Enertech Bentone BG 450 Technical specifications

Providing sustainable energy solutions worldwide

178 011 75-2 2016-11-28

Installation- and maintenance instruction

BG 450

!

Warning

DESCRIPTION

Warning

172 155 15 07-01

- Read the manual before assembling or commissioning.

- The contents of this manual are to be observed by all who work for any reason

on the unit and its appertaining system parts.

- This manual is intended especially for authorised personnel.

- This manual is to be regarded as part of the burner and shall always be

available near the place of installation.

- The burner is only to be installed by qualified personnel

- Check that the burner is suitable for the boiler´s power range.

- The burner is to be installed such that it complies with any local regulations

relating to electrical safety, boilers and fuel distribution.

- Check that the burner is approved for the gas quality intended used.

- No burner safety systems are to be disengaged.

- The fitter is to ensure that the boiler room is supplied with fresh air ventilation

that is sufficient in accordance with local standards.

- Before servicing, shut off the fuel supply and the power supply to the burner.

- The outer temperature of the boiler´s components can exceed 60 °C.

- Check that the guide stop is installed before servicing.

- Take great care when servicing. Trap and pinch risks can be present.

- The boiler´s sound level can exceed 85 dBA during operation. Use ear

protectors when present in the boiler room.

Safetydirections - The electrical installation shall be made according to valid regulations for

heavy current and in a professional way, so that the risk of leaking gas, fire

or personal injury is avoided.

- If another electrical connection is used than the one recommended by

Enertech, there might be a risk of material damage or personal injury.

- Notice should be carefully taken by the installer that no electrical cables or

gas pipes get squeezed or damaged when installing or at service

- If the boiler is provided with an opening door, this should be interlocked with

a door switch.

Acceptanceinspection - Ensure that everything is delivered and that there is no transport

damage.

- If there is anything wrong with the delivery, please report it to the supplier.

- Any transport damage should be reported to the forwarding company.

Preparations for installation - Ensure that the size and capacity range of the burner are suitable for the

boiler.

- Power data on the data plate refer to the minimum and maximum power of

the burner.

