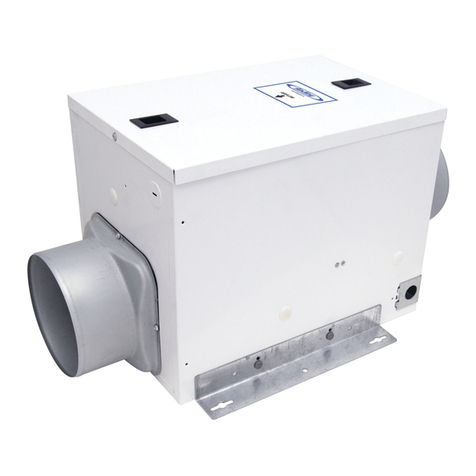

Envirco MAC 10 LEAC2 Instruction manual

ENVIRCO Technical Support: 800-884-0002

MAC 10®LEAC2

Fan Filter Unit

Standard & RSRE Models

INSTALLATION, OPERATION & MAINTENANCE MANUAL

2 Innovators in Clean Air Technology | www.envirco.com | Installation, Operation, & Maintenance

Installation, Operation, & Maintenance Manual

MAC 10®LEAC2

Fan Filter Unit

Table of Contents

Important Information ....................................................................................................... 3

Contact Information .......................................................................................................... 3

Critical Operations of the MAC 10®.................................................................................. 4

Warnings .......................................................................................................................... 4

Part Numbers ................................................................................................................... 4

Installation ........................................................................................................................ 5

Unit Control Box ............................................................................................................... 6

ENAC Control Card .......................................................................................................... 6

Cleaning the Prelter (Foam) ........................................................................................... 7

Cleaning the Prelter (G4 Pleated)................................................................................... 7

Service: Removal and Replacement of Standard Filters.................................................. 8

Service: Removal and Replacement of RSRE Filters ...................................................... 9

Service: Standard Motor Removal and Installation ......................................................... 10

Service: RSRE Motor Removal and Installation...............................................................11

Troubleshooting............................................................................................................... 12

MAC 10 LEAC2 Wiring Diagrams.................................................................................... 13

MAC 10 LEAC2 Replacement Parts Diagrams ............................................................... 14

MAC 10 LEAC2 Airow Curves: Standard 2x4................................................................ 15

MAC 10 LEAC2 Airow Curves: Standard 2x3................................................................ 16

MAC 10 LEAC2 Airow Curves: Standard 2x2................................................................ 17

MAC 10 LEAC2 Airow Curves: RSRE 2x4 .................................................................... 18

MAC 10 LEAC2 Airow Curves: RSRE 2x3 .................................................................... 19

MAC 10 LEAC2 Airow Curves: RSRE 2x2 .................................................................... 20

Limited Warranty ............................................................................................................. 21

Testing ............................................................................................................................. 21

3

■Important Information

To ensure ordering of the proper replacement parts or complete MAC 10 unit, record the information from the serial

number label, located adjacent to the electrical box, in the elds below for easy future reference. If you cannot locate

the Sales Order Number, please contact ENVIRCO for this information.

■Contact Information

Innovators in Clean Air Technology | www.envirco.com | Installation, Operation & Maintenance

Installation, Operation, & Maintenance Manual

MAC 10®LEAC2

Fan Filter Unit

Order Number

CO-XXXXXXX

Serial Number

150412345-BA-AS1CH

Unit Part Number

11250-001

Date

MM/DD/YYYY

SERIAL/DATA LABEL SAMPLE

N

R

Fan Filter Unit

AC: 120v 60 Hz 1.80 amps

Covered by one or more

of the following patents:

nos. 4,560,395, & 5,470,363

Envirco

1-800-884-0002

www.envirco.com

LABEL PN 268177-XXX

150412345-BA-AS1CH

LISTED 2F82

AIR FILTER

E152685

Innovators in clean air technology

LEAC2

SUITABLE FOR COMMERCIAL

OR INDUSTRIAL USE ONLY

C

R

R

R

Company Purchased From _____________________________________________________________________________

ENVIRCO Job Number ________________________________________________________________________________

Order Number _______________________________________________________________________________________

Serial Number _______________________________________________________________________________________

Unit Part Number ____________________________________________________________________________________

Date ______________________________________________________________________________________________

Airows per Certication _______________________________________________________________________________

Serial No. Label

ENVIRCO USA

101 McNeill Road

Sanford, NC 27330

Tel: (919) 775-2201

Tel: (800) 884-0002

Fax: (800) 458-2379

4

■Critical Operation Conditions of the MAC 10 LEAC2

1. Touching the HEPA lter will damage it and will void the lter warranty. The screen is only to protect against an accidental

‘touch’ of the lter. Never place a hand or tool on the lter. Never lie lter face at down on a surface; always have lter

on its side to protect from damage.

