Enertronica Santerno SINUS PENTA User manual

•15W0102B500 •

SINUS PENTA

PENTA MARINE

IRIS BLUE

SOLARDRIVE PLUS

USER MANUAL

- Motor Drives Accessories -

Issued on 05/06/2019

R.01

Issued on 01/10/2015

R.07

Enertronica Santerno S.p.A.

Via della Concia, 7 –40023 Castel Guelfo (BO) Italy

Tel. +39 0542 489711 –Fax +39 0542 489722

santerno.com [email protected]om

•This manual is integrant and essential to the product. Carefully read the instructions contained herein

as they provide important hints for use and maintenance safety.

•This device is to be used only for the purposes it has been designed to. Other uses should be

considered improper and dangerous. The manufacturer is not responsible for possible damages caused

by improper, erroneous and irrational uses.

•Enertronica Santerno S.p.A. is responsible for the product in its original setting.

•Any changes to the structure or operating cycle of the product must be performed or authorized by

Enertronica Santerno S.p.A..

•Enertronica Santerno S.p.A. assumes no responsibility for the consequences resulting by the use of

non-original spare-parts.

•Enertronica Santerno S.p.A.reserves the right to make any technical changes to this manual and to

the product without prior notice. If printing errors or similar are detected, the corrections will be included

in the new releases of the manual.

•The information contained herein is the property of Enertronica Santerno S.p.A. and cannot be

reproduced. Enertronica Santerno S.p.A. enforces its rights on the drawings and catalogues according

to the law.

E n g l i s h

MOTOR DRIVES

ACCESSORIES

USER MANUAL

2/312

REVISION INDEX

The following subjects covered in this User Manual (ID number 15W0102B500,revision R.01) have been

added, changed or suppressed with respect to the previous version of this User Manual (ID number

15W0102B500, revision R.00).

The ENERTRONICA GROUP logo has been added.

The nameplates for BU200 and BU600 have been edited.

A note reading “Decisive voltage class C according to EN 61800-5-1” has been added for BU600.

The operating conditions of the available Braking Resistors have been made clearer.

IP23 Box Resistors, 4 kW to 64 kW: Part Numbers have been split between 1 kV and 3 kV.

The NEMA 1 GLANDKIT section has been added.

Input inductors: a note concerning the dedicated transformer featuring Vdc=5% or higher has been added.

The Output Toroidal Filters section has been added.

Option Boards For Fieldbus (Slot B): compatibility to firmware version has been added.

Option Boards For Fieldbus (Slot B): CClink and Powerlink removed (not available).

The meaning of the LEDs for each field bus has been made clearer in Status LEDs on the B40 Series

Boards.

The BRIDGE MINI (SLOT B) section has been added.

The ES851 Datalogger Board (SLOT B) has been removed.

In ES847 I/O Expansion Board (Slot C), inputs XAIN1, XAIN2, XAIN3, XAIN6 have been removed (not

available).

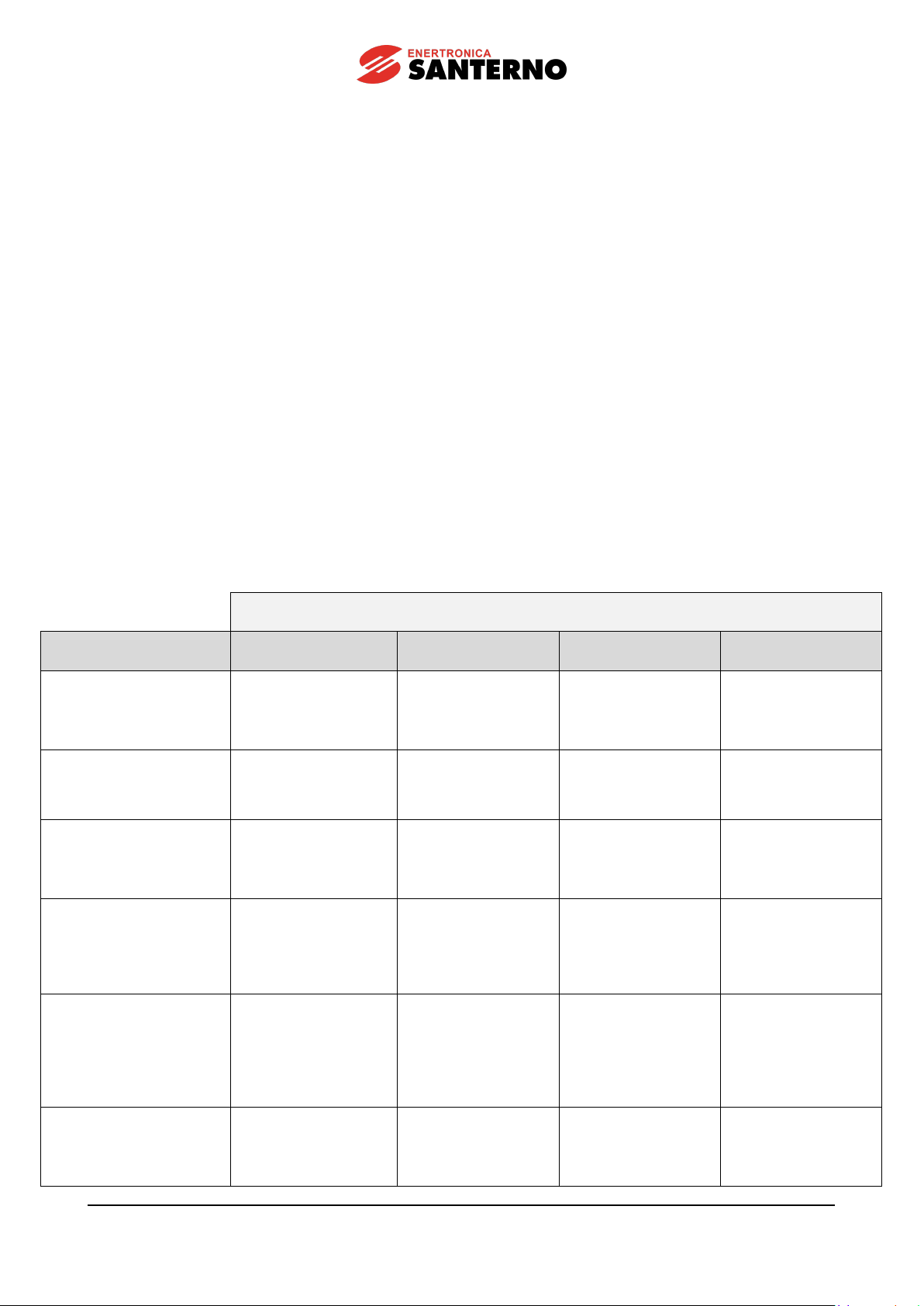

SANTERNO USER MANUALS MENTIONED IN THIS GUIDE

The following Santerno User Manuals are mentioned throughout this User Manual:

