. Make the appropriate selection at J8 for 50 or 60 Hz mains.

2 Current waveforms obtained using a Pearson model 2877 current transformer (1.0 A/V) with 4 primary turns. The current

transformer is terminated by the scope’s 1.0 MΩ input impedance.

Enerpro Document No: OP-0106, Rev. B Page 6 of 14 ECO #19-11089; Release Date: 08/02/2019

12.4. Energize the mains voltage. Ensure that PD2, the power on LED, illuminates.

12.5. Verify the presence of regulated 12 Vdc ± 5% at J4-6 and regulated 5 Vdc ±5% at J4-7

with a multimeter.

12.6. Enable firing via the enable commands and bring SIG HI slightly above 0.5 Vdc. Ensure

that the INHIBIT LED, PD1, extinguishes.

12.7. Adjust the BIAS (R6) and SPAN (R7) potentiometers to achieve the required delay angle

command signal response (see Section 5 of this document).

12.8. Observe the voltage at TP7 to verify that the PLL is in lock. The TP7 voltage should be

(+/-.5V) centered at 5 Vdc with a variable amount of ripple dependent on the SIG HI signal. The

TP7 ripple will be at its minimum value at the minimum and maximum SIG HI voltages, as in

Figures 4 and 5, respectively. The TP7 ripple will be at its maximum value when the delay angle

command is near α = 90° as in Figure 6. Sweep the SIG HI voltage over the full range to ensure

that the average voltage does not deviate from 5 Vdc.

Figure 4 VCO control voltage and phase detector waveform, SIG HI = 5.0 Vdc

Channel 1: TP6

Channel 2: TP7

Figure 5 VCO control voltage and phase detector waveform, SIG HI = 0.5 Vdc

Channel 1: TP6

Channel 2: TP7

Enerpro Document No: OP-0106, Rev. B Page 7 of 14 ECO #19-11089; Release Date: 08/02/2019

Figure 6 VCO control voltage and phase detector waveform, SIG HI = 2.75 Vdc

Channel 1: TP6

Channel 2: TP7

Enerpro Document No: OP-0106, Rev. B Page 8 of 14 ECO #19-11089; Release Date: 08/02/2019

