Envirovent heatSava User manual

SHOULD YOU ENCOUNTER ANY PROBLEMS INSTALLING THIS UNIT CALL

Contents

Page

01 Introduction 2

02 Box Contents 3-4

03 Technical Specications 5-6

04 Safety 7

05 Installation 8-17

Installation with wall seal 17-18

06 Controls 19

07 Maintenance 19-20

08 Wiring Diagrams 21-22

Scan the QR code to watch the step by step installation video

AFTER INSTALLING THIS UNIT PLEASE LEAVE THIS INSTALLATION GUIDE WITH THE USER

DO NOT THROW AWAY

02

Gold Standard After Sales Service

In the unlikely event of any on-site installation problems or queries regarding the EnviroVent heatSava, just call our

hotline number. We will take your details and appoint a regional installation manager to call you back to discuss the

problem. In the majority of cases, the problem can be resolved over the phone. However, in cases where the problem

cannot be resolved over the phone, we will arrange a visit from our Gold Standard Engineer. They will meet with your

contractor/direct labour on-site to discuss and resolve the problem, will provide training and also give advice on the

installation of the unit.

INSTALLER HOTLINE: 07540 050 147

Ensure that this product is treated with care, installed and maintained correctly i.e. for

the life of the building. Remember, if you have any problems please call our dedicated

Technical Team.

Thank you for choosing EnviroVent

The fastest growing ventilation company in the UK

01 Introduction

SHOULD YOU ENCOUNTER ANY PROBLEMS INSTALLING THIS UNIT CALL

02 Box Contents

heatSava Unit1

Heat Cell2

SELV (optional)3

Instructions Guide4

Halo5

Wall Seal6

AFTER INSTALLING THIS UNIT PLEASE LEAVE THIS INSTALLATION GUIDE WITH THE USER

DO NOT THROW AWAY

04

02 Box Contents

Description Quantity Item

heatSava Unit 1x

Heat Cell 1x

SELV (optional) 1x

Fixing Kit 1x

No.8 x 1½Screws -

(Fixing Kit Contents) 11x

M5 x 40 Screws -

(Fixing Kit Contents) 3x

Red Wall Plugs -

(Fixing Kit Contents) 3x

Wall Kit Contents

Halo (optional) 1x

Wall Seal (optional) 1x

SHOULD YOU ENCOUNTER ANY PROBLEMS INSTALLING THIS UNIT CALL

03 Technical Specications

Unit Dimensions

Front Assembly

(Supply Fan)

Badge

Centre Assembly

(Electronics)

Rear Assembly

(Extract Fan)

AFTER INSTALLING THIS UNIT PLEASE LEAVE THIS INSTALLATION GUIDE WITH THE USER

DO NOT THROW AWAY

06

03 Technical Specications

Heat Cells Options

Cell - Ø150mm / 500 Wall Depth

Cell - Ø100mm / 500 Wall Depth

Cell - Ø150mm / 600 Wall Depth

Cell - Ø100mm / 600 Wall Depth

Cell - Ø150mm / 430 Wall Depth

Cell - Ø100mm / 430 Wall Depth

Cell - Ø100mm / 310 Wall Depth

Cell - Ø150mm / 310 Wall Depth

SHOULD YOU ENCOUNTER ANY PROBLEMS INSTALLING THIS UNIT CALL

04 Safety

Never modify the fan or electronics•

Do not store inammable products in the vicinity of this product•

This appliance is not intended for use by persons (including children) with•

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children should be

supervised to ensure that they do not play with the appliance.

For a bathroom application the power supply should be installed outside the•

bathroom as it is 230V.

This unit draws air in from atmosphere and you must ensure that any emissions•

from any other systems such as gas or oil boilers, do not contaminate the air

entering the heatSava product. Therefore, before installation, consider where

the external cowl will be located in relation to any boiler ues etc. Externally,

we recommend that the unit to be positioned a minimum distance away of; 1

metre horizontally, 1 metre below or 3 metres above any boiler ue etc. Also

refer to Building Regulations, Document J – Combustion Appliances & Fuel

Storage Systems.