User Manual Part Number

User Manual

Sinus Penta

Penta Marine

Iris Blue

Solardrive Plus

Programming Guide

15R0102B200 SINUS

PENTA Programming

Guide

15R0102B200 SINUS

PENTA Programming

Guide

15R1102B200 IRIS

BLUE Programming

Guide

15P00SDB100

SOLARDRIVE PLUS

Installation and

Programming Guide

Installation Guide

15P0102B1 SINUS

PENTA Installation

Guide

15P0102B1 SINUS

PENTA Installation

Guide

15P1102B100 IRIS

BLUE Installation

Guide

15P00SDB100

SOLARDRIVE PLUS

Installation and

Programming Guide

Guide to the Regenerative

Application

15Q0102B00 SINUS

PENTA –Guide to the

Regenerative

Application

15Q0102B00 SINUS

PENTA –Guide to the

Regenerative

Application

N/A

N/A

Guide to the

Synchronous Motor

Application

15Q0102B200 SINUS

PENTA –Guide to the

Synchronous Motor

Application

15Q0102B200 SINUS

PENTA - Guide to the

Synchronous Motor

Application

N/A

N/A

PROFIdrive

COMMUNICATIONS

BOARD –Installation and

Programming Guide

15G0010B1

PROFIdrive

COMMUNICATIONS

BOARD –Installation

and Programming

Guide

15G0010B1

PROFIdrive

COMMUNICATIONS

BOARD - Installation

and Programming

Guide

15G0010B1

PROFIdrive

COMMUNICATIONS

BOARD - Installation

and Programming

Guide

15G0010B1

PROFIdrive

COMMUNICATIONS

BOARD - Installation

and Programming

Guide

BRIDGE MINI –User

Manual

15P4600B100

BRIDGE MINI –User

Manual

15P4600B100

BRIDGE MINI –User

Manual

15P4600B100

BRIDGE MINI –User

Manual

15P4600B100

BRIDGE MINI –User

Manual

USER MANUAL

MOTOR DRIVES

ACCESSORIES

3/312

User Manual Part Number

User Manual

Sinus Penta

Penta Marine

Iris Blue

Solardrive Plus

Sine Filters –User

Manual

15N0040B100 Sine

Filters –User Manual

15N0040B100 Sine

Filters –User Manual

15N0040B100 Sine

Filters –User Manual

15N0040B100 Sine

Filters –User Manual

Assembly Instructions for

Through-panel Kit S22

15W0102B100 SINUS

PENTA - Assembly

Instructions for

Through-panel Kit S22

15W0102B100 SINUS

PENTA - Assembly

Instructions for

Through-panel Kit S22

N/A

15W0102B100 SINUS

PENTA - Assembly

Instructions for

Through-panel Kit S22

Assembly Instructions for

Through-panel Kit S32

15W0102B200 SINUS

PENTA - Assembly

Instructions for

Through-panel Kit S32

15W0102B200 SINUS

PENTA - Assembly

Instructions for

Through-panel Kit S32

N/A

15W0102B200 SINUS

PENTA - Assembly

Instructions for

Through-panel Kit S32

Safe Torque Off Function

–Application Manual

15W0102B300 Safe

Torque Off Function –

Application Manual

15W0102B300 Safe

Torque Off Function –

Application Manual

15W0102B300 Safe

Torque Off Function –

Application Manual

15W0102B300 Safe

Torque Off Function –

Application Manual

AC/DC Units

15P0102B300 AC/DC

UNIT 465 –AC/DC

UNIT 1050

15P0102B300 AC/DC

UNIT 465 –AC/DC

UNIT 1050

N/A

N/A

RemoteDrive

16B0901B1 Remote

Drive REMOTE

CONTROL –User

Manual

16B0901B1 Remote

Drive DRIVE REMOTE

CONTROL –User

Manual

N/A

N/A

BU600 –Programming

Guide

15R0102B500 BU600 –

Programming Guide

15R0102B500 BU600

–Programming Guide

N/A

N/A

MOTOR DRIVES

ACCESSORIES

USER MANUAL

4/312

TABLE OF CONTENTS

REVISION INDEX......................................................................................................... 2

SANTERNO USER MANUALS MENTIONED IN THIS GUIDE.................................... 2

1. OVERVIEW.............................................................................................................16

2. POWER SUPPLY UNIT FOR DRIVES S41..S52 (SU465)......................................16

2.1. DELIVERY CHECK................................................................................................17

2.2. INSTALLING AND OPERATING THE SU465........................................................17

2.3. SU465 NAMEPLATE..............................................................................................17

2.4. SU465 OPERATING MODE...................................................................................18

2.4.1. SU465 OPERATION AS A 12-PULSE SUPPLY UNIT................................................ 18

2.5. SYSTEM REQUIREMENTS...................................................................................19

2.6. TECHNICAL SPECIFICATIONS ............................................................................19

2.7. INSTALLING THE SU465 ......................................................................................20

2.7.1. ENVIRONMENTAL REQUIREMENTS FOR THE SU465 INSTALLATION, STORAGE

AND TRANSPORT ...................................................................................................... 20

2.7.2. MOUNTING THE SU465 ............................................................................................. 21

2.7.3. IP21 KIT....................................................................................................................... 22

2.7.4. THROUGH-PANEL KIT ............................................................................................... 23

2.7.5. NEMA1 KIT.................................................................................................................. 24

2.7.6. POWER TERMINALS AND SIGNAL TERMINALS LAYOUT...................................... 25

2.7.7. SIGNAL CONNECTIONS ............................................................................................ 26

2.7.8. WIRING THE SU465 ................................................................................................... 29

2.8. CROSS-SECTIONS OF THE POWER CABLES AND SIZES OF THE PROTECTIVE

DEVICES WHEN THE SU465 IS INSTALLED.......................................................30

2.9. EARTH BONDING OF THE SU465........................................................................31

2.10. SCHEDULED MAINTENANCE OF THE SU465.....................................................31

2.11. INDUCTORS TO BE APPLIED TO THE DRIVE AND THE SU465 –12-PULSE

CONNECTION.......................................................................................................31

2.12. INDUCTORS TO BE APPLIED TO THE DRIVE AND THE SU465 –18-PULSE

CONNECTION.......................................................................................................32

3. RESISTIVE BRAKING.............................................................................................33

3.1 BRAKING RESISTORS TO BE SUPPLIED TO THE DRIVES EQUIPPED WITH

INTERNAL BRAKING UNIT...................................................................................34

3.1.1. APPLICATIONS WITH DUTY CYCLE 10% - CLASS 2T............................................ 35

3.1.2. APPLICATIONS WITH DUTY CYCLE 20% - CLASS 2T............................................ 36

3.1.3. APPLICATIONS WITH DUTY CYCLE 50% - CLASS 2T............................................ 37

3.1.4. APPLICATIONS WITH DUTY CYCLE 10% - CLASS 4T............................................ 38

3.1.5. APPLICATIONS WITH DUTY CYCLE 20% - CLASS 4T............................................ 39

3.1.6. APPLICATIONS WITH DUTY CYCLE 50% - CLASS 4T............................................ 40

USER MANUAL

MOTOR DRIVES

ACCESSORIES

5/312

3.1.7. APPLICATIONS WITH DUTY CYCLE 10% - CLASS 5T............................................ 41

3.1.8. APPLICATIONS WITH DUTY CYCLE 20% - CLASS 5T............................................ 42

3.1.9. APPLICATIONS WITH DUTY CYCLE 50% - CLASS 5T............................................ 43

3.1.10. APPLICATIONS WITH DUTY CYCLE 10% - CLASS 6T............................................ 44

3.1.11. APPLICATIONS WITH DUTY CYCLE 20% - CLASS 6T............................................ 45

3.1.12. APPLICATIONS WITH DUTY CYCLE 50% - CLASS 6T............................................ 46

3.2. BRAKING UNIT (BU200 2T-4T) FOR S41-S51 AND S60-S60P.............................47

3.2.1. DELIVERY CHECK...................................................................................................... 47

3.2.2. OPERATION................................................................................................................ 49

3.2.3. CONFIGURATION JUMPERS..................................................................................... 49

3.2.4. ADJUSTING TRIMMERS ............................................................................................ 50

3.2.5. INDICATOR LEDS....................................................................................................... 51

3.2.6. RATINGS..................................................................................................................... 51

3.2.7. INSTALLING THE BU200............................................................................................ 52

3.2.8. EARTH BONDING OF THE BU200............................................................................. 56

3.2.9. SCHEDULED MAINTENANCE OF THE BU200......................................................... 56

3.2.10. BRAKING RESISTORS FOR BU200 2T..................................................................... 57

3.2.11. BRAKING RESISTORS FOR BU200 4T..................................................................... 59

3.3. BRAKING UNITS FOR S41..S52 AND THEIR PARALLEL CONFIGURATION AND

DRIVES S60-S60P (BU600 4T-5T-6T)...................................................................61

3.3.1. DELIVERY CHECK...................................................................................................... 61

3.3.2. OPERATING MODE OF THE BU600 CONNECTED TO DRIVES S41..S52 AND THEIR

CONFIGURATION IN PARALLEL............................................................................... 62

3.3.3. OPERATING MODE OF THE BU600 WHEN CONNECTED TO S60 AND S60P

DRIVES OR A DC-BUS MADE UP OF SINUS PENTA /PENTA MARINE DRIVES

FROM DIFFERENT SIZES.......................................................................................... 63

3.3.4. BU600 USED AS A GENERAL-PURPOSE BRAKING UNIT TO BE CONNECTED TO A

DC-BUS ....................................................................................................................... 63

3.3.5. DIAGNOSTICS ............................................................................................................ 64

3.3.6. SPECIFICATIONS....................................................................................................... 65

3.3.7. INSTALLING THE BU600............................................................................................ 65

3.3.8. EARTH BONDING OF THE BU600............................................................................. 74

3.3.9. PROTECTING THE BRAKING RESISTORS.............................................................. 74

3.3.10. SCHEDULED MAINTENANCE OF THE BU600......................................................... 74

3.3.11. BRAKING RESISTORS TO BE APPLIED TO BU600 4T ........................................... 75

3.3.12. BRAKING RESISTORS TO BE APPLIED TO BU600 5T-6T...................................... 78

3.3.13. SERIAL COMMUNICATIONS...................................................................................... 83

3.3.14. AUXILIARY POWER SUPPLY .................................................................................... 86

3.4. BRAKING UNIT BU1440 FOR MODULAR INVERTERS (BU1440 4T AND BU1440

5T-6T)....................................................................................................................87