172 205 92 99-02

DESCRIPTION

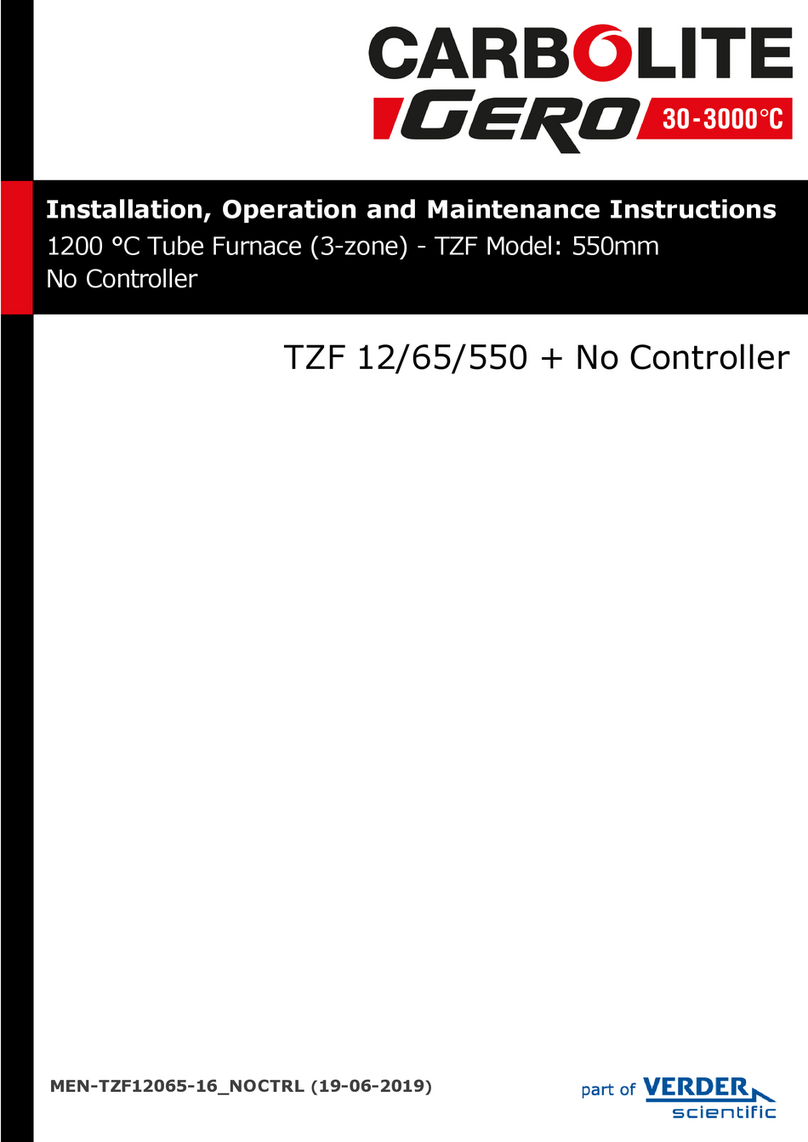

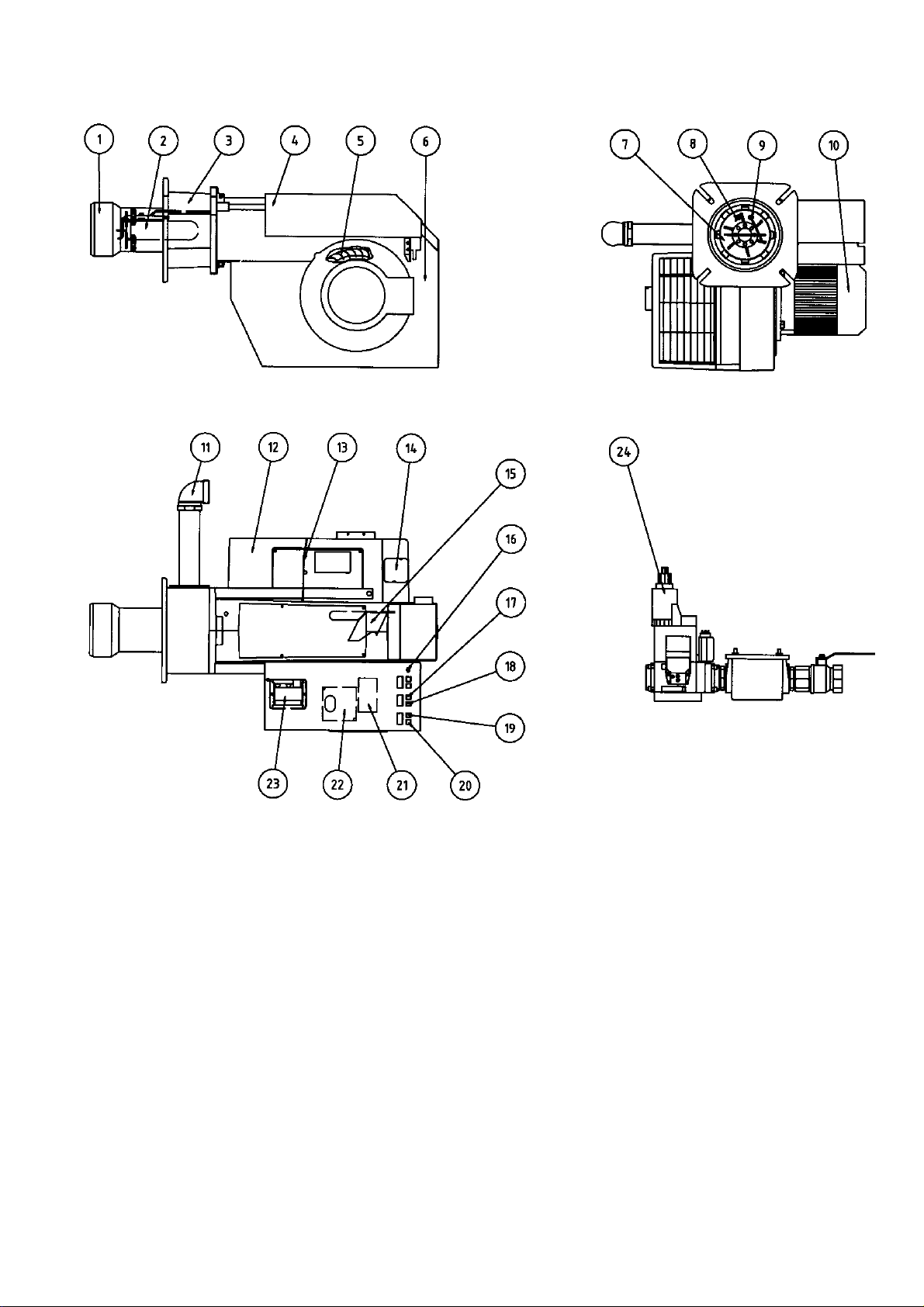

COMPONENTS

1. Flame cone

2. Inner assembly

3. Fixing flange

4. Electric panel

5. Fan wheel

6. Fan house

7. Shrouded disc

8. Ignition electrode

9. Ionisation electrode

10. Motor

18. Switch l-ll

(For modulating burner:

Change-over switch manually-

automatically)

19. Indicating lamp Stage 1

20. Switch 0-1

21. Contactor

22. Control box

23. Ignition transformer

24. MultiBloc

11. Connection gas fittings

12. Air intake

13. Air damper

14. Air pressure switch

15. Conical shield plate

16 Fuse

17. Indicating lamp Stage 2

(For modulating burner:Change-

over switch increase-decrease)

Armatur 2) Motor Ignition transformer

Natural gas LPG 1-fas, 450W, 2 800 r/m, Primary 230 V, 1 A

1 1/2" 230/240 V Secondary 8 000 V

2) Town gas

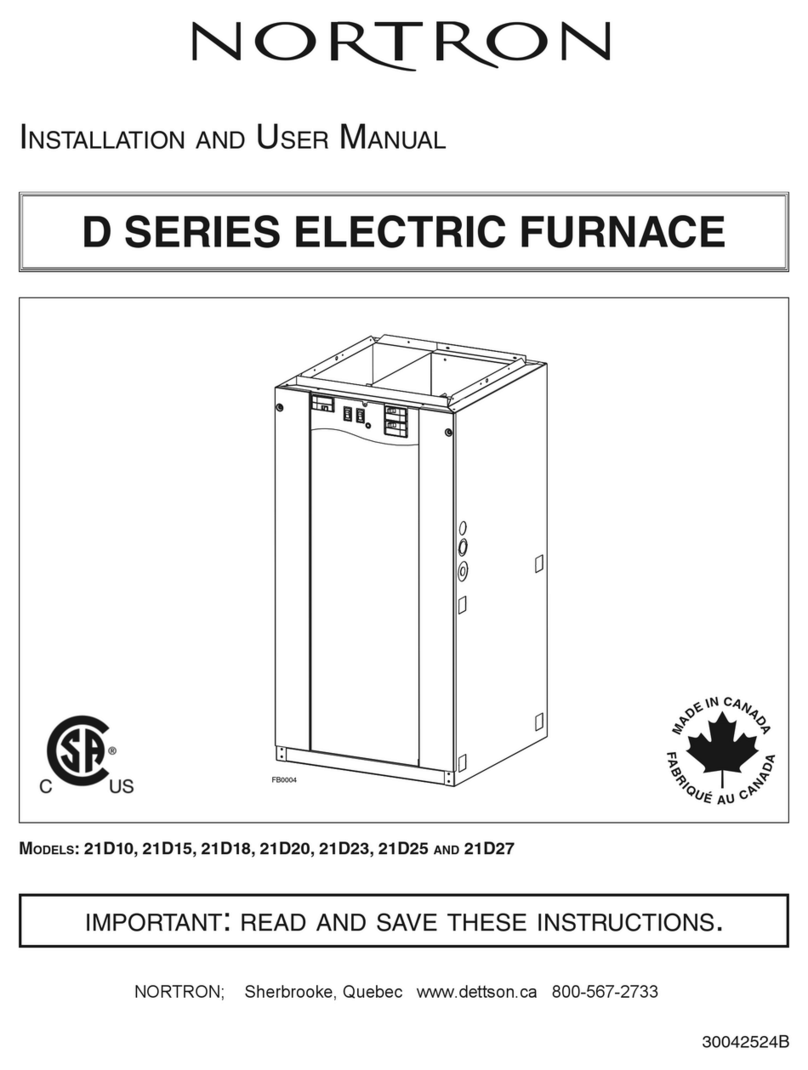

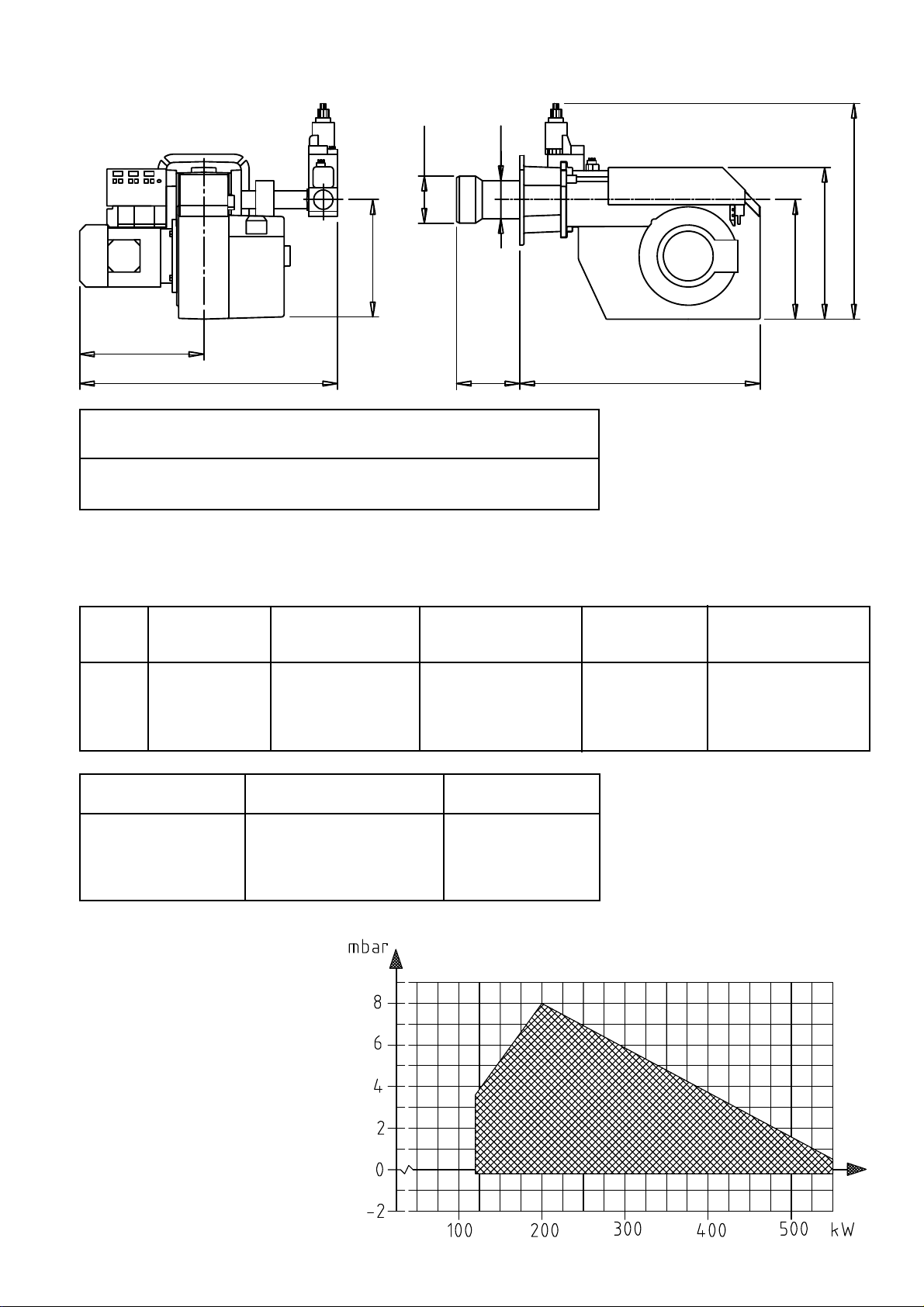

CAPACITYCHARTACCORDINGTO

EN 676

Type Capacity Gas volume at a min. Gas volume at a max Max. inlet Rated inlet pressure

