enware Custodian WMSSB-000 User manual

I00348_Jun 20

Installation and Maintenance Instructions

The Custodian

®

Smart Board

Call 1300 369 273

www.enware.com.au

Enware Australia Pty Limited

9 Endeavour Rd Caringbah NSW 2229 Australia

Ph: 02 8536 4000 info@enware.com.au

WMSSB-000 - without solenoids

WMSSB-001 - with solenoids

2 Call 1300 369 273 www.enware.com.au

product description

The Custodian®Smart Board directly controls and monitors the delivery of water in secure or

controlled bathroom environments. The compact and easy to install unit houses the Electronic

Thermostatic Mixing Valve (eTMV), eTMV Control Hub (WMSSB-000 model), with Basin/

Shower solenoids and service isolation/strainers and check valves (WMSSB-001 model).

Features:

• Rapid installation of pre-assembled and tested plumbing assembly

• Integrated control of water flow and thermostatic temperature control of shower and basin

• Toilet full and half flush connections

• Plug-and-play cable connectors for all fixtures and Smartflow Water Management System

The eTMV Control Hub is designed to be a generic smart hardware platform which is used for

multiple applications such as shower and basin tapware and toilet flush valves in domestic /

public / aged care / hospital / detention plumbing systems depending on the configuration.

The hub has a RS485 network interface to connect to either a local or cloud based water

management system. The network connection allows the hub to be configured, monitored

and updated remotely.

When activated, water is delivered to the shower or basin outlet at the selected thermostatic

temperature and for a pre-configured runtime. This is achieved by using an Electronic

Thermostatic Mixing Valve (eTMV) for temperature control and a solenoid for flow control. The

available activation methods depend on the configured mode.

www.enware.com.au Call 1300 369 27 3

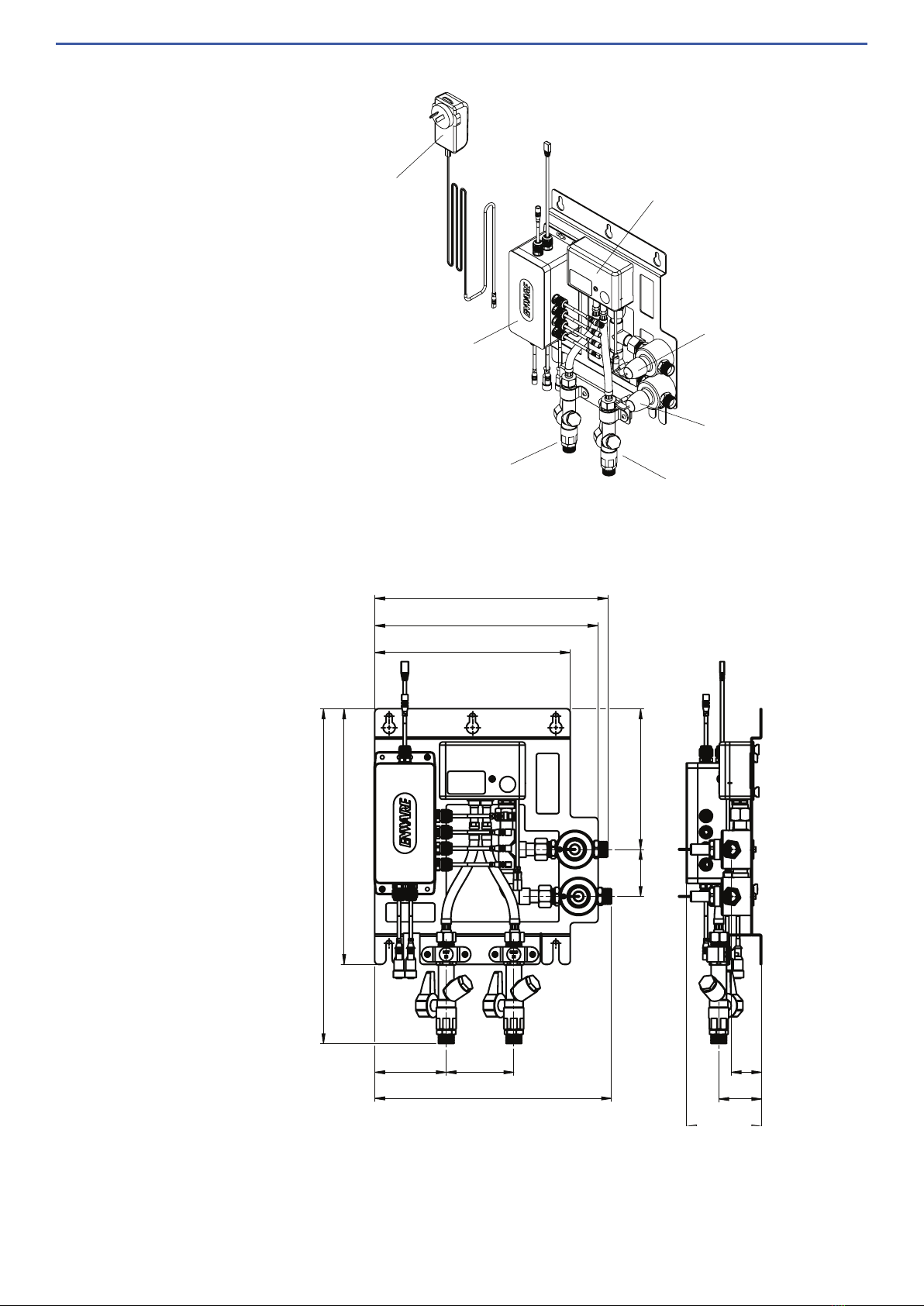

260

340

445

297

310

95

315

187

63

90

100

57

41

SOLENOID

MIXED TO SHOWE

R

SOLENOID

MIXED TO BASIN

HOT INLET

ISOLATION, STRAINER

& CHECK VALVE COLD INLET

ISOLATION, STRAINER

& CHECK VALVE

ETMV

CONTROL HUB

ELECTRONIC TMV

TRANSFORMER

12V DC

All measurements are in millimetres.

The Custodian®Smart Board

(WMSSB-001 Model)

(WMSSB-001 Model)

4 Call 1300 369 273 www.enware.com.au

technical data - electronic tmv

Water Supply

Inlet Temperatures Cold: Min. 5°C Max. 30°C

Hot: Min. 55°C Max. 85 °C

Outlet Temperature Range

(Temperature limits and sengs controlled by

Smarlow System)

Min. 5 °C Max. 50 °C (+/- 2˚C)

Thermal Flush Temperature

(Temprorarily enabled by server, acvated on site)

Max. 70 °C

Dynamic Inlet Pressures Min. 100 kPa Max. 500 kPa

Dynamic Pressure Dierenal

Between Hot and Cold Supplies

Must be less than 100 kPa*

Stac Inlet Pressure

For Tesng Purposes / System Commissioning

Max. 1600kPa

Minimum Flow Rate 2 Litres/min

Maximum Flow Rate 32 Litres/min @ 300 kPa pressure loss

as per ow sizing graph

Inlet & Outlet Connecons 1/2" BSP Male

*AS3500.4 clause 1.9.4.2 - The dynamic pressure differential between hot and cold supplies when

mixed at a thermostatic mixing valve shall not exceed 10%.