3.4.1. DELIVERY CHECK...................................................................................................... 87

3.4.2. OPERATION................................................................................................................ 88

3.4.3. RATINGS..................................................................................................................... 88

3.4.4. INSTALLING THE BU1440.......................................................................................... 89

MOTOR DRIVES

ACCESSORIES

USER MANUAL

6/312

3.4.5. EARTH BONDING OF THE BU1440........................................................................... 97

3.4.6. SCHEDULED MAINTENANCE OF THE BU1440....................................................... 97

3.4.7. BRAKING RESISTORS FOR BU1440 4T................................................................... 97

3.4.8. BRAKING RESISTORS FOR BU1440 5T-6T............................................................ 100

3.5. AVAILABLE BRAKING RESISTORS ...................................................................104

3.5.1. 350W MODELS (IP55)............................................................................................... 104

3.5.2. 550W MODELS (IP33)............................................................................................... 105

3.5.3. IP54 MODELS FROM 1100W TO 2200W................................................................. 106

3.5.4. IP20 MODELS FROM 4KW-8KW-12KW................................................................... 108

3.5.5. IP23 BOXES FROM 4KW TO 64KW......................................................................... 110

4. NEMA 1 GLANDKIT ..............................................................................................119

4.1.1. NAMEPLATE NEMA 1 GLANDKIT............................................................................ 119

4.2. IDENTICATION DATA .........................................................................................120

4.2.1. 2T-4T VOLTAGE CLASSES...................................................................................... 120

4.2.2. 5T-6T VOLTAGE CLASSES...................................................................................... 120

4.2.3. OVERALL DIMENSIONS WHEN INSTALLING AN INVERTER WITH THE NEMA 1

GLANDKIT................................................................................................................. 121

5. KEYPAD REMOTING KIT.....................................................................................122

5.1. REMOTING THE KEYPAD ON THE CABINET....................................................122

6. INDUCTORS.........................................................................................................123

6.1. INPUT INDUCTORS............................................................................................123

6.2. OUTPUT INDUCTORS (DU/DT FILTERS)...........................................................126

6.3. APPLYING THE INDUCTOR TO THE INVERTER...............................................127

6.3.1. CLASS 2T –AC AND DC INDUCTORS.................................................................... 127

6.3.2. CLASS 4T –AC AND DC INDUCTORS.................................................................... 128

6.3.3. CLASS 5T-6T –AC AND DC INDUCTORS .............................................................. 129

6.4. INDUCTANCE RATINGS.....................................................................................130

6.4.1. CLASS 2T-4T –AC 3-PHASE INDUCTORS............................................................. 130

6.4.2. CLASS 5T-6T –AC 3-PHASE INDUCTORS............................................................. 130

6.4.3. CLASS 2T-4T –DC INDUCTORS............................................................................. 132

6.4.4. CLASS 5T-6T –DC INDUCTORS............................................................................. 132

6.4.5. CLASS 2T, 4T, 5T, 6T –3-PHASE DU/DT INDUCTORS ......................................... 134

6.5. CLASS 2T –3-PHASE AC INDUCTORS IN IP54 CABINET................................135

6.6. CLASS 4T –3-PHASE AC INDUCTORS IN IP54 CABINET................................136

6.7. CLASS 5T-6T –3-PHASE AC INDUCTORS IN IP54 CABINET...........................138

6.8. OUTPUT SINGLE-PHASE INDUCTORS FOR MODULAR INVERTERS S75, S80,

S90 140

6.8.1. AC SINGLE-PHASE INDUCTORS –CLASS 4T-5T-6T............................................ 140

6.9. SINE FILTERS.....................................................................................................141

6.10. OUTPUT TOROIDAL FILTERS............................................................................142

7. ES836/2 ENCODER BOARD (SLOT A)................................................................143

7.1. IDENTIFICATION DATA ......................................................................................143

USER MANUAL

MOTOR DRIVES

ACCESSORIES

7/312

7.2. ENVIRONMENTAL REQUIREMENTS.................................................................144

7.3. ELECTRICAL SPECIFICATIONS.........................................................................144

7.4. INSTALLING ES836/2 ENCODER BOARD ON THE INVERTER (SLOT A).........145

7.5. TERMINALS IN ENCODER BOARD....................................................................146

7.6. CONFIGURATION DIP-SWITCHES ....................................................................146

7.7. JUMPER SELECTING THE TYPE OF ENCODER SUPPLY................................147

7.8. ADJUSTING TRIMMER .......................................................................................148

7.9. ENCODER WIRING AND CONFIGURATION......................................................148

7.10. WIRING THE ENCODER CABLE ........................................................................153

8. ES913 LINE DRIVER ENCODER BOARD (SLOT A)............................................154

8.1. IDENTIFICATION DATA ......................................................................................154

8.2. ENVIRONMENTAL REQUIREMENTS.................................................................154

8.3. ELECTRICAL SPECIFICATIONS.........................................................................155

8.4. INSTALLING THE LINE DRIVER BOARD ON THE INVERTER (SLOT A) ..........156

8.5. TERMINALS IN THE LINE DRIVER ENCODER BOARD.....................................157

8.6. CONFIGURATION DIP-SWITCHES ....................................................................157

8.7. ENCODER SUPPLY SELECTION JUMPER........................................................158

8.8. ADJUSTING TRIMMER .......................................................................................159

9. ES860 SIN/COS ENCODER BOARD (SLOT A) ...................................................160

9.1. IDENTIFICATION DATA ......................................................................................162

9.2. INSTALLING ES860 BOARD ON THE INVERTER (SLOT A)..............................162

9.2.1. SIN/COS ENCODER CONNECTOR......................................................................... 164

9.3. ES860 CONFIGURATION AND OPERATING MODES .......................................165

9.3.1. CONFIGURING AND ADJUSTING THE ENCODER SUPPLY VOLTAGE............... 166

9.4. CONNECTING THE ENCODER CABLE..............................................................167

9.5. ENVIRONMENTAL REQUIREMENTS.................................................................168

9.6. ELECTRICAL RATINGS ......................................................................................168

10. ES822 ISOLATED SERIAL BOARD (SLOT B).............................................170

10.1. IDENTIFICATION DATA ......................................................................................170

10.2. ENVIRONMENTAL REQUIREMENTS.................................................................170

10.3. ELECTRICAL FEATURES...................................................................................171

10.4. INSTALLING ES822 BOARD ON THE INVERTER (SLOT B)..............................172

10.5. JUMPER FOR RS232/RS485 SELECTION .........................................................173

10.6. DIP-SWITCH FOR RS485 TERMINATOR...........................................................173

11. OPTION BOARDS FOR FIELDBUS (SLOT B).............................................174

11.1. IDENTIFICATION DATA ......................................................................................175

11.2. INSTALLING THE FIELDBUS BOARD ON THE INVERTER (SLOT B) ...............176

11.3. STATUS LEDS ON THE B40 SERIES BOARDS.................................................178

11.3.1. NSTA/MSTA LEDS - PROFIBUS DP ........................................................................ 178

11.3.2. NSTA/MSTA LEDS - DEVICENET............................................................................ 178

MOTOR DRIVES

ACCESSORIES

USER MANUAL

8/312

11.3.3. NSTA/MSTA LEDS - PROFINET............................................................................... 179

11.3.4. NSTA/MSTA LEDS LEDS - MODBUS/TCP.............................................................. 179

11.3.5. NSTA/MSTA LEDS - ETHERNET IP......................................................................... 179

11.3.6. NSTA/MSTA LEDS - ETHERCAT ............................................................................. 179

11.3.7. PROFINET LINK LEDS ............................................................................................. 180

11.3.8. MODBUS/TCP LINK LEDS........................................................................................ 180

11.3.9. ETHERNET IP LINK LEDS........................................................................................ 180

11.3.10. ETHERCAT LINK LEDS ............................................................................... 180

11.4. STATUS LEDS ON THE ANYBUS-S BOARDS ...................................................182

11.4.1. LEDS FOR FIELDBUS INTERFACE CPU DIAGNOSTICS ...................................... 182

11.4.2. LEDS FOR PROFIBUS-DP®BOARD DIAGNOSTICS.............................................. 183

11.4.3. LEDS FOR DEVICENET®BOARD DIAGNOSTICS.................................................. 183

11.4.4. LEDS FOR CANOPEN®BOARD DIAGNOSTICS..................................................... 184

11.4.5. LEDS FOR ETHERNET BOARD DIAGNOSTICS..................................................... 184

11.5. B40 SERIES BOARD FOR PROFIBUS-DP®.......................................................185

11.5.1. PROFIBUS® FIELDBUS CONNECTOR................................................................... 186

11.5.2. BUS CONFIGURATION ............................................................................................ 186

