Entec EVRC2A-N6-NT User manual

RECLOSER CONTROL EVRC2A-N6,NT

USER’S MANUAL

ENTEC

ELECTRIC & ELECTRONIC CO., LTD

ENTEC

Copyright © 2002 by ENTEC ELECTRIC & ELECTRONIC CO., LTD all right reserved. Forerunner Distribution & Automation

Release Date: Feb. 2013 / Manual Revision: 7.13

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

i

ENHANCED

TECHNOLOGY

Release Note:

[Oct. 2006] Ver4.00

1. Add explanations for new additional function below

-Support ETHERNET Port(Port4) for EVRC2A

-Support IEC60870-5-104 Protocol Communication (add the setup menu)

[Sept. 2007] Ver4.10

1. Add explanations for new additional function below

-Dialing Modem Support(add the setup menu)

[Sept. 2009] Ver4.12

1. Add explanations for new additional function below

-Support IEC60870-5-101 Protocol Communication (add the setup menu)

-Support Overfrequency Protection Element (add the setup menu)

[Jan. 2010] Ver5.00

After the Ver5.00, the manual is applied to the

“EVRC2A-N(Network type)”

.

1. Support “ETIMS(ENTEC Integration Management Software)” function(add the setup menu).

This function is used to interface with ETIMS over Ethernet port.

2. Separate “Communication” setting into “Protocol” and “Port” settings.

3. Describe elements consisting of “Protection” section in order of the menu shown in LCD.

4. Add “CLOSE Function at Normal Frequency restored” in Frequency element.

5. Add the description related with “STATUS” menu omitted in the previous version.

6. Add the description related with “MAINTENANCE” menu omitted in the previous version.

7. Add “Fault Trip(option)” in “EVENT RECORDER” menu.

[Jul. 2010] Ver5.10

1. Add contents of RVD(Resistance Voltage Divider), one of Voltage Divider Inputs.

[Sep. 2010] Ver5.11

1. Add “6.10. Set Group Change”.

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

ii ENHANCED

TECHNOLOGY

[Mar. 2011] Ver5.20

1. Add “Loss of Phase” in “PROTECTION” menu according to an additional function (option),

“Loss of Phase”.

2. Add “Supply Outage Measurement” as an additional function in menu.

-Add “S-Outage” and “S-O Dura” set-up in “RELAY SETUP/ EVENT RECORDER” menu.

-Add “S-Outage Count” and “S-Outage Event” set-up in “RELAY SETUP/ CLEAR SAVED

DATA” menu.

-Add “S-OUTAGE COUNTER” in “MAINTENANCE” menu.

-Add “SUPPLY OUTAGE” in “EVENT RECORDER” menu.

[Jan. 2012] Ver6.00

After the Ver6.00, the manual is applied to the

“EVRC2A-N6(Network type)”

.

[Jan. 2012] Ver6.00

1. Change the terms related with battery testing.

[Feb. 2012] Ver6.01

1. Add “Power Quality” set-up in “SYSTEM SETUP” menu.

2. Change “Supply Outage” to “Power Quality” in some menus.

-Change “S-Outage Counter” to “Power Quality” in “MAINTENANCE” menu.

-Change “Supply Outage” to “Power Quality” in “EVENT RECORDER” menu.

-Change “S-Outage Count” and “S-Outage Event” to “P-Quality Count” and “P-Quality” in

“RELAY SETUP/ CLEAR SAVED DATA” menu.

3. Add “HARMONICS” in “MAIN MENU/6.METERING” menu.

[Jun. 2012] Ver6.02

Changed the manual based on EVRC2A-N6 firmware V6.12 upgrading.

1. Section to be rectified in the manual as a result of adding measuring function of

voltage/current unbalance.

-Change “METERING” in “1.2. Summary of Features”.

-Change “Table 2-1. Metering Accuracy” in “2.3. Metering Accuracy”.

-Add “10.1.9. Unbalance”.

-Change “Table 10-1. Metering Accuracy” in “10.2. Accuracy”.

2. Section to be rectified in the manual as a result of adding detection function of

voltage/current unbalance.

-Change “MONITORING” in “1.2. Summary of Features”.

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

iii

ENHANCED

TECHNOLOGY

-Change “RECORDER” in “1.2. Summary of Features”.

-Add “Power Quality” in “2.5. Monitoring”.

-Change “SYSTEM EVENT RECORDER”, “POWER QUALITY EVENT RECORDER”,

“COUNTER” in “2.6. Recorder”.

-Change “Figure 3-12. Menu Structure Tree” in “3.2.1. Main Menu Summary”.

-Add settings for Unbalance in “6.10. Power Quality”.

-Add Unbalance Counter in “11.4. Power Quality”.

-Change “12.2. System Event Recorder”.

-Change “12.6. Power Quality Event Recorder”.

3. Section to be rectified in the manual as a result of adding “Daily Max I” and “Daily Energy”

settings.

-Change “5.2.5. EVENT&ETC”.

4. Section to be rectified in the manual as a result of changed range of reclose interval 1.

-Change “Reclose interval 1” in “2.4. Protection Elements/ Reclose Control”.

-Change “Range of Reclose 1” in “7.1. Reclose(79)”.

[Aug. 2012] Ver7.00

Changed the manual based on EVRC2A_N6 firmware V6.15 upgrading.

1. Change “5.3. Clock”.

2. Change “5.8. Time Set & Display Type”.

-Add “Set Type”, “GMT Sign”, “GMT Hour”, “GMT Min” and “Evt Send Type” set-up in

“RELAY SETUP/ TIME SET & DIS TYPE” menu.

3. Change “SEF Pickup Current Setup” in “7.4. Sensitive Earth Fault (SEF)”.

4. Change “9.3. Clock”.

5. Change “10.1.4. Synchro Voltage”.

6. Change “Table 14-1. Warning Events” in “14.1. Warning Events”.

[Nov. 2012] Ver7.10

1. Changed the manual based on EVRC2A_NT firmware V7.04 upgrading.

-Change “5.2.2.1. DNP 3.0 Protocol – Option” : Add “Time Req(m)” set-up in

“COMMUNICATION / PROTOCOL SETUP / DNP1 and DNP2” menu.

-Change “5.2.3.1. PORT2-RS232” : Add “Parity Bit”, “Data Bit” and “Stop Bit” set-up in

“COMMUNICATION/ PORT SETUP/ PORT1-RS232” menu.

-Change “5.2.5. EVENT&ETC” : Add “Time Syn’ Ref” and “Evt Time Type” set-up in

“COMMUNICATION/ EVENT&ETC” menu.

-Change “5.8. Time Set & Display Type – Option” : Add “Time Syn’ Ref” set-up in “RELAY

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

iv ENHANCED

TECHNOLOGY

SETUP / TIME SET&DIS TYPE” menu.

2. Changed the manual based on EVRC2A_NT firmware V7.06 upgrading.

-Change “5.2.2.2. IEC60870-5-101 Protocol – Option” : Add the setting items in

“COMMUNICATION / PROTOCOL SETUP / IEC60870-5-101” menu.

-Change “5.2.2.3. IEC60870-5-104 Protocol – Option” : Add the setting items in

“COMMUNICATION / PROTOCOL SETUP / IEC60870-5-104” menu.

-Change “6.3. Line VL Sensing” : Add “Install Type” set-up in “SYSTEM SETUP / LINE

VL SENSING” menu.

3. Change the description for “SKIP at Fault” and “Fault ‘I’ Evt” setting in “5.2.5.

EVENT&ETC”.

4. Add the Note in “6.4. System Power”.

[Nov. 2012] Ver7.12

1. Changed the manual based on EVRC2A_NT firmware V7.07 upgrading : Delete “Tx Delay”

set-up in “COMMUNICATION / PROTOCOL SETUP / DNP1 and DNP2” menu.

-Change the description for “Tx Delay” setting in “5.2.2.1. DNP3.0 Protocol – Option”.