In kitchens, if the unit has to be tted above a cooker, it should be installed a •

minimum distance of 650mm above electric cookers and 750mm above gas

cookers, and not have a pullcord tted.

Be sure to have read and understood these instructions before

beginning the installation process. Electrical Assembly

When wiring the unit in, a suitable disconnect device such as

a switched fused spur should be used, do not use a plug. The

means of disconnecting the unit from the mains power supply

must be incorporated in the xed wiring in accordance with the

wiring rules.

There must be a necessity to allow disconnection of the

appliance from the supply after installation, unless the appliance

incorporates a switch complying with the wiring rules. The

disconnection may be achieved by incorporating a switch in

the xed wiring in accordance with the wiring rule.

The electrical install comprises of a power supply unit (Fig.1) or a

low voltage box - SELV (Fig.2). The 2 and 3 core cables are to be

supplied by the installer. See pages 21-22 for wiring diagrams..

Connect 3 core

cable into unit

Connect 2 core cable

from SELV box into unit

Connect 3 core

cable into SELV

3 core2 core

SELV Box

Fan

Board

Power

Supply

SELV

MAINS

Fig.1

Fig.2

IPX4 Rated

This unit has been tested to IPX4 and is suitable for installation

within Zone 1 of bathrooms. However, we recommend that

you must position the unit above any water devices such

as taps, showerheads or jets and ensure water is not aimed

directly at the unit. Do not use jets or shower heads etc to

clean this unit.

AFTER INSTALLING THIS UNIT PLEASE LEAVE THIS INSTALLATION GUIDE WITH THE USER

DO NOT THROW AWAY

Introduction

Designed for through the wall installation, the heatSava is ideal

for both refurbishment and new build properties. The outside

diameter of the heat exchange casing is smaller than a standard

wall sleeve and can therefore utilize an existing one already in

place. The heatSava also takes into account the complexities

of different wall depths to offer 4 different main lengths that the

heat exchange casing is manufactured to (see page 6). The unit

is installed from the inside out to allow for ease of installation in

high-rise applications.

Built with intelligent humidity tracking controls means no

user intervention is required and heatSava silent-night mode

prevents noisy running at night. The heatSava is exceptionally

versatile and can be installed horizontally or vertically in 4

different positions through 360° (Fig.1).

Pre-Installation Checklist

Before starting the installation process, ensure that you have all

the necessary equipment and the following:

Check wall depth•

heatSava Unit•

Heat Cell•

Fixing Kit•

Wall Seal Kit (optional)•

Low Voltage Box (optional)•

Choose position and orientation•

Heat Cell Orientation

When tting the heat cell into a wall, ensure that the cowl end is

correctly orientated with the end always facing down. (Fig 2.)

Clearance

The heatSava has been designed to allow easy installation into

an existing wall sleeve which is located near the ceiling. When

core drilling into an existing wall, make sure you have enough

space to move around and distance between the wall and any

objects nearby i.e cupboards (Fig.3).

Ensure the unit is sited in a suitable position for adequate

clearance on all sides for easy access to the unit for maintenance

purposes and to ensure that access to the release clips on the

front cover is not inhibited.

08

05 Installation

Fig.2

Fig.1

3

12

6

9Cell

logo

Cell

Fig.3

heatSava

cupboard

LEAVE ADEQUATE CLEARANCE

SHOULD YOU ENCOUNTER ANY PROBLEMS INSTALLING THIS UNIT CALL

05 Installation

Clearance

First measure the wall depth.

If installing into a new build application, we recommend that

the unit should be installed in the position below (option 1). If

installing into an existing wall sleeve which is located near to the

ceiling, the heatSava can be installed horizontally or vertically

(options 2-4).

Ceiling

Ceiling

30mm

min

30mm

min

Option 1

Option 3 Option 4

Option 2

20mm

min

20mm

min

Cover release

clips

AFTER INSTALLING THIS UNIT PLEASE LEAVE THIS INSTALLATION GUIDE WITH THE USER

DO NOT THROW AWAY

10

05 Installation

Before core drilling, determine which heat cell will be

inserted through the wall and core drill accordingly

(Fig.2A & 2B).