11.5.3. CONNECTION TO THE FIELDBUS.......................................................................... 187

11.6. B40 SERIES BOARDS FEATURING ETHERNET INTERFACE (PROFINET IRT,

MODBUS/TCP, ETHERCAT, ETHERNET/IP)......................................................188

11.6.1. ETHERNET CONNECTOR ....................................................................................... 189

11.6.2. CONNECTION TO THE NETWORK......................................................................... 189

11.6.3. CONFIGURING B40 SERIES BOARDS WITH ETHERNET INTERFACE............... 190

11.7. B40 SERIES BOARD FOR DEVICENET®............................................................193

11.7.1. FIELDBUS DEVICENET TERMINAL BOARD........................................................... 193

11.7.2. CONNECTION TO THE FIELDBUS.......................................................................... 194

11.8. ANYBUS-S PROFIBUS-DP®BOARD ..................................................................195

11.8.1. PROFIBUS® FIELDBUS CONNECTOR................................................................... 196

11.8.2. CONFIGURATION OF THE PROFIBUS-DP COMMUNICATIONS BOARD ............ 196

11.8.3. CONNECTION TO THE FIELDBUS.......................................................................... 198

11.9. ANYBUS-S PROFIDRIVE®BOARD.....................................................................199

11.10. ANYBUS-S DEVICENET®BOARD.............................................................199

11.10.1. DEVICENET®FIELDBUS TERMINALS........................................................ 200

11.10.2. BOARD CONFIGURATION.......................................................................... 200

11.10.3. CONNECTION TO THE FIELDBUS............................................................. 201

11.11. ANYBUS-S CANOPEN®FIELDBUS BOARD..............................................202

11.11.1. CANOPEN®FIELDBUS CONNECTOR........................................................ 203

11.11.2. BOARD CONFIGURATION.......................................................................... 203

11.11.3. CONNECTION TO THE FIELDBUS............................................................. 204

11.12. ANYBUS-S ETHERNET BOARD FOR MODBUS/TCP...............................205

11.12.1. ETHERNET CONNECTOR........................................................................... 206

11.12.2. CONNECTION TO THE NETWORK ............................................................ 206

USER MANUAL

MOTOR DRIVES

ACCESSORIES

9/312

11.12.3. CONFIGURATION OF THE ETHERNET BOARD FOR MODBUS/TCP...... 208

11.13. ENVIRONMENTAL REQUIREMENTS COMMON TO ALL BOARDS .........215

12. ES919 COMMUNICATIONS BOARD (SLOT B)...........................................216

12.1. IDENTIFICATION DATA ......................................................................................216

12.2. ENVIRONMENTAL REQUIREMENTS COMMON TO ALL BOARDS ..................216

12.3. ELECTRICAL FEATURES COMMON TO ALL BOARDS.....................................217

12.4. INSTALLING THE ES919 BOARD ON THE DRIVE (SLOT B).............................217

12.4.1. ES919 BOARD FOR METASYS®N2........................................................................ 218

12.4.2. CONFIGURATION..................................................................................................... 219

12.4.3. RS485 CONNECTOR................................................................................................ 219

12.4.4. LEDS ON THE ASP485 PROTOCESSOR MODULE ............................................... 219

12.4.5. BAUD RATE DIP-SWITCHES................................................................................... 220

12.4.6. ADDRESS DIP-SWITCHES ...................................................................................... 220

12.5. ES919 BOARD FOR BACNET/ETHERNET.........................................................220

12.5.1. ETHERNET CONNECTOR ....................................................................................... 221

12.5.2. LEDS ON THE FFP485 PROTOCESSOR MODULE................................................ 221

12.5.3. TROUBLESHOOTING TIPS...................................................................................... 222

12.5.4. BOARD CONFIGURATION....................................................................................... 223

12.6. ES919 BOARD FOR BACNET/RS485.................................................................224

12.6.1. RS485 CONNECTOR................................................................................................ 224

12.6.2. BOARD CONFIGURATION....................................................................................... 225

13. BRIDGE MINI (SLOT B)................................................................................226

13.1. IDENTIFICATION DATA ......................................................................................227

13.2. INSTALLING THE BOARD ON THE INVERTER (SLOT B)..................................227

13.3. CONNECTIVITY ..................................................................................................227

14. ES847 I/O EXPANSION BOARD (SLOT C)..................................................228

14.1. IDENTIFICATION DATA ......................................................................................229

14.2. INSTALLING ES847 BOARD ON THE INVERTER (SLOT C)..............................229

14.3. ES847 BOARD TERMINALS ...............................................................................231

14.4. CONFIGURATION DIP-SWITCHES ....................................................................233

14.5. POSSIBLE SETTINGS FOR DIP-SWITCHES SW1 AND SW2............................234

14.6. WIRING DIAGRAMS............................................................................................236

14.6.1. CONNECTION OF “FAST” DIFFERENTIAL ANALOG INPUTS............................... 236

14.6.2. CONNECTION OF “FAST” CURRENT INPUTS....................................................... 237

14.6.3. CONNECTING “SLOW” ANALOG INPUTS TO VOLTAGE SOURCES ................... 237

14.6.4. CONNECTING “SLOW” ANALOG INPUTS TO CURRENT SOURCES................... 238

14.6.5. CONNECTING “SLOW” ANALOG INPUTS TO THERMISTOR PT100.................... 238

14.6.6. CONNECTING ISOLATED DIGITAL INPUTS........................................................... 239

14.6.7. CONNECTION TO AN ENCODER OR A FREQUENCY INPUT.............................. 240

14.6.8. CONNECTION TO ISOLATED DIGITAL OUTPUTS................................................. 241

14.7. ENVIRONMENTAL REQUIREMENTS.................................................................242

MOTOR DRIVES

ACCESSORIES

USER MANUAL

10/312

14.8. ELECTRICAL RATINGS ......................................................................................243

14.8.1. ANALOG INPUTS...................................................................................................... 243

14.8.2. DIGITAL INPUTS....................................................................................................... 245

14.8.3. DIGITAL OUTPUTS................................................................................................... 246

14.8.4. SUPPLY OUTPUTS................................................................................................... 246

15. ES870 RELAY I/O EXPANSION BOARD (SLOT C).....................................247

15.1. IDENTIFICATION DATA ......................................................................................247

15.2. INSTALLING ES870 BOARD ON THE INVERTER (SLOT C)..............................248

15.3. ES870 BOARD TERMINALS ...............................................................................249

15.4. CONNECTION TO AN ENCODER OR A FREQUENCY INPUT ..........................250

16. I/O EXPANSION BOARD 120/240VAC ES988 (SLOT C) ............................251

16.1. IDENTIFICATION DATA ......................................................................................252

16.2. INSTALLING THE ES988 OPTION BOARD ON THE DRIVES (SLOT C)............252

16.3. DIGITAL INPUT TERMINALS AND RELAY OUTPUT..........................................255

16.4. ES988 OPERATING MODE.................................................................................256

16.5. MAIN FEATURES................................................................................................258

16.6. ENVIRONMENTAL CONDITIONS.......................................................................258

16.7. ELECTRICAL SPECIFICATIONS.........................................................................259

17. ES861 RESOLVER AND INCREMENTAL ENCODER BOARD (SLOT C)...261

17.1. IDENTIFICATION DATA ......................................................................................262

17.2. INSTALLING ES861 BOARD ON THE INVERTER (SLOT C)..............................263

17.2.1. RESOLVER CONNECTOR ....................................................................................... 265

17.2.2. INCREMENTAL ENCODER AND DIGITAL LINES CONNECTORS........................ 266

17.3. ES861 CONFIGURATION AND OPERATING MODES .......................................267

17.4. CONFIGURING AND ADJUSTING THE ENCODER SUPPLY VOLTAGE...........267

17.5. CONNECTING THE RESOLVER CABLE............................................................269

17.6. ENVIRONMENTAL REQUIREMENTS.................................................................270

17.7. ELECTRICAL RATINGS ......................................................................................270

18. ES950 BISS/ENDAT ENCODER BOARD (SLOT C)....................................272

18.1. IDENTIFICATION DATA ......................................................................................274

18.2. INSTALLING ES950 BOARD ON THE INVERTER (SLOT C)..............................275

18.2.1. BISS/ENDAT ENCODER CONNECTOR.................................................................. 277

18.2.2. INCREMENTAL ENCODER AND DIGITAL LINE CONNECTORS........................... 278

18.3. ES950 CONFIGURATION AND OPERATING MODES .......................................279

18.3.1. BISS OPERATING MODE......................................................................................... 280

18.3.2. ENDAT OPERATING MODE..................................................................................... 280

18.3.3. CONFIGURING AND ADJUSTING THE ENCODER SUPPLY VOLTAGE............... 280

18.4. CONNECTING THE ENCODER CABLE..............................................................282

18.4.1. ENVIRONMENTAL REQUIREMENTS...................................................................... 284

18.4.2. ELECTRICAL RATINGS............................................................................................ 284