2. Prior to powering the unit, verify the voltage on the label and that the unit has been wired to the correct voltage. The serial

number label on the top of the MAC 10 unit has the required voltage, as shown on page 3.

■Warning

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A. Installation work and electrical wiring must be done by qualied person(s) in accordance with all applicable codes and

standards, including re-rated construction.

B. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

C. If this unit is to be installed over an area using liquid, such as water or chemical cleaning solutions, it must be marked as

appropriate for the application.

D. Use this unit only in the manner intended by the manufacturer. If you have any questions, contact the manufacturer.

E. Before servicing or cleaning the unit, switch power off at unit service panel and lock service panel to prevent power from

being switched on accidentally.

■Part Numbers Covered by This Manual

Note: A “Z” in the part number indicates that the unit is special. This may indicate a size change from standard or a special

lter. Please contact the factory for part numbers if this is the situation.

Installation, Operation, & Maintenance Manual

MAC 10®LEAC2

Fan Filter Unit

Innovators in Clean Air Technology | www.envirco.com | Installation, Operation, & Maintenance

RSRE Filter

2x4 120V HEPA 11254-001

2x4 220V HEPA 11254-002

2x4 277V HEPA 11254-003

2x4 120V ULPA 11254-004

2x4 240V ULPA 11254-005

2x4 277V ULPA 11254-006

2x3.5 120V HEPA 11255-001

2x3.5 220V HEPA 11255-002

2x3.5 277V HEPA 11255-003

2x3.5 120V ULPA 11255-004

2x3.5 240V ULPA 11255-005

2x3.5 277V ULPA 11255-006

2x3 120V HEPA 11256-001

2x3 220V HEPA 11256-002

2x3 277V HEPA 11256-003

2x3 120V ULPA 11256-004

2x3 240V ULPA 11256-005

2x3 277V ULPA 11256-006

2x2 120V HEPA 11257-001

2x2 220V HEPA 11257-002

2x2 277V HEPA 11257-003

2x2 120V ULPA 11257-004

2x2 240V ULPA 11257-005

2x2 277V ULPA 11257-006

Standard Filter

2x4 120V HEPA 11250-001

2x4 220V HEPA 11250-002

2x4 277V HEPA 11250-003

2x4 120V ULPA 11250-004

2x4 240V ULPA 11250-005

2x4 277V ULPA 11250-006

2x3.5 120V HEPA 11251-001

2x3.5 220V HEPA 11251-002

2x3.5 277V HEPA 11251-003

2x3.5 120V ULPA 11251-004

2x3.5 240V ULPA 11251-005

2x3.5 277V ULPA 11251-006

2x3 120V HEPA 11252-001

2x3 220V HEPA 11252-002

2x3 277V HEPA 11252-003

2x3 120V ULPA 11252-004

2x3 240V ULPA 11252-005

2x3 277V ULPA 11252-006

2x2 120V HEPA 11253-001

2x2 220V HEPA 11253-002

2x2 277V HEPA 11253-003

2x2 120V ULPA 11253-004

2x2 240V ULPA 11253-005

2x2 277V ULPA 11253-006

5

Installation, Operation, & Maintenance Manual

MAC 10®LEAC2

Fan Filter Unit

■Installation

Note: The MAC 10 LEAC2 Fan Filter Unit is completely assembled at the factory with the exception of the optional ¼” (0.64

cm)-20 eyebolts that are used when hanging the unit from an engineered support system and with installation of the HEPA/

ULPA lters. (Eyebolts are not included and need to be ordered separately, p/n 222449-001.)

Step 1. Carefully remove the unit from the shipping carton and inspect for any damage that may have occurred during

transportation. (See Figure 1.)

Note: When ordering RSRE units, the HEPA lters may be shipped separately to be installed into units after the fan box has

been installed.

Figure 1: Unboxing

Step 2. Wipe down plastic bag and move unit into cleanroom. (Double bagging is available upon request.)

Step 3. If using rigidly supported grid (usually 2” (50 mm) or wider), raise unit through ceiling and lower onto the gasketed

grid. If using a exible grid (typically supported with wires), the unit must be secured to an engineered support system with

eyebolts, s-hooks, and chain. Screw the four eyebolts into the nutserts on the lid assembly before lifting into an overhead

position. (See Figure 2.)