Using the template provided, align it with a spirit level

against the wall and draw around the circle for the location

of the core hole (Fig 1A).

For the 100m model, drill a hole with a diameter of 107mm or

117mm if using a wall seal. For the 150mm model drill a hole

with a diameter of 158mm or 162mm if using a wall seal. If

tting with a wall seal see pages 17-18.

Mark out the locations for the 3 xing holes. Use either A or B

depending on how smooth the wall surface is (Fig 1B).

(The rear assembly has 6 feet to help when xing to uneven surfaces)

Marking Out - Template Sheet

Installation Process - Core Drilling

Fig.1A Fig.1B

Fig.2A Fig.2B

SHOULD YOU ENCOUNTER ANY PROBLEMS INSTALLING THIS UNIT CALL

Using a screwdriver remove the badge and undo screw

(Fig.3A). Next remove the front cover of the unit using the

release clips as shown.

Installation Process - Front Cover

05 Installation

To remove the front cover, release the top clip rst and then

release the two clips at the bottom by pushing in at the points

indicated on the centre assembly of the unit (Fig.3B).

Fig.3A Fig.3B

Using a spirit level, align the rear assembly of the unit to

the wall ensuring it lines up with the marked out xing

holes locations (Fig.4A).

Installation Process - Rear Assembly

Fig.4A

Drill 3x xing holes and t 3x wall plugs.

AFTER INSTALLING THIS UNIT PLEASE LEAVE THIS INSTALLATION GUIDE WITH THE USER

DO NOT THROW AWAY

12

Detach the electronics lid from the centre assembly by

removing the screws. Then using a screwdriver pierce

through the grommet (Fig.6A).

Feed the power cable through the hole. Push the fan cable

through the hole and secure using the grommet. Inside connect

the fan cable to the fan board (Fig.6B).

Installation Process - Centre Assembly

Fig.6A Fig.6B

There are 3 cable entries on the rear assembly. Locate

the one suitable for the install and pull the mains cable

through the selected entry hole (Fig.5A).

Fig.5A Fig.5B

Fit the rear assembly to the wall using the 3 screws (Fig.5B).

05 Installation

Installation Process - Rear Assembly

SHOULD YOU ENCOUNTER ANY PROBLEMS INSTALLING THIS UNIT CALL

05 Installation

Pull the mains cable through the entry hole and pierced

grommet in the centre assembly. Connect the cable to the

mains supply or SELV board depending on the model being

installed (Fig.7A). See pages 21-22 for wiring diagrams.

Installation Process - Centre Assembly

Fig.7A Fig.7B

Now securely x the centre assembly to the rear assembly

together on the 4 xing points using the screws provided

(Fig.7B).

Detach the strip from the electronics lid and securely x it

in place to restrain the cable (Fig.8A).

Make sure all cables are connected correctly, then x the

electronics lid back on using the screws provided (Fig.8B).

Fig.8A Fig.8B

AFTER INSTALLING THIS UNIT PLEASE LEAVE THIS INSTALLATION GUIDE WITH THE USER

DO NOT THROW AWAY

14

05 Installation

The next step is to t the pullcord. Depending on the

orientation of the unit, the pullcord can be situated in 4

positions (Fig.9A & 9B).

Fig.9A Fig.9B

Choose the suitable one for the install and make sure the

pullcord is always facing downwards.

Installation Process - Pullcord

Dependent on the installation orientation, when tting the

pullcord, make sure it is neatly tucked within the grooves.

(Fig.10A & 10B).

Fig.10A Fig.10B

SHOULD YOU ENCOUNTER ANY PROBLEMS INSTALLING THIS UNIT CALL

The heat cell can now be inserted through the aperture.

The cowl end is removable to enable correct orientation.

Apply solvent cement and ensure it is always facing

downwards (Fig.11A).