USER MANUAL

MOTOR DRIVES

ACCESSORIES

11/312

19. ES966 ENCODER BOARD HIPERFACE (SLOT C).....................................286

19.1. PART NUMBER...................................................................................................288

19.2. INSTALLING THE ES966 BOARD ON THE INVERTER (SLOT C)......................288

19.3. HIPERFACE® ENCODER CONNECTOR............................................................291

19.4. INCREMENTAL ENCODER CONNECTORS AND DIGITAL LINES ....................292

19.5. OPERATING MODE AND CONFIGURATION OF HIPERFACE ENCODER BOARD

293

19.6. HIPERFACE® OPERATING MODE.....................................................................294

19.7. CONFIGURING AND ADJUSTING THE ENCODER SUPPLY VOLTAGE...........295

19.8. TEMPERATURE SENSOR CONFIGURATION....................................................297

19.9. CONNECTING THE ENCODER CABLE..............................................................297

19.10. ENVIRONMENTAL REQUIREMENTS........................................................299

19.11. ELECTRICAL SPECIFICATIONS................................................................299

20. ES914 POWER SUPPLY UNIT BOARD.......................................................301

20.1. IDENTIFICATION DATA ......................................................................................303

20.2. WIRING ES914 BOARD.......................................................................................303

21. “LOC-0-REM” KEY SELECTOR SWITCH AND EMERGENCY PUSH-BUTTON

FOR IP54 MODELS ..............................................................................................308

21.1. WIRING IP54 INVERTERS WITH OPTIONAL “LOC-0-REM” KEY SELECTOR

SWITCH AND EMERGENCY PUSH-BUTTON....................................................310

22. INDEX...........................................................................................................311

MOTOR DRIVES

ACCESSORIES

USER MANUAL

12/312

Index of Figures

Figure 1: Nameplate for SU465....................................................................................................................... 17

Figure 2: The SU465 in 12-pulse configuration............................................................................................... 18

Figure 3: The SU465 as a supply unit of a conversion unit............................................................................. 18

Figure 4: Dimensions and fixing points for the SU465 .................................................................................... 21

Figure 5: Overall dimensions when using IP21 kit .......................................................................................... 22

Figure 6: Dimensions and fixing points when using the through-panel kit for the SU465............................... 23

Figure 7: NEMA1 kit and kit installation on the SU465.................................................................................... 24

Figure 8: Overall dimensions when installing the NEMA1 kit.......................................................................... 24

Figure 9: Power terminals................................................................................................................................ 25

Figure 10: Position of the jumpers in the ES840/1 board................................................................................ 28

Figure 11: Signal terminal board ..................................................................................................................... 28

Figure 12: Example of a 9-pin shielded cable for signal connection............................................................... 29

Figure 13: S41–S52 connections with 12- and 18-pulse SU465..................................................................... 29

Figure 14: Nameplate for BU200 2T-4T.......................................................................................................... 48

Figure 15: Positions of BU200 configuration jumpers ..................................................................................... 49

Figure 16: Positions of BU200 adjusting trimmers .......................................................................................... 50

Figure 17: Position of the Indicator LEDs........................................................................................................ 51

Figure 18: Dimensions and fixing points of BU200 ......................................................................................... 53

Figure 19: Terminals in BU200........................................................................................................................ 54

Figure 20: Connecting one BU200 to the inverter........................................................................................... 55

Figure 21: Master –Slave multiple connection................................................................................................ 56

Figure 22: Nameplate for BU600 4T-5T-6T..................................................................................................... 61

Figure 23: BRAKE connector supplied with the drive...................................................................................... 62

Figure 24: Cable connecting the drive to braking unit BU600......................................................................... 62

Figure 25: Diagnostic LEDs............................................................................................................................. 64

Figure 26: Dimensions and fixing points of braking unit BU600...................................................................... 66

Figure 27: Power terminals.............................................................................................................................. 68

Figure 28: Signal terminals in the BU600........................................................................................................ 70

Figure 29: Wiring diagram of a single drive with braking unit BU600.............................................................. 71

Figure 30: Signal connections of two BU600 operating as slaves .................................................................. 72

Figure 31: Power connections and location of two BU600 operating as slaves.............................................. 73

Figure 32: Example of direct and multidrop connection .................................................................................. 83

Figure 33: Recommended wiring diagram for “2-wire” MODBUS connection................................................. 85

Figure 34: Nameplate for BU1440 4T.............................................................................................................. 87

Figure 35: Dimensions and fixing points of BU1440 ....................................................................................... 90

Figure 36: External power connections for modular inverters S65-S70 provided with BU1440 ..................... 92

Figure 37: External power connections for modular inverters S75-S80 provided with BU1440 ..................... 93

Figure 38: ES841 Unit gate board for the braking unit.................................................................................... 94

Figure 39: Connection points on ES842 for the braking unit optical fibres ..................................................... 95

Figure 40: Internal wiring of inverters S65-S70 provided with a braking unit.................................................. 96

Figure 41: Overall dimensions, 350W resistor............................................................................................... 104

Figure 42: Overall dimensions for 550W braking resistor ............................................................................. 105

Figure 43: Overall dimensions for braking resistors from 1100W to 2200W................................................. 106

Figure 44: Overall dimensions for braking resistors 4kW, 8kW, 12kW ......................................................... 108

Figure 45: Overall dimensions of IP23 Box resistors .................................................................................... 110

Figure 46: Position of electrical connections in box resistors........................................................................ 110

Figure 47: Typical nameplate for SINUS PENTA NEMA KIT accessory ...................................................... 119

Figure 48: Example of a NEMA 1 Kit installed on a SINUS PENTA ............................................................. 120

Figure 49: Wiring diagram for optional inductors........................................................................................... 123

Figure 50: Amplitude of harmonic currents (approximate values)................................................................. 125

Figure 51: Output inductor wiring .................................................................................................................. 126

Figure 52: Mechanical features of a 3-phase inductor.................................................................................. 131

Figure 53: Mechanical features of a DC inductor.......................................................................................... 133

Figure 54: Mechanical features of the 3-phase du/dt inductors .................................................................... 134

Figure 55: Mechanical features of three-phase inductors for Class 2T-4T in IP54 cabinet .......................... 137

USER MANUAL

MOTOR DRIVES

ACCESSORIES

13/312

Figure 56: Mechanical features of a 3-phase inductor for Class 5T-6T in IP54 cabinet ............................... 139

Figure 57: Mechanical features of a single-phase output inductor................................................................ 140

Figure 58: Sine filter....................................................................................................................................... 141

Figure 59: Output toroidal filter...................................................................................................................... 142

Figure 59: Encoder board (ES836/2)............................................................................................................. 143

Figure 60: Position of slot A for the installation of the encoder board........................................................... 145

Figure 61: Encoder board fastened to its slot................................................................................................ 145

Figure 62: Positions of DIP-switches and their factory-setting...................................................................... 146

Figure 63: LINE DRIVER or PUSH-PULL encoder with complementary outputs......................................... 149

Figure 64: PUSH-PULL encoder with single-ended outputs......................................................................... 150

Figure 65: PNP or NPN encoder with single-ended outputs and external load resistors.............................. 151

Figure 66: PNP or NPN encoder with single-ended outputs and internal load resistors............................... 152

Figure 67: Wiring the encoder cable.............................................................................................................. 153

Figure 68: ES913 Encoder board.................................................................................................................. 154

Figure 69: Position of slot A for the installation of the encoder board........................................................... 156

Figure 70: Encoder board fastened to its slot................................................................................................ 156

Figure 71: Location of the configuration DIP-switches.................................................................................. 157

Figure 72: Location of the jumpers selecting the encoder supply voltage .................................................... 159

Figure 73: ES860 Sin/Cos Encoder board .................................................................................................... 161