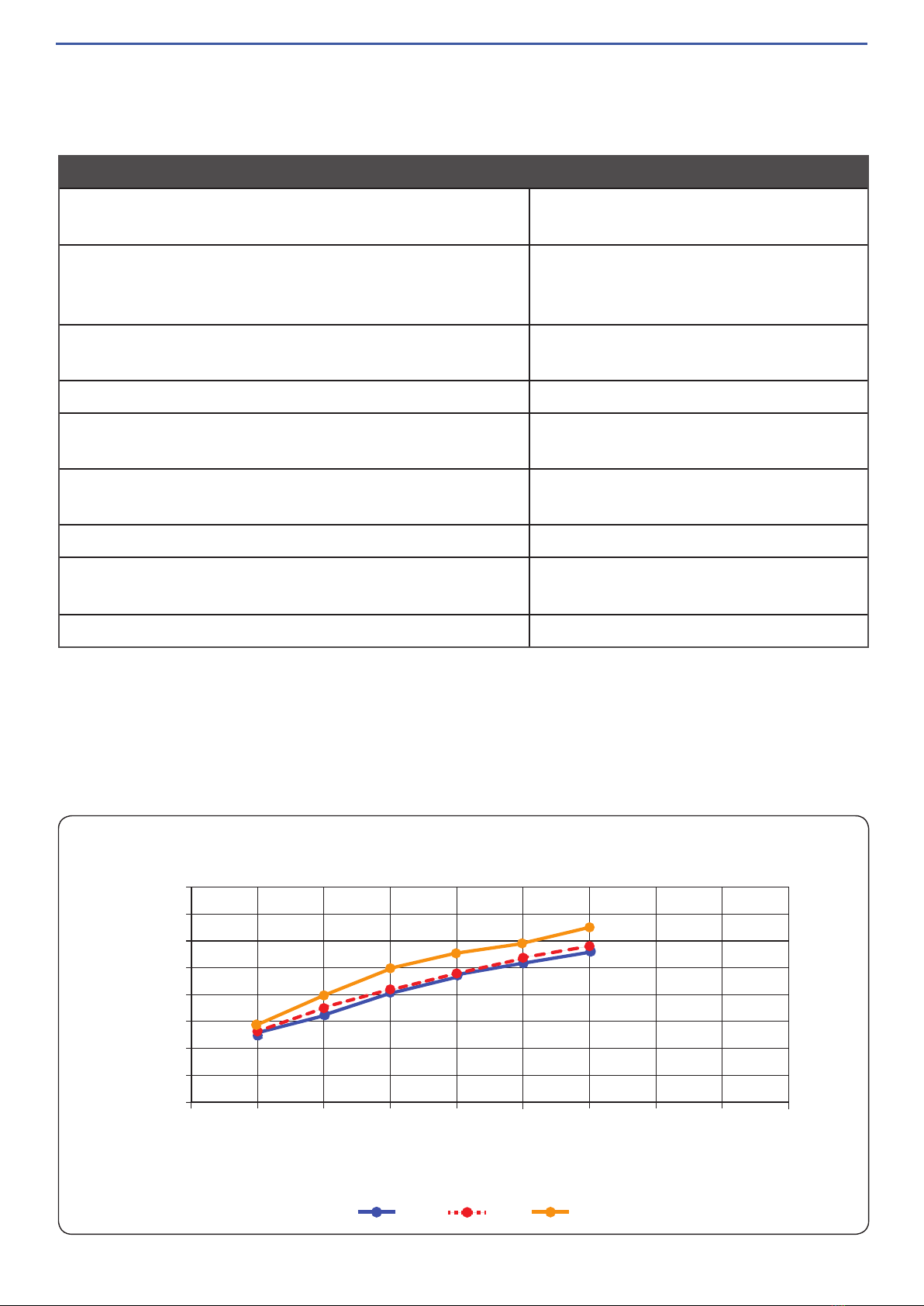

Electronic Thermostatic Mixing Valve (eTMV)

eTMV Flow Sizing Graph

FLOW RATE VS PRESSURE LOSS

40

35

30

25

20

15

10

5

0

050 100 150 200 250 300 350 400

450

Flow rate ( litres / minute )

Dynamic pressure (kPa)

cold hot mixed

www.enware.com.au Call 1300 369 27 5

Power

Included Power Supply Input Requirements 100-240VAC 50/60Hz

Nominal Input Voltage 12VDC

Input Voltage Tolerance 10%

Typical Power Consumpon 1W

Maximum Power Consumpon 36W

Environmental Specicaons

Heat Output (BTU/HR) 3.4

Operang Temperature 5 - 50 °C

Communicaon Ports

Type of Port Smarlow Communicaon Port

Number of Connectors 1

Serial Port Protocol RS485

Serial Port Speed 38400 baud

Piezo Buon Ports

Number of Inputs 4

Type of Inputs Piezo Buons

Number of Connectors 2

Type of Connector KCC SK5/5 Male

TLI Control Wheel Port

Number of Connectors 2

Type of Connector KCC SK9/8 Male

Flushing Solenoid Ports

Number of Outputs 1

Type of Outputs 10W solenoid

Voltage of Outputs 12V

Number of Connectors 1

Connector Type KCC SK2/2 Female

eTMV Control Hub

technical data - eTMV control hub

6 Call 1300 369 273 www.enware.com.au

installation

1. The Custodian®Smart Board should be

securely fixed to a wall in close proximity

to the interface facia plate(s), flushing

solenoid, and within 1m of a 240VAC

GPO ideally located above the Smart

Board.

It should be placed in a clean dry

environment, in an access duct or service

duct or some other appropriate location

where it can be accessed for servicing.

Fix Smart Board to a wall, using

appropriate screws. SEE IMAGE 01

Enware products are to be installed in accordance with the Plumbing Code of Australia (PCA)

and AS/NZS3500. Installations not complying with PCA and AS/NZS 3500 may void the

product and performance warranty provisions.

Reference should also be made to the Australasian Health Facility Guidelines (AHFG), ABCB

and Local Government regulations when considering the choice of, and the installation of

these products.

NOTE: Enware Australia advises:

1. Due to ongoing Research and Development, specifications may change without notice.

2. Component specifications may change on some export models.

For use with potable water only.