Note: Conrm fan dimensions to match T-grid dimensions. Special size units are available to t specic cleanroom grid systems.

Figure 2: Hanger Supports

Step 3.1. If using a support grid, continue...

Step 4. Raise the unit and secure it into place using the chosen support system method suspended from a structural support

bracing.

Step 5. Have an electrician wire the unit to the appropriate voltage, according to the wiring diagram (page 13), and all national

and local electrical codes. If optional power cord was purchased, plug unit into a grounded receptacle. The optional power

cord is not acceptable for plenum installations.

Step 6. Turn on the power using the rocker switch (ON/OFF) located on the electrical box. For RSRE units, let the unit run for

a few hours to purge off particulate (if lters are shipped loose) that may be adhered to the inside of the unit before installing

the lters. Do not run fan at full speed, as this may cause overload condition.

Note: Your fan lter controls may have been shipped separately.

EYEBOLT

FAN FILTER

UNIT

Innovators in Clean Air Technology | www.envirco.com | Installation, Operation & Maintenance

6

■Unit Control Box

ON/OFF Switch - Speed/Airow Adjustment

MAC 10 LEAC2 units are equipped with a two-position rocker switch (ON/OFF) and Solid State Speed Control (SSSC), which

are located on the front side of the electrical box. (See Figure 3.)

Recommended fan speed during initial start-up and operation is at a low speed. As airow eventually decreases due to lter

loading, fan speed may be increased by moving the SSSC rst to a medium speed and eventually to a high speed. Periodic

airow readings (per IEST specications) should be conducted to determine the lter condition and appropriate fan setting.

Figure 3: Speed/Airow Adjustment

■ENAC Control Card (Optional)

MAC 10 LEAC2 units will have the capability to include a unique ENAC control card in lieu of the SSSC for networking

purposes. Contact the factory for part number.

SOLID STATE

SPEED CONTROL

Turn clockwise for higher speed

Turn counterclockwise for lower speed

ON/OFF SWITCH

INCOMING POWER

CONDUIT PLATE

Figure 3 - Speed/Airflow Adjustment

Installation, Operation, & Maintenance Manual

Innovators in Clean Air Technology | www.envirco.com | Installation, Operation, & Maintenance

MAC 10®LEAC2

Fan Filter Unit

7

■Cleaning the LEAC2 Prefilter (Standard Foam)

Tools Required: None.

Note: To keep the lter in top operating condition, washing the foam prelter

(if installed) is recommended every three to six months.

Step 1. To gain access to the prelter, remove the ceiling panel next to the

unit, if applicable.

Step 2. Switch the ON/OFF switch to the OFF position.

Step 3. Remove the prelter from the snap-in frame. (See Figure 4, below.)

Step 4. Clean the prelter by hand washing in water with a mild detergent or by using a vacuum cleaner. Allow prelter to dry

completely before replacing.

Step 5. Complete by reversing the above steps.

■Changing the LEAC2 Prefilter (G4 Pleated)

Tools Required: None.

Note: To keep the lter in top operating condition, replacing the pleated

prelter is recommended every twelve months or sooner.

Step 1. To gain access to the prelter, remove the ceiling panel next to the

unit, if applicable.

Step 2. Switch the ON/OFF switch to the OFF position.

Step 3. Remove the prelter from the snap-in frame. The beverage board frame has slots that have to be depressed to release

the lter from the prelter housing (See Figure 5, above.)

Step 4. After removing the new G4 pleated prelter from the box, remove the die cut slots from the beverage board frame and

install on prelter bracket.

Step 5. Complete by reversing the above steps.

Installation, Operation, & Maintenance Manual

MAC 10®LEAC2

Fan Filter Unit

Figure 4 - Foam Prefilter Cleaning

ON/OFF SWITCH

PREFILTER SURFACE ON TOP SIDE

(3/8" THK BLACK 20 PPI OPEN CELL POLYURETHANE FOAM)

SUPPORT SCREEN ON BOTTOM SIDE

(UNI-GRID EXPANDED ALUMINUM 85% OPEN)

20" x 20" Prelter

Figure 4: Foam Cleaning Prelter

Figure 5 - G4 Prefilter Placement

ON/OFF SWITCH

20" x 20" Prelter

Prelter retention slots

Beverage board frame

Figure 5: G4 Prelter Placement

WARNING

DISCONNECT THE UNIT FROM THE

ELECTRICAL POWER SOURCE BEFORE

ATTEMPTING ANY SERVICE.