kW output Nm3/h 1) output Nm3/h 1) pressure mbar mbar

Natural gas/LPG Natural gas LPG Natural gas LPG Natural gas LPG

450 120-550 12 4,6 55 21 360 40 30-50

2) Town gas 2) Town gas 2) Town gas 2) Town gas

OUTRANGE

TECHNICAL DATA

Type designation BG 450

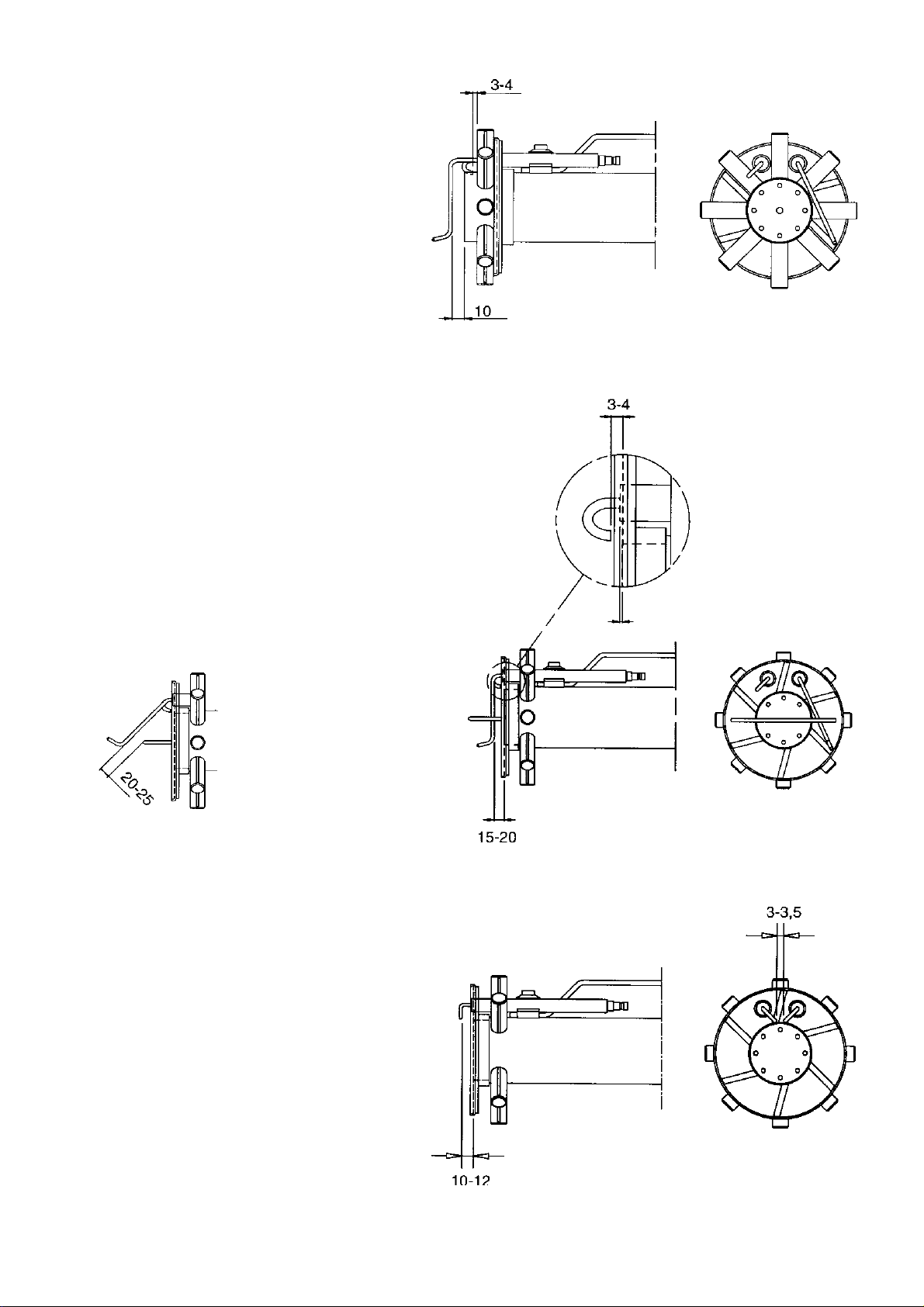

DIMENSIONS

1) Calorific value:

Natural gas 10 kWh/Nm3

LPG 26 kWh/Nm3m3

2) Dimension and capacity depen-

ding on gas quality and available

inlet pressure

Length of burner Flange

tube Measure A

Standard 256 226

Long design 356 326

The above dimensions are max. measurements. Depending on the components

used, the measurements may vary.