installation compliance

IMAGE 01

www.enware.com.au Call 1300 369 27 7

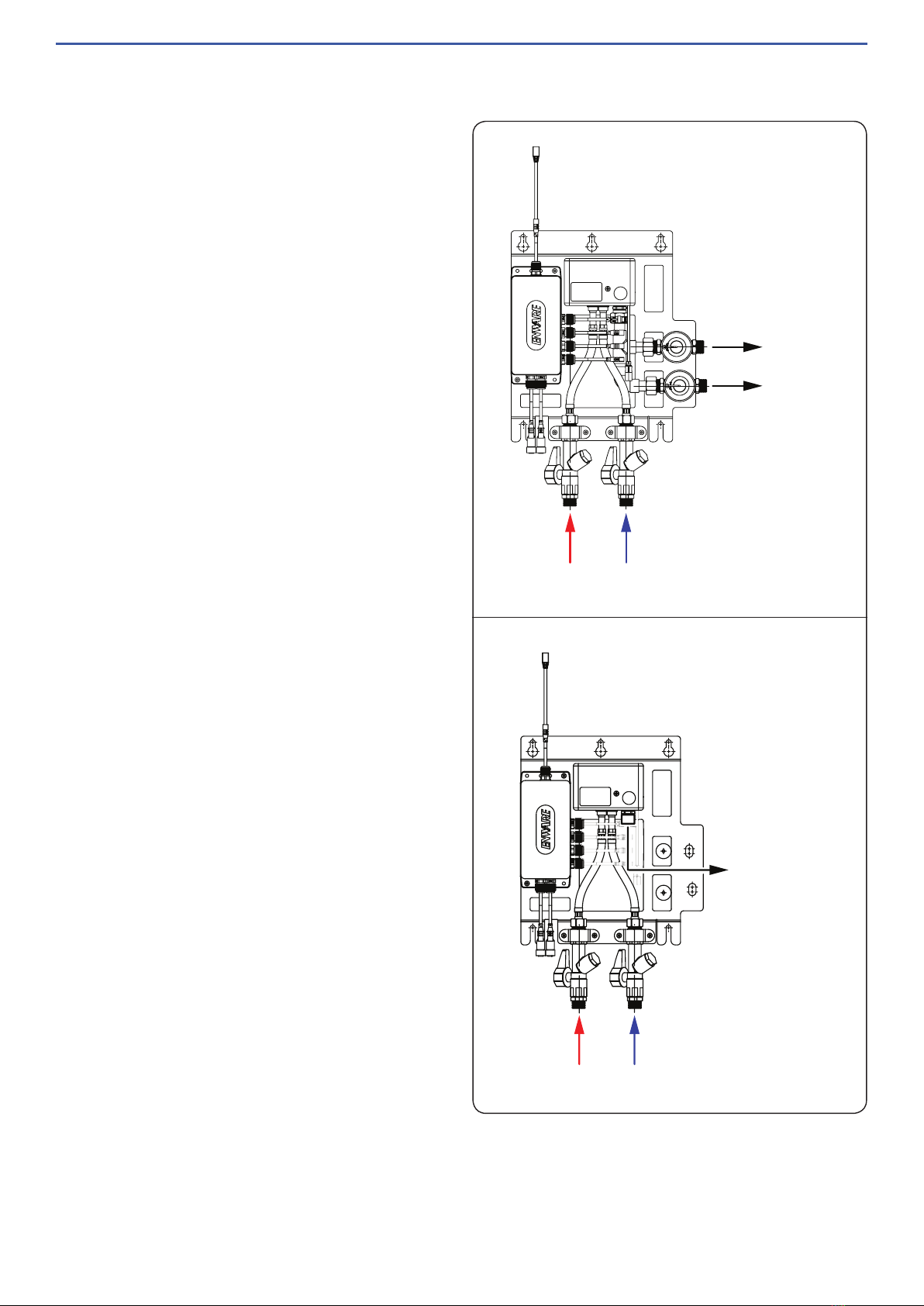

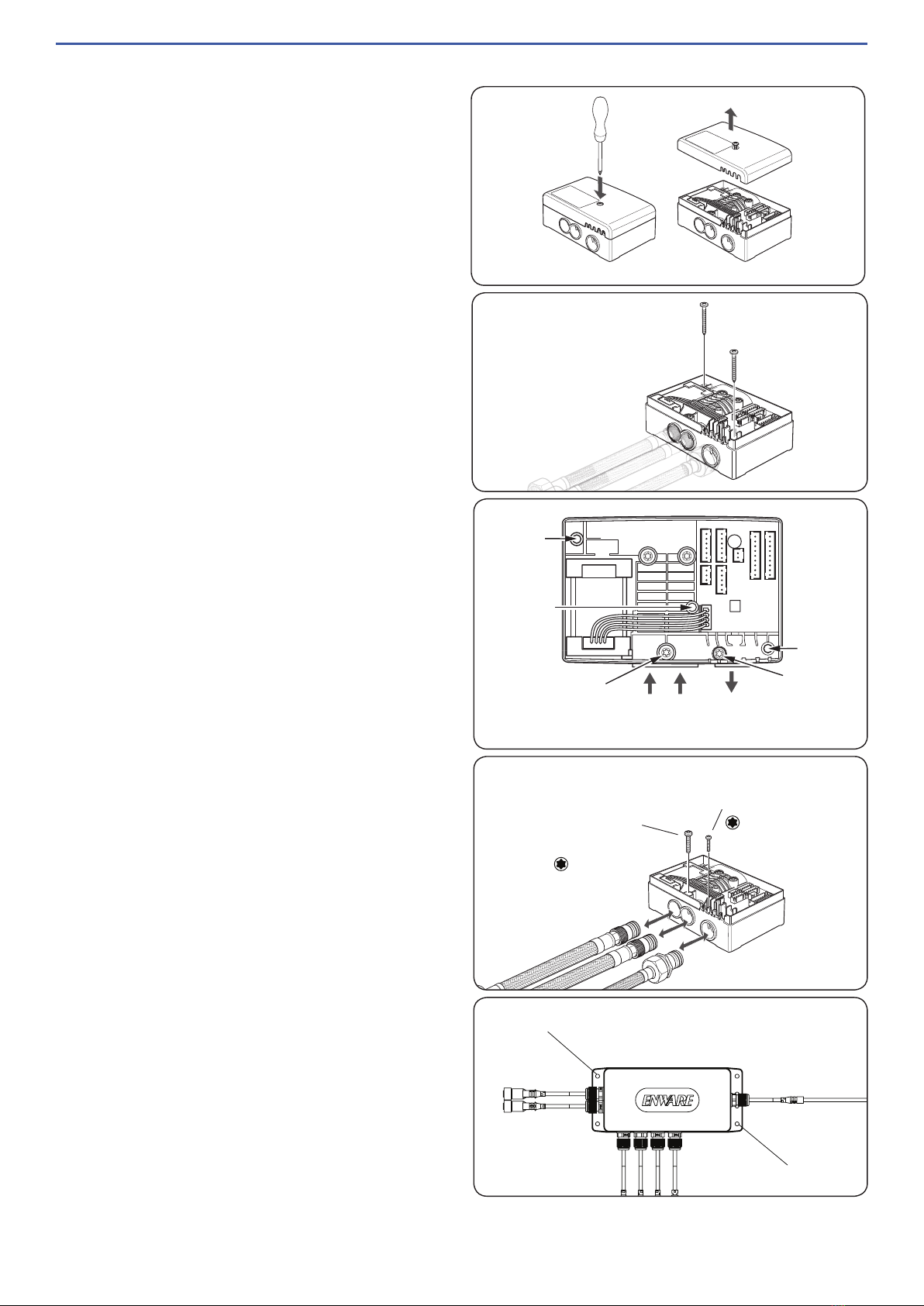

2. Flush water supply lines and ensure the

lines are clear of any debris.