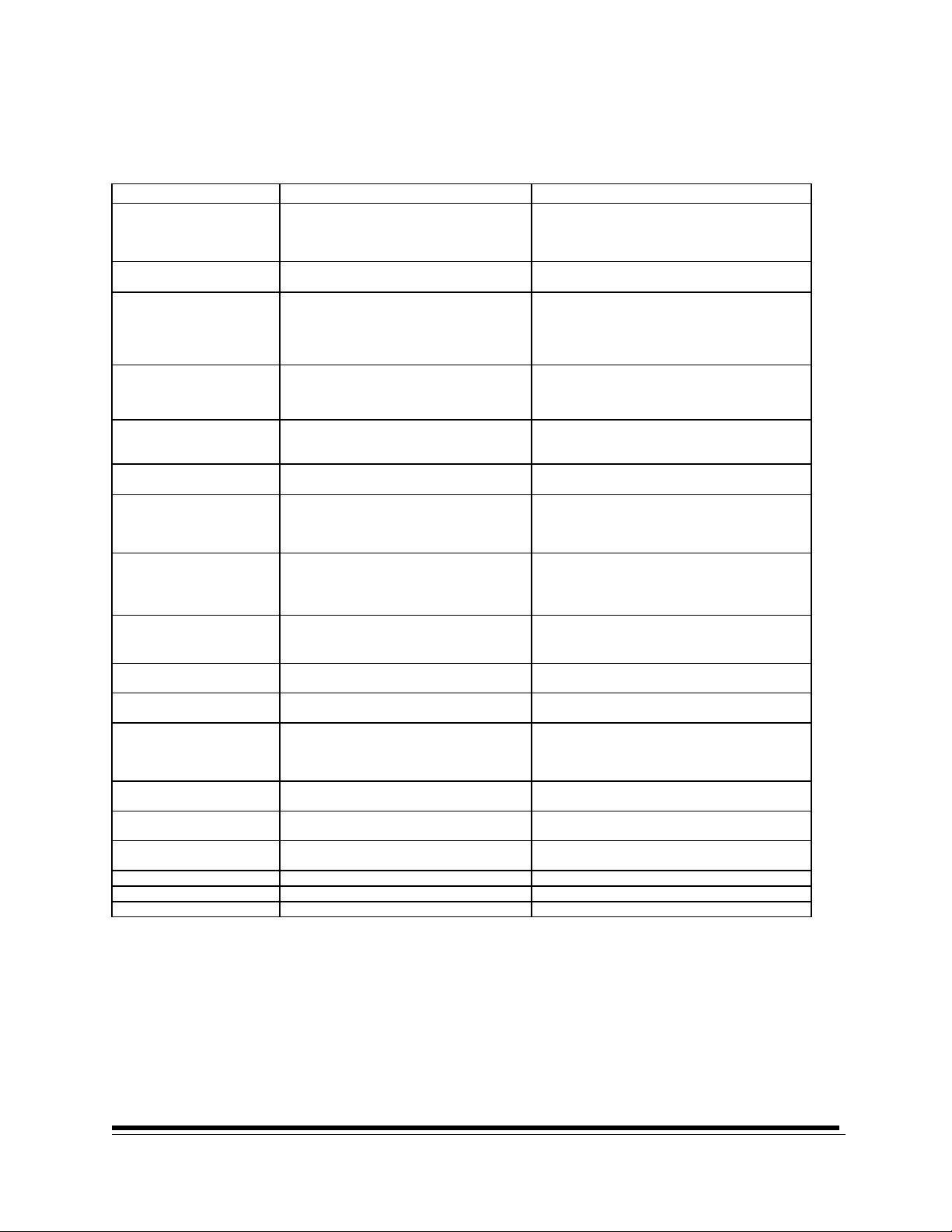

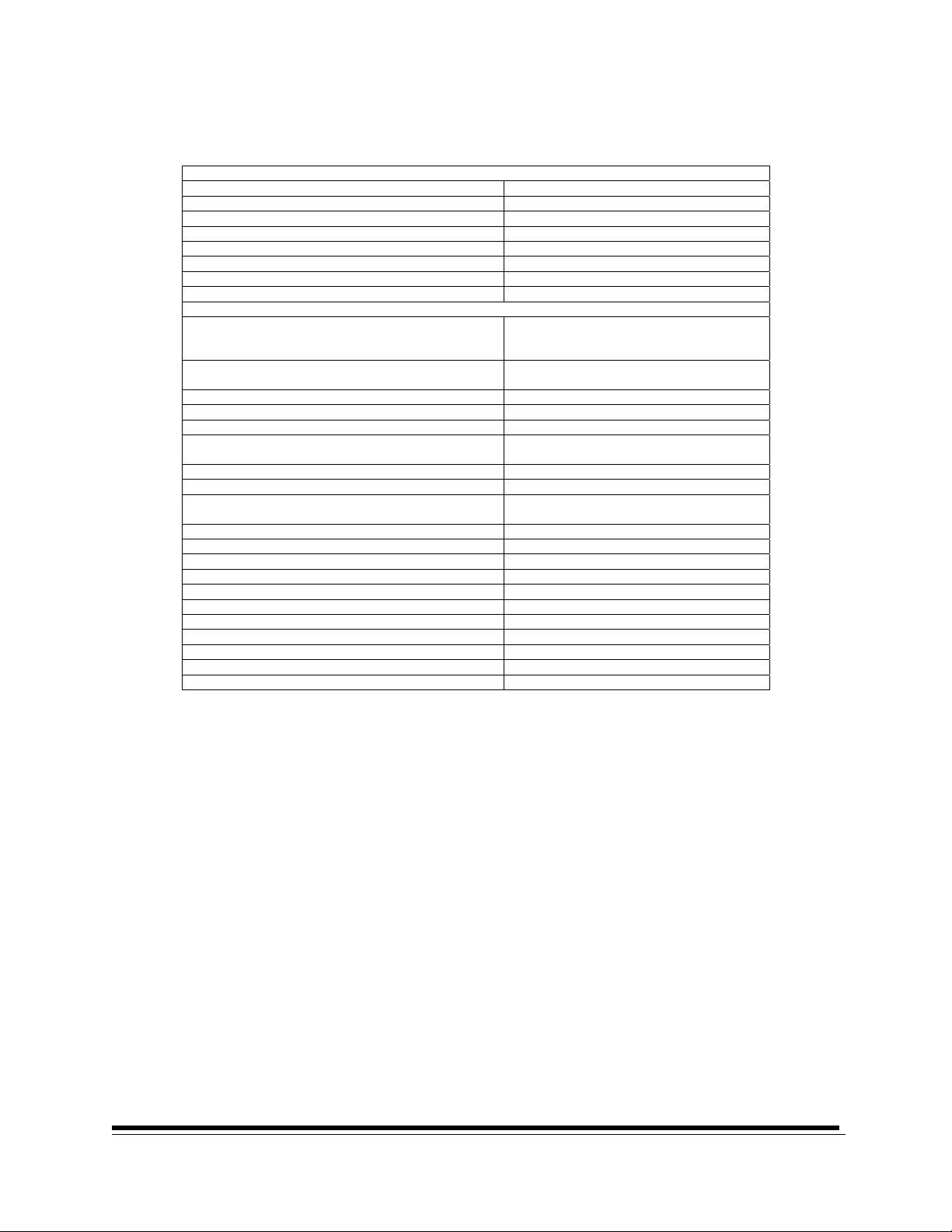

13.0 Electrical Specifications

The electrical specifications of the General Purpose Firing Board are summarized in the table

below. Part numbers refer to drawing E168 revision L.