WARNING

DISCONNECT THE UNIT FROM THE

ELECTRICAL POWER SOURCE BEFORE

ATTEMPTING ANY SERVICE.

Innovators in Clean Air Technology | www.envirco.com | Installation, Operation & Maintenance

8

Installation, Operation, & Maintenance Manual

MAC 10®LEAC2

Fan Filter Unit

■Service: Removal and Replacement of Standard HEPA/ULPA Filters

Note: All lters should be visually inspected for freight damage before installation. It is necessary to use two workers when

removing the lter and for installation to avoid twisting or separation of the media seals. Handle the lter only by the frame

and never place anything on the upstream lter side of the lter. Additionally, it is important to keep the lter level to prevent

any shearing force on the media itself.

For Standard Filters:

Tools Required: Phillips head screwdriver, rivet hand tool, Ø5/32 aluminum rivet grip range .126-.187

Step 1. Remove unit from ceiling.

Step 2. Remove the eight screws holding the HEPA/ULPA lter to the lid assembly.

Step 3. Lift the lid assembly off the HEPA/ULPA lter. (See Figure 6.) Discard the used lter as per requirements of the

applicable regulations.

Note: Before replacing with a new HEPA/ULPA lter, carefully inspect the new lter for any visual damage. Also, inspect the

gasket in the “tee” bar to ensure a tight seal. Replace as necessary.

Step 4. Install rivets in ends to plug unused holes.

Step 5. Replace with the new HEPA/ULPA lter and complete by reversing the above steps.

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL

POWER SOURCE BEFORE ATTEMPTING

ANY SERVICE.

WARNING

THE STANDARD FILTER IS PROTECTED WITH AN

EXPANDED METAL FACE SCREEN. THIS IS

NEVER TO BE USED TO HANDLE THE FILTER.

IT IS ONLY FOR PROTECTION AGAINST AN

ACCIDENTAL TOUCH OF THE FILTER.

ONLY HANDLE THE FILTER BY THE FRAME.

Ø5/32 RIVET (6X)

(NONE ON 2X2)

#8x3/8 FLAT HEAD PHILLIPS SHEET METAL SCREW

2X4 & 2X3.5 = 10X; 2X3 & 2X2 = 8X

LID ASSEMBLY

STD FILTER

Figure 6 - Standard Filter Replacement

Figure 6: Standard Filter Replacement

Innovators in Clean Air Technology | www.envirco.com | Installation, Operation, & Maintenance

9

Installation, Operation, & Maintenance Manual

MAC 10®LEAC2

Fan Filter Unit

■Service: Removal and Replacement of RSRE Gel Seal Filters

Note: All lters should be visually inspected for freight damage before installation. It is necessary to use two workers when

removing the lter and for installation to avoid twisting or separation of the media seals. Handle the lter only by the frame

and never place anything on the upstream lter side of the lter. Additionally, it is important to keep the lter level to prevent

any shearing force on the media itself.

For RSRE Filters:

Tools Required: Phillips head screwdriver, 3/16” ball driver hex head wrench

Step 1. Remove the diffuser screen by removing the six 10-32x1/2 screws.

Step 2. Loosen the six 1/4x20 socket cap head screws far enough to rotate the lter clip 90°. The lter will not drop during this

operation. Slowly pull the lter away from the knife-edge seal, taking care not to touch the lter face during this operation. It

is important to pull the lter slowly and evenly away from the seal so that the gel remains in the lter gel track.

Step 3. Inspect lter for visual damage. If damaged, set aside for replacement or repair.

Step 4. Inspect the gel seal if reinstalling the removed lter. Determine if the gel has lost its ability to seal. If so, have a certied

professional replace the missing, dried out, and/or severely damaged gel.

Step 5. Place the lter evenly against the lter plenum housing of the RSRE unit. Install lter clips and screws. The clips

can be rotated and angled into place. Using the clips as a lever, the lter can be seated. It is recommended to work either

clockwise or counter-clockwise around the lter and raise the lter into the gel.

Step 6. Reinstall screen. Reinstall and hand-tighten diffuser screen screws. Avoid overtightening the screen hardware.

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL

POWER SOURCE BEFORE ATTEMPTING

ANY SERVICE.

WARNING

THE RSRE FILTER IS PROTECTED WITH AN

EXPANDED METAL FACE SCREEN. THIS IS

NEVER TO BE USED TO HANDLE THE FILTER.

IT IS ONLY FOR PROTECTION AGAINST AN

ACCIDENTAL TOUCH OF THE FILTER.