3. Connect water lines to each connection.

SEE IMAGE 02

CONNECTION TO SHOWER

CONNECTION TO BASIN

COLD INLET

1/2” BSP MALE

HOT INLET

1/2” BSP MALE

IMAGE 02

ETMV OUTLET

CONNECTION

COLD INLET

1/2” BSP MALE

HOT INLET

1/2” BSP MALE

WMSSB-001 Model

WMSSB-000 Model

www.enware.com.au Call 1300 369 27 8

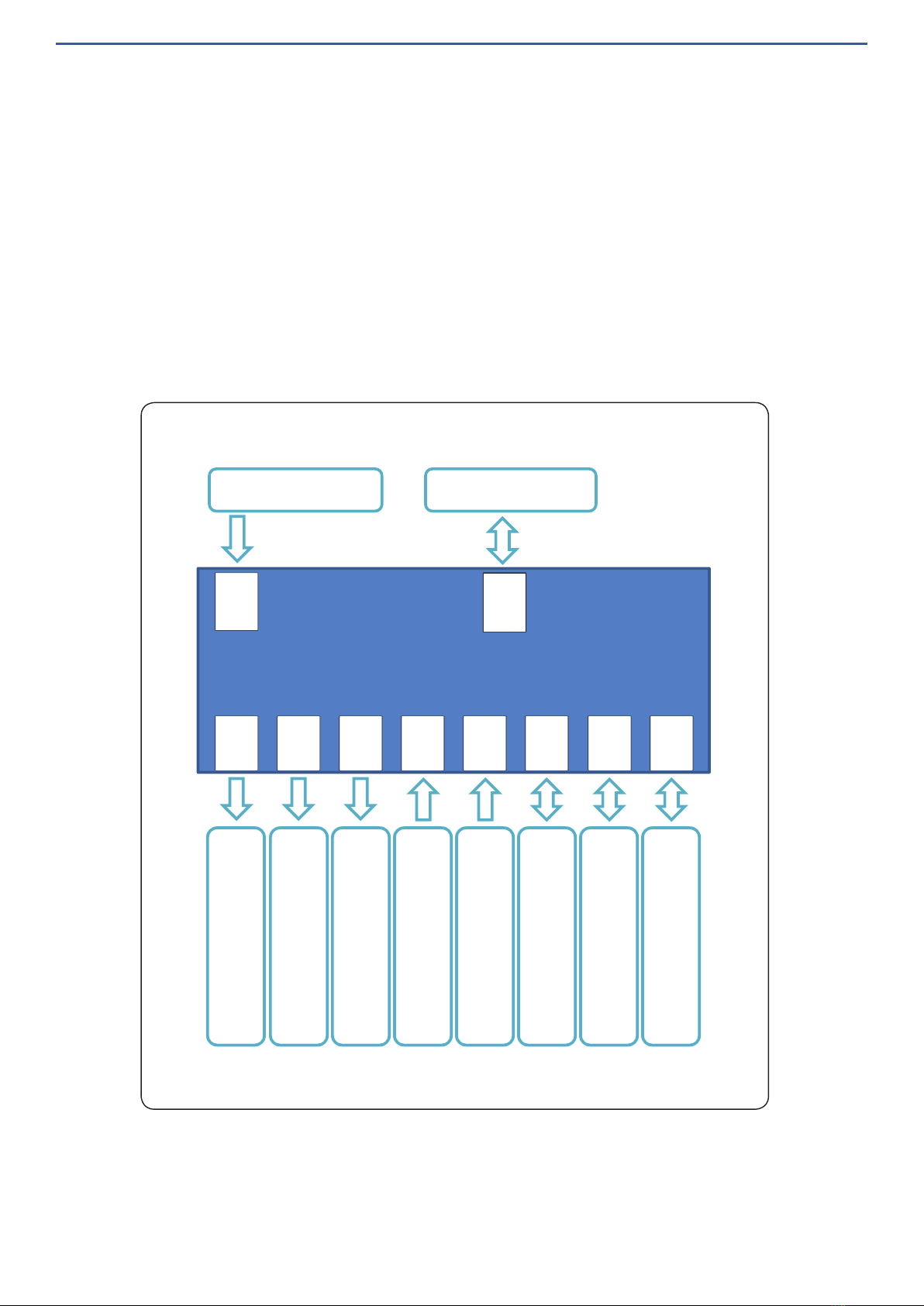

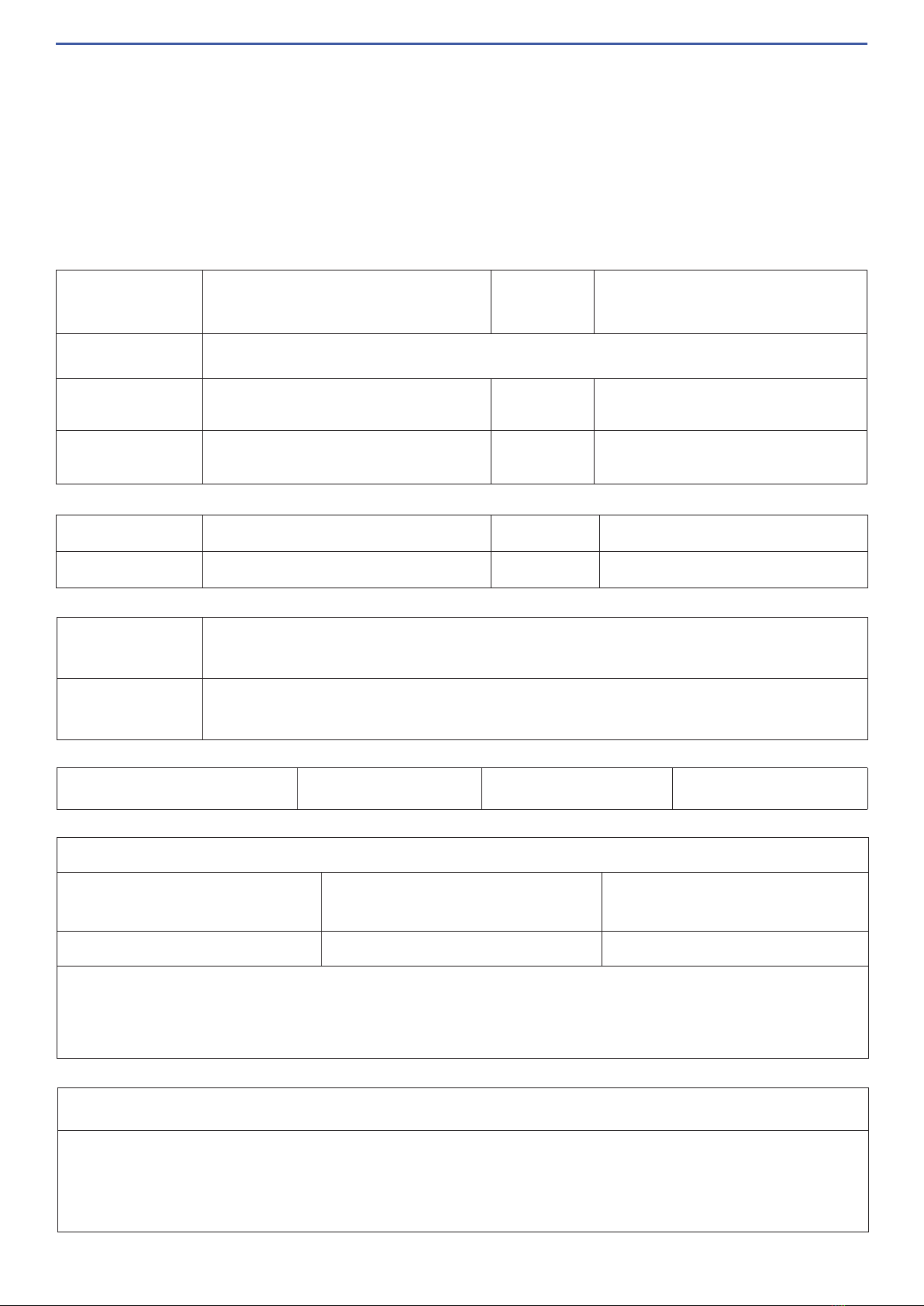

Control Hub Overview

SN3SN2SN1ETMV

12V

DC

RS485

B1,B2

TLI1

TLI3

B3,B4

eTMV Control Hub Cable Connections

1. Connect cable connections for the control plate(s) and flushing solenoid to eTMV Control

Hub.

The cable connections should be plugged into the eTMV Control Hub in the location

marked with the same designator - e.g. “w1” should be connected to the other cable

labeled “w1”.

Care should be taken with the position and orientation of the connections. Align white

marking on the connectors when connecting. When unplugging cables, hold the cable

connectors themselves, and do not pull on the cables.

Follow the installation instructions for eTMV Control Panel for correct cable connections.

2. Connect RJ45 Network cable to the surface mount RJ45 Jack.

The main Backbone Cable will have already been installed and a surface mount RJ45

Jack will be fitted less than 1m above the Custodian Smart Board location.

3. Finally connect the power supply (supplied transformer) to power the Custodian®Smart

Board.

9 Call 1300 369 273 www.enware.com.au

eTMV Control Hub Connections

• 1x RJ45 network cable for communications and updates (external)

• 1x power supply input (external)

• 4x piezo button inputs (external)

• 2x TLI control wheels (external)

• 1x ETMV output (on Smart Board)

• 2x shower / basin solenoid outputs (on Smart Board)

• 1x flushing solenoid output (external)