Characteristic Performance Requirement Supporting. Information

1. Board mounted power

supply for control

electronics and SCR

gate drive.

Connect to mains at J3-5 and J3-1 for

240/480V or J3-3 and J3-5 for 120/240V.

24VA 1Ø 50/60Hz fused board mounted

transformer T1. Center-tapped primary

connected for 240V or 480V.

2. SCR gate waveform. Pulse Profile: 180 -

burst with a 32.6µs

pulse width.

3. Input control signal. 0 Vdc to 5.0 Vdc control signal. Input

impedance is 10.0kΩ.

Option : a shunt resistance (R11) across signal

input can be selected for milliamp control

signal.

R11 = 249 Ω for 4 to 20mAdc current control

signal.

4. Gate delay steady-state

transfer function.

Increase in command voltage produces a

proportional decrease in gate delay angle,

.

max. and

min. change equally with change

in Rbias (R6).

( max-min) changes with Rspan (R7).

5. Gate delay dynamic

transfer function

bandwidth.

Attenuation = -3dB at 67Hz. Phase shift =

-45° @ 57Hz.

Frequency response can be modified by

changing summing amplifier parameters.

6. Effect of frequency. ∆/∆f = 1.5°/Hz. For 50Hz operation,

compensate by removing R13.

Jumper J8 for 50/60 selectable operation

7. Lock acquisition time. Approximately 30ms. Gating is inhibited for 20ms or longer at power-

on.

Inhibit period depends on Soft-Start time

constant.

8. Soft-Start Gating commences at

max. and

exponentially decays to the commanded

delay when NOT(I2) is ungrounded (J4-

12).

Soft-Start time constant is set by C2 and R14.

T = (1.5k + R14)(C2)(0.579)

T in ms, R in kΩ, C in µF

R14 ≥ 20.0kΩ

9. Soft-Stop Gate-delay angle ramps to

max. before being inhibited when

NOT(I2) is grounded.

Soft-Stop time constant is set by C2 and R15.

T = R15(C2)(1.84)

R15 ≥ 1.0kΩ

10. Power-on inhibit. Inhibit circuit is activated at power-on. Same delay angle response as with the soft-

start circuit.

11. Low Signal Inhibit Inhibit circuit is activated if SIG HI <

0.5Vdc.

Eliminate this feature by removing CR6.

12. Instantaneous inhibit. Opening the connection of NOT(I1) (P4-4 )

to +12V instantly inhibits SCR gating.

Closing the connection of NOT(I1) to +12V

instantly enables SCR gating.

Gating is inhibited if P4 is removed.

13. Peak gate drive open

circuit voltage

15V With a 30Vdc supply voltage

14. Peak gate drive short

circuit current.

1.7A Measured with a 30 Vdc supply voltage and a

1.0Ω load resistor

15. Gate drive current rise

time(short circuit)

.5A in .5µs Measured with a 30 Vdc supply voltage and a

1.0Ω load resistor

16. Frequency sensitivity 2.6°el./Hz

17. Temp. sensitivity ±2°el. for 0° C<Ta<70° C

18. Ambient temperature. 0°C to 70°C

Enerpro Document No: OP-0106, Rev. B Page 9 of 14 ECO #19-11089; Release Date: 08/02/2019