Fig.11A Fig.11B

Carefully insert the heat cell ensuring it meets the 3 xing feet

(Fig.11B).

05 Installation

Installation Process - Heat Cell Insertion

Secure the heat cell to the 3 xing points on the centre

assembly using the screws provided (Fig.12A).

Ensure the plastic screw is xed to the centre of the heat cell

and the cell key is placed back in its holder (Fig.12B).

Fig.12A Fig.12BFig.12A Fig.12B

AFTER INSTALLING THIS UNIT PLEASE LEAVE THIS INSTALLATION GUIDE WITH THE USER

DO NOT THROW AWAY

16

Take the front cover and connect the fan leads together

(Fig.13A).

Fig.13A Fig.13B

Ensure the fan leads are neatly tucked down the side and do

not trap them against the end of the cell before putting the front

cover on (Fig.13B).

Installation Process - Front Cover

05 Installation

Click and shut the front cover, and x it in place using the

screw. Place the fan badge on the front cover (Fig.14A).

Tidy the mains cable and if required use conduit etc. Make the

electrical connection via a fused spur and switch the unit on

and leave to run in trickle mode. Use the pullcord to test trickle

and boost modes (Fig.14B).

Fig.14A Fig.14B

SHOULD YOU ENCOUNTER ANY PROBLEMS INSTALLING THIS UNIT CALL

Mark out the seal line on the heat cell. Always t heat cell

through unit BEFORE tting seal (Fig.16A & Fig 19).

After following instructions on page 10, take the centre

assembly and t it over the heat cell, then repeat the process

using the rear assembly (Fig.16B).

Externally: Complete the installation by tting the halo

using sealant - DO NOT SEAL AROUND THE CASING

(Fig.15A & 15B).

Fig.15A Fig.15B

Installation Process - Halo Fixing

05 Installation

Fig.16A Fig.16B

Installation Process - Wall Seal option

AFTER INSTALLING THIS UNIT PLEASE LEAVE THIS INSTALLATION GUIDE WITH THE USER

DO NOT THROW AWAY

18

05 Installation

Take the wall seal and t it over the heat cell. The seal

must be tted inside the wall depth. Use the marked seal

line as reference (Fig.17A).

Installation Process - Wall Seal option

Carefully insert the heat cell through the aperture ensuring the

cowl end is facing downwards (Fig.17B).

Feed the power cable through the hole (See page 12,

Fig.5A & 5B). Secure the rear and centre assembly

together using the screws provided (Fig.18A).

Fig.17A

Fig.18A

Fig.17B

heatSava

60mm + wall depth = Seal Line

Wall seal

Mark out

seal line

INTERNAL EXTERNAL

SHOULD YOU ENCOUNTER ANY PROBLEMS INSTALLING THIS UNIT CALL

06 Controls

07 Maintenance

Pullcord (Manual)

The heatSava comes complete with a pull cord to activate the

boost if required. Pull once to activate the boost and once to

deactivate

Intelligent Humidity Tracking (Automatic)

The heatSava has been engineered with intelligent controls

to think for itself, meaning that you don’t need to press any

buttons or light switches to turn it on.

When the heatSava senses a rise in humidity, caused by

increased moisture generation such as through cooking or

showering, the extract and supply airows will slowly begin to

increase in direct proportion to the increase in humidity. It will

then automatically track back down again when humidity falls.

This controls condensation quietly and efciently.

Summer Mode (Automatic)

During warmer days, the heatSava prevents warm air from

entering the room and switches to provide extract ventilation

only. As the temperature falls it automatically returns to heat

recovery mode.

Frost Protection (Automatic)

The heatSava has an automatic built-in frost protection

mechanism to prevent any damage to the heat exchange cell

in cold conditions.

Cleaning

General cleaning of the vents and cells should be every 6

months max, or as required, as environments will vary.

Service Intervals

General maintenance should ideally take place every 12 months

and should be carried out by a competent person adhering to

the instructions stated in the cleaning section below.

5 Year Service

The heat exchange cell and all components and parts should

be inspected every 5 years.