ETMV CONTROL HUB

SHOWER SOLENOID

BASIN SOLENOID

FLUSH SOLENOID

SHOWER TLI

BASIN TLI

ETMV

SHOWER AND BASIN

ACTIVATION BUTTONS

FULL AND HALF FLUSH

BUTTONS

SN2

SN1

SN3

B1,B2

B3,B4

W1

W3

ETMV

Smart Flow RS485

RS485

12VDC

12V POWER PACK

10 Call 1300 369 273 www.enware.com.au

operation

Piezo Button Activation

WC HALF FLUSH

ACTIVATION

WC FULL FLUSH

ACTIVATION

BASIN OUTLET

ACTIVATION

SHOWER

ACTIVATION

PRESS ONCE TO ACTIVATE

CONTROL PANEL

IMAGE 03

Lightly press the piezo button once to activate. SEE IMAGE 03

www.enware.com.au Call 1300 369 27 11

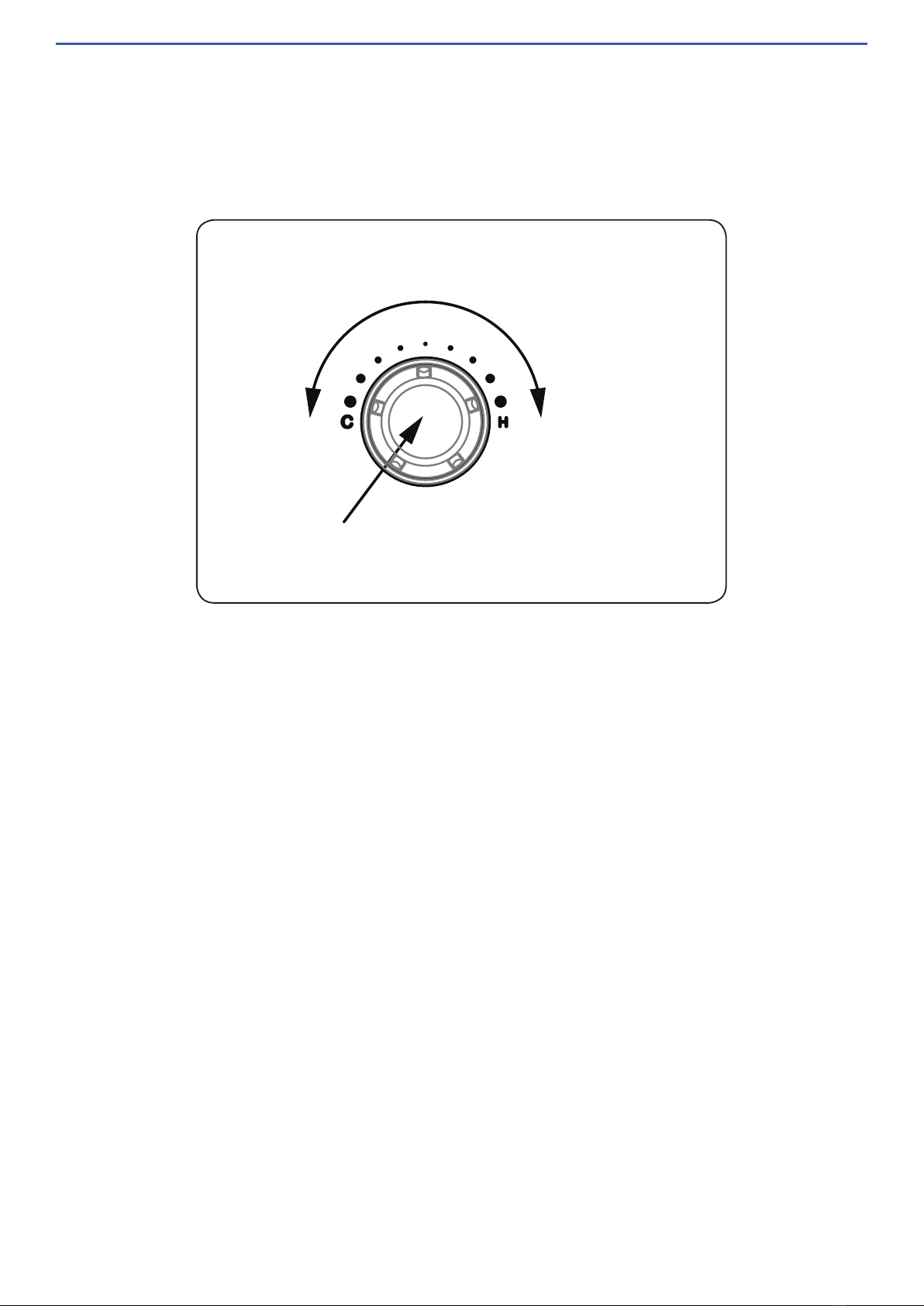

The temperature control wheel activation button (TLI) adjusts the temperature of water

delivered to shower or basin, and is also a push activation button for shower or basin

(depending on the configuration).

The lights in the TLI are used to provide feedback to the user on the current operating state.

When activated the TLI colour will change from blue to orange to red as the temperature set

point is adjusted from cold to warm to hot.

TLI Wheel Light Indicators:

• Time Pulse: A number of pulses proportional to the number of minutes the shower

has been running will take place periodically. The time between each set of pulses is

configurable.

• Eco Pulse: The TLI will pulse green, orange or red depending on how long the shower has

been running. The time between each set of pulses is configurable.

• End Flash: The TLI will flash in the last few seconds of the shower.

• 30 Second Warning Flash: The TLI will flash a few times when there is 30s remaining.

Disabled if Time Pulse or Eco Pulse are enabled.

• Water Pulse: The water will turn off for 1s then back on when it reaches the pre-set time

remainder time before the shower turns off automatically.

• When Disabled: if the user attempts to use a disabled interface it will flash pink 4 times on

all TLI control wheels.

TURN TO ADJUST TEMPERATURE

+

-

PUSH TO ACTIVATE SHOWER / BASIN TAP*

* FOR SELECTED MODELS WITH NO PIEZO BUTTON ACTIVATION

BLUE

ORANGE

RED

°C

°C

Temperature Control Wheel and Activation Button (TLI)

IMAGE 04

Push the wheel button once to activate.*

Turn the wheel to adjust outlet temperature.

12 Call 1300 369 273 www.enware.com.au

commissioning - eTMV

Upon completion of the installation, the valve should be tested and commissioned as per the

procedure outlined below or as specified by the local authority.

A calibrated digital thermometer having rapid response time with maximum temperature

hold will be required to measure the outlet mixed temperature of the valve. (Enware Code

ATMS1200 - Aquablend Test Kit)

1. Check the Outlet Temperature

1. Open the cold supply line to eTMV, then open the hot supply line, ensuring there are no

leaks.

2. Activate and open the outlet that is serviced by the shortest length of pipework between

the mixing valve and outlet fixture. To do this, press the piezo button or Temperature

Control Wheel on the Fascia Control Plate to activate shower or basin tap.

(The default maximum run time per activation is 2 minutes for basin and 45 minutes for

shower.)

3. Turn the Temperature Control Wheel clockwise to the highest warm water temperature

setting.

4. Allow the mixed outlet to flow for at least 60 seconds to allow the temperature to stabilize,

then take a temperature reading at the outlet with a digital thermometer.

The flow rate should be at least 2L/min. The flow rate can be checked with the aid of a

known size container and a stopwatch.

5. Activate the other outlet (if applicable) while the first one is running. Check that the outlet

temperature is stable over the full range of flow rates, and that the temperature and flow

rate is adequate for the application.

www.enware.com.au Call 1300 369 27 13

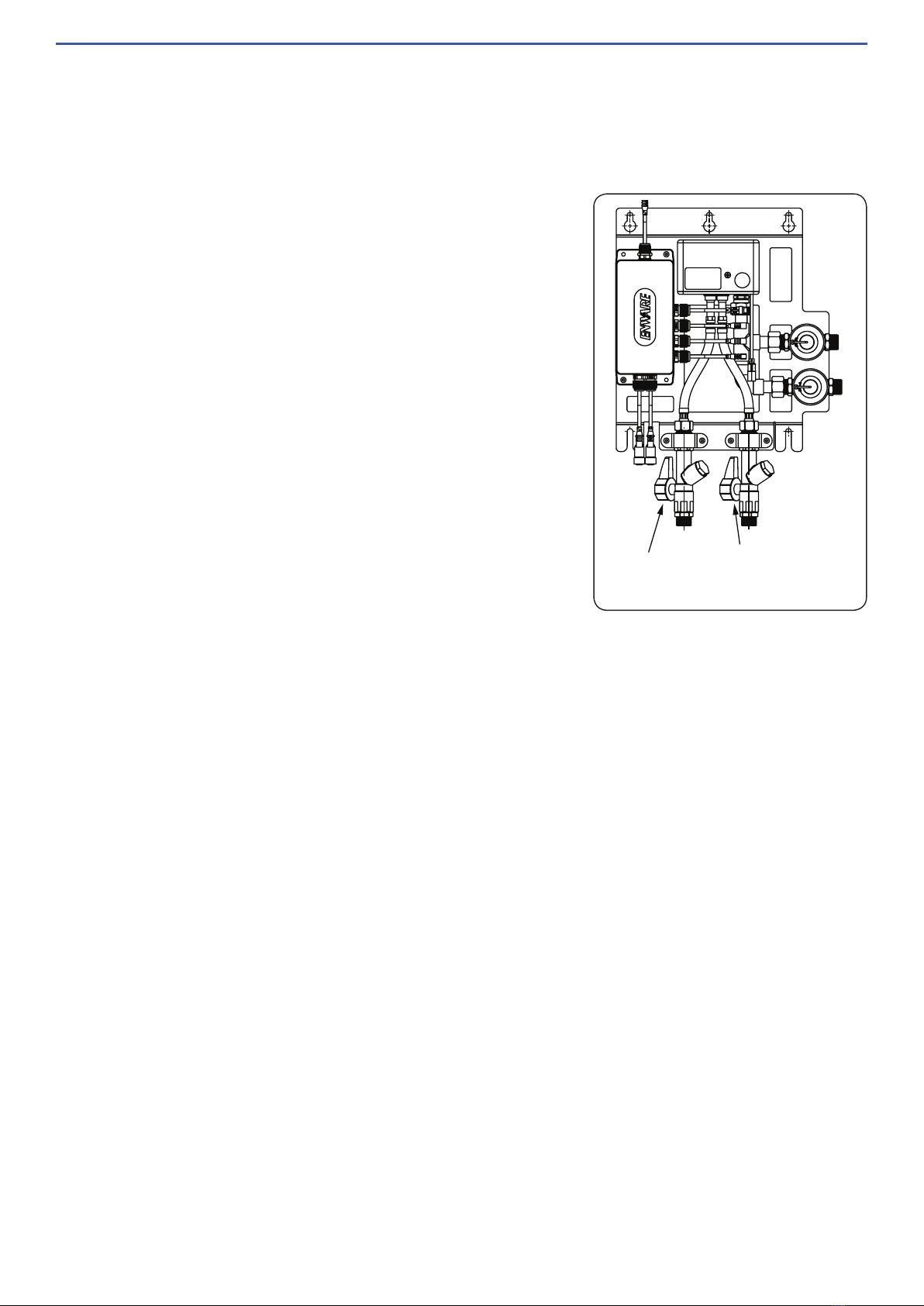

HOT ISOLATION

VALVE

COLD ISOLATION

VALVE

2. Shut Down Test

Now that the temperature has been checked, it is

necessary to perform a shut down test.

1. Turn on the outlet and turn the Temperature

Control Wheel clockwise to the highest warm

water temperature setting. Allow the mixed water

temperature to stabilise and note the outlet

temperature.

2. While holding a digital thermometer in the outlet flow,

quickly isolate the cold water supply to the valve by

shutting the cold water inlet isolation valve.

(SEE IMAGE 05)

The outlet flow should quickly cease flowing. The flow

should be less than 0.1L/min following the isolation.