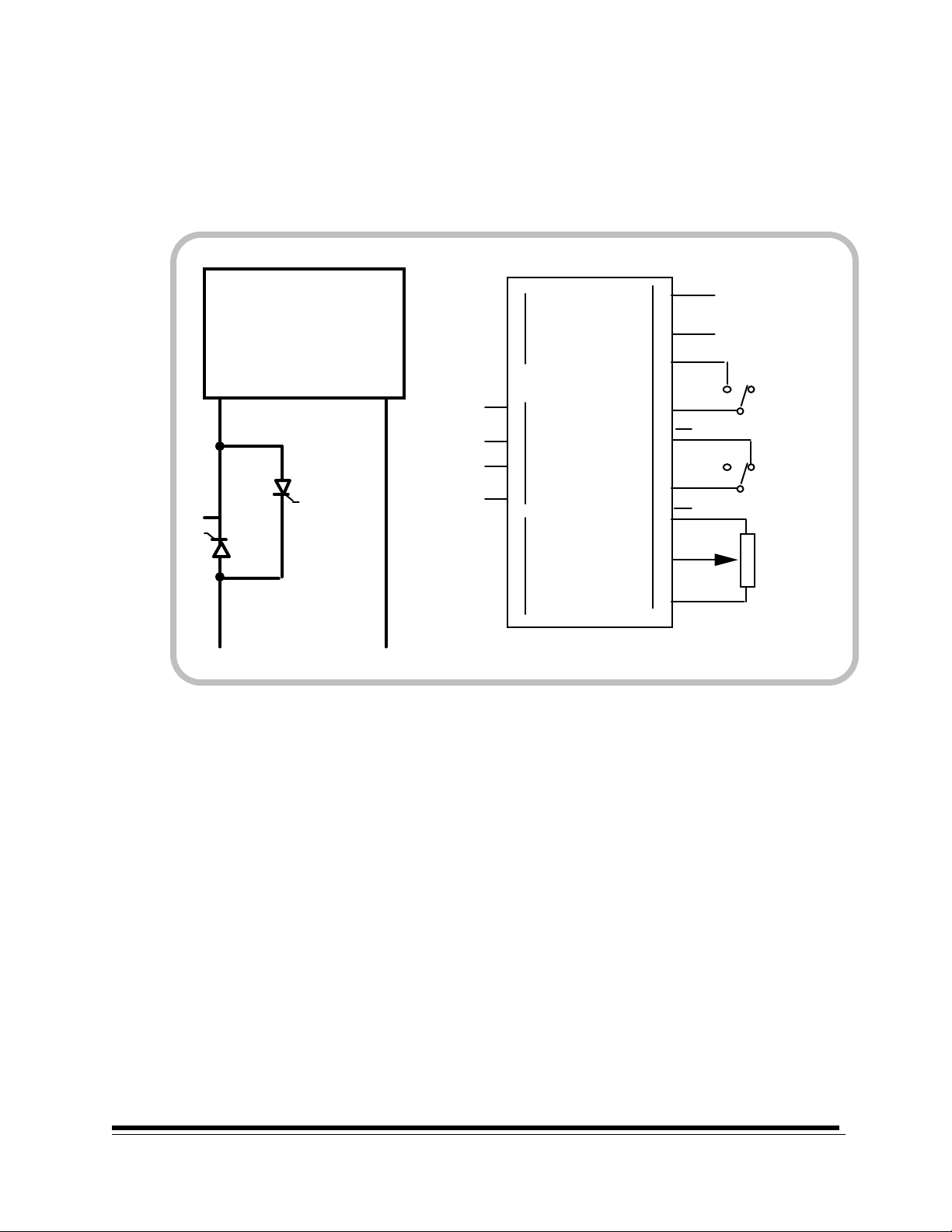

14.0 TYPICAL CONNECTION DIAGRAMS

Figures 7 through 11 show the basic connections required for several common uses of the

FCRO4100 firing board. If additional information is required, please contact the Enerpro

applications department.