Using a screwdriver remove the badge and undo the screw

(Fig.20B). Next remove the front cover of the unit using the

3 release clips. Carefully keep hold of the front cover and

disconnect the fan connectors.

Vacuum clean the side of the grille (Fig.20A)

Fig.20BFig.20A

Other manuals for heatSava

4

Table of contents

Popular Swimming Pool Heater manuals by other brands

Pentair

Pentair MT Sizes 500 Installation and operation instructions

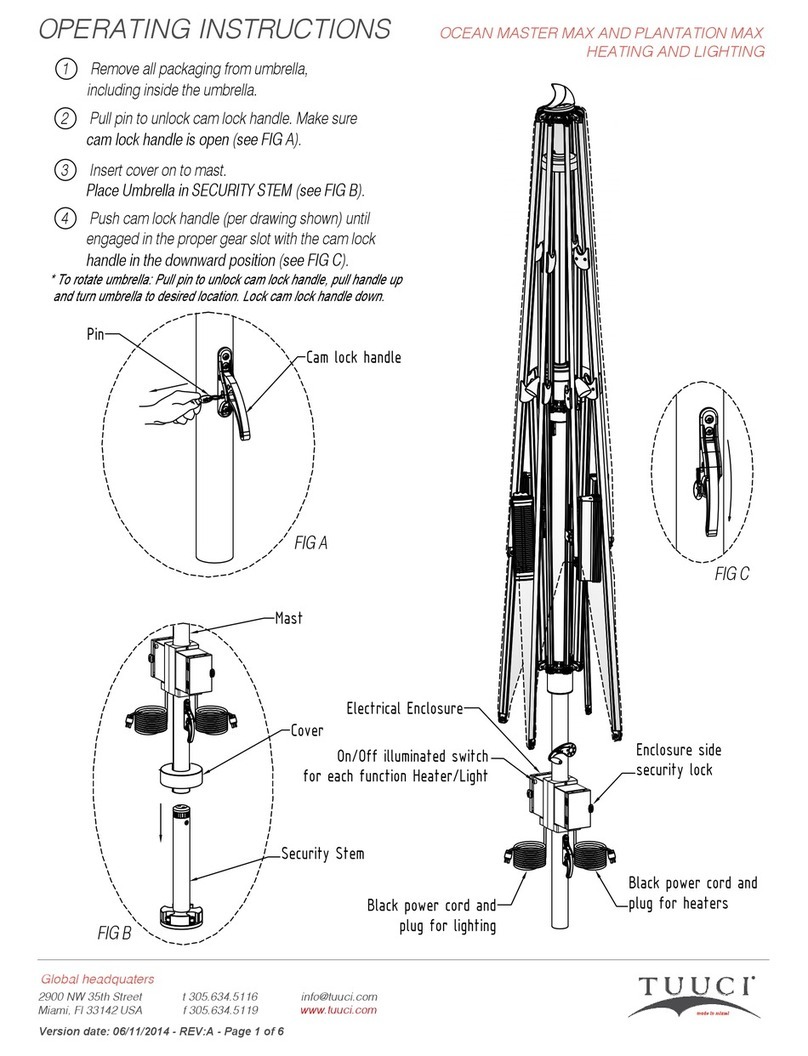

Tuuci

Tuuci OCEAN MASTER MAX operating instructions

Hayward

Hayward H150FD Service & installation manual

EINHELL

EINHELL FWW 2000 operating instructions

ambiance

ambiance pc14ss owner's manual

Intex Marketing

Intex Marketing HT30220 owner's manual

Alfalaval

Alfalaval AquaPool-7 Installation, commissioning and maintenance manual

Racer

Racer Direct manual

Thermomart

Thermomart DTH101 quick start guide

Hayward

Hayward H150FD owner's manual

MICRODOS

MICRODOS Pooltec Installation, Programming and Maintenance Instructions

Magen eco-Energy

Magen eco-Energy UMA Solar Sunstar Solar Pool Heating Homeowner's manual