ONLY HANDLE THE FILTER BY THE FRAME.

FILTER PLENUM

(DOWN STREAM)

1/4-20 CAP SCREW

FILTER CLIP

SCREEN HARDWARE:

#10-32x1/2 PHP SCREW

#10 NYLON WASHER

GEL TRACK

PLENUM KNIFE EDGE

FILTER PLENUM

(UP STREAM)

GEL SEAL FILTER

PERFORATED DIFUSSER

SCREEN

SCREEN HARDWARE

FILTER CLIP

1/4-20 CAP SCREW

2-PIECE WELDED

FILTER PLENUM

HOUSING

FAN FILTER UNIT

GEL SEAL FILTER

Figure 7 - RSRE Filter Replacement

FILTER MEDIA

PERFORATED DIFUSSER SCREEN

Figure 7: RSRE Filter Replacement

Innovators in Clean Air Technology | www.envirco.com | Installation, Operation & Maintenance

10

Installation, Operation, & Maintenance Manual

MAC 10®LEAC2

Fan Filter Unit

■Service: Standard Motor Removal and Installation from Above Ceiling

Tools Required: Phillips head screwdriver, wire cutters to remove tie-down and install replacement tie-downs

Step 1. To gain access to the motor, remove the ceiling panel next to the unit, if applicable.

Step 2. Switch the ON/OFF switch to the OFF position.

Step 3. Remove the prelter off the prelter frame.

Step 4. Loosen the electrical cover screws (two), and slide/lift off cover. (See Figure 9.1.)

Step 5. Disconnect incoming power connections.

Step 6. Using a low torque setting, remove challenge port tubing, if applicable. (See Figure 8.)

Step 7. Remove the eight screws to free the motor/blower assembly from the lid assembly. If using power drivers, set the unit

to a low torque setting to avoid stripping the sheet metal screws (See Figure 9.1.)

Step 8. Lift motor/blower assembly lid and turn upside down.

Step 9. Disconnect motor wire harness connector from prelter bracket.

Step 10. Remove the four screws mounting the blower bracket to the blower assembly plate, and cut cable tie securing blower

cable to blower bracket. Remove motor mount assembly from plate.

Step 11. Remove the four screws mounting the blower to the blower bracket. (Note orientation of blower cable to bracket.)

Step 12. Install new motor/blower and components previously removed in reverse order to complete work. Don’t forget to

reinstall challenge port tubing, if applicable.

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL

POWER SOURCE BEFORE ATTEMPTING

ANY SERVICE.

WARNING

ELECTRICAL SERVICE SHOULD ONLY

BE PERFORMED BY LICENSED ELECTRICIANS OR

AUTHORIZED ENVIRCO SERVICE TECHNICIANS.

PUSH-FIT BULKHEAD UNION

PREFILTER BRACKET

PRESS RING IN AND

PULL OUT ELBOW

(FFU ASSEMBLY SHOWN WITHOUT PREFILTER AND ELECTRICAL COVER)

Figure 8 - Motor Replacement

Figure 8: Challenge Port Detail

PREFILTER

ELECTRICAL COVER

COVER MOUNTING HARDWARE (2X)

PREFILTER BRACKET

VENTURI RING

MOTOR/BLOWER ASSEMBLY

PREFILTER BRACKET

HARDWARE (8X)

FILTER (STD)

FILTER PLENUM (RSRE - NOT SHOWN)

CONDUIT PLATE

Figure 9.1 - Motor Replacement

LID PANEL ASSEMBLY

MOTOR/BLOWER MOUNTING

BRACKET

Figure 9.1: Standard Motor Replacement

Innovators in Clean Air Technology | www.envirco.com | Installation, Operation, & Maintenance

11

Installation, Operation, & Maintenance Manual

MAC 10®LEAC2

Fan Filter Unit

■Service: RSRE Motor Removal and Installation

Tools Required: 3/16 hex head wrench, Phillips head screwdriver

Note: It is highly recommended to also change the motor capacitor when changing the motor.

Step 1. To gain access to the motor, remove the gel seal HEPA/ULPA lter.

Step 2. Switch the ON/OFF power switch on top of the unit to the OFF position, or, if easier, OFF at the breaker panel.

Step 3. Disconnect motor wire harness connector from top panel, per lter removal instructions on page 9.

Step 4. Remove the four screws mounting the blower bracket to the upper plate, and cut cable tie securing blower cable to

blower bracket. Remove motor mount assembly from plate.