Figure 74: Location of Slot A inside the drive terminal board covers............................................................ 162

Figure 75: Fitting the ES860 board inside the drive ...................................................................................... 163

Figure 76: Pin layout on the high density connector ..................................................................................... 164

Figure 77: DIP-switch SW1 setting in three-channel mode........................................................................... 165

Figure 78: DIP-switch SW1 setting for five-channel mode............................................................................ 165

Figure 79: Position of the jumper and voltage adjusting trimmer.................................................................. 166

Figure 80: Recommended dual shielded connection for encoder cable ....................................................... 167

Figure 81: ES822 board................................................................................................................................. 170

Figure 82: Position of the slot for the installation of the serial isolated board ............................................... 172

Figure 83: Jumper setting RS232/RS485...................................................................................................... 173

Figure 84: Configuration of terminator DIP-switch for line RS485................................................................. 173

Figure 85: Location of the slot B inside the terminal board cover of Santerno drives................................... 176

Figure 86: Checking contacts in the slot B .................................................................................................... 177

Figure 87: Fastening the communications board to slot B............................................................................ 177

Figure 88: Position of the status LEDs on the B40 series board................................................................... 181

Figure 89: Position of indicator LEDs on the board....................................................................................... 182

Figure 90: PROFIBUS-DP®fieldbus communications board ........................................................................ 185

Figure 91: Example of a Profibus network (the correct setting of the line terminators is highlighted) .......... 186

Figure 92: Profibus® FC (FastConnect) connector with line termination settings ........................................ 187

Figure 93: B40 series Fieldbus comms board with Ethernet interface.......................................................... 189

Figure 94: DeviceNET Fieldbus Comms Board............................................................................................. 193

Figure 95: PROFIBUS-DP®fieldbus communications board ........................................................................ 195

Figure 96: Example of a Profibus network (the correct setting of the line terminators is highlighted) .......... 197

Figure 97: Example of the rotary-switch position to set Profibus address “19” ............................................. 197

Figure 98: DeviceNet®Fieldbus communications board............................................................................... 199

Figure 99: Outline of the topology of a DeviceNet trunk line......................................................................... 201

Figure 100: CANopen®fieldbus communications board ............................................................................... 202

Figure 101: Example of the position of the rotary-switches for 125kbits/s and Device Address 29.............. 203

Figure 102: Ethernet Fieldbus Communications Board................................................................................. 205

Figure 103: Cable of Cat. 5 for Ethernet and standard colour arrangement in the connector ...................... 206

Figure 104: Windows 7 - Accessing directly to the network configuration folder .......................................... 209

Figure 105: Setting a computer for a point-to-point connection to the inverter............................................. 210

Figure 106: Setting the DIP-switches to set the IP address 192.168.0.2...................................................... 211

Figure 107: Internal webserver...................................................................................................................... 212

Figure 108: Example of the ping command to the IP address of the inverter interface board...................... 213

Figure 109: Anybus IP config utility ............................................................................................................... 213

Figure 110: Setting ModScan for a Modbus/TCP connection....................................................................... 214

Figure 111: Display of the output variables of the inverter through the Modbus/TCP protocol..................... 214

Figure 112: Position of the slot for ES919 board........................................................................................... 218

Figure 113: ES919 Board for Metasys®N2................................................................................................... 218

Figure 114: RS485 connector for Metasys®N2............................................................................................. 219

Figure 115: ES919 Board for BACnet/Ethernet............................................................................................. 220

MOTOR DRIVES

ACCESSORIES

USER MANUAL

14/312

Figure 116: BACnet LEDs ............................................................................................................................. 221

Figure 117: BACnet IP Configuration ............................................................................................................ 223

Figure 118: ES919 Board for BACnet/RS485 ............................................................................................... 224

Figure 119: RS485 connector for BACnet/RS485......................................................................................... 224

Figure 120: BACnet MSTP Configuration...................................................................................................... 225

Figure 121: Bridge Mini Embedded............................................................................................................... 227

Figure122: Bridge Mini Stand alone .............................................................................................................. 227

Figure 123: Signal conditioning and additional I/Os board (ES847) ............................................................. 229

Figure 124: Removing the inverter cover; location of slot C.......................................................................... 230

Figure 125: Fitting the strips inside ES847 board and fixing the board on slot C ......................................... 230

Figure 126: Connection of a bipolar voltage source to a differential input .................................................... 236

Figure 127: Connection of 0÷20mA (4÷20mA) sensors to “fast” current inputs ............................................ 237

Figure 128: Connecting a voltage source to a “slow” analog input ............................................................... 237

Figure 129: Connecting thermoresistors PT100 to analog channels XAIN8–11 / T1–4 ............................... 238

Figure 130: PNP input wiring......................................................................................................................... 239

Figure 131: Connecting the incremental encoder to fast inputs XMDI7 and XMDI8..................................... 240

Figure 132: Signal sent from a 24V, Push-pull frequency output.................................................................. 240

Figure 133: XMDOx output connection as PNP for relay command with internal power supply .................. 241

Figure 134: XMDOx output connection as PNP for relay command with external power supply ................. 241

Figure 135: XMDOx output connection as NPN for relay command with internal power supply .................. 242

Figure 136: XMDOx output connection as NPN for relay command with external power supply ................. 242

Figure 137: Relay I/O expansion board ES870............................................................................................. 247

Figure 138: Removing the inverter cover; location of slot C.......................................................................... 248

Figure 139: ES988 option board, DIGITAL I/O 120/240 Vrms...................................................................... 251

Figure 140: Location of slot C inside the terminal board cover ..................................................................... 252

Figure 141: Terminal strips inserted into SLOT C......................................................................................... 253

Figure 142: Fastening ES988 option board inside the inverter ..................................................................... 254

Figure 143: Input-output signal terminal blocks............................................................................................. 255

Figure 144: Block diagram for ES988 interfacing.......................................................................................... 256

Figure 145: Utilization example of digital inputs on ES988 option board...................................................... 257

Figure 146: ES861 Incremental Encoder and Resolver expansion board .................................................... 262

Figure 147: Location of slot C inside the terminal board cover of the drives ................................................ 263

Figure 148: Terminal strips inserted into SLOT C......................................................................................... 264

Figure 149: Fitting the ES861 board inside the drive .................................................................................... 264

Figure 150: Pin layout on the D-sub 9-pin female connector........................................................................ 265

Figure 151: Input-output signal terminal boards............................................................................................ 266

Figure 152: Jumpers and trimmer for power supply configuration................................................................ 267

Figure 153: Recommended dual shielded connection for resolver cable ..................................................... 269

Figure 154: ES950 encoder BiSS/EnDat board ............................................................................................ 273

Figure 155: Location of slot C inside the terminal board cover in the drives................................................. 275

Figure 156: Terminal strips inserted into SLOT C......................................................................................... 276

Figure 157: Fitting the ES950 board inside the inverter................................................................................ 276

Figure 158: Pin layout on CN7 D-sub 15-pin female connector.................................................................... 277

Figure 159: Input-output signal terminal board.............................................................................................. 278

Figure 160: Block diagram for ES950 board interface .................................................................................. 279

Figure 161: Jumpers and trimmer for power supply configuration................................................................ 281

Figure 162: Recommended dual shielded connection for encoder cable ..................................................... 283

Figure 163: ES966 Hiperface Encoder Board............................................................................................... 287

Figure 164: Location of slot C inside the terminal board cover of the drive .................................................. 289

Figure 165: Inserting terminal strips to slot C................................................................................................ 289

Figure 166: Fixing the ES966 board inside the drive .................................................................................... 290

Figure 167: Pin layout on HD female D-sub 26 connector............................................................................ 291

Figure 168: Input-output signal terminals...................................................................................................... 292

Figure 169: Block diagram of ES966 interface board.................................................................................... 293

Figure 170: Location of the jumpers, trimmers and DIP-switches of ES966................................................. 296

Figure 171: Connection method recommended for the double-shield encoder cable on ES966.................. 298

Figure 172: ES914 Power supply unit board................................................................................................. 301

Figure 173: Dimensions of ES914 board....................................................................................................... 301

Figure 174: Basic wiring diagram for ES914 board....................................................................................... 302

Figure 175: Block-diagram with 3-zone insulation......................................................................................... 303

Figure 176: Position of the LEDs and DIP-switches in ES914 board............................................................ 307

USER MANUAL

MOTOR DRIVES

ACCESSORIES

15/312

Figure 177: Wiring diagram for IP54 inverters............................................................................................... 310

Index of Tables

Table 1: Product –Power Supply Unit SU465 compatibility............................................................................ 16