Monitor the maximum outlet flow temperature,

and record this on the Commissioning Report. The

temperature should not exceed that allowed by the

applicable standard or code of practice for each

state.

3. Restore the cold water supply to the valve. After

the mixed water temperature has stabilised, note

the outlet temperature again, ensuring the outlet

temperature has re-established.

4. Repeat the above test, except this time quickly isolate the hot water supply to the valve by

shutting the hot water inlet isolation valve. The outlet flow should quickly slow to a trickle.

The trickle should be less than 0.1L/min following the isolation.

5. Restore the hot water supply to the valve. After the mixed water temperature has

stabilised, measure and record the outlet temperature, ensuring the outlet temperature has

re-established.

6. Turn off the outlets.

Ensure that all details of the Commissioning Report are completed and signed by the relevant

signatories, and a copy is kept with the installer and owner of the premises.

The valve is now commissioned and it can be used within the technical limits of

operation.

IMAGE 05

14 Call 1300 369 273 www.enware.com.au

Commissioning Mode - Explanation

Once installed and commissioned the Custodian®Smart Board can operate as an

independent device in Commissioning Mode. The operation and control of the fixtures will be

determined by the firmware in the eTMV Control Hub.

Commissioning Mode allows for the automatic flushing of pipes, especially during

commissioning phase or for rooms with an extended vacancy.

Commissioning Mode is enabled by default (for Custodian®devices only) and eTMV Control

Hub will operate in this mode until commissioning mode is manually disabled or the firmware

is changed. This can be achieved via the software operating on the central control PC via

the main Backbone Network Cable, or by a standalone laptop connected directly to the

Custodian®eTMV Control Hub.

Manager Activation

It can be enabled or disabled using the Smart Flow Software or manually by unscrewing the

lid and pressing the blue button quickly 3 times.

Data Logging

Temperature and flow is recorded.

Sequence

The following sequence will occur at a random time (to prevent all hubs running

simultaneously) if Commissioning Mode is enabled:

1. T=0m 00s: TLIs start flashing orange, wait 10 seconds

2. T=0m 10s: Shower runs at 40°C for 30 seconds

3. T=0m 40s: Shower stops, wait 3 seconds

4. T=0m 43s: Shower runs at 15°C for 10 seconds

5. T=0m 53s: Shower stops, wait 3 seconds

6. T=0m 56s: Basin runs at 40°Cfor 30 seconds

7. T=1m 26s: Basin stops, wait 3 seconds

8. T=1m 29s: Basin runs at 15°C for 10 seconds

9. T=1m 39s: Basin stops, wait 3 seconds

10. T=1m 42s: Toilet runs for 3 seconds

11. T=1m 45s: Toilet stops, TLIs return to flashing white

www.enware.com.au Call 1300 369 27 15

maintenance and servicing - eTMV

The eTMV is a compact Thermostatic Mixing Valve that uses modern self-controlling

multiprocessor technology to monitor and control the temperature and flow, by means of

ceramic discs and electromechanical drives.

eTMV does not have a thermostatic wax element or dynamic O-rings that are typically

used in traditional thermostatic mixing valves. Instead, ceramic discs are controlled by

electromechanical drives, and eTMV has no parts to service or replace during regular

servicing.

The eTMV is constantly monitored for real-time performance by the Enware Smartflow TMV

monitoring system.

The eTMV will only require minimal preventative maintenance work to ensure it operates at

its optimum level of performance. The valve should be commissioned, and serviced annually,

unless the installed conditions dictate more frequent servicing is necessary.

Every 12 months eTMV should be inspected and tested. The valve and surrounding area

should be inspected for leaks or water damage and action taken if required. Ensure a clean

dry work area is available.

Servicing of eTMV is in line with AS4032.3.

Cleaning the Strainers

Firstly isolate the hot and cold supplies

to the mixing valve by closing the inlet

isolation valves. With a suitable spanner

remove strainer cap on the inlet fitting then

remove mesh strainer.

Clean strainers with a suitable descaling

solvent (such as CLR) diluted with water.

Check for physical damage and thoroughly

rinse with clean water. Strainers can then

be re-installed into the ball valve and

strainer cap replaced and tightened to a

maximum torque of 15Nm into the inlet ball

valve bodies.

Non-Return Valve Operation

To check Non-Return Valve on the HOT

inlet side, carry out the following steps:

annual maintenance procedure

CHECK VALVE

STRAINER

ISOLATION

STRAINER CAP

IMAGE 06

16 Call 1300 369 273 www.enware.com.au

5-year maintenance

The eTMV has no mechanical or electronic actuation component to service or replace at

regular servicing, and there are no parts to service or replace at 12-month or 5-year intervals

as described in the Australian Standard AS4032.3 Section B 4.2 and Section 2.7.1.

No replacement of thermostat or o-rings is required as the eTMV does not have any.

The 5-year maintenance will simply be an annual service. Refer to annual maintenance

procedure on page 15.

1. Turn OFF the isolation valve on the HOT inlet only (COLD inlet must be open).

2. Unscrew and remove Strainer Cap on the HOT side. SEE IMAGE 06

After releasing water pressure initially, observe any water leaking through the strainer.

3. If water continues leaking through this may indicate a fouled or faulty Non-Return Valve. If

this is the case, inspect the non-return valve for damage or any debris. Clean or replace

the combination ball valve if necessary.

If water does not leak through, this indicates the check valve is working correctly.

4. Re-install Strainer Cap.

5. Turn back ON the isolation tap on the HOT inlet.

6. To check Non-Return Valve on the COLD inlet side, repeat the above steps using the

COLD inlet side.

Check that the strainer caps are tight, and that there is no evidence of water leakage.

Recommissining and Shut Down Test

The valve must then be recommissioned as per instructions on page 12, including

temperature adjustment and shut down test.

If the valve fails to shut down or fails to maintain its set temperature, refer to Troubleshooting

on page 19.

Enware products should be cleaned with a soft damp cloth using only mild liquid

detergent or soap and water. Do not use cleaning agents containing a corrosive acid,

scouring agent or solvent chemicals. Do not use cream cleaners, as they are abrasive.

Use of unsuitable cleaning agents may damage the surface. Any damage caused in this

way will not be covered by warranty.

cleaning

www.enware.com.au Call 1300 369 27 17

thermal flush procedure

Thermal Flush feature in eTMV allows the facility’s maintenance team or licensed service

contactors to perform a controlled thermal flush to the eTMV and warm water plumbing

system. (Note: The thermal flush procedure is optional and does not form part of

commissioning and service requirements set out in AS4032.3.)

Before commencing the thermal flush, a site-specific procedure must be implemented to

control the risk of scalding. Hot water will run directly to the outlets fed by the Electronic

Thermostatic Mixing Valve, and precautions shall be taken to prevent the chance of injury.

Note: full temperature hot water will flow from the tapware. Care must be taken

to prevent scalding.

Manager Activation

It can be enabled or disabled using the Smart Flow Software, or by unscrewing the lid of

Control Hub and pressing the blue button quickly 15 times.

Data Logging

Temperature and flow is recorded.

Thermal Flush Sequence

1. When Thermal Flush is enabled through Smart Flow Software, the temperature control

wheels (TLI) will start flashing red and white. Note this will automatically disable after 3

minutes if left in this state.

2. Within 3 minutes, press a TLI button for 10 seconds until it begins rapidly flashing red. (If

there are multiple TLI's, only one of them needs to be pressed.)

3. Within 5 seconds, press the TLI button once. A slow, red flashing will start.

4. After 3 seconds, the shower and basin solenoids will open simultaneously and the eTMV

will run for 3 seconds at 15°C.

5. Next, eTMV will allow full hot water to pass through the eTMV and solenoids for 1 minute

to allow the temperature to stabilise.

6. It will then run for 5 minutes at 70°C or 10 minutes at 60-70°C.

7. The eTMV will deliver cold water for 30 seconds. The TLI’s will pulse blue during this

period.

8. The water stops and the TLIs will flash white 3 times if the thermal flush was a success. If

there is any issue with the system during this process (e.g. it didn’t achieve the minimum

60°C temperature) then the TLI with flash orange to show there was an error that needs

investigating.

9. The thermal flush process can be stopped at any time by pressing a TLI button, which will

send the system back to step 1.

18 Call 1300 369 273 www.enware.com.au

access to components

Replacing eTMV

1. Unscrew cover of eTMV.

SEE IMAGE 07

2. Loosen 2 screws holding eTMV to board

and keep at hand.

SEE IMAGE 09

3. Unplug eTMV cable. When unplugging

cables, hold the connectors, do not pull

on the cables to unplug.