640

262

A 538

252

ø160

ø130

500

328

252

172 215 50 00-01

TECHNICAL DATA

DIMENSIONSOFFLANGE

172 215 19 00-01

14

(ø210)ø254-280

ø163

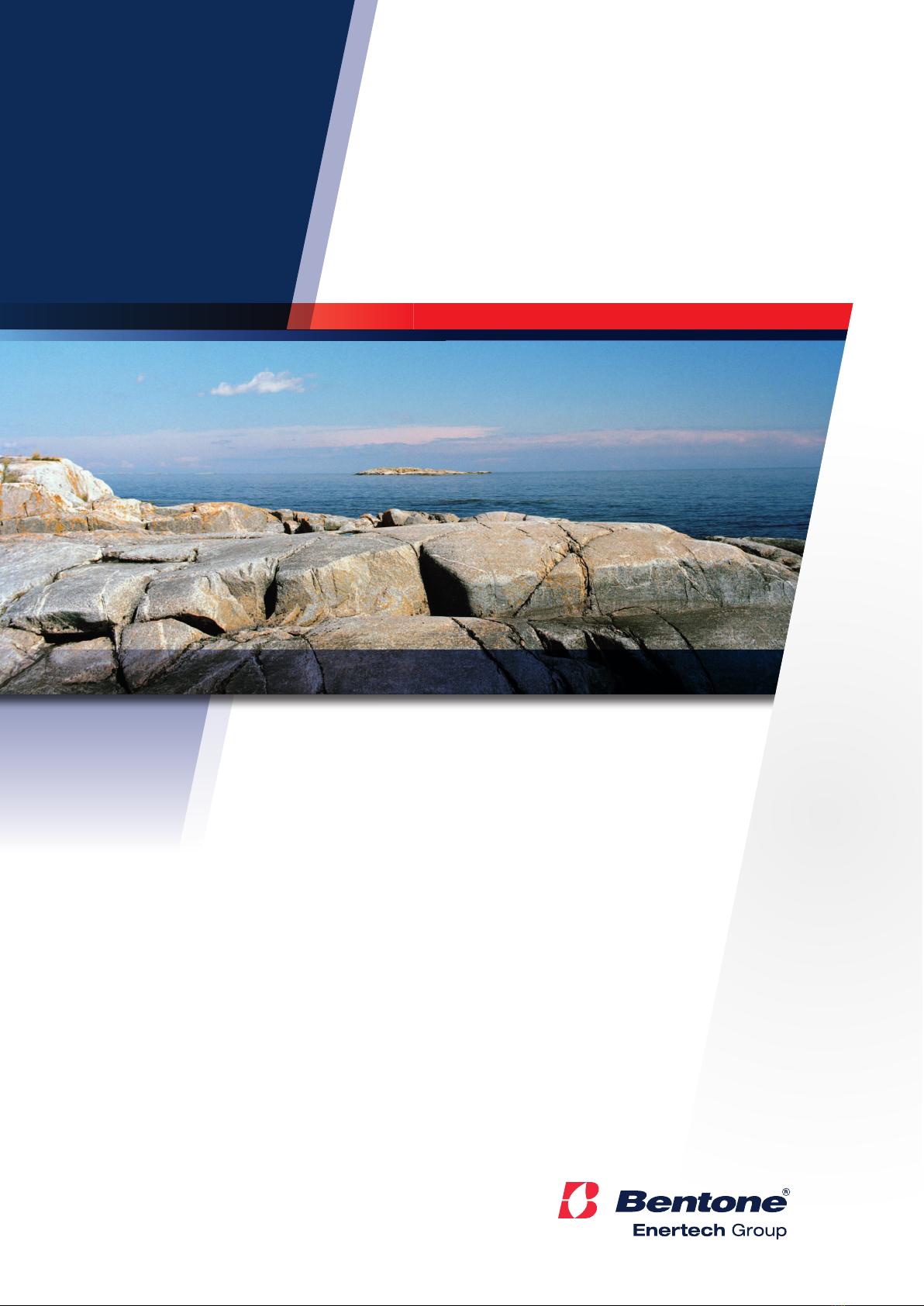

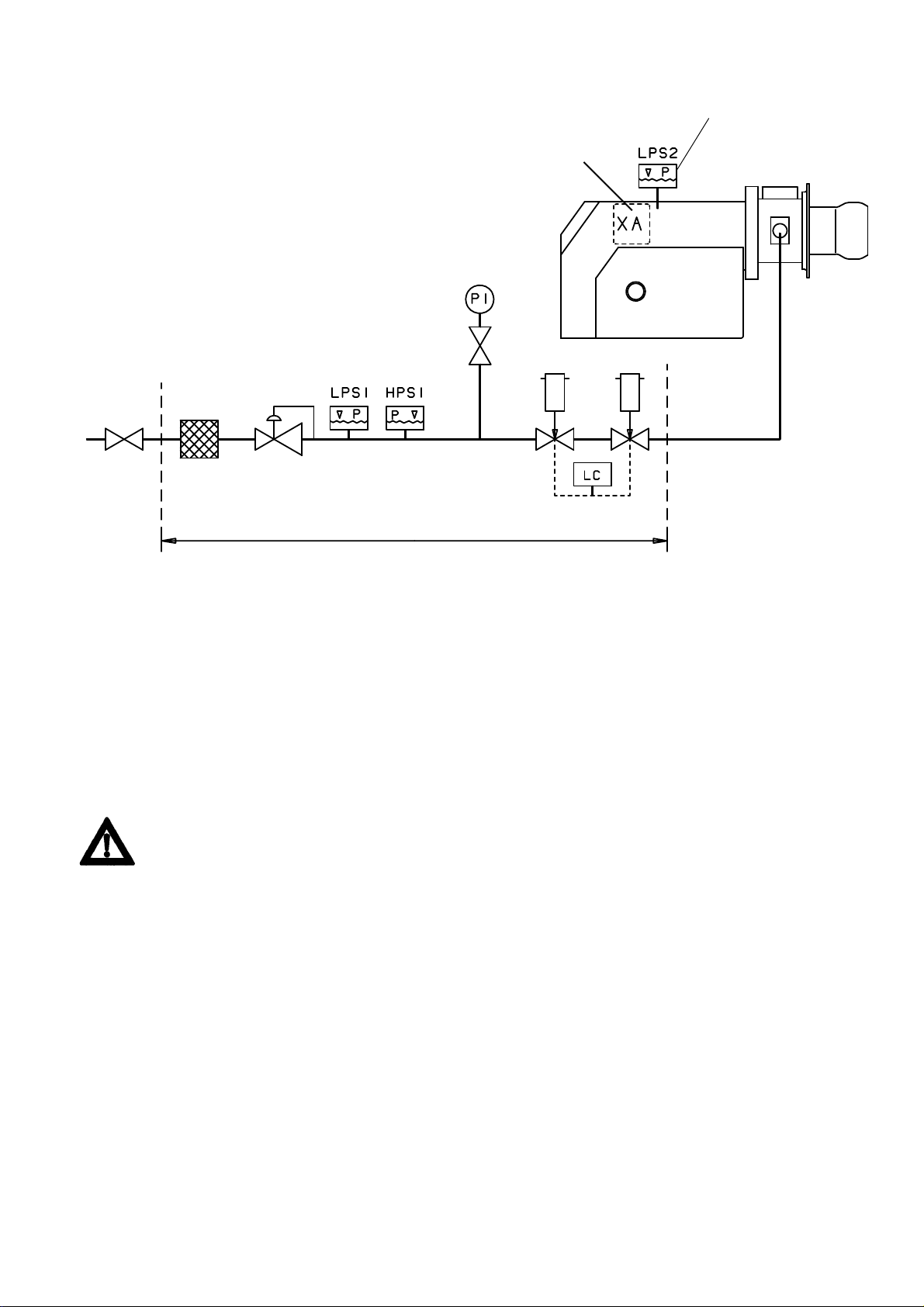

SKELETON DIAGRAMS

1. Ball valve

2. Filter

3. Governor

4. Pressure gauge with shut-off cock

5a. Gas pressure switch, mini

5b. Gas pressure switch, maxi

6a. Main valve.

7

123

5a 5b

4

6b 6a

10

Incorporated in the MultiBloc

9

6b. Safety valve

1) 7. Valve proving system

9. Air pressure switch

10. Gas burner control

Pos. 5b, 7: Components not required

according to EN 676.

1) Required over 1200 kW according

to EN 676.

172 415 08 03-01

When Bio gas is used, Bentone shall always be contacted.