Table 2: Product –Resistive braking compatibility.......................................................................................... 33

Table 3: Alarm ID and Type of fault on BU600 with the TYPE OF FAULT LED............................................. 64

Table 4: BU600 Power terminals..................................................................................................................... 67

Table 5: Product –NEMA 1 GLANDKIT compatibility................................................................................... 119

Table 6: Product –Keypad remoting kit compatibility ................................................................................... 122

Table 7: Product –Inductors compatibility..................................................................................................... 123

Table 8: Product –ES836/2 Encoder board compatibility............................................................................. 143

Table 9: Product –ES913 Encoder board compatibility................................................................................ 154

Table 10: Product –ES860 Encoder board compatibility.............................................................................. 160

Table 11: Product –ES822 Optoisolated serial board compatibility ............................................................. 170

Table 12: Product –Fieldbus board compatibility ......................................................................................... 174

Table 13: Product –ES919 Communications board compatibility ................................................................ 216

Table 14: Product –Bridge Mini compatibility ............................................................................................... 226

Table 15: Product - ES847 I/O Expansion board compatibility ..................................................................... 228

Table 16: Product –ES870 I/O Expansion board compatibility .................................................................... 247

Table 17: Product –ES988 I/O Expansion board compatibility .................................................................... 251

Table 18: Product –ES861 Resolver and incremental encoder board compatibility.................................... 261

Table 19: Product –ES950 BISS/EnDat Encoder board compatibility ......................................................... 272

Table 20: Product –ES966 Hiperface Encoder board compatibility............................................................. 286

Table 21: Configuration of incremental encoder power supply..................................................................... 295

Table 22: Configuration of Hiperface encoder power supply ........................................................................ 295

Table 23: DIP-switch configuration for the temperature sensor on ES966 ................................................... 297

Table 24: Configuration of jumper J7 ............................................................................................................ 298

Table 25: Product –ES914 Power Supply Unit board compatibility ............................................................. 301

Table 26: Product –Key selector switch and Emergency push-button for IP54 models compatibility ......... 308

MOTOR DRIVES

ACCESSORIES

USER MANUAL

16/312

1. OVERVIEW

This manual covers the specifications and installation instructions for the option boards and external

accessories available for the following products manufactured by Santerno:

-Sinus Penta

-Penta Marine

-Iris Blue

-Solardrive Plus

The accessory-product compatibility is stated in the Compatibility Table at the beginning of each section in

this manual.

2. POWER SUPPLY UNIT FOR DRIVES S41..S52 (SU465)

Product-Accessory Compatibility

Product

Power Supply Unit SU465

Comments

Sinus Penta

√

Penta Marine

√

Iris Blue

-

Solardrive Plus

-

Table 1: Product –Power Supply Unit SU465 compatibility

The power supply for the S41..S52 drives (see the 12-pulse Connection for Modular Inverters in the

Installation Guide) requires the SU465.

The SU465 must be installed next to the inverter and is to be connected as described below.

Instructions on how to transport, handle and unpack the product, please refer to the general instructions

given in the Transport and Handling and Unpacking in the Installation Guide.

The SU465 may be utilized as a 12-pulse rectifier for the following drive sizes:

1. S41

2. S42

3. S51

4. S52

Alternatively, it may be used as a standard rectifier.

The voltage input must range from 200Vac to 690Vac; the maximum allowable current for the SU465 is

465A.

An 18-pulse connection may be obtained by using N.2 supply units SU465.

The supply unit may also be used as a stand-alone supply unit. Please refer to the specific manual AC/DC

Units.

The SU465 is an Open Type device featuring IP00 degree of protection suitable for installation inside a

cabinet featuring at least IP3X degree of protection.

USER MANUAL

MOTOR DRIVES

ACCESSORIES

17/312

2.1. Delivery Check

Make sure that the equipment is not damaged and that it complies with the equipment you ordered by

referring to the nameplate located on the inverter front part. The inverter nameplate is described below. If the

equipment is damaged, contact the supplier or the insurance company concerned. If the equipment does not

comply with the one you ordered, please contact the supplier as soon as possible.

If the equipment is stored before being started, make sure that the ambient conditions do not exceed the

acceptable ratings (temperature: –25°C to +70°C; relative humidity <95%, no condensation). The equipment

guarantee covers any manufacturing defect. The manufacturer has no responsibility for possible damages

occurred when shipping or unpacking the inverter. The manufacturer is not responsible for possible damages

or faults caused by improper and irrational uses; wrong installation; improper conditions of temperature,

humidity, or the use of corrosive substances. The manufacturer is not responsible for possible faults due to

the inverter operation at values exceeding the inverter ratings and is not responsible for consequential and

accidental damages. The equipment is covered by 2-year guarantee starting from the date of delivery.

2.2. Installing and Operating the SU465

Please refer to the general instructions given in section Installing and Operating the Equipment in the

Installation Guide.

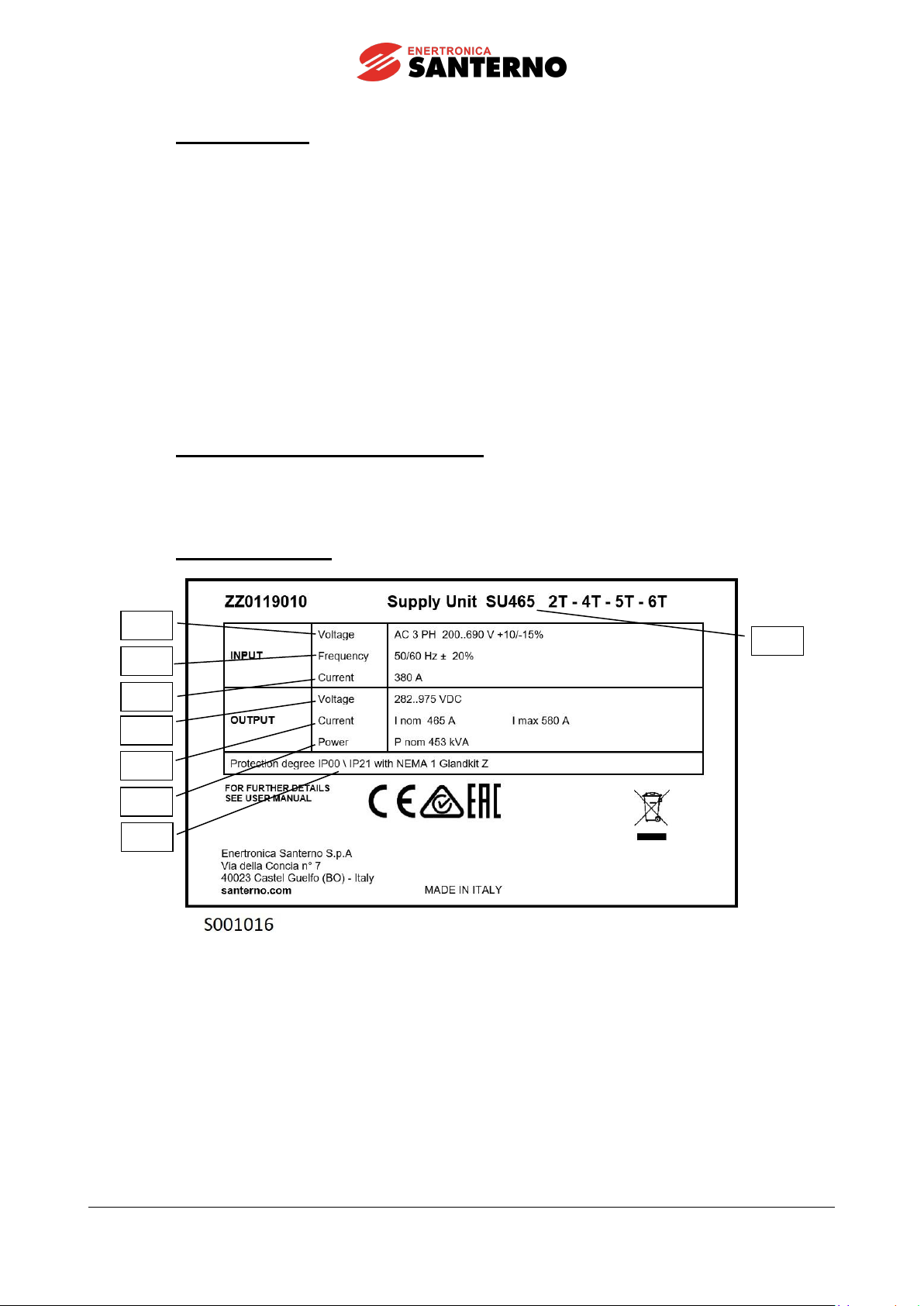

2.3. SU465 Nameplate

Figure 1: Nameplate for SU465

1. Model: SU465

2. Input voltage: 200-690 Vac

3. Input frequency: 50-60 Hz

4. Input current: 380 A nominal current

5. Output voltage: 282-975 Vdc

6. Output current: 465 A nominal 580 A maximum

7. Nominal power: 453 kVA

8. Degree of protection: IP00 \ IP21

2

3

4

5

6

7

8

1

MOTOR DRIVES

ACCESSORIES

USER MANUAL

18/312

2.4. SU465 Operating Mode

The SU465 may operate as follows:

•In parallel to a 12-pulse converter (this solution reduces the harmonic contents to the power supply

mains):

Figure 2: The SU465 in 12-pulse configuration

•As a supply unit for a conversion unit:

Figure 3: The SU465 as a supply unit of a conversion unit

2.4.1. SU465 Operation as a 12-pulse Supply Unit

The 12-pulse supply unit is controlled directly by the drive. When operating as an additional rectifier bridge

for the 12-pulse connection, the following diagnostics functions are performed by the driver board of the

drive:

•Phase detection and measurement

•Heatsink overtemperature measurement and alarm

•Precharge control

USER MANUAL

MOTOR DRIVES

ACCESSORIES

19/312

2.5. System Requirements

As the input current is automatically controlled, the system must meet the following requirements:

•Provide the drive and the supply unit with line inductors as detailed in section Inductors to be Applied

to the Drive and the SU465.

•The three-phase transformer must be:

oSymmetrical

oWith Dy11d0 or Dy5d0 vector unit

oThe secondary output voltages must range:

▪Within 5% of relative variation at full load

▪Within 0.5% under no-load conditions

oThe short-circuit current must be Vsc>4%

•Wiring to the transformer, the supply unit and the drive shall be as close as possible in terms of cable

length and cable cross-section.

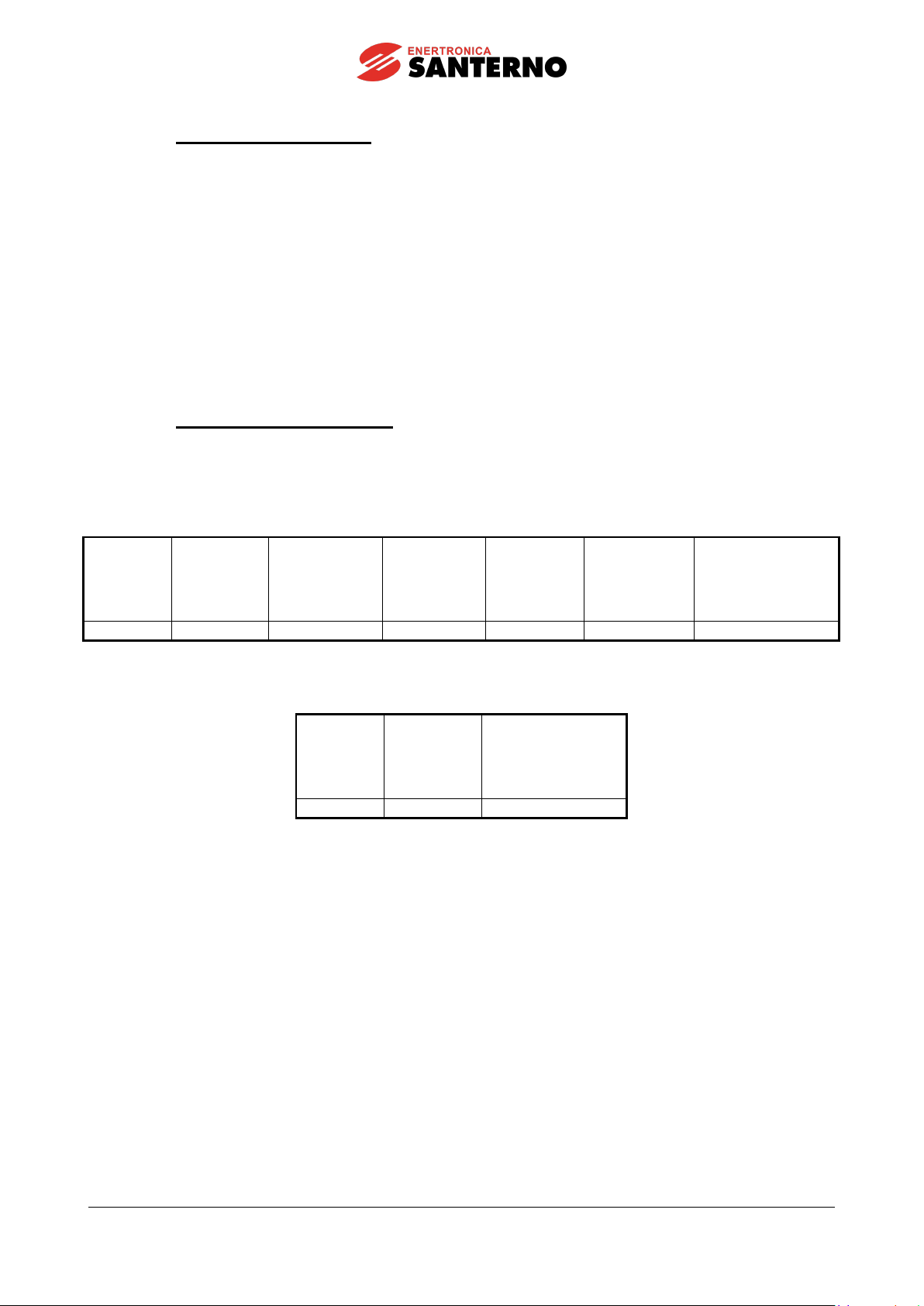

2.6. Technical Specifications

Electrical specifications:

Overvoltage category III (according to EN 61800-5-1)

MODEL

Rated input

current (A)

Supply

voltage

Rated

output

current (A)

Maximum

output

current (A)

Output

voltage

Dissipated power

(at rated current)

(W)

SU465

380

200-690Vac

465

580

0-975Vdc

1160

Mechanical specifications:

MODEL

Degree of

protection

Sound pressure

(dB)

SU465

IP00(*)

57

(*) NEMA1 when using the special optional kit

MOTOR DRIVES

ACCESSORIES

USER MANUAL

20/312

2.7. Installing the SU465

2.7.1. Environmental Requirements for the SU465 Installation, Storage and

Transport

Maximum surrounding air

temperature

–10 to +40°C with no derating

from +40°C to +55°C with 2% derating of the rated current for each

degree beyond +40°C

Ambient temperatures for storage

and transport

–25°C to +70°C.

Installation environment

Pollution degree 2 or better (according to EN 61800-5-1).

Do not install in direct sunlight and in places exposed to conductive dust,

corrosive gases, vibrations, water sprinkling or dripping (depending on IP

ratings); do not install in salty environments.

Altitude

Max. altitude for installation 2000 m a.s.l. For installation above 2000 m

and up to 4000 m, please contact Enertronica Santerno S.p.A..

Above 1000 m, derate the rated current by 1% every 100 m.

Operating ambient humidity

From 5% to 95%, from 1g/m3to 29g/m3, non-condensing and non-

freezing (class 3K3 according to EN 61800-5-1).

Storage ambient humidity

From 5% to 95%, from 1g/m3 to 29g/m3, non-condensing and non-

freezing (class 1K3 according to EN 61800-5-1).

Ambient humidity during transport

Max. 95%, up to 60g/m3; condensation may appear when the equipment

is not running (class 2K3 according to EN 61800-5-1).

Storage and operating

atmospheric pressure

From 86 to 106 kPa (classes 3K3 and 1K4 according to EN 61800-5-1).

Atmospheric pressure during

transport

From 70 to 106 kPa (class 2K3 according to EN 61800-5-1).

CAUTION

Ambient conditions strongly affect the inverter life. Do not install the equipment

in places that do not have the above-mentioned ambient conditions.

This manual suits for next models

3

Table of contents

Popular Media Converter manuals by other brands

Ace Plus

Ace Plus EX-G037 user manual

Delta Electronics

Delta Electronics PMF Series instruction manual

GoMax Electronics

GoMax Electronics CV-910S user manual

ON Semiconductor

ON Semiconductor LM339 Reference manual

Ross

Ross ADC-8432 user manual

Omnitron Systems Technology

Omnitron Systems Technology Omnitron iConverter GX/TM2 user manual