Figure 7. 2-Thyristor In-Line AC Controller

FCRO4100

FIRING BOARD

12

J2

4512

J1 5613

J3

5

+X1 -X1

DELAY

COMMAND

SOFT

INHIBIT

INSTANT

INHIBIT

J4

710 812 11 46

12

on

off

on

off

24

VAC

+5

com

com

+12

I2

I1

gk

Figure 5. 2-Thyristor In-Line AC Controller

-X1

+X1

gk

SINGLE

PHASE

LOAD

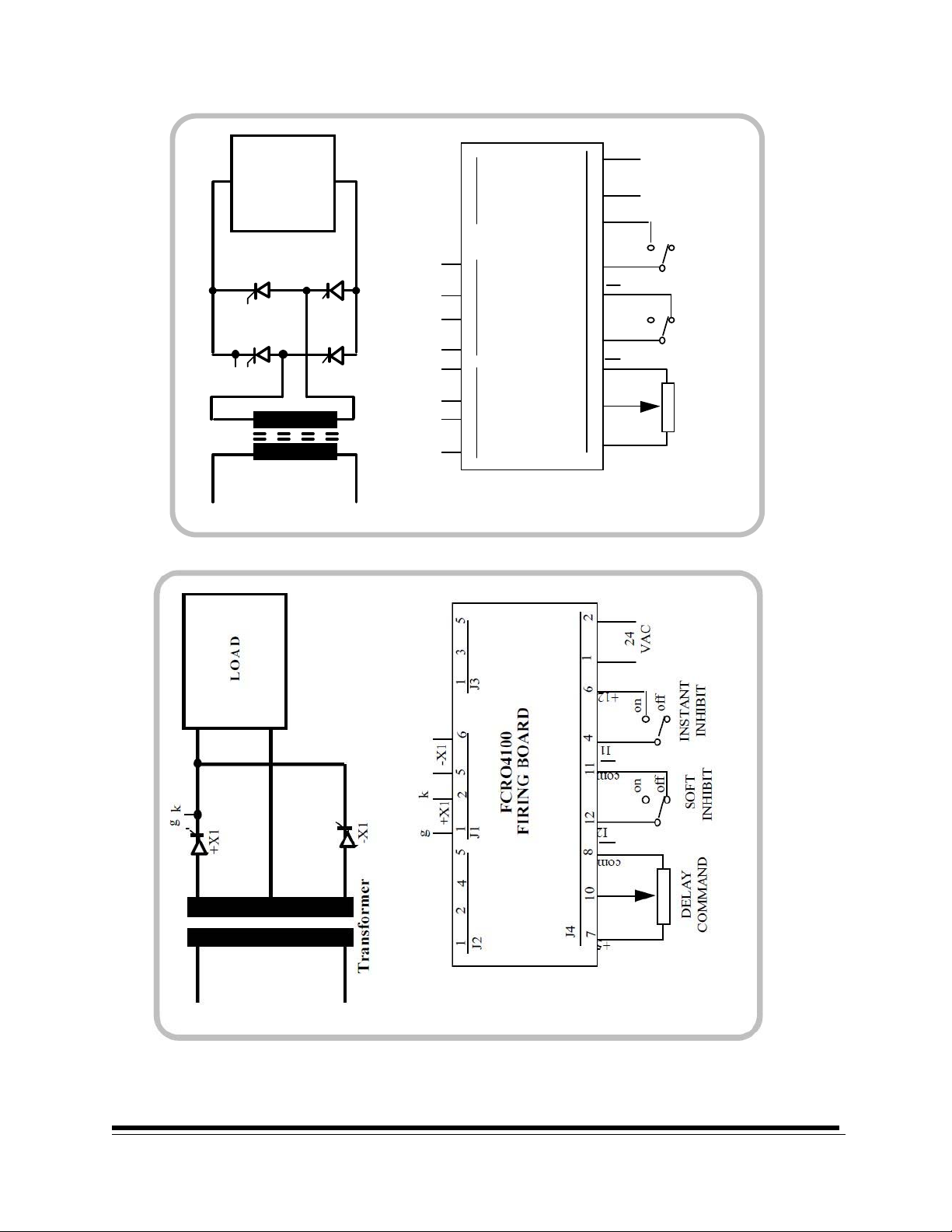

Enerpro Document No: OP-0106, Rev. B Page 10 of 14 ECO #19-11089; Release Date: 08/02/2019

FCRO4100

FIRING BOARD

12

J2

4512

J1

5613

J3 5

+X2 -X2 +X1 -X1

DELAY

COMMAND

SOFT

INHIBIT

INSTANT

INHIBIT

J4

710 8 12 11 4 6 12

on

off

on

off

24

VAC

+5

com

com

+12

I2

I1

gk

Figure 7. 4-Thyristor Bridge Rectifier

-X1

+X1

g

k

LOAD

Transformer

+X2

-X2

Figure 8. 4-Thyristor Bridge Rectifier

Figure 9. 2-Thyristor Center Tapped Transformer

Enerpro Document No: OP-0106, Rev. B Page 11 of 14 ECO #19-11089; Release Date: 08/02/2019