4. Unscrew 2 fixing screws holding the inlet

and outlet adaptors.

SEE IMAGE 09 & 10

5. Once eTMV is loose, pull up the eTMV to

release it from water connections.

SEE IMAGE 10

To connect new eTMV to water connections,

align inlets and slowly but firmly push eTMV

into position. SEE IMAGE 10

Take cover off. Fix eTMV to board with the 2

screws that was taken in step 2.

Fit 2 screws taken in step 3 to lock the water

inlet adaptors in place. Re-fit cover.

When reconnecting cables, align the white

marking on the connectors to ensure correct

orientation.

Commission eTMV, by following the

commissioning procedure on page 12.

LOCKING SCREW

FOR INLET FITTING

LOCKING SCREW

FOR OUTLET FITTING

TORX T20

TORX T10

Replacing eTMV Control Hub

1. Unscrew 2 screws holding the Control

Hub. SEE IMAGE 11

2. Unplug cables. When unplugging cables,

hold the connectors and do not pull on

the cables to avoid damage.

3. Replace eTMV Control Hub with a new

one.

FIXING SCREW

FIXING SCREW

OutletHot Cold

Inlets

Fixing screw

hole

Fixing screw

hole

Cover retaining

screw hole

Inlet tting

locking screw

Outlet tting

locking screw

IMAGE 07

IMAGE 08

IMAGE 09

IMAGE 10

IMAGE 11

www.enware.com.au Call 1300 369 27 19

troubleshooting

spare parts

Name Part Code

Electronic TMV WMSSB-ETMV

Smart Board Hoses -

8mm x 1/2" BSP

(1 pair)

1/2” BSPM10 Male

200 WMSSB-HOSE

Solenoid - Basin /

Shower (each) ENMS207

FAULT / SYMPTOM CAUSE RECTIFICATION

1. Desired mix temperature

can’t be obtained / is diffi-

cult to set

* Supply water pressure is too

high

* Pressure differential between hot

and cold supplies are too high

* Flow rate is too high or too low

* Debris in line

* Temperature setting is too high /

too low

* Ensure water supplies are

within limits of the valve as

outlined in Technical Table on

page 4

* Check for debris in line and

clean

* Check system temperature

setting

2. Mixed water temperature

too hot or cold

3. Flow rate reduced or fluctu-

ating

4. eTMV is noisy

5. The valve will not shut down * Supply water temperature too

high or too low

* Ceramic disc in eTMV has failed

* Debris in line

* See Rectification 1

* Replace eTMV

6. Hot water flows into cold

water system or vice versa

* Check valve has failed

* Debris fouling check valve

Dismantle and clean / replace

combination inlet valve

7. Water leaks from outlet /

Water drips and does not

shut off

* Debris in line

* Supply water pressure too high

* Solenoid has failed

* See Rectification 1

* Check solenoid for debris

and clean. Replace solenoid

if required

8. Water is not flowing /

9. Poor water flow

* Aerator/ line is blocked by debris

* Water or power turned off

* eTMV has shut down

* Dismantle aerator or flow

control and clean

* Turn on power / water

* See Rectification 1

For further assistance, call Enware on 1300 369 273.

20 Call 1300 369 273 www.enware.com.au

Commissioning / Service Report for Thermostatic Mixing Valve

Name of

Establishment

(Name) Owner /

Occupier

(Name)

Street Address

Contact Name (Name) Phone

Date of Test Work

Order No.

Valve ID No. Model No.

Make of TMV Size

Valve location

/ Building

Area Serviced

by Valve

Number of Outlets Served Basin Shower Bath

Valve installed to requirements of

1. The local water supply

authority

2. The valve manufacturer /

supplier requirements

3. The Australian Standards

for Plumbing and Drainage

YES NO YES NO YES NO

If NO, give details and action taken:

Use a separate form for each valve.

The original report is to be retained on site for a minimum of 7 years.

Copies of the report shall be : provided to the owner/ occupier or the person responsible ; retained by the tester ; and

where required, forwarded to the relevant authority.

The test method is in accordance with AS4032.3 Appendix B.

Valve functioning in accordance with the application requirements: YES NO

If NO, give details and action taken:

This manual suits for next models

1

Popular Industrial Electrical manuals by other brands

Hotline

Hotline 47HLB150 Harrier Installation guide and warranty

Dallas Semiconductor

Dallas Semiconductor Maxim MAXQ3210 manual

Eaton

Eaton PKZM0-XDM12-PI Instruction leaflet

S&C

S&C PMH Series Operation

Murata

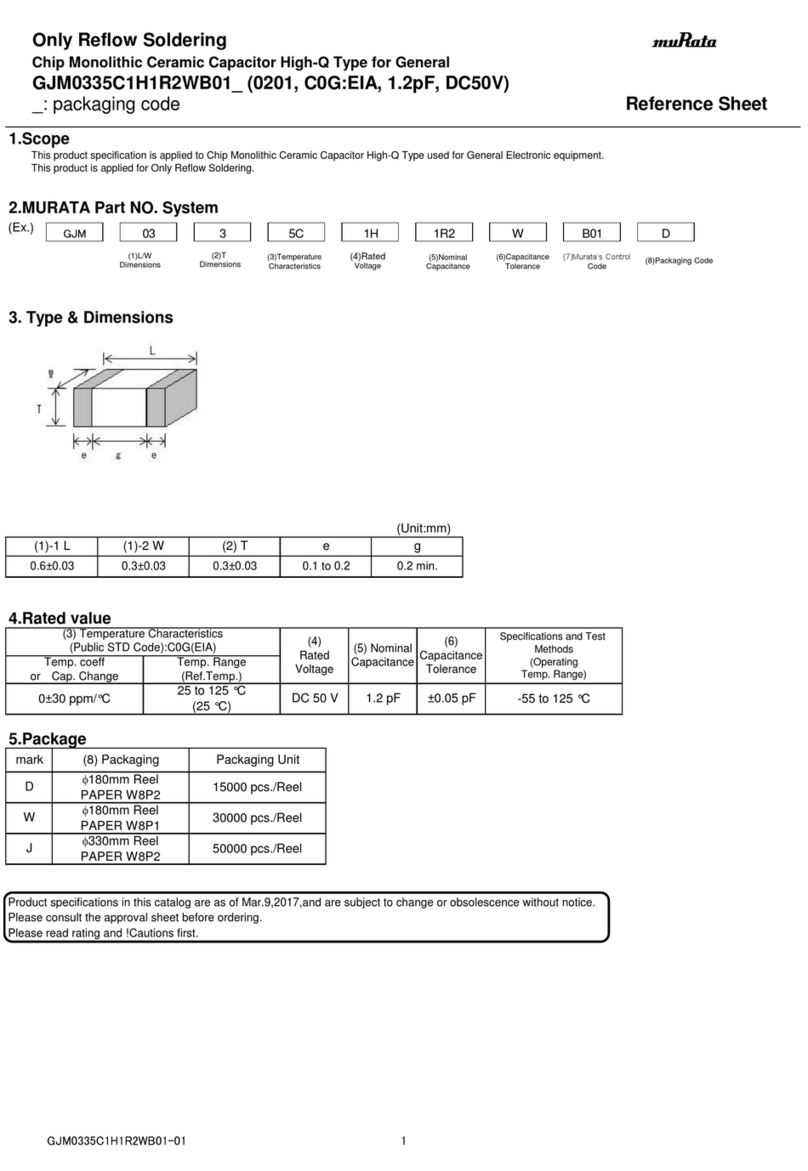

Murata GJM0335C1H1R2WB01 Series Reference sheet

Murata

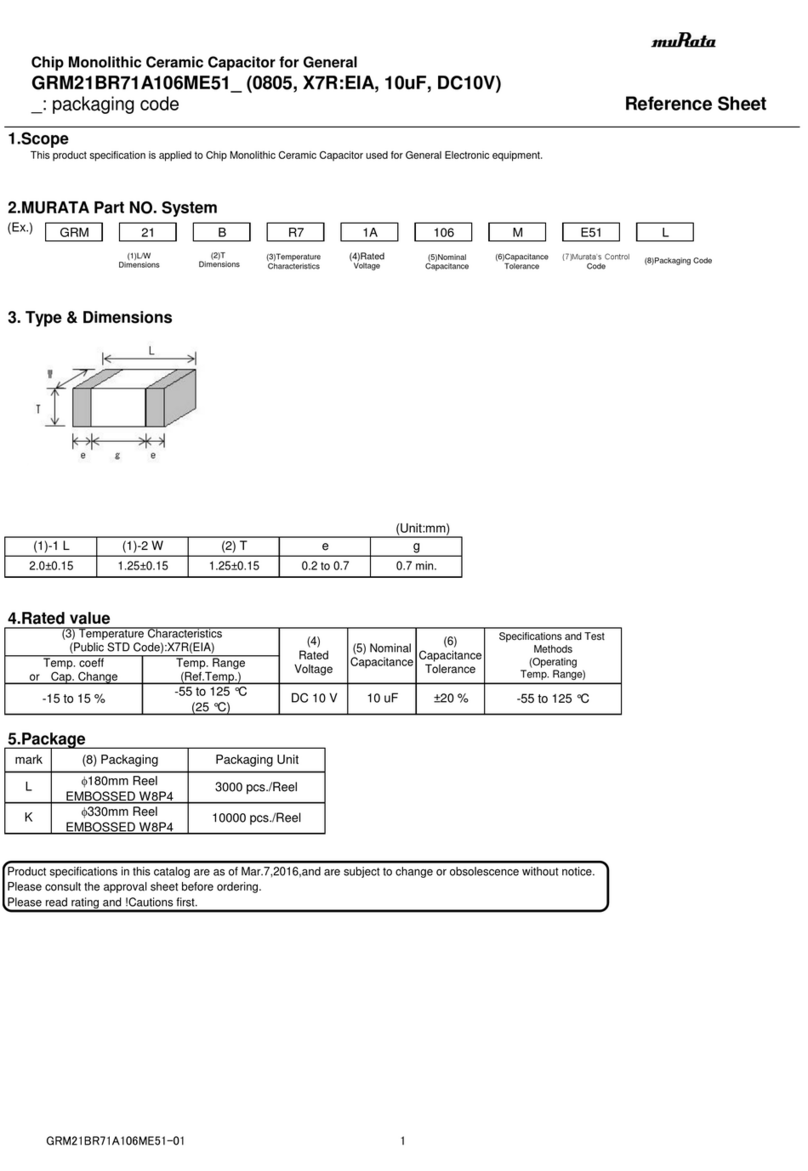

Murata GRM21BR71A106ME51 Series Reference sheet

Burkert

Burkert AirLINE Ex 8650 quick start

Murata

Murata GRM033R70J122KA01 Series Reference sheet

Murata

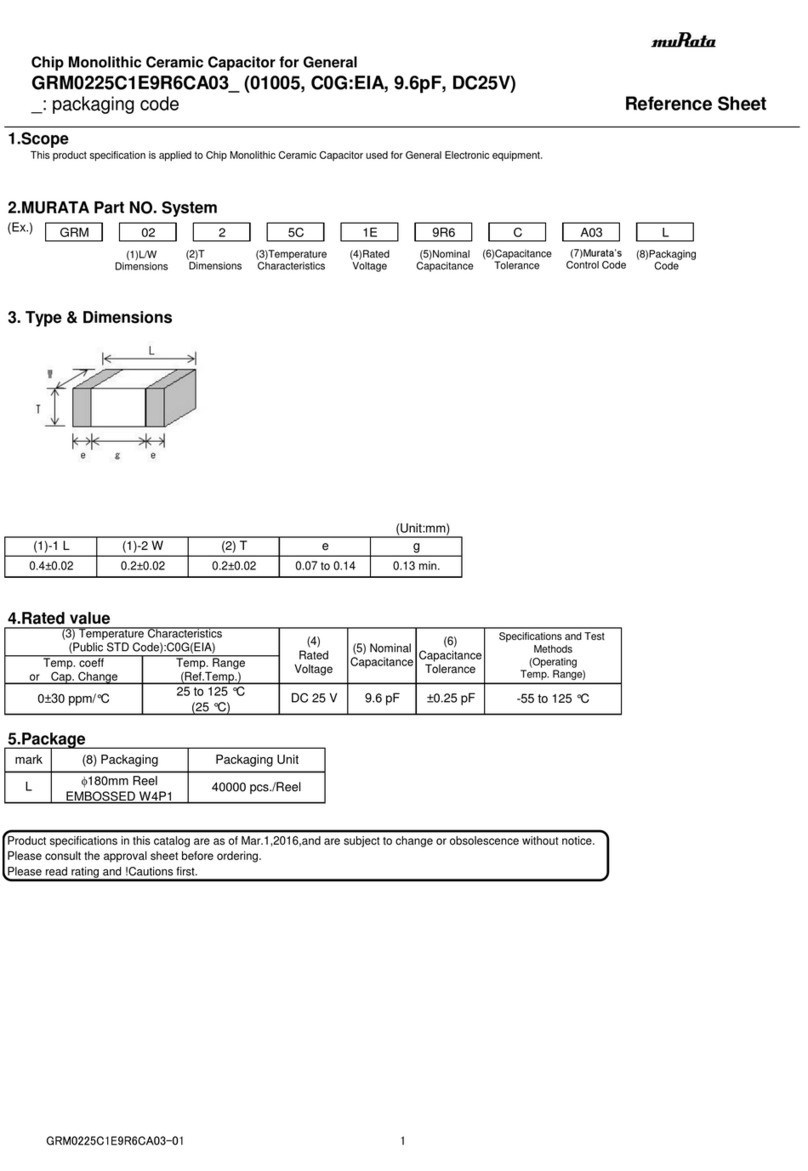

Murata GRM0225C1E9R6CA03 Seris Reference sheet

Murata

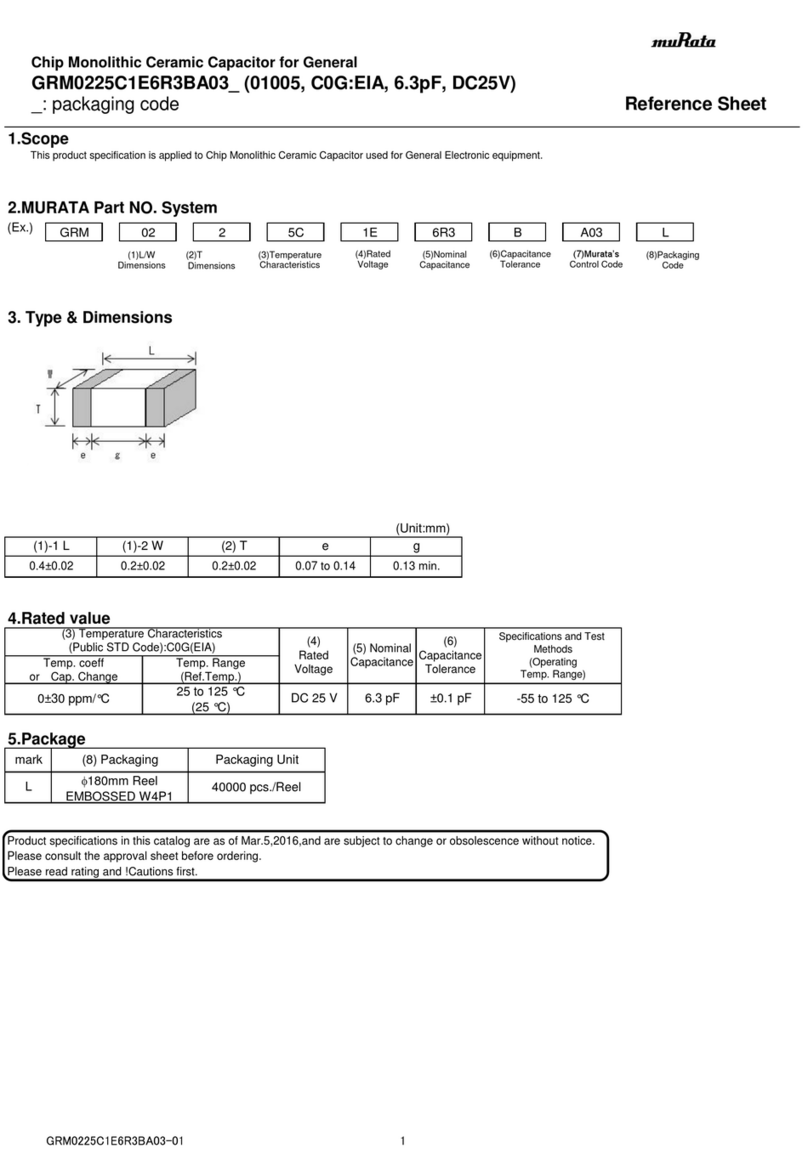

Murata GRM0225C1E6R3BA03 Series Reference sheet

Murata

Murata GRM0225C1E9R9CA03 Series Reference sheet

Murata

Murata GRM0335C1E100JA01 Series Reference sheet