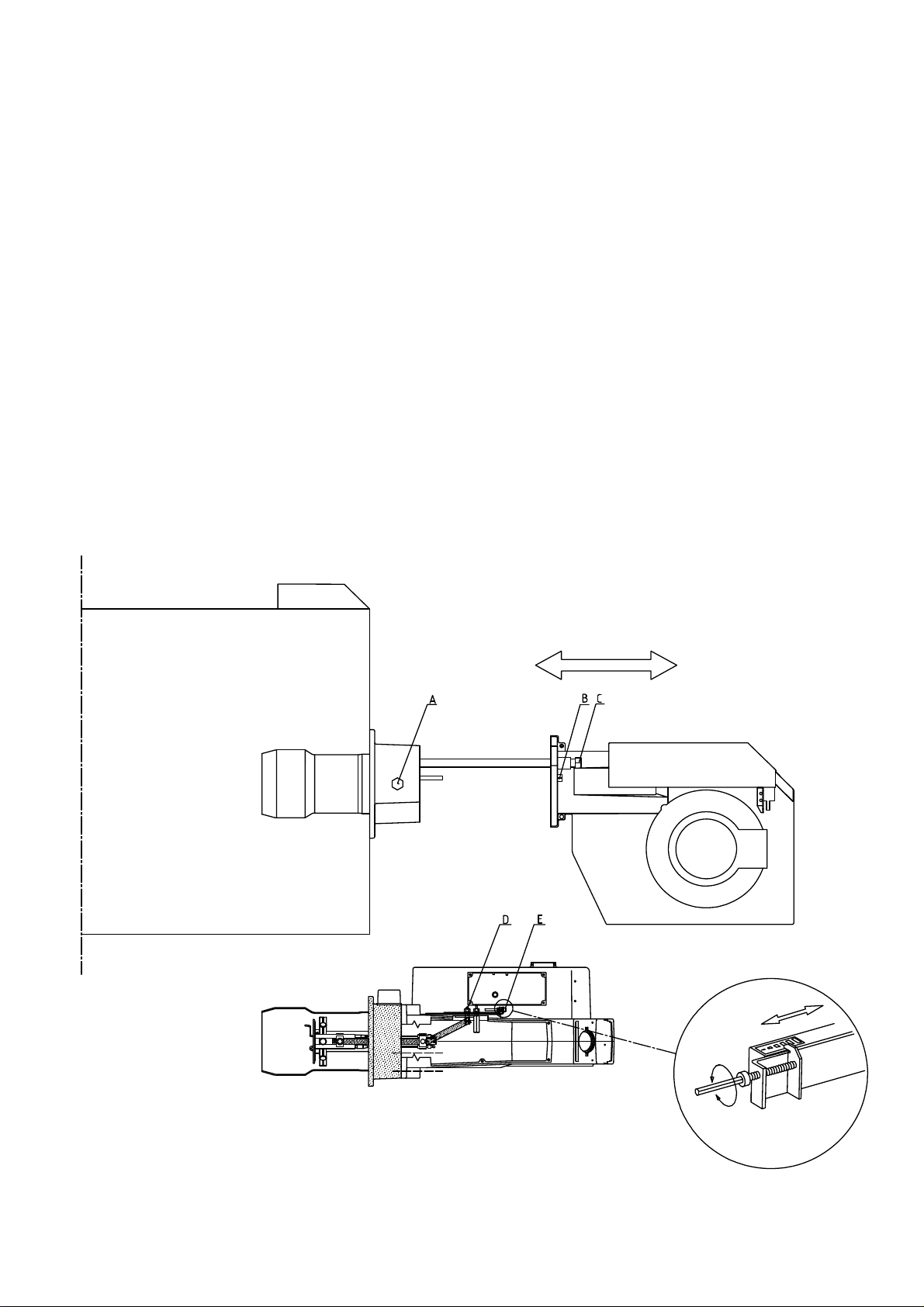

MOUNTING OF THE BURNER

172 205 20 01-01

Fit the burner to the boiler by means of

4 bolts M12. For flange and bolt dimen-

sions see technical data.

If for some reason you want to sepa-

rate the burner from the gas flange with

burner head and valve package you

can do so.

DO LIKE THIS:

- Remove the cover of the fan hou-

sing.

- Loosen the nut D of the gas assem-

bly package.

- Loosen the electric cables to the

valve package.

- Loosen the screws B on both sides.

- Loosen the stop bolt C on the pull

rods.

- Loosen the ignition cable and the

ionisation cable from the gas ass-

embly.

- Pull out the burner on the pull rods

and put it in a suitable place.

When the burner head and the gas

flange have been fitted to the boiler it is

easy to lift up the burner to where it

belongs.

INSPECTIONOFGASASSEMBLY

If the gas assembly needs to be in-

spected the pull rods are very useful.

DO LIKE THIS:

- Remove the cover of the fan hous-

ing.

- Loosen the nut D of the gas assem-

bly package.

- Loosen ignition cable and ionisa-

tion cable of gas assembly.

- Loosen the screw A on both sides.

- Pull out the burner on the pull rods.

- Loosen the screws B on the gas

flange.

- Withdraw the gas assembly.

Ensure that the O-ring between the

gas assembly and the gas flange will

be in the correct position when the gas

assembly is fitted again.

ADJUSTMENT OF THE POSITION

OF THE SHROUDED DISC IN THE

BLASTTUBE

Sometimes it is necessary to adjust

the position of the shrouded disc in the

blast tube. This can be done with the

screw E (can be adjusted when the

burner is in operation). If you turn the

screw to the left the shrouded disc will

move forward (+), to the right it will

move backward.

SERVICEPOSITION

NOTE!

For maintenance of the brake plate,

nozzles, electrodes etc, when using a

long design of the burner tube, you

have to removethenozzleassembly

fromtheconnectingpipeandmove

the assembly backwards in the fan

housing (from the boiler).

MEASURES AND CHECKS BEFORE START-UP, 1-STAGE BURNER

GENERALRULES

Care should be taken by the installer to

ensure that no electrical cables or fuel/

gas pipes are trapped or damaged

during installation or service/

maintenance.

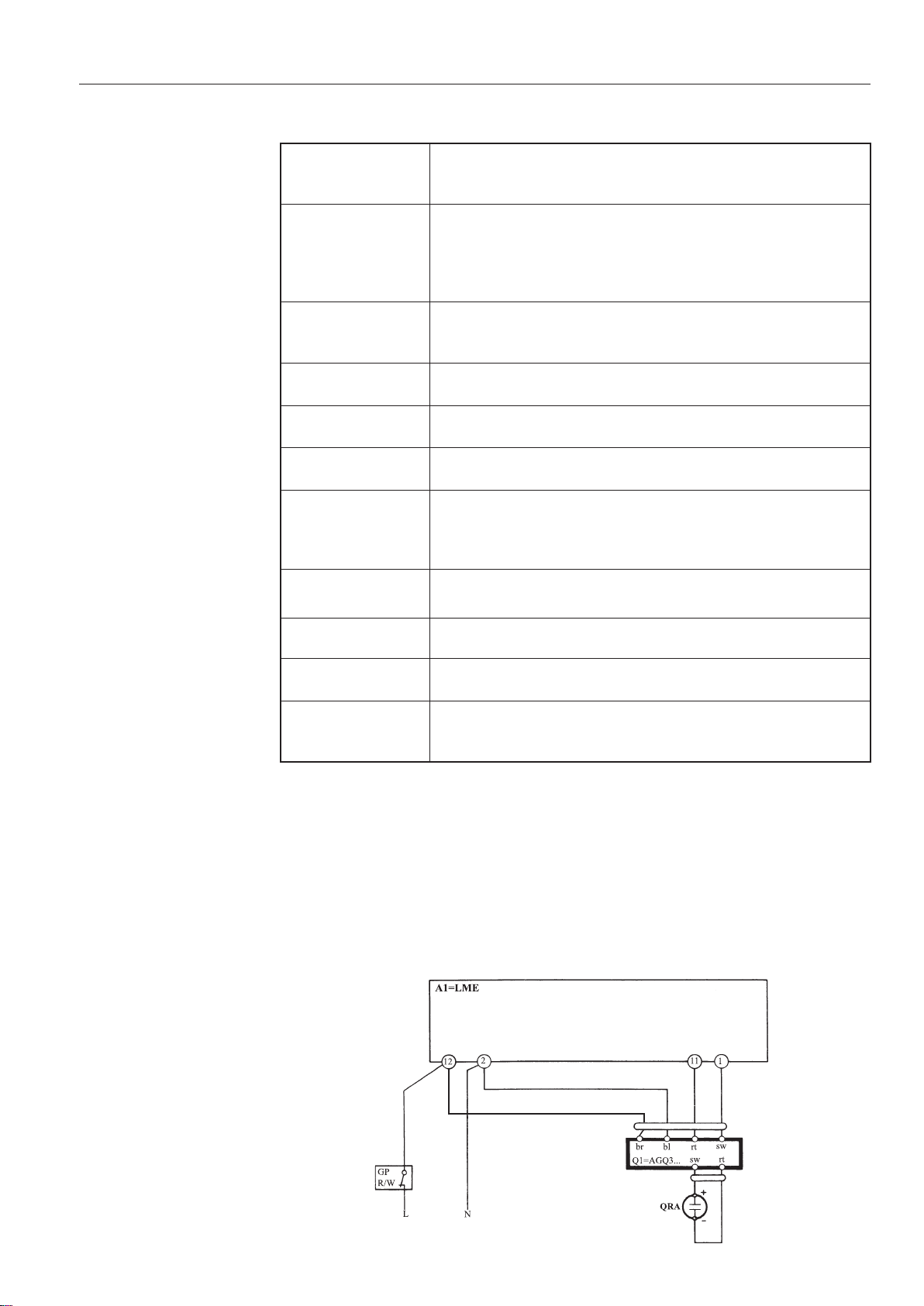

INNERASSEMBLY

Ensure that the ignition and ionisation

electrodes are correctly adjusted. The

sketch shows the correct measure-

ments.