FCRO4100

FIRING BOARD

12

J2

4512

J1

5613

J3

5

+X1F -X1F

DELAY

COMMAND

SOFT

INHIBIT

INSTANT

INHIBIT

J4

71081211

4612

on

off

on

off

24

VAC

+5

com

com

+12

I2

I1

gk

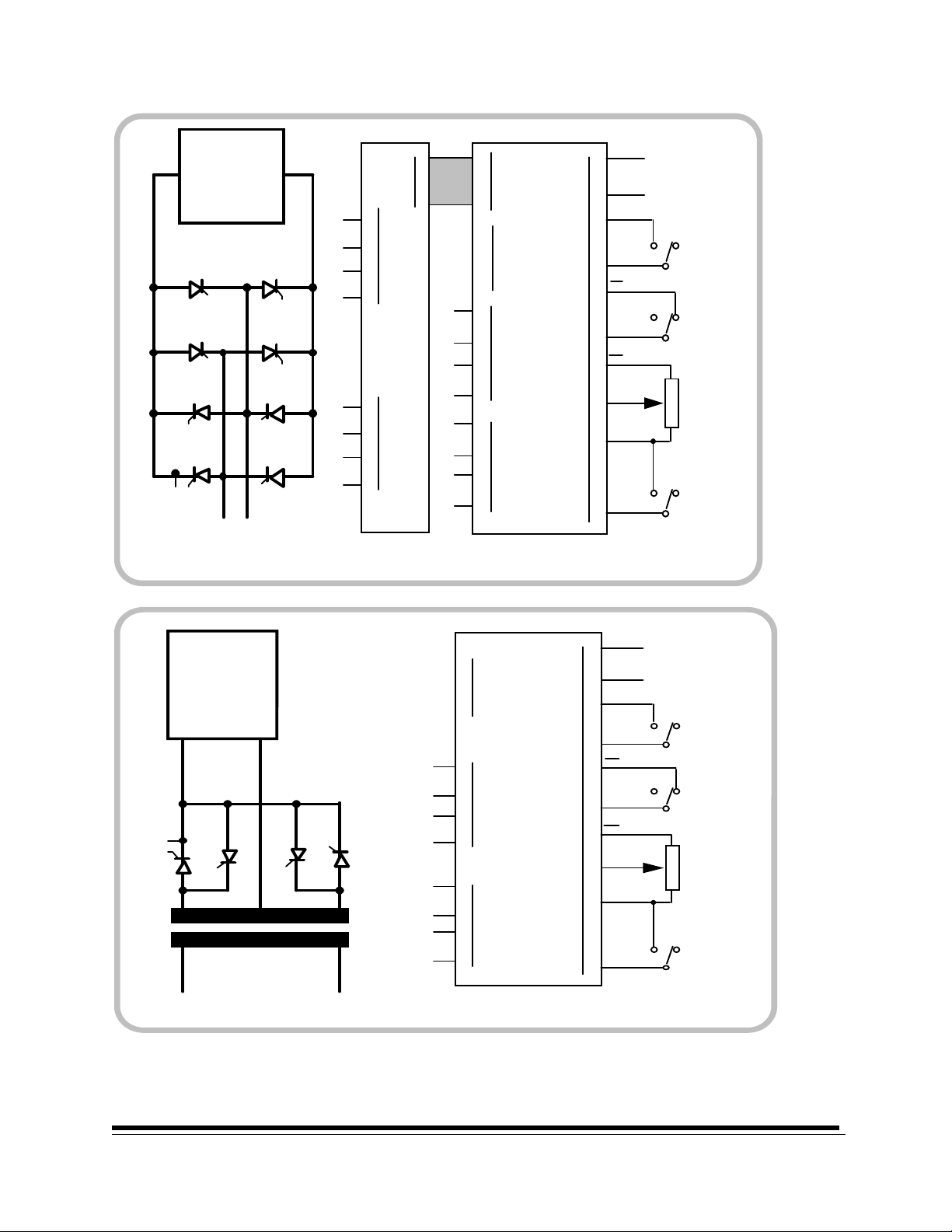

Figure 9. 8-Thyristor Two Bridge Rectifiers

+X2F -X2F

POLARITY

COMMAND

reverse

forward

5

P

-X1F

+X1F

g

k

LOAD

+X2F

-X2F -X1R

+X1R

+X2R

-X2R

12

J1

45 12

J2

12

FCOAUX60 AUXILIARY

FIRING BOARD J3

J7

+X2R -X2R

+X1R -X1R

• Cut trace as indicated by note 13 on E168

Figure 10. 8-Thyristor Two Bridge Rectifiers

FCRO4100

FIRING BOARD

12

J2

4512

J1

5613

J3

5

+X1 -X1

DELAY

COMMAND

SOFT

INHIBIT

INSTANT

INHIBIT

J4

710

812 11 4 6 12

on

off

on

off

24

VAC

+5

com

com

+12

I2

I1

gk

Figure 8. 4-Thyristor Center Tapped Transformer

+X2 -X2

POLARITY

COMMAND

reverse

forward

5

P

• Cut trace as indicated by note 13 on E168

-X1

+X1

gk

LOAD

Transformer

+X2

-X2

Figure 11. 4-Thyristor Center Tapped Transformer

Enerpro Document No: OP-0106, Rev. B Page 12 of 14 ECO #19-11089; Release Date: 08/02/2019