2. Change the description for “TX Post Delay” and “TX Pre Delay” in “5.2.3.1. PORT2 –

RS232”.

3. Change the setting examples of “Use of VD(CVD or RVD)” in “6.2. Line VS Sensing / 6.2.3.

Setting Examples”.

[Dec. 2012] Ver7.12

1. Add the Note in “5.8. Time Set & Display Type – Option”.

2. Add the Note in “5.2.5. EVENT&ETC”.

3. Change “Figure 7-33. Non Standard Curves (11, 13, 14, 15, 16, 17, 18)” in “7.18. Time

Overcurrent Curves”.

[Feb. 2013] Ver7.13

1. Add the Notes in “2.4. Protection Elements”.

2. Add the Note of “SEF Pickup Current Setup” in “7.4. Sensitive Earth Fault (SEF)”.

3. Add the Note of “SEF” setting in “7.12.3. Cold Load Pickup Setup”.

4. Add the Note in “9.4. Control Type”.

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

v

ENHANCED

TECHNOLOGY

TABLE OF CONTENTS

1. INTRODUCTION ........................................................................................................... 1

1.1. Description .......................................................................................................................... 1

1.2. Summary of Features .......................................................................................................... 2

2. TECHNICAL SPECIFICATIONS................................................................................. 5

2.1. Inputs and Outputs .............................................................................................................. 5

2.2. Type Withstand Tests........................................................................................................... 8

2.3. Metering Accuracy .............................................................................................................. 9

2.4. Protection Elements........................................................................................................... 11

2.5. Monitoring......................................................................................................................... 16

2.6. Recorder ............................................................................................................................ 19

2.7. Communications................................................................................................................ 22

3. USER INTERFACE PANEL ........................................................................................ 23

3.1. Construction ...................................................................................................................... 24

3.2. LCD Display ..................................................................................................................... 33

3.3. Using the LCD Menu ........................................................................................................ 37

4. SELECT SETBANK ..................................................................................................... 40

5. RELAY SETUP.............................................................................................................. 41

5.1. Passcode ............................................................................................................................ 41

5.2. Communication ................................................................................................................. 42

5.3. Clock ................................................................................................................................. 76

5.4. Event Recorder.................................................................................................................. 78

5.5. Clear Saved Data............................................................................................................... 79

5.6. Factory Debug................................................................................................................... 79

5.7. Gas Sensor Type................................................................................................................ 80

5.8. Time Set & Display Type – Option ................................................................................... 80

6. SYSTEM SETUP........................................................................................................... 82

6.1. Current Sensing................................................................................................................. 82

6.2. Line VS Sensing................................................................................................................ 84

6.3. Line VL Sensing................................................................................................................ 86

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

vi ENHANCED

TECHNOLOGY

6.4. System Power .................................................................................................................... 88

6.5. Panel Sleep Time............................................................................................................... 91

6.6. Opto Input Set - Option ..................................................................................................... 91

6.7. Output Relay Set - Option ................................................................................................. 93

6.8. Loop Control - Option....................................................................................................... 96

6.9. Set Group Change - Option ............................................................................................. 115

6.10. Power Quality - Option ................................................................................................. 116

7. PROTECTION ............................................................................................................ 120

7.1. Reclose (79)..................................................................................................................... 122

7.2. Phase (Fast/Delay) Time Overcurrents (51P).................................................................. 128

7.3. Ground (Fast/Delay) Time Overcurrent (51G)................................................................ 132

7.4. Sensitive Earth Fault (SEF)............................................................................................. 136

7.5. Negative Sequence (Fast/Delay) Time Overcurrent (46)

.......................................................... 138

7.6. Phase High Current Trip (50P-1)..................................................................................... 142

7.7. Ground High Current Trip (50G-1) ................................................................................. 144

7.8. Negative Sequence High Current Trip (46(50)-1)........................................................... 146

7.9. Phase High Current Lockout (50P-2).............................................................................. 148

7.10. Ground High Current Lockout (50G-2) ........................................................................ 150

7.11. Negative Sequence High Current Lockout (46(50)-2)

............................................................ 152

7.12. Cold Load Pickup.......................................................................................................... 154

7.13. Directional Controls (67)............................................................................................... 162

7.14. Undervoltage (27).......................................................................................................... 170

7.15. Overvoltage (59)............................................................................................................ 172

7.16. Frequency(81) ............................................................................................................... 174

7.17. Other Element................................................................................................................ 177

7.18. Time Overcurrent Curves .............................................................................................. 180

7.19. Loss of Phase - Option .................................................................................................. 207

8. MONITORING ........................................................................................................... 208

8.1. Demand ........................................................................................................................... 208

8.2. Synchronism Check (25)................................................................................................. 211

8.3. Trip Counter .................................................................................................................... 213

8.4. Recloser Wear.................................................................................................................. 215

8.5. Battery Test...................................................................................................................... 217

8.6. Fault Locator ................................................................................................................... 218

8.7. Gas Low Lock – Option .................................................................................................. 220

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

vii

ENHANCED

TECHNOLOGY

8.8. EXT’ Trip & Lock – Option............................................................................................ 220

8.9. Live Load Block – Option............................................................................................... 221

9. STATUS ........................................................................................................................ 222

9.1. OPTO Inputs ................................................................................................................... 222

9.2. Relay Outputs.................................................................................................................. 222

9.3. Clock ............................................................................................................................... 223

9.4. Control Type.................................................................................................................... 224

10. METERING............................................................................................................... 225

10.1. Metering Elements ........................................................................................................ 226

10.2. Accuracy........................................................................................................................ 235

11. MAINTENANCE....................................................................................................... 237

11.1. Counters......................................................................................................................... 237

11.2. Wear Monitor................................................................................................................. 237

11.3. Output Relay Test .......................................................................................................... 238

11.4. Power Quality - Option ................................................................................................. 239

12. EVENT RECORDER................................................................................................ 241

12.1. Waveform Capture ........................................................................................................ 241

12.2. System Event Recorder ................................................................................................. 245

12.3. Load Profile................................................................................................................... 247

12.4. Diagnostic Event Recorder............................................................................................ 250

12.5. Fault Trip Event Recorder - Option............................................................................... 252

12.6. Power Quality Event Recorder - Option ....................................................................... 254

13. INSTALLATION ....................................................................................................... 257

13.1. User Interface Door and Power Switch......................................................................... 257

13.2. Vent and Outer Cover .................................................................................................... 258

13.3. Dimensions and Mounting Plan .................................................................................... 259

13.4. Earth Wiring Diagram ................................................................................................... 261

13.5. Inner Structure............................................................................................................... 262

13.6. Mount Accessories Dimensions .................................................................................... 263

13.7. User-Available DC Power ............................................................................................. 264

13.8. Terminal Block and Fuses ............................................................................................. 265

13.9. EVRC2A Wiring Diagram – VD Type.......................................................................... 266

13.10. EVRC2A Wiring Diagram - VT Type ......................................................................... 267

13.11. Side Panel .................................................................................................................... 268

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

viii ENHANCED

TECHNOLOGY

13.12. Current Inputs Wiring Diagram................................................................................... 269

13.13. VD Wiring Diagram .................................................................................................... 270

13.14. VT Wiring Diagram..................................................................................................... 271

13.15. Current and Voltage Inputs Phase Rotation................................................................. 272

13.16. Control Cable Receptacle Pin Descriptions ................................................................ 273

13.17. Control Cable Assembling / De-assembling................................................................ 275

13.18. AC Power Receptacle Pin Descriptions ...................................................................... 275

13.19. AC Power Cable .......................................................................................................... 276

13.20. Fuses............................................................................................................................ 276

13.21. Battery and Control run time....................................................................................... 277

13.22. Charge Circuit ............................................................................................................. 278

13.23. Battery Change............................................................................................................ 278

13.24. Battery Protection........................................................................................................ 278

13.25. Communications.......................................................................................................... 279

13.26. Communication Cables ............................................................................................... 281

13.27. Hardware Block Diagram............................................................................................ 282