Step 5. Place motor mount assembly on workstation. Remove the four screws mounting the motor to the blower bracket.

(Note orientation of blower cable to bracket.)

Step 6. Install new motor/blower and components previously removed in reverse order to complete work. Carefully tighten

motor mount bracket screws. Don’t forget to reinstall challenge port tubing.

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL

POWER SOURCE BEFORE ATTEMPTING

ANY SERVICE.

WARNING

ELECTRICAL SERVICE SHOULD ONLY

BE PERFORMED BY LICENSED ELECTRICIANS OR

AUTHORIZED ENVIRCO SERVICE TECHNICIANS.

MOTOR MOUNTING BRACKET

CABLE TIE (FOR MOTOR CABLE)

MOTOR/BLOWER ASSEMBLY

MOTOR/BLOWER ASSEMBLY CONNECTOR

MOTOR BRACKET MOUNTING HARDWARE (4X)

#10-32 x 1/2 PHP SCREW

#10 LOCKWASHER

MOTOR MOUNTING HARDWARE (4X)

M6x16mm PHP SCREW

M6 LOCKWASHER

NOTE ORIENTATION OF MOTOR/BLOWER ASSEMBLY

AND MOTOR MOUNTING BRACKET, CABLE IS ORIENTED

AT NOTCH IN MOTOR MOUNTING BRACKET AND CABLE

TIED TO SIDE OF THE MOTOR MOUNTING BRACKET.

PREFILTER BRACKET

Figure 9.2 - Motor Replacement

Figure 9.2: RSRE Motor Replacement

PUSH-FIT BULKHEAD UNION

PREFILTER BRACKET

PRESS RING IN AND

PULL OUT ELBOW

(FFU ASSEMBLY SHOWN WITHOUT PREFILTER AND ELECTRICAL COVER)

Figure 8 - Motor Replacement

Figure 8: Challenge Port Detail

Innovators in Clean Air Technology | www.envirco.com | Installation, Operation & Maintenance

12

Installation, Operation, & Maintenance Manual

MAC 10®LEAC2

Fan Filter Unit

■Troubleshooting

IF LOW AIR VELOCITY

Step 1. Check prelter media; replace or clean as necessary.

Step 2. Adjust SSSC clockwise for higher blower output.

Step 3. Check power supply for proper voltage, amperage, and distribution frequency.

Step 4. Replace HEPA lter if the air velocity remains low.

IF HIGH AIR VELOCITY

Adjust SSSC counterclockwise for lower blower output.

NON-LAMINAR FLOW AND/OR EXCESSIVE CONTAMINATION

Step 1. Ensure that no large obstructions are upstream of airow pattern.

Step 2. Determine that no other air-moving devices are operating in or around cleanroom which disrupt room’s airow pattern.

Step 3. Check air velocity and, if low, conduct the “Low Air Velocity” procedure outlined above.

Step 4. Conduct smoke and photometer test on HEPA lter. Seal or replace HEPA lter as necessary.

Contact Technical Support at:

ENVIRCO

101 McNeill Road

Sanford, NC 27330, USA

Tel: (800) 884-0002

Fax: (800) 458-2379

Email: [email protected]

Innovators in Clean Air Technology | www.envirco.com | Installation, Operation, & Maintenance

13

Installation, Operation, & Maintenance Manual

MAC 10®LEAC2

Fan Filter Unit

■MAC 10 LEAC2 Wiring Diagrams

Figure 10 - WIRING DIAGRAM (SSSC)

BLUE

MOTOR

BROWN

BLACK

GRN/YEL

WHITE

GRN/YEL

SPEED CONTROL

WHITE

GRN/YEL

BLUE

GRN/YEL

WHITE

MAC10 LEAC2

INPUT

POWER

CAPACITOR

Figure 10: Wiring Diagram (SSSC)

Figure 11 - WIRING DIAGRAM (ENAC)

BLUE

MOTOR

BROWN

BLACK

GRN/YEL

WHITE

GRN/YEL

WHITE

GRN/YEL

BLUE

WHITE

MAC10 LEAC2

INPUT

POWER

CAPACITOR

AC LINE AC NEUT MTR NEUT MTR AUX MTR MAIN

BLUE

UNIQUE ENAC CARD

Figure 11: Wiring Diagram (ENAC)

Innovators in Clean Air Technology | www.envirco.com | Installation, Operation & Maintenance