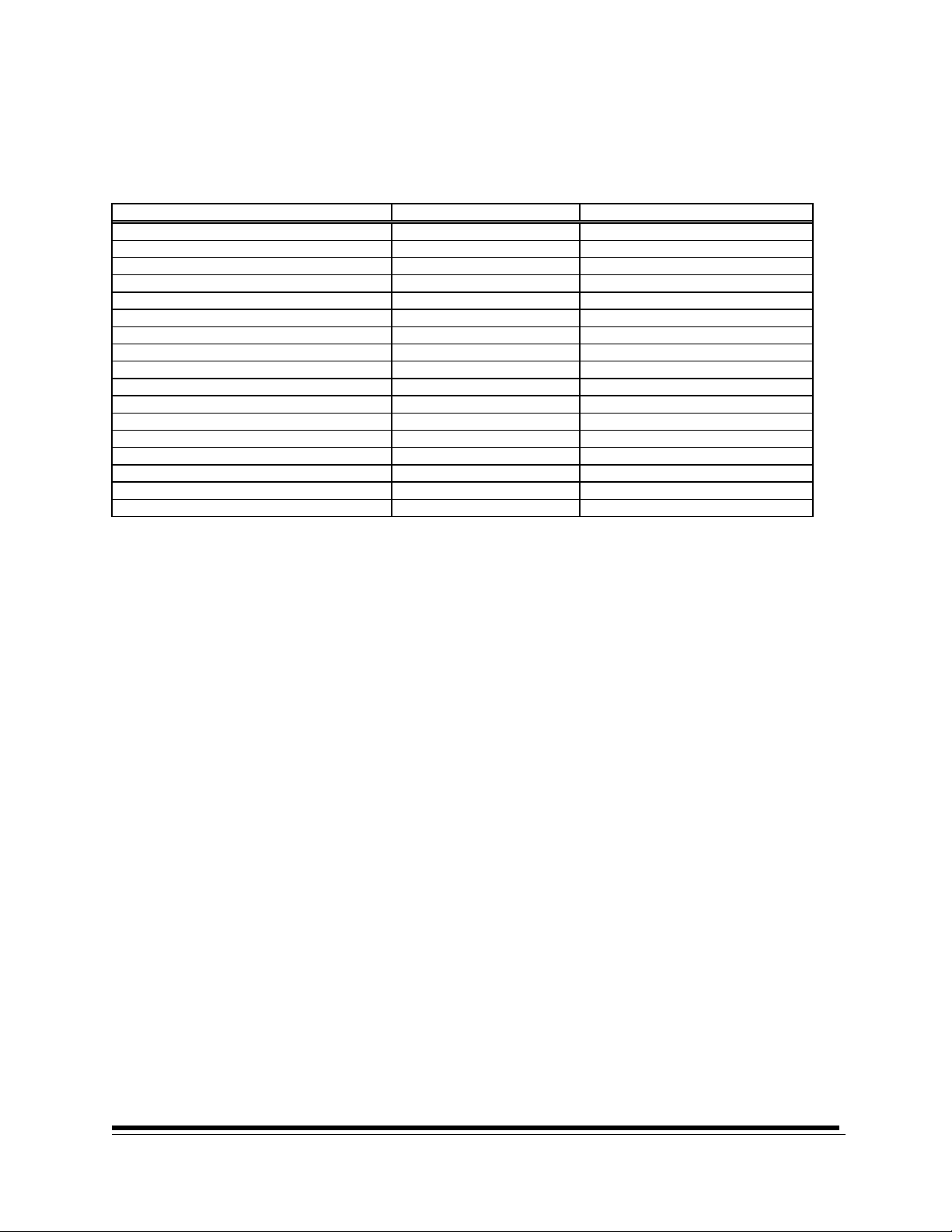

15.0 General Specifications

Table 1. Specifications.

Maximum Ratings

AC mains voltage 480 Vac

Pulse transformer hipot 3500 Vac (60 seconds)

Operating temperature range -5 to 85 C

Board ac supply voltage 28 Vac (24 Vac nominal)

12 V regulator output current 20 mA (30 Vdc supply)

5 V reference output current 5 mA (30 Vdc supply)

Auxiliary control power output from 24 Vac/30 Vdc 2 W

Delay angle range 10° ≤ α ≤ 170°

Electrical Characteristics

Delay angle command signal, SIG HI Voltage: 0-5

Current: 4-20 mA

Or per customer specification

Control signal isolation from ground Galvanic isolation provided by pulse

transformers and control power transformers

Gate delay steady-state transfer function Delay angle decreases as SIG HI increases

Gate delay dynamic transfer function bandwidth -3 dB at 67 Hz, phase shift -45° at 57 Hz

Gate drive phase balance ±1° (max)

Delay angle variance Δ(α)/Δ(f) = 1.5°/Hz

50/60 Hz compensation via J3 selection

Lock acquisition time 30 ms (typ)

Soft-start/stop time (independently configurable) 0.05 – 20.0 s (typical)

Low SIG HI inhibit Firing inhibited when SIG HI < 0.48 Vdc.