13.28. Recloser Trip and Close Circuits................................................................................. 283

13.29. Uninterruptible Power Supply for Trip & Close ......................................................... 284

13.30. Main Board.................................................................................................................. 285

13.31. Analog Board............................................................................................................... 286

13.32. Recloser EVR Wiring Diagram ................................................................................... 287

13.33. Recloser EPR Wiring Diagram.................................................................................... 288

13.34. Recloser Current Transformer (CT) ............................................................................ 289

13.35. Recloser Voltage Divider (VD) ................................................................................... 289

13.36. Recloser Pressure Sensor (Only EVR Type) ............................................................... 290

13.37. Recloser 52 contact and 69 contact ............................................................................. 292

13.38. Recloser Trip and Close Coil....................................................................................... 292

13.39. Recloser Test Kit ......................................................................................................... 293

14. MAINTANANCE ...................................................................................................... 294

14.1. Warning Events ............................................................................................................. 294

14.2. Malfunction Events ....................................................................................................... 296

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

1

ENHANCED

TECHNOLOGY

1. INTRODUCTION

1.1. Description

yEVRC2A with the microprocessor-based digital control technology is designed to provide

protective coordination and fault clearance of distribution systems for the continuous best

quality of electric service.

yRemote monitoring and control can be provided by RTU(Remote Terminal Unit - Option)

which fundamentally installed.

yIn order to perform the protection function, line voltage and current signal filtered with

analog filter and digital DFT full-cosin filter is used.

yEVRC2A provides protection, control, and monitoring functions with both local and remote.

It also displays the present trip/alarm conditions, and measured system parameters.

yRecording of past trip, alarm or control events, maximum demand levels, and energy

metering is also performed.

yUsers can operate Close and Trip, and also control EVRC2A with key buttons on the user

interface panel; Protection Enabled, Ground Enabled, SEF Enabled, Reclose Enabled,

Control Locked, Remote enabled, Alternate-settings, Program 1, Program 2, Hot line tag.

yUsers can manage the Recloser interface software using a portable PC for modification of

settings, acquisition of event data, and management of operation history.

yEVRC2A contains many T-C characteristic curves developed by IEEE C37.112, IEC255-3,

McGraw Edison, and KEPCO to provide fully protective coordination for the continuous

best quality of electric distribution. Users can select any time of current curve simply by

programming and modifying.

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

2ENHANCED

TECHNOLOGY

1.2. Summary of Features

PROTECTION

yPhase Instantaneous Over-current Element

yPhase Time Over-current Elements

yPhase Definite Time High Current Lockout Element

yGround Instantaneous Over-current Element

yGround Time Over-current Elements

yGround Definite Time High Current Lockout Element

ySensitive Earth Fault Elements

yNegative Instantaneous Over-current Element

yNegative Time Over-current Elements

yNegative Definite Time High Current Lockout Element

yPhase, Ground, Sensitive Earth and Negative Sequence Directional Control

yAutomatic Reclosing(Up To 4 Shots)

yCold Load Pickup with Voltage Control

ySequence Coordination Control

yTwo Under-voltage Elements

yTwo Over-voltage Elements

yUnder-frequency Element

yOver-frequency Element

yLoop Control - Option

yLoss of Phase - Option

METERING

yPhase, Ground and Sensitive Ground Current and Phasors

yLine and Phase Voltage and Phasors(Source Side and Load Side)

yCurrent and Voltage Symmetrical Component Phasors

yFrequency Magnitude and Rate

ySynchronizing Voltage, Phasor and Frequency

ySynchronizing Delta㎸, Delta ㎐and Delta Leg

ySingle and Three Phase Power(MW, Mvar, MVA, PF)

yEnergy(MWh, Mvarh)

yMaximum Demand(Ia, Ib, Ic, MW, Mvar, MVA)

yVoltage and current harmonics - Option

yVoltage and current unbalance - Option

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

3

ENHANCED

TECHNOLOGY

MONITORING

yFault Locator

yDemand trip and alarm(Ia, Ib, Ic, Ig, I2)

yTrip Counter Limit

ySynchronism Check

yRecloser main contact Wear(Per Phase)

yRecloser Operation Failure

yVoltage Transformer Failure

yBattery Automatic Load Test

yBreaker Failure with Current Supervision

yPower Quality - Option

yRecloser Gas Over and Low pressure - Option

NOTE : According to a recloser type, there may be no gas pressure monitoring.

COMMUNICATIONS

yFront Panel PORT1 RS232 Serial Port : EVRC2A interface software

ySide panel PORT2 RS232 Serial Port : EVRC2A interface software , DNP 3.0, MODBUS or

IEC60870-5-101 Protocol - Option

ySide panel PORT3 RS485 or R232* Serial Port : DNP 3.0, MODBUS or IEC60870-5-101

Protocol – Option

ySide panel PORT4 RJ45 Port : DNP 3.0, MODBUS or IEC60870-5-104 Protocol and

EVRC2A interface software – Option

NOTE : The Port3 type of EVRC2A-N is a fixed RS485 port. However, the Port3 type of

EVRC2A-N6,NT can be selected as RS485 or RS232 by a user. In order to use

RS485 port for EVRC2A-N6,NT, the Pin4 and Pin5 of RS485 should be connected.

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

4ENHANCED

TECHNOLOGY

RECORDER

yTrip and fault counter

ySupply outage counter and time – Option

ySag/Swell detection counter – Option

yVoltage and current unbalance detection counter - Option

ySystem event recorder - last 2048 events

yDiagnostic event recorder - last 512 events

yLoad profile recorder - last 213days

yFault Waveform - 15 cycles × 32 events

yFault trip event recorder - last 512 events - Option

yPower Quality event recorder - last 512 events - Option

USER INTERFACE

yFault indicators

yManual Battery Load Test: Battery Voltage and Charge Voltage

yDual Functional keypads

y20×4 Character Display(LCD or VFD : Vacuum Fluorescent Display)

y32 LED indicators - Fault indications, sequence status, battery status, etc

yRS232 port

yContext Help Messages

yAccess Security(Passcode)

AUXILIARY OUTPUTS - Option

y7 Programmable Relays

y1 Programmable Alarm Relay

AUXILIARY INPUTS - Option

y8 Opto-isolated Programmable Inputs

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

5

ENHANCED

TECHNOLOGY

2. TECHNICAL SPECIFICATIONS

2.1. Inputs and Outputs

Systems

y3phase-3wire or 3phase-4wire, 38㎸maximum, 800 Amp maximum

Frequency

y50 / 60㎐system and ABC/ACB phase rotation

Control Voltage Input

yAC Voltage Input 110V/220Vac or other voltage (+10%,-15%)