14

Installation, Operation, & Maintenance Manual

MAC 10®LEAC2

Fan Filter Unit

■MAC 10 LEAC2 Replacement Parts Diagrams

ITEM DESCRIPTION

1

2

4

5

6

PREFILTER BRACKET

ELECTRICAL COVER

LID PANEL

FILTER PLENUM

MOTOR MOUNTING BRACKET

DIFFUSER SCREEN

7B

3

1PRE-FILTER, 20X20, FOAM (STANDARD)

1

2

2

2

3

4

5

5

5

6

6

6

PRE-FILTER, 20X20, 2" PLEATED (OPTIONAL

CAPACITOR, 440VAC, 3µF (230V)

VENTURI RING

ROCKER SWITCH, DPST (ON/OFF)

SPEED CONTROL (115V)

SPEED CONTROL (230V)

SPEED CONTROL (277V)

MOTOR/BLOWER ASSEMBLY (115V)

MOTOR/BLOWER ASSEMBLY (230V)

MOTOR/BLOWER ASSEMBLY (277V)

CAPACITOR, 440VAC, 4µF (277V)

CAPACITOR, 440VAC, 16µF (115V)

PART NUMBER

62981-038

64125-001

268110-001

268110-002

268110-003

268109-001

63739-002

268716-115

268716-230

268716-277

268171-115

268171-230

268171-277

ITEM FILTER REPLACEMENT, FFU SIZE (ACTUAL

FILTER SIZE)

7A STD FILTER, 2X4 (23.63 x 47.63)

HEPA (99.99%)

69600S-001HAPXX

7A STD FILTER, 2X3.5 (23.63 x 41.63)

7A STD FILTER, 2X3 (23.63 x 35.63)

7A STD FILTER, 2X2 (23.63 x 23.63)

ULPA (99.9995%)

69600S-001UAPXX

PART NUMBER

69600S-002HAPXX 69600S-002UAPXX

69600S-003HAPXX 69600S-003UAPXX

69600S-004HAPXX 69600S-004UAPXX

7B RSRE FILTER, 2X4 (21.00 x 45.00) 69601-001H

7B RSRE FILTER, 2X3.5 (21.00 x 39.00)

7B RSRE FILTER, 2X3 (21.00 x 33.00)

7B RSRE FILTER, 2X2 (21.00 x 21.00)

69601-001U

69601-002H 69601-002U

69601-003H 69601-003U

69601-004H 69601-004U

1

2

4

5

6

PREFILTER BRACKET

ELECTRICAL COVER

LID PANEL

MOTOR MOUNTING BRACKET

7A

3

Standard Style RSRE Style

Innovators in Clean Air Technology | www.envirco.com | Installation, Operation, & Maintenance

15

Installation, Operation, & Maintenance Manual

MAC 10®LEAC2

Fan Filter Unit

■Limited Warranty

LIMITED WARRANTY: Unless otherwise expressly

stated in ENVIRCO’s published specifications for the

Goods, ENVIRCO warrants that Goods are free from

defects in material and workmanship, except for services

which are warranted to be performed in a competent and

diligent manner in accordance with any mutually agreed

specifications. The foregoing warranty shall apply for

eighteen (18) months from the date of shipment from

ENVIRCO’s facility, except for services for which the

warranty shall apply for ninety (90) days from the date

of performance (the “Warranty Period”). Provided Buyer

informs ENVIRCO in writing of any breach of warranty

prior to the expiration of the applicable Warranty Period,

ENVIRCO shall, as its sole obligation and Buyer’s sole

and exclusive remedy for any breach of this warranty,

repair or replace/re-perform the Goods which gave rise

to the breach or, at ENVIRCO’ option, refund the amounts

paid by Buyer for the Goods which gave rise to the breach.

Any repair, replacement or re-performance by ENVIRCO

hereunder shall not extend the applicable Warranty Period.

The parties shall mutually agree on the specifications of

any test to determine the presence of a defect. Unless

otherwise agreed upon by ENVIRCO in writing, Buyer shall

bear the costs of access, de-installation, re-installation

and transportation of Goods to ENVIRCO and back to

Buyer. These warranties and remedies are conditioned

upon (a) the proper storage, installation, operation,

and maintenance of the Goods and conformance with

the proper operation instruction manuals provided by

ENVIRCO or its suppliers or subcontractors, (b) Buyer

keeping proper records of operation and maintenance

during the applicable Warranty Period and providing

ENVIRCO access to those records, and (c) modification

or repair of the Goods only as authorized by ENVIRCO.