GASQUALITY

Ensure that the burner head is meant

for the gas quality to be used (see fig.).

VENTING

The gas line is vented by loosening the

screw on the test nipple for the inlet

pressure. Connect a plastic hose and

conduct the gas into the open. After

having vented the gas line tighten the

screw again.

LEAKAGECONTROL

When making a leakage control of the

gas supply system the solenoid valve

should be closed. Connect a pressure

gauge to the test nipple Pa, see fig.

The test pressure in the system should

be 1,5x max. inlet pressure or min.

150 mbar. If any leakage, locate the

source by means of soapy water or a

leak location spray. After tightening

repeat the test.

ELECTRICFUNCTIONTEST:

Ensure that phase and neutral are not

reversed. The gas shut-off cock should

be closed.To prevent the gas pressure

switch from locking out it should be

linked temporarily.

After the main switch has been swit-

ched on and the thermostats have

been adjusted the pre-purging period

begins (30-35sec.). At the end of this

period the pre-ignition period starts

(0,5-2,5 sec. dependent on the design

of the gas control). The gas valve is

energized and opens and flame is

established. At the end of the safety

time (2-3 sec.) the gas control locks

out. The solenoid valve and the motor

will be "dead". Remove the link from

the gas pressure switch after the test

is finished.

172 205 33 07-01

LEAKAGE CONTROL

NOTE! APPLIES ONLY TO GAS

BURNERCONTROLLFL1.

When using LPG (Propane) the burner

should be connected for post-purge.

Move connection to terminal 6 to ter-

minal 7 in the base of LFL1.

MEASURES AND CHECKS BEFORE START-UP

INNER ASSEMBLY

Town gas

INNER ASSEMBLY

Natural gas, LPG

INNER ASSEMBLY

Biogas ((UV-detector)

172 205 18 97-01

Propan Naturgas

172 205 16 98-01

DETERMINATION OF GAS VOLUME FOR THE INSTALLATION

V = Gas volume Nm3/h

Q = Boiler output 120 kW

Hu= Calorific value of the gas A. 37 144 kJ/Nm3, B. 10.3 kWh/Nm3

η= Expected efficiency 90%

Ex. A

Ex. B

If the barometer height, pressure and temperature of the gas deviate very much from the normal values this must be taken

into account as follows:

f=

t = Temperature of the gas at the gas meter (15°C)

B = Barometer height (945 mbar)

Pu= Pressure of the gas at the gas meter (15,0 mbar)

f=

f≈1.11

The gas volume read on the gas meter actually reads 1,11 .12,9 = 14,4 m3/h.

Net calorific value

Gas quality kWh/Nm3kJ/Nm3kcal/Nm3

Natural gas 10.3 37 144 8 865

Propane 26.0 93 647 22 350

Butane 34.3 123 571 29 492

Town gas 4.9 17 653 4 213

Bio gas 7.0 25 219 6 019

Specifications on natural gas, town

gas and bio gas vary. For more exact

information please contact the gas

distributor.

EXAMPLE HOW TO CALCULATE THE GAS VOLUME (NATURAL GAS)

273+15

273 .1013,25

945+15

V=120

10,3 · 0,90 ≈12,9 Nm3/h

B+Pu

273+t

273 .1013,25

120 .3 600

37 144 .0,90

V=Q .3 600

Hu · η =≈12,9 Nm3/h

172 425 99 16-01

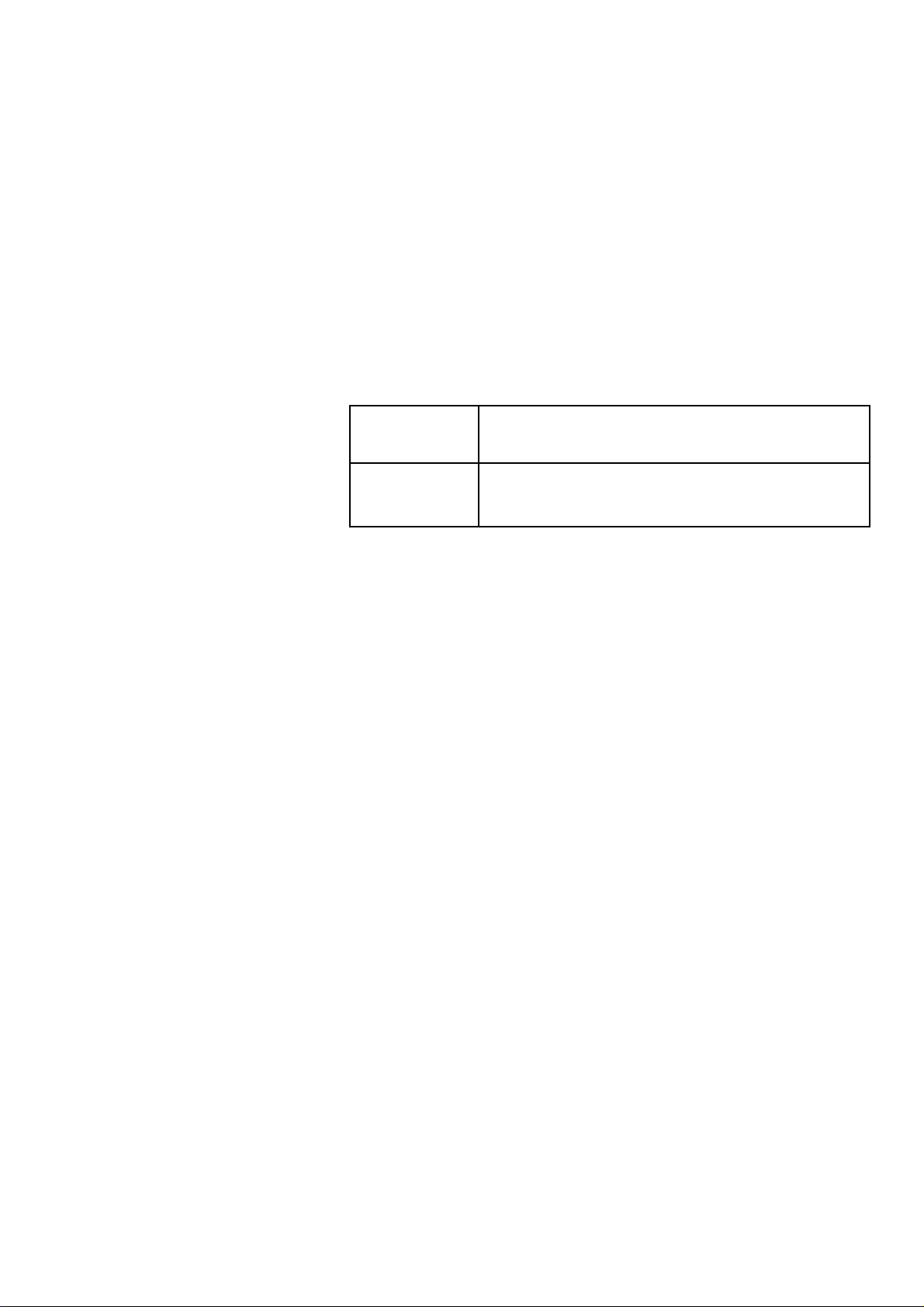

ELECTRIC EQUIPMENT

Gas burner control: LME11/LME21

Wiring diagram

1(3)