yNominal Battery Voltage : 24Vdc

yBased on user requirement, prepare 110V/220V Selectable Switch - Option

User available DC power Output - Option

yDC Power Voltage : 12, 15, 24Vdc

yDC Power Continuous : 40W

yDC Power for 60Sec : 60W

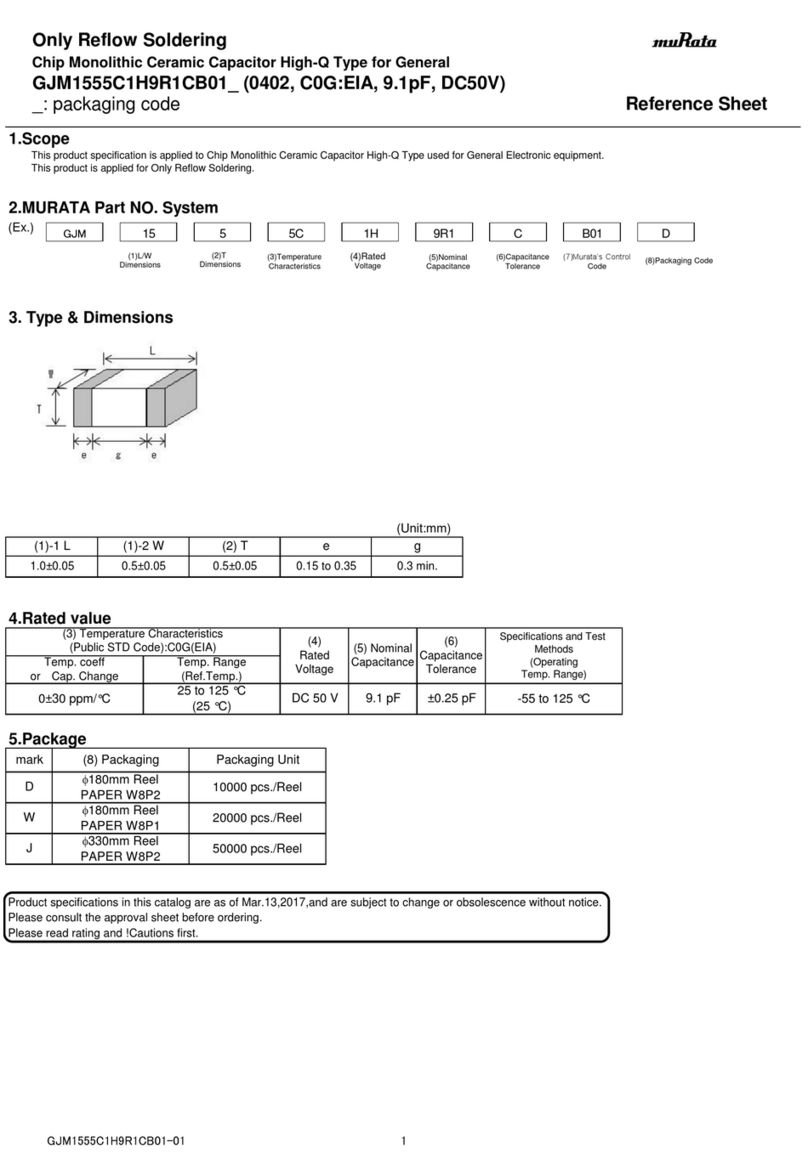

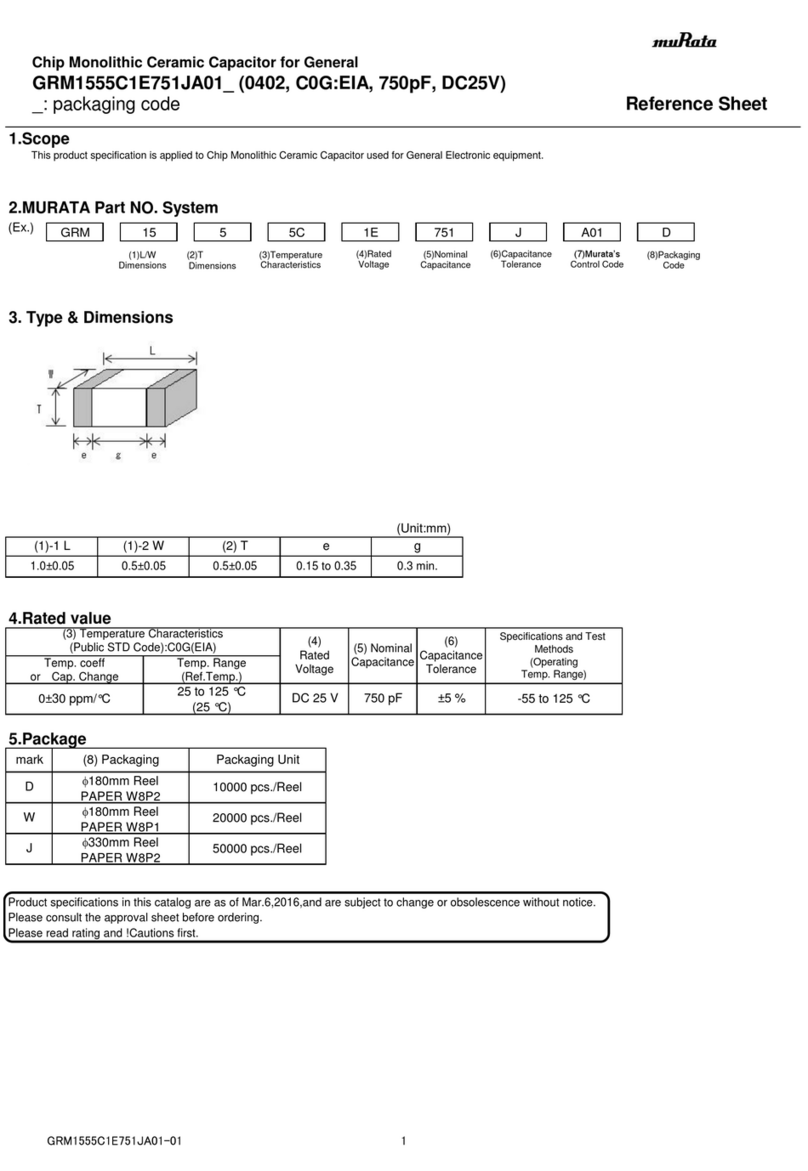

Voltage Divider Inputs (VD) - Standard

Capacitor Voltage Divider Inputs (CVD) – Only EVR

yMaximum Input Voltage : 5V

yBurden : 2e-6 VA

ySystem Voltage : 15㎸, 27㎸, 38㎸

yCapacitor value

-Phase Capacitor value : 20㎊

Resistance Voltage Divider Inputs (RVD) – Only EPR

yMaximum Input Voltage : 5V

yBurden : Bow 0.0015 VA

ySystem Voltage : 15㎸, 27㎸

yResistance value

-Phase Resistance value : 100MΩ

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

6ENHANCED

TECHNOLOGY

Voltage Transformer Inputs (VT) - Option

yVoltage Inputs

EVRC2A-N : 4 Channel(VA, VB, VC and VL)

EVRC2A-N6,NT : 6 Channel

-Source Voltage 1 VA,VB,VC

-Source Voltage 2 VR,VS,VT

yInput Voltage Range : Phase-Neutral Continuous <300V

yBurden: 0.6VA(300V), 0.2VA(220V), 0.05VA(120V), 0.02VA(67V)

Current Transformer Inputs (CT)

yCurrent Inputs IA,IB,IC and IG, SEF

yIA,IB,IC,IG Input Current Range

1A Nominal

2A continuous

25A 1 second

Burden : 0.38VA(1A)

ySEF Input Current Range

0.05A Nominal

0.16A Continuous

0.6A 1 second

Burden : 0.0375VA(0.05A)

Control Inputs - Option

yControl Inputs 8 Channel

yNominal Voltages and Operating Range

250Vdc(-15%,+20%)

125Vdc(-15%,+20%)

48Vdc(-15%,+20%)

24Vdc(-15%,+20%)

12Vdc(-10%,+30%)

yOperating current : <5mA at Nominal Voltages

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

7

ENHANCED

TECHNOLOGY

Control Output Contacts - Option

yControl Outputs 8 Channel

Normal Open 5 Channel

Normal Close 2 Channel

ALARM 1 Channel

y300Vac / 350Vdc Varistor for differential surge protection

yOperate / Release time : <5ms at +20℃(+68℉)

yMaximum operating power

(L/R=7ms)

125Vdc 0.1A

48Vdc 0.8A

24Vdc 3A

(cosΦ=0.4) 250Vac 3A

125Vac 5A

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

8ENHANCED

TECHNOLOGY

2.2. Type Withstand Tests

Dielectric Strength

yCT inputs, VT inputs, Control Power inputs, Opto-isolated inputs and Relay outputs

2㎸(60㎐) for 1 minute

Impulse Voltage

yIEEE C62.45 (1992) Withstand Capability of Relay Systems to Radiated Electromagnetic

Interference Transceivers, 6㎸(1.2×50㎲), 3㎄(8×20㎲)

Surge Withstand Capability

yIEEE C37.90.1 - 1989 IEEE SWC Tests for Protective Relays and Relay Systems

(3㎸oscillatory 1㎒to 1.5㎒, 5㎸fast transient 1.2×50㎲)

yIEEE C37.90.2 - 1987 IEEE Trial-Use Standard, Withstand Capability of Relay Systems to

Radiated Electromagnetic Interference from Transceivers, 10 V/m

(150㎒and 450㎒, 5 W transmitter 10㎝)

Vibration Test

yIEC 255-21-1 - 1988 Electrical relays, Part 21 : Vibration, shock, bump, and seismic tests on

measuring relays and protection equipment, Section One - Vibration tests (sinusoidal), Class 2.