Remove D6 to defeat this feature

Power-on inhibit Automatic

Instant/soft inhibit/enable inputs Dry contact

Gate pulse burst frequency 256 times line frequency

Initial gate pulse open circuit voltage 15 V (30 Vdc supply)

Sustaining gate pulse open circuit voltage 7.0 V (30 Vdc supply)

Peak gate drive short circuit current 1.5 A (30 Vdc supply, 1.0 Ω gate load)

Sustaining gate drive short circuit current 0.5 A (30 Vdc supply, 1.0 Ω gate load)

Short-circuit gate drive current rise time 1.0 A/μs (30 Vdc supply, 1.0 Ω gate load)

Board dimensions 191 x 152 x 35 mm (L x W x D)

Minimum creepage distance to ac mains 13 mm

Conformal coating per MIL-1-46058, Type UR

Enerpro Document No: OP-0106, Rev. B Page 13 of 14 ECO #19-11089; Release Date: 08/02/2019

Control Signals are supplied

here.

(See Figures 1 and 2.

Also see Dwg. #E168)

CAUTION!

g k g k

CONNECTOR

FOR

T1 EXCITATION

(Board Power)

LOWER VOLTAGE TO

J3 PINS 3 & 5

HIGHER VOLTAGE TO

J3 PINS 1 & 5

N/C

+X2 -X2 +X1 -X1

g k g k

TO SCR'S

J8

J4

6.75"

Center

to Center

5.0"

Center

to Center

WARNING Check these connections very carefully before energizing the firing board. Improper connections

will result in product and/or customer equipment damage! If you have any questions concerning these

connections, call for assistance

J5

J2 J1

COM

"POWER

ON"

Green LED

PD2

"INHIBIT"

RED LED

PD1

J3

120/240

or

240/480

50/60 HZ

PROGRAMMING

Plug for

optional

Regulator

Board

P#

VRCL1P-1

R7

SPAN

R6

BIAS

N/C

N/C

12 3456 135

123 45

2A

2A

J6

PM3 PM4 PM1 PM2

R4

U3

147

AC Current & Voltage

Feedback;

Current Limit Command

FCRO4100

Enerpro Document No: OP-0106, Rev. B Page 14 of 14 ECO #19-11089; Release Date: 08/02/2019

APPENDIX A

The following AMP Mate-N-Lok™ information is provided for your convenience. The part numbers referenced are

valid as of this date and are currently used by Enerpro. However, these numbers are subject to change.

Description

A

MP Numbe

r

Enerpro Stock Numbe

r

J1: 6-position Header (right angle) 640583-1 C2MNLRPH06

J1: 6-position Header (vertical) 350711-1 C2MNLVPH06

P1: 6-position Plug 640581-1 C2MNLPLG06

J2: 5-position Header (right angle) 1-350945-0 C2MNLRPH05

J2: 5-position Header (vertical) 640900-1 C2MNLVPH05

P2: 5-position Plug 350809-1 C2MNLPLG05

J3: 5-position Header (right angle) 1-350945-0 C2MNLRPH05

J3: 5-position Header (vertical) 640900-1 C2MNLVPH05

P3: 5-position Plug 350809-1 C2MNLPLG05

J4: 12-position Header (vertical) 350713-1 C2MNLVPH12

P4: 12-position Plug 350735-1 C2MNLPLG12

J5: 4-position Header (vertical) 350792-1 C2MNLVPH04

P5: 4-position Plug 350779-1 C2MNLPLG04

Contact Socket (20 - 14 AWG) 350552-1 N/A

Keying Plug 1-640415-0 C2KP94V0

Universal Crimp Tool 90287-1 N/A

AMP extraction Tool 458994-2 M2T458994

Table 2. AMP Mate-N-Lok™ Cross Reference

Table of contents

Popular Motherboard manuals by other brands

Gigabyte

Gigabyte GA-G41MT-ES2L user manual

Alpha Microsystems

Alpha Microsystems AM-990 Service manual

Linear Technologie

Linear Technologie DC1619A Demo Manual

mikroElektronika

mikroElektronika mikromedia for PIC24 Schematics

Asus

Asus EX-H310M-X manual

GIGA-BYTE TECHNOLOGY

GIGA-BYTE TECHNOLOGY H510M DS2V user manual