1N ~ 50/60 Hz 230 V

List of components

A1 Gas burner control

B1 Ionization electrode

F1 Fuse

H1 Lamp, low capacity

H3 Alarm signal 220 V

K1 Motor contactor

M1 Burner motor

P1 Time meter, total operating time

S1 Operating switch

S3 Control thermostat

S4 Temperature limiter

S5 Micro switch for hinged door

S7 Main switch

S8 Air pressure swith

S9 Gas pressure switch

T1 Ignition transformer

X1 Connection terminal board

X2 Earth terminal

X3 Plug-in contact, burner

X4 Plug-in contact, boiler

Y1 Gas solenoid valve

Mains connection in accordance with

local regulations.

If there is no Plug-in

contact (X4,X6) on

the boiler, connect

to the contact

enclosed. Max loading K1

Connection A1,A2 / 95, 96 / 97, 98

Max 0,2A/15W

172 425 99 16-01

2(3)

ELECTRIC EQUIPMENT

Control diagnosis under fault conditions and lockout indication

Gas burner control: LME....

Colour codes

Diagnostics alarm trigger

The red alarm signal lamp lights continuously after the alarm is disconnected.

Limit on start attempts

or goes out during operation. LME 11 … permits a maximum of three start attempts if

the start cycle is uninterrupted.

Continuous

Off

Red

Yellow

Green

Colour code table for multi-coloured signal lamps (Light diodes)

Status Colour codes Colours

Waiting time «tw», other waiting times ○………………… Off

Ignition phase, ignition checked •○ •○ •○ •○ •○ • Flashing yellow

Normal operation Green

Flashing green

Green-Red

Undervoltage Yellow-Red

Disruption, alarm Red

Flashing code for fault codes Flashing red

Interface diagnostics

AL

FS

Flash code Pause Flash code

Approx. 3 s

lights red Press the reset

button > 3 s

172 425 99 16-01

3(3)

ELECTRIC EQUIPMENT

Control diagnosis under fault conditions and lockout indication

Gas burner control: LME...

During alarm trigger diagnostics, control outputs are to be disconnected from all

power.

– The burner is disconnected

– Exception, the «AL» alarm signal at connection block 10

– The burner is only to be reconnected after it is reset

– Press the reset button 0.5...3 s

Interface diagnostics

To switch to interface mode, hold the reset button depressed for more than 3 s. To

unit is in the alarm mode, it is reset by pressing the reset button 0.5...3 s.

Alarm control table

on signal lamp

(LED)

Possible causes

Flashing 2 x

••

•

–

– Defective or obscured fuel valves

– Poor burner installation

– Defective ignition unit

Flashing 3 x

•••

«LP» defective

– No air monitor signal after «t10»

– «LP» is welded in the open position

Flashing 4 x

••••

Flashing 5 x

•••••

Time out «LP»

– «LP» is welded in the closed position

Flashing 6 x

••••••

Free

Flashing 7 x

•••••••

– Poor burner installation

– Defective or obscured fuel valves

–

Flashing 8 x

••••••••

Free

Flashing 9 x

•••••••••

Free

Flashing 10 x

••••••••••

Connections fault or internal fault,

outgoing contacts or other fault

Flashing 14 x

••••••••••

••••

CPI contact not closed

ADJUSTMENT OF MULTI-BLOC, MB-DLE 405-420

Max. inlet pressure: 360 mbar.

Adjustable governor pressure:

405 - 412 S50 = 4 - 50 mbar

415 - 420 S20 = 4 - 20 mbar

415 - 420 S50 = 20 - 50 mbar

Solenoid valve: Slow opening valves

with adjustable start load and max.

flow.

1. Protective cover start load ad-

justment

2. Hydralic damping

3. Fixing screw

4. Test nipple (inlet pressure)

5. Test nipple (pressure after go-

vernor)

6. Test nipple (pressure in inner

assembly)

7. Governor

8. Filter

9. Gas pressure switch

10. Solenoid valve

FLOWADJUSTMENT

Loosen the fixing screw a. Turn the

hydraulic device b:

to the right = the gas flow is reduced

to the left = the gas flow is increased

Do not forget to tighten the fixing screw

again.

The flow adjustment can also be made

by means of the governor. Adjust the

outlet pressure to a value giving the

desired gas flow on the fully open

valve. At small capacities (gas flows) it

is also necessary to adjust as abore.

ADJUSTMENT OF GOVERNOR

Adjust outlet pressure from governor

by means of a screw . Min. and max.

outlet pressures corresponds to appr.

60 turns of the spring. It is not possible

to change pressure springs in order to

change the outlet pressure.

Turn to the right = the outlet pressure

is increased

Turn to the left = the outlet pressure is

reduced

ADJUSTMENT OF START GAS

FLOW

Remove the protective cover c.

Turn the adjustment knob d (use the

protective cover as a tool) to the desi-

red start gas flow.

Turn to the right = the start gas flow is

reduced

Turn to the left = the start gas flow is

increased

ADJUSTMENT OF START GAS

FLOW

ADJUSTMENT OF GOVERNOR

FLOWADJUSTMENT

172 505 02 97-02

GENERAL INSTRUCTIONS

ADJUSTMENT OF BURNER

The burner is from the factory pre-set

to an average value that must then be

adjusted to the boiler in question.

All burner adjustments must be made in

accordance with boiler manu-facturers

instructions.These must include the

checking of flue gas temperatures,

average water temperature and CO2or

O2concentration.

GENERALINSTRUCTIONS

The installation of the gas burner must

be carried out in accordance with

current regulations and standards. The

installers of gas burners should there-

fore be acquainted with all regulations

and ensure that the installation comp-

lies with the requirements. The instal-

lation,mountingandadjustment should

be made with the greatest care and

only the correct gas should be used.

OPERATINGINSTRUCTIONS

The operating instructions accompanying

the burner should be left in a prominent

position in the boiler room.

INSTRUCTIONS

The user should be thoroughly in-

structed in the function of the gas

burner and the whole installation. The

supplier must instruct the user.

INSPECTIONANDMAINTENANCE

Daily inspection is advisable.

START UP

After the burner has been fitted to the

boiler and the electric connection, the

leakage control, the venting and the

electric function test have been car-

ried out, the burner will be ready for

start-up.

Howerer, study the sections dealing

with adjustments of multi-bloc, com-

bustion air and combustion head.

Open the ball valve and switch on the

main switch. If the burner starts the

actual adjustment can be made.

ADJUSTMENT OF BURNER HEAD

The burner is equipped with an ad-

justment device changing the position

of the brake plate in the burner head.

This is used to adjust the correct pres-

sure drop over the combustion device

in order to obtain a good pulsation free

combustion.

Which position to use depends on

input and overpressure in the boiler. 172 305 28 97-01

A general rule is that the lower capa-

city the smaller the opening between

brake plate and combustion device.

COMMISSIONINGOFINSTALLA-

TION

Control of the combustion. The com-

bustion quality is checked by means

of a flue gas analysis device. Adjust

the burner to appr. 20% excess air in

accordance with the table. Check the

flue gas temperature. Calculate the

efficiency. Check also the actual gas

volume on the gas meter so that the

correct input is achieved.