Control Operating Temperature

yOperating range : -25℃∼+70℃(-13℉∼+158℉)

yLCD : -20℃∼+70℃(-4℉∼+158℉) - standard

yVFD : -40℃∼+85℃(-40℉∼+185℉) - option(Vacuum Fluorescent Display)

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

9

ENHANCED

TECHNOLOGY

2.3. Metering Accuracy

The harmonic components of current and voltage are removed from the input voltage and current

parameters, so all measurements based on these quantities respond to the fundamental

components only except the measurement of harmonics.

Table 2-1. Metering Accuracy(1/2)

Measurements Parameters Unit Accuracy Range

CURRENT

Phase A RMS Current

Phase B RMS Current

Phase C RMS Current

Phase G RMS Current

Phase SEF RMS Current

A ±1% of 2×CT 20×CT

VOLTAGE

A–N (A–B) RMS Voltage

B–N (B–C) RMS Voltage

C–N (C–A) RMS Voltage

R–N (R–S) RMS Voltage

S–N (S–T) RMS Voltage*

T–N (T–R) RMS Voltage*

㎸±1% –

SYMMETRICAL

COMPONENTS

I1, I2, 3I0

V1, V2, 3V0

A

㎸

±1% of 2×CT

±1%

–

POWER FACTOR

Phase A, B, C

3ΦPhase

Rate ±0.02 –1.000 to 1.000

3ΦREAL POWER

Phase A, B, C

3ΦPhase

MW ±2% –32.000 to 32.000

3ΦREACTIVE

POWER

Phase A, B, C

3ΦPhase

MVar ±2% –32.000 to 32.000

3ΦAPPARENT

POWER

Phase A, B, C

3ΦPhase

MVA ±2% –32.000 to 32.000

WATT-HOURS

Phase A, B, C

3ΦPhase

MWH ±2% –32000 to 32000

VAR-HOURS

Phase A, B, C

3ΦPhase

MVarH ±2% –32000 to 32000

DEMAND

Phase A/B/C/RG Current

A/B/C, 3ΦReal Power

A/B/C, 3ΦReactive Power

A

MW

MVar

±2%

±2%

±2%

–

RECLOSER CONTROL EVRC2A-N6,NT http://www.entecene.co.kr

10 ENHANCED

TECHNOLOGY

Table 2-1. Metering Accuracy(2/2)

Measurements Parameters Unit Accuracy Range

FREQUENCY

A-N (A-B) Source Voltage

R-N (R-S) Load Voltage

㎐±0.02 40.00~70.00

HARMONICS

1st~7th Harmonic of Current

1st~7th Harmonic of Voltage

THD of Current

THD of Voltage

–

±1%

±1%

±3%

±3%

0% to 100%

0% to 100%

0% to 100%

0% to 100%

UNBALANCE

Voltage unbalance(V2/V1) in source side

Voltage unbalance(V2/V1) in load side

Current unbalance(I2/I1)

%

±2%

±2%

±2%

0% to 999%

0% to 999%

0% to 999%

If the VT connection type is set to delta, all single phase voltage quantities are displayed as zero.