ENVIRCO does not warrant the Goods or any repaired

or replacement parts against normal wear and tear or

damage caused by misuse, accident, or use against the

instructions of ENVIRCO. Any modification or repair of any

of the Goods not authorized by ENVIRCO shall render

the warranty null and void. EXCEPT AS EXPRESSLY

SET FORTH HEREIN, ENVIRCO MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES

OF MERCHANTABILITY, NON-INFRINGEMENT OR

FITNESS FOR A PARTICULAR PURPOSE WHICH ARE

HEREBY DISCLAIMED TO THE EXTENT PERMITTED

BY APPLICABLE LAW.

■Testing

Each MAC 10 LEAC2 filter unit is thoroughly tested at

the factory before shipment. However, because of the

“rigors” of shipping, ENVIRCO encourages its re-test after

installation.

ENVIRCO recommends that the customer contact an

independent organization, with technicians trained and

experienced in performance evaluation and maintenance

of clean air equipment.

HEPA filters (Type J) are tested to IEST-RP-00034.

ULPA filters are tested to (Type F) IEST-RP-00034.

All filters are UL 900 recognized. Your filters may have

special requirements; please see original engineering

specifications for your specific project.

All units that are airflow tested at ENVIRCO are tested

using a Shortridge Airdata Multimeter 870 with a Velgrid

head. The recommended method of reading is to place

one corner of the Velgrid head 1-1/4” from the corner of

the filter face, take four readings evenly spaced along the

four foot side, then repeat these reads three additional

times. This gives a total of eight readings to test the unit.

All advertised data is based on using the Velgrid with eight

readings (128 velocity points). ENVIRCO recognizes that

using eight readings during a cleanroom start-up may be

time-consuming and recommends that using four Velgrid

readings taken on each 2x2 filter section will approximate

the same as eight readings.

Innovators in Clean Air Technology | www.envirco.com | Installation, Operation & Maintenance

Clean air solutions built for you.

MORE INFORMATION AVAILABLE AT WWW.ENVIRCO.COM

ENVIRCO MAC 10 is a registered trademark of ENVIRCO, USA. Specications subject to modications or changes without notice. US patents 4,560,395 and 5,470,363. Other patents issued and pending in foreign countries.

Copyright © 2017 ENVIRCO. All Rights Reserved.

Form P/N #: 268195-001 Rev. 02/17

Industrial

Cleanroom Products

»MAC 10®Original

»MAC 10®IQ™

»MAC 10®IQ™ LAF

»MAC 10®LEAC™

»MAC 10®LEAC2™

»MAC 10®LEDC™

»Ducted Ceiling Module:

DCM & RSR

»AC or DC Control Systems

»MAC-T Ceiling Grid System

Hospital & Healthcare

Hospital & Healthcare

»IsoClean®and IsoClean

with Ultraviolet Light

»AirCeil®

»Hospi-Gard®Room

Pressure Monitor

Enviramedic Products

»HOR Horizontal Flow

Enclosure

»HCF Horizontal Flow

Surgery Room

»VOR Vertical Flow Surgery

Isolator

Pharmaceutical

Pharmaceutical &

Medical Device

»Unimodule M2 Vertical

Laminar Flow Workstation

»METD 100% Exhausted

Vertical Flow Workstation

»Laminar Downow Module

Laboratory & Research

Laboratory & Research

»100-Plus Horizontal or

Vertical Flow Clean Bench

»Unidirectional Flow

Horizontal Flow Bench (LF)

»TT Table Top Horizontal

Flow Clean Bench

»EnviraLab Sterility Module:

ESM

ENVIRCO®

101 McNeill Road | Sanford, NC 27330, USA

tel: 919.775.2201 | toll free: 800.884.0002 | fax: 800.458.2379

Table of contents

Popular Fan manuals by other brands

Ebmpapst

Ebmpapst A3G500-BA73-S1 operating instructions

Ebmpapst

Ebmpapst 8412 NGLLE-287 operating manual

Ebmpapst

Ebmpapst W3G710-GS30-01 operating instructions

Ebmpapst

Ebmpapst D4D225-FH02-01 operating instructions

HOMEDEPOT

HOMEDEPOT DB30TBN-LP Use and care guide

Ebmpapst

Ebmpapst K3G500-PB33-01 operating instructions

Comfort Zone

Comfort Zone CZHVP30CN owner's manual

Super Vac

Super Vac V20-BL user guide

Duracraft

Duracraft DFS-211N owner's manual

Ebmpapst

Ebmpapst K3G200-AD21-01 operating instructions

Atlas IED

Atlas IED TT-FK10-1 installation manual

System air

System air SAVE VTR 250/B Service & Accessories Installation Manual