SERVICE

Service should only be carried out by

qualified personnel. Replacement

parts should be of the same make

and approved by the same authoriti-

es as the original. If the burner is

converted to fire another gas quality it

must be re-commissioned. If town

gas is to be fired the combustion head

must be converted and the gas train

adjusted to suit (e.g.a larger gas ar-

mature or a different spring in the

governor may be required).

Gas quality CO2%0

2% max. CO2%

lambda 1,2

Natural gas 10,0 3,5 11,9

LPG 11,5 3,5 13,9

172 305 25 00-01

FLAMEMONITORINGANDMEASU-

REMENTOFIONISATIONCURRENT

The burner is monitored according to

the ionisation principle. Check the io-

nisation current on start-up and on

each service call.

The reason for a low ionisation current

may be leaking currents, bad connec-

tion to earth, dirt or a faulty position of

the flame electrode in the burner head.

Sometimes also a faulty gas/air mixtu-

re may cause too weak a ionisation

current.

The ionisation current is measured by

means of a microampere meter (μA)

connected in series with the flame

electrode and the gas burner control.

Connect the μA-meter, see figure.

Min. required ionisation current ac-

cording to table. In practice this cur-

rent must be considerably higher, pre-

ferably more than 10 μA. All the gas

burners are equipped with a ionisation

cable that can be slit which facilitates

the connection of the μA-device.

GAS PRESSURE SWITCHES:

Adjustment range:

2,5-50 mbar GW 50

5-150 mbar GW 150

ADJUSTMENTOFMIN.GASPRES-

SURE SWITCH

The min. pressure switch should react

if the gas pressure is too low and

prevent the burner from starting. Too

low a gas pressure during operation

should stop the burner. The burner

may start again when the rated gas

pressure has been reached.

Remove the protective cover. Connect

a pressure gauge for measuring the

rated pressure. Decide on pressure at

which the gas switch should switch off.

Set this pressure by means of the

valve. Carefully turn the knob (see

figure) until the gas pressure switch

switches off. The value shown on the

scale should then approximately cor-

respond with the value shown on the

pressure gauge. Tolerance on scale

appr. ± 15 %. Open the ball valve.

GENERAL INSTRUCTION

ADJUSTEMNTOFMAX.GASPRES-

SURE SWITCH

The burner is equipped with a max. gas

pressure switch only on request. It

should stop the burner if the gas pres-

sure exceeds the set value. The burner

can then only be re-started manually

(gas burner control or overpressure

switch).

Remove the protective cover. Connect

a pressure gauge for measuring the

rated gas pressure. Decide on pres-

sure at which the gas pressure switch

should switch off. Turn the adjustment

knob to this value. Tolerance on the

scale ±15%.

ADJUSTMENT OF AIR PRESSURE

SWITCH

The air presure switch should stop the

burner if the air volume is reduced.

The air proving device shall be adjus-

ted in such a way that if there is

insufficient air supply at the highest or

lowest burner operating stage, the

device operates before the supervised

pressure is less than 80% of the pres-

sure at the controlled stage and the CO

content of the combustion products

exceeds 1% by volume.

AIR PRESSURE SWITCH:

Adjustment range ca:

1-10 mbar LGW 10

2,5-50 mbar LGW 50

FLAMEMONITORING

GAS PRESSURE SWITCH, AIR

PRESSURESWITCH

Gas control Connection to terminal Min. ionisation

in gas control current required

LMG 1 2 μA

LGB 1 10 μA

LFL 24 10 μA

MMI 810 2 5 μA

TMG 740-3 1 5 μA

HANDING OVER OF THE INSTALLATION

172 305 17 93-01

- Make repeated start attempts to

ensure that the adjustments func-

tion.

- Close the ball valve during opera-

tion to check that the gas switch

switches off at the set value.

- Remove the hose for the air pressu-

re switch to check that the burner

locks out.

- Check that all protective covers

and measurement nipples are

mounted and fastened.

- Fill out necessary test reports.

- Instruct the persons in charge of the

operation on the service and main-

tenance of the installation and what

to do should any troubles occur.

-Inspection and service must only

be carried out by authorized

people.

FAULT LOCATION, FUNCTIONAL

TROUBLES

Trouble free operation is dependent on

three factors: electricity, gas and air

supply. Should there be any changes

in the ratio between these three factors

there is a risk of break downs. It has

been proved that most break downs are

caused by simple faults. Before calling

the service engineer, the following

should therefore be checked:

- Is the gas cock open?

- Are all fuses in order and the cur-

rent switched on?

- Are the thermostats correctly set?

- Are pressostats, overheating pro-

tection etc. in operating position

and not locked-out?

- Is the gas pressure sufficient?

- Is the gas burner control in start

position?

- Has the gas control or the motor

protector locked out? - Reset.

- Is the circulation pump in opera-

tion?

- Is there a supply of fresh air to the

installation?

If integral components are of a diffe-

rent make from what is stated in this

manual, see the enclosed loose-leaf.

170 091 16 97-01

Gas burner

FAULTLOCATIONGUIDE

The basis for trouble free operation can only be ensured

by the correct combined effect of the three factors:

electricity, gas flow and combustion air. Should any of

these factors change troubles may arise.

It has been proved that many troubles have rather simple

causes. Before calling the serviceman the following

checks should be made:

1. Are the gas cocks of the installation open?

2. Are the fuses in order and the current switched on?

3. Are the controls (room thermostat, boiler thermostat

etc.) correctly adjusted?

4. Is the gas pressure to the burner sufficient?

5. Is the gas relay of the burner ready for start and not

locked out?

6. Is the air supply to the burner sufficient?

To facilitate fault location we have drawn up a scheme

showing the most frequent faults in a gas burner instal-

lation and the remedies.

CAUSE

The burner does not start

No gas

No voltage

The burner motor fails to start

The gas relay is defective

Burnermotorisrunningbutnoignitionafterthepre-

purge time has elapsed

No voltage on the terminals

The ignition electrodes in contact with each other or with

earth

The porcelain of the electrodes is broken

Check that all gas cocks are open.

Check fuses, thermostats and electrical connections.

The thermal protection has locked out. Motor defective.

Replace

Check the contact. Replace faulty relay

Adjust

Replace the electrodes

REMEDY

1(4)

REMEDY

Improve the contact

Replace

Replace the transformer

Change

Replace

Replace coil or the whole valve if necessary.

Check the contact

Test the adjustment and the function of the air pressure

switch.

Reduce or increase the gas supply, reduce the quantity

of air.

Replace

Check the adjustment and readjust.

Adjust the ionisation electrode and the UV-cell, examine

cables and connections.

Replace the relay

CAUSE

The cable shoes have bad contact

The ignition cables are damaged

The ignition transformer is damaged, no voltage on the

secondary side

The ignition cable and the ionisation cable have been

transposed.

Noflameestablishmentinspiteofatroublefreestart

The gas solenoid valve defective

The gas solenoid valve does not open in spite of its

obtaining voltage

No voltage to the solenoid valve

No electrical connection through the air pressure switch

The starting load is not correctly adjusted

Gas relay defective

Air pressure switch incorrectly adjusted or defective

No reponse as the cams of the servomotor are not

correctly adjusted or out of position.

Theburnerlocksoutafterthesafetytimehaselapsed

inspiteofflameestablishment

No ionisation current or the UV-cell in wrong position

The supervision part of the gas relay is defective

2(4)

Table of contents

Other Enertech Furnace manuals

Popular Furnace manuals by other brands

ICP

ICP NTC6/GNE Series installation instructions

International Comfort Product

International Comfort Product WFEU Series installation instructions

Lennox

Lennox ML193UH instruction manual

Goodman

Goodman MH8 installation instructions

Bryant

Bryant 312A Installation, start-up, operating and service and maintenance instructions

Unitary products group

Unitary products group DLAS Use and care instruction