Table of contents

Popular Industrial Electrical manuals by other brands

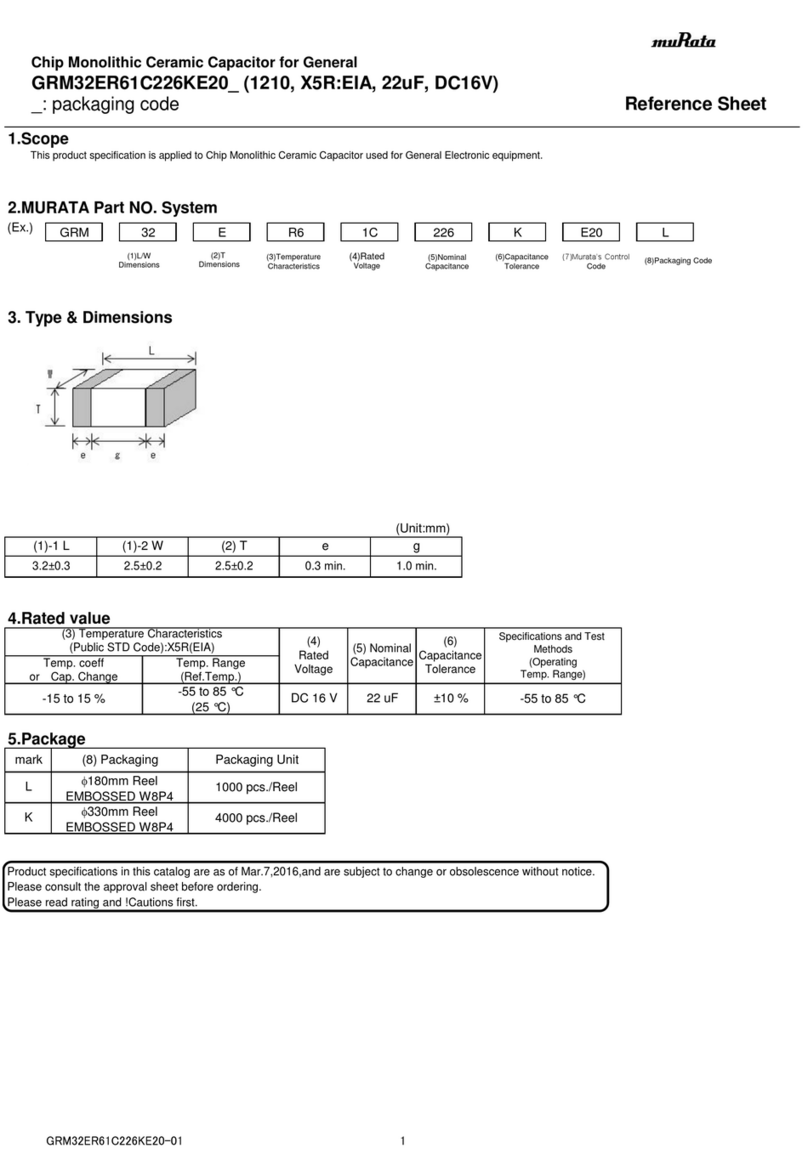

Murata

Murata GRM1555C2A6R2CA01 Series Reference sheet

Delta Tau

Delta Tau Accessory 82M user manual

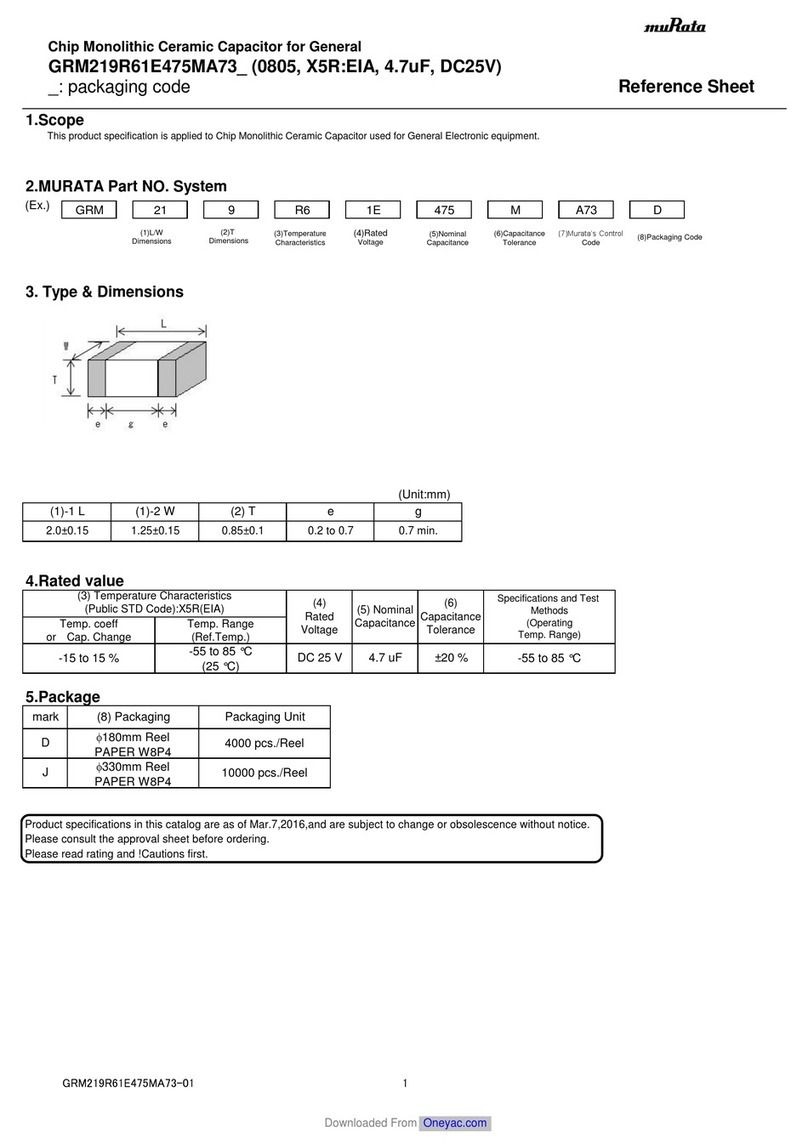

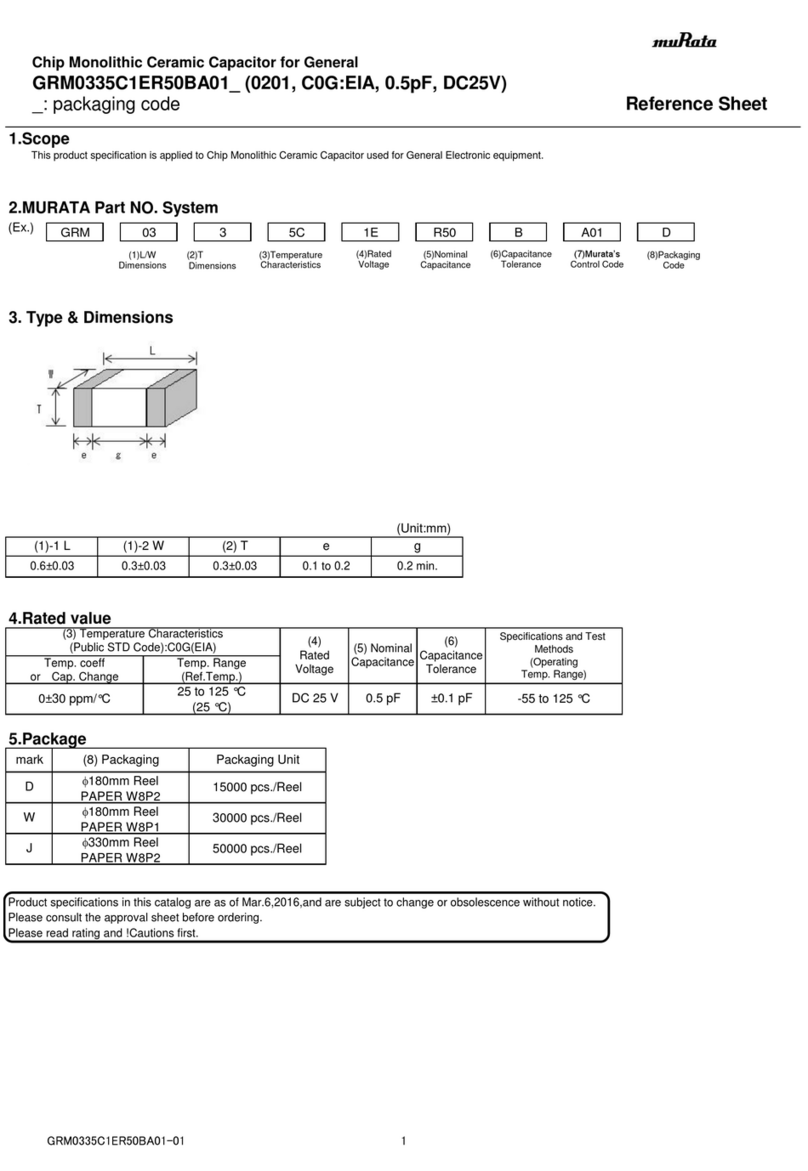

Murata

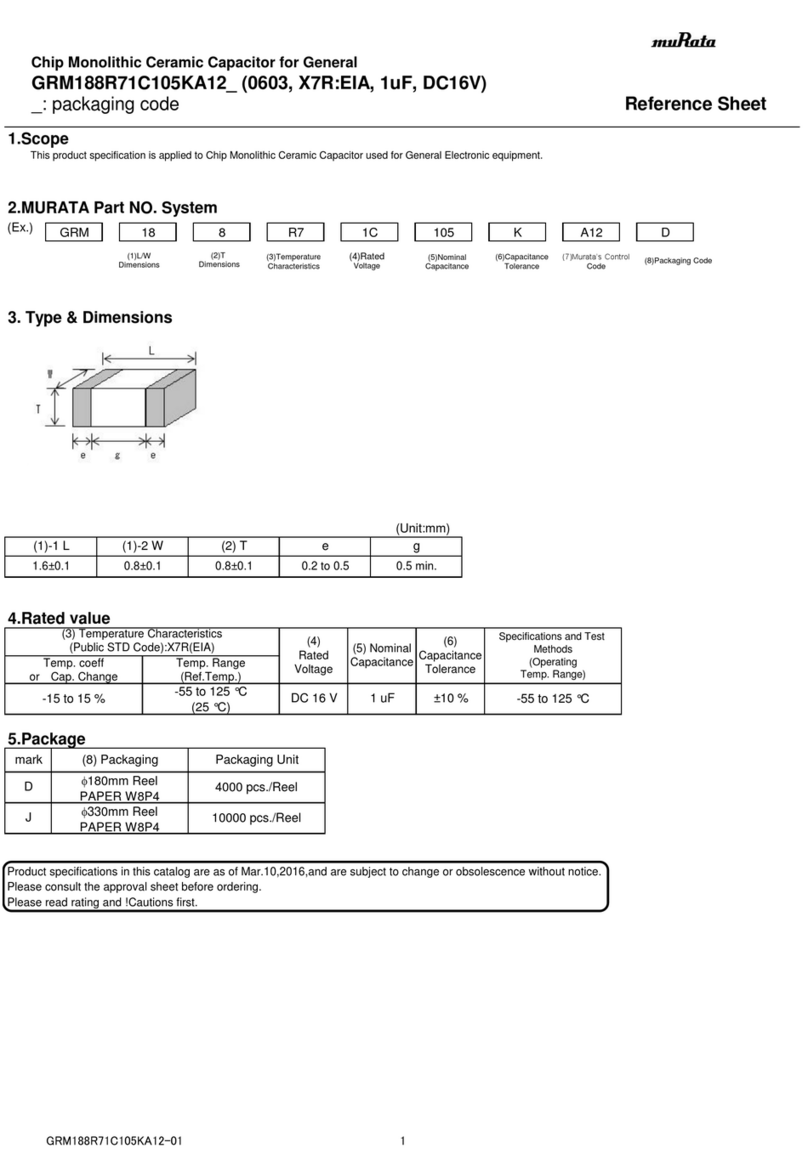

Murata GRM188R71C105KA12 Series Reference sheet

Akapp-Stemmann

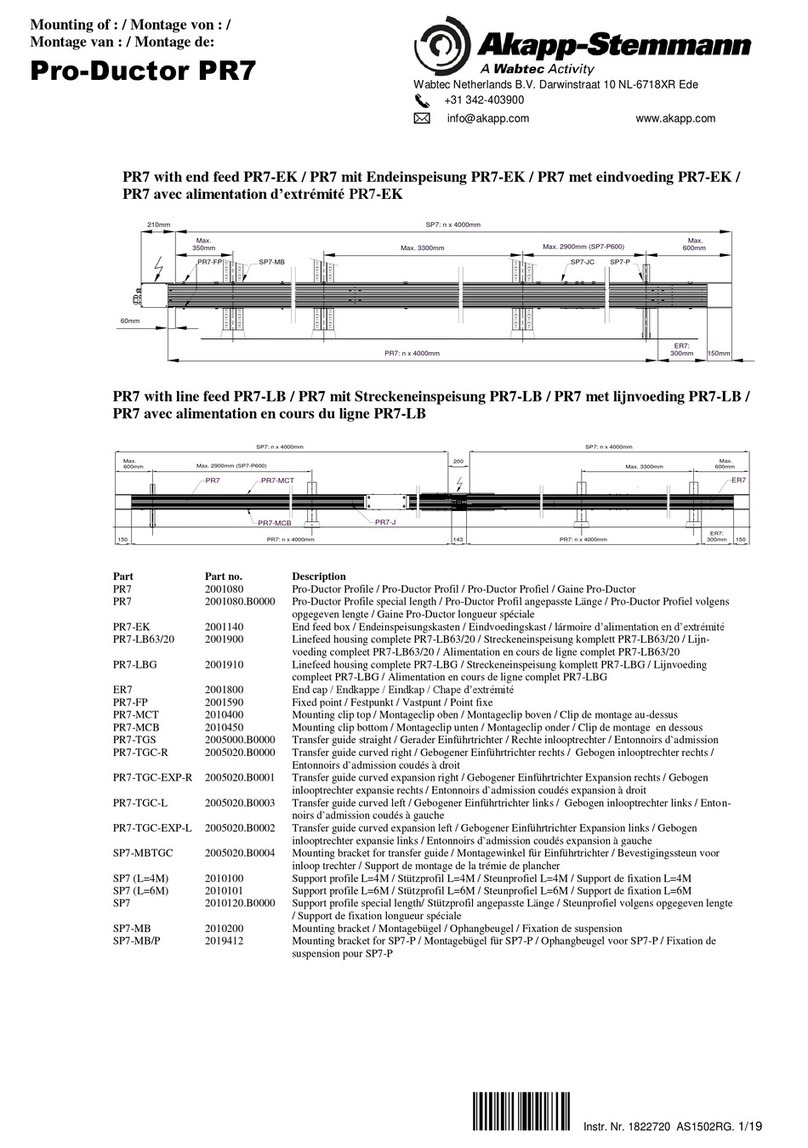

Akapp-Stemmann Pro-Ductor PR7 Mount Guide

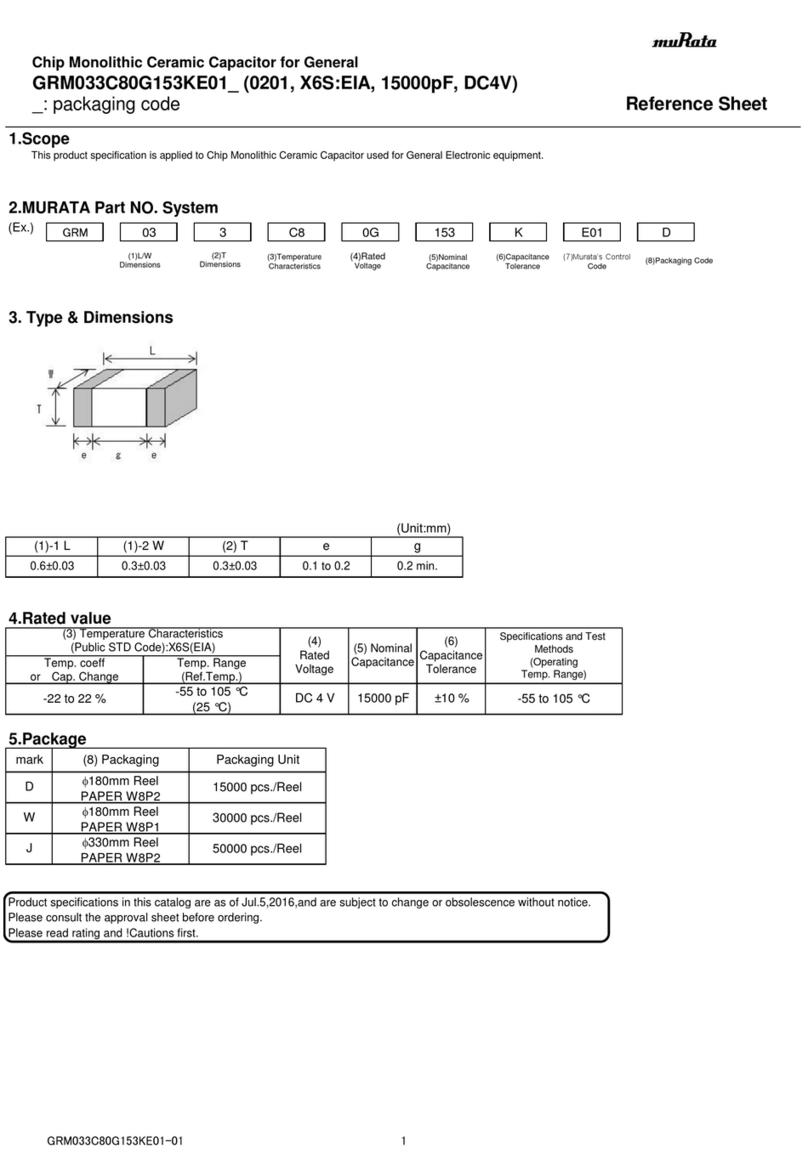

Murata

Murata GRM033C80G153KE01 Series Reference sheet

Murata

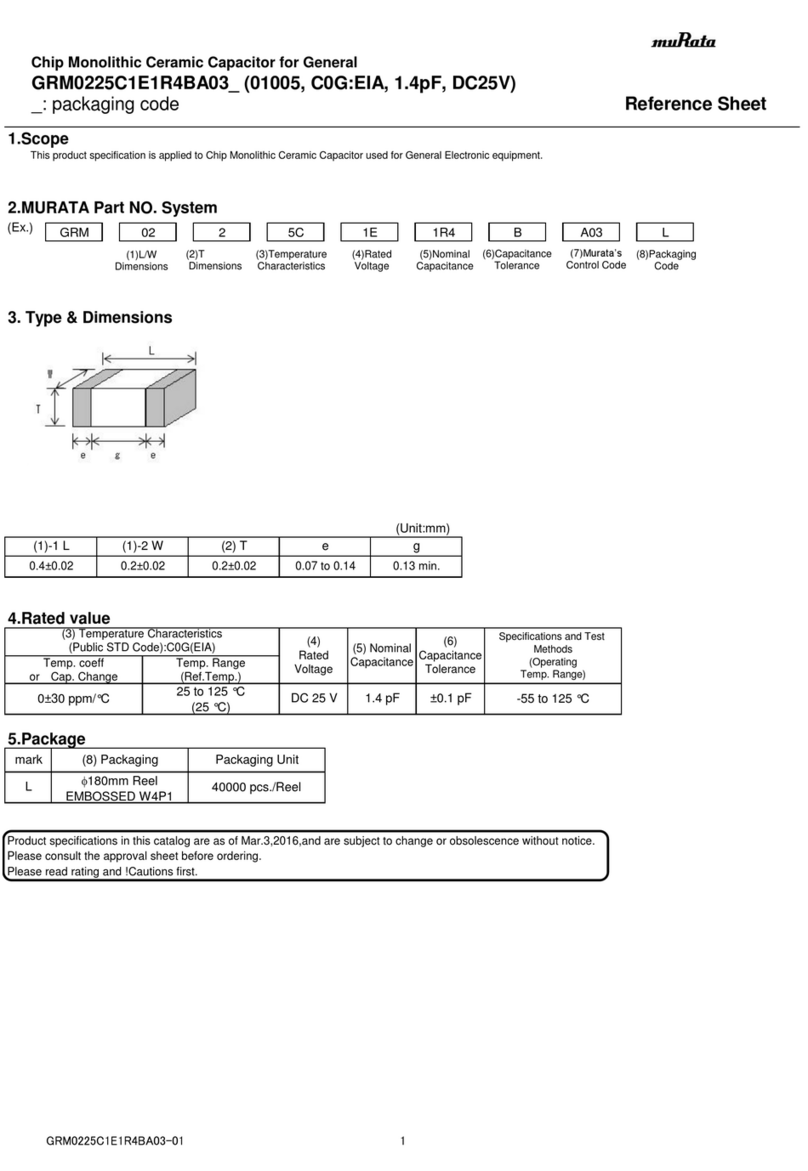

Murata GRM0225C1E1R4BA03 Series Reference sheet

Murata

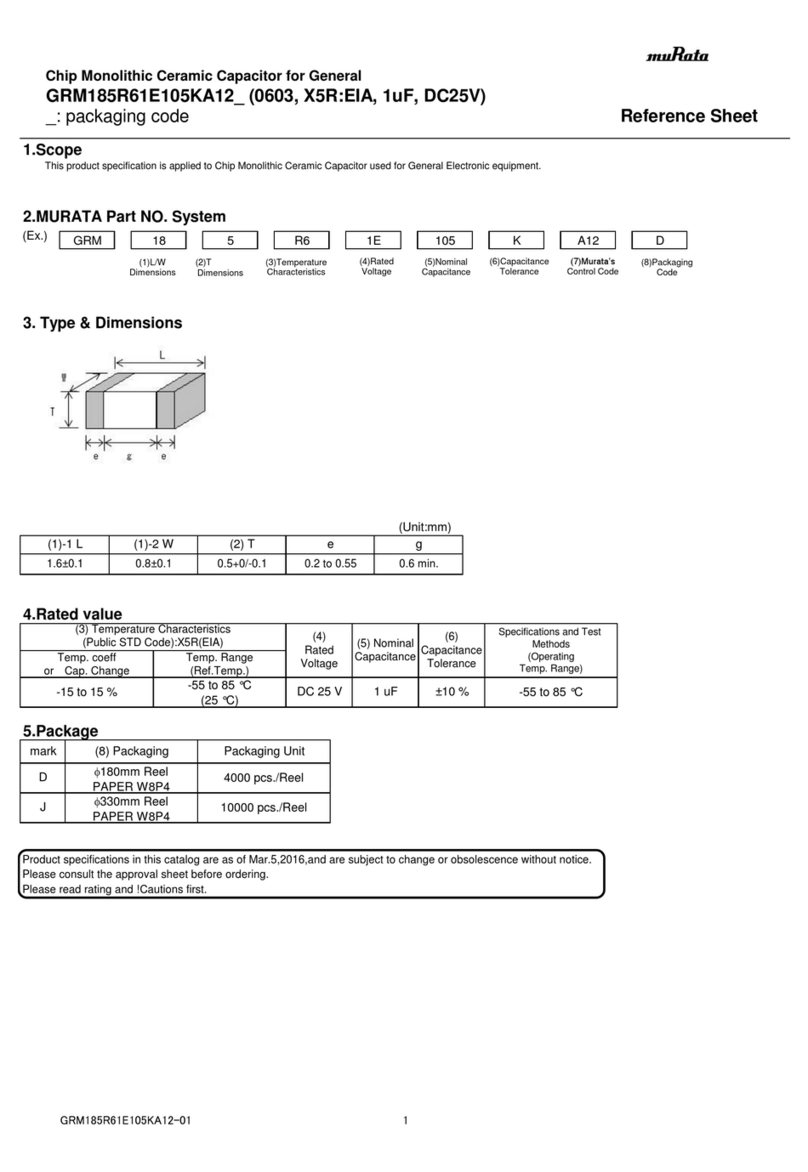

Murata GRM185R61E105KA12 Series Reference sheet

ProSoft Technology

ProSoft Technology inRAx MVI46-N2 user manual

Murata

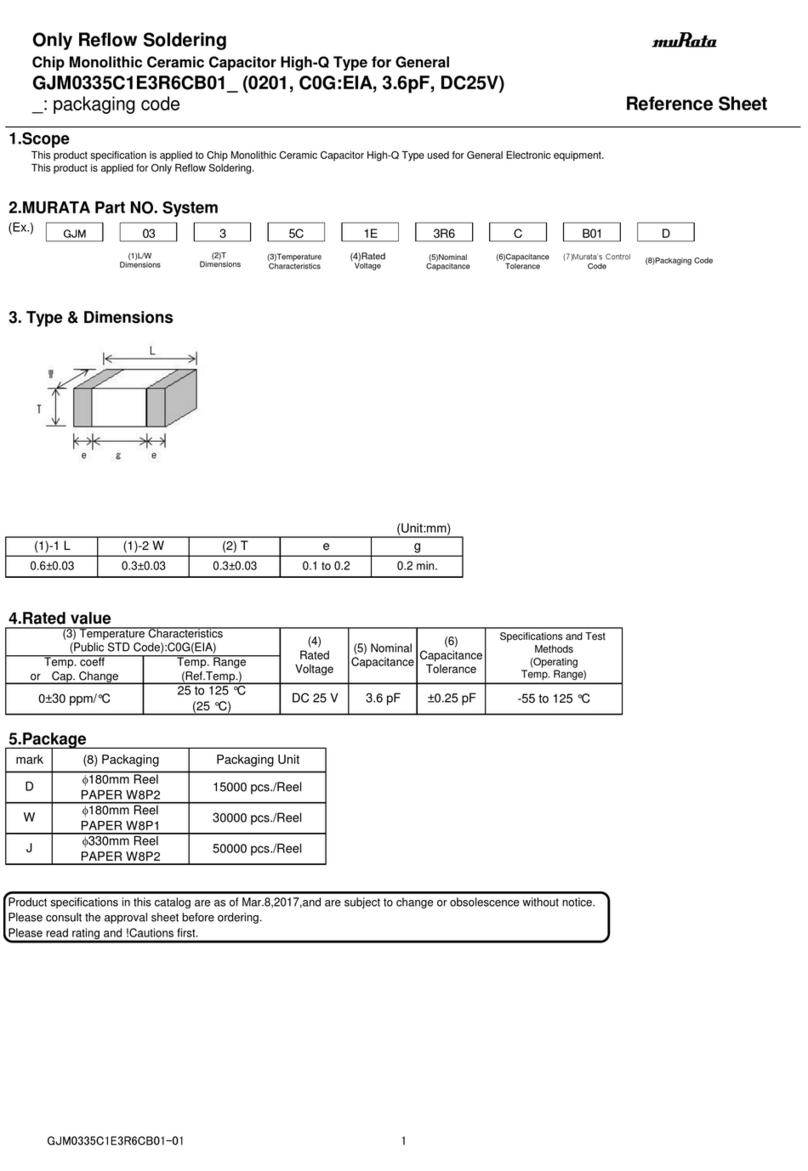

Murata GJM0335C1E3R6CB01 Series Reference sheet

Murata

Murata GRM32ER61C226KE20 Series Reference sheet

Murata

Murata GRM0335C1ER50BA01 Series Reference sheet

OEZ

OEZ CS-BH-A021 